Cutting equipment for electronic products

An electronic product and cutting technology, which is applied in the direction of metal sawing equipment, metal processing equipment, large fixed members, etc., can solve the problem of cutting work efficiency reduction and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

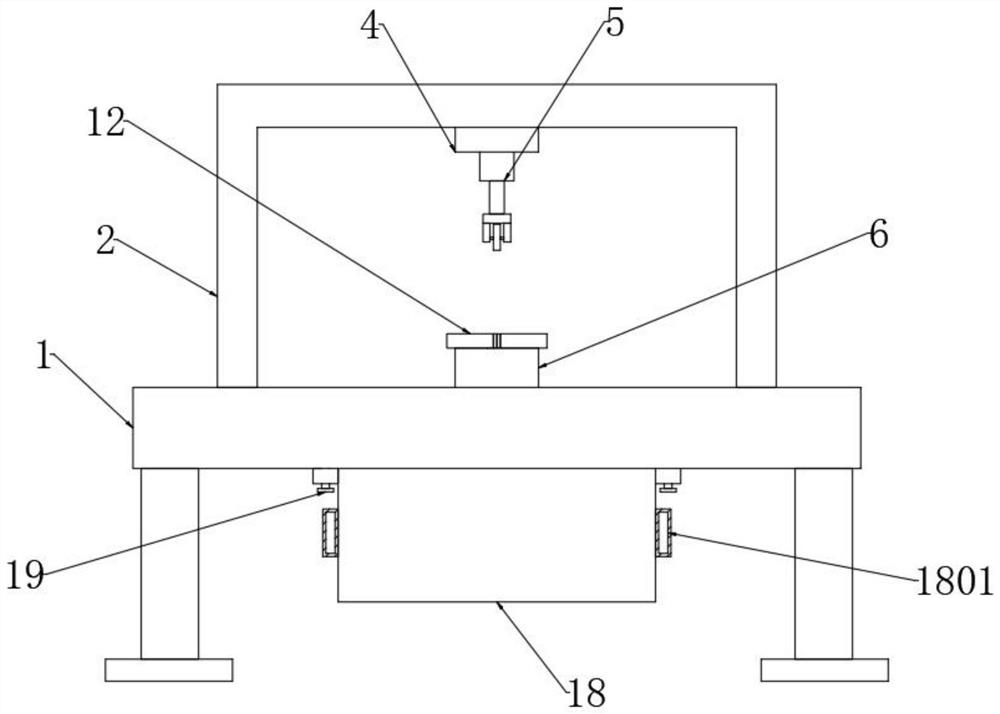

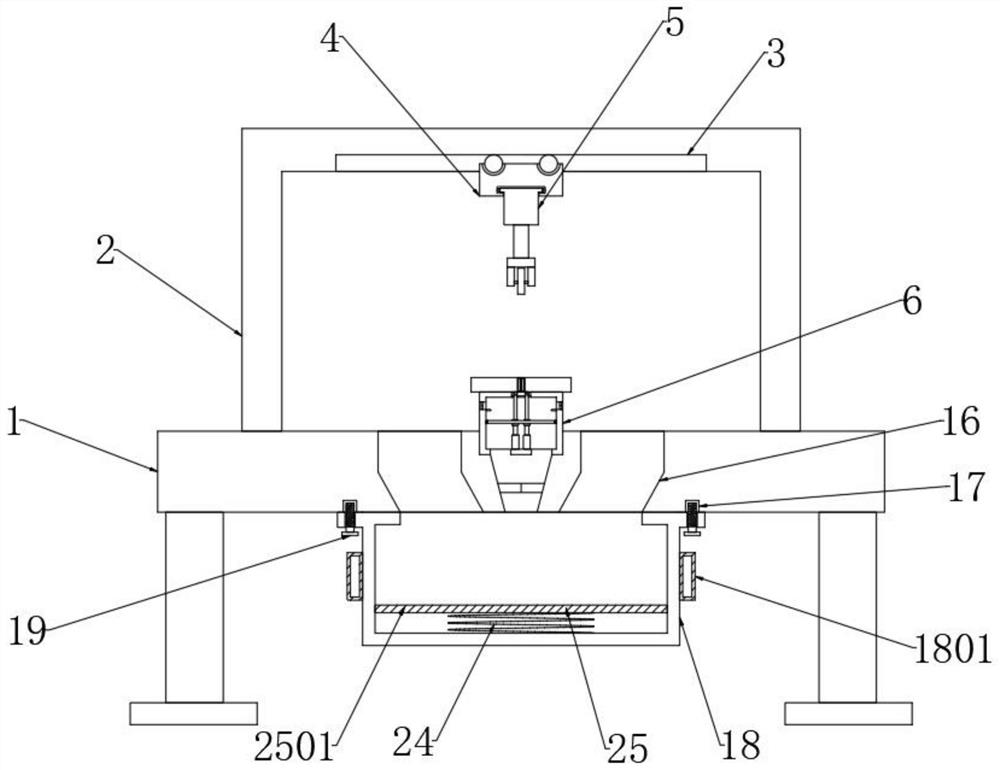

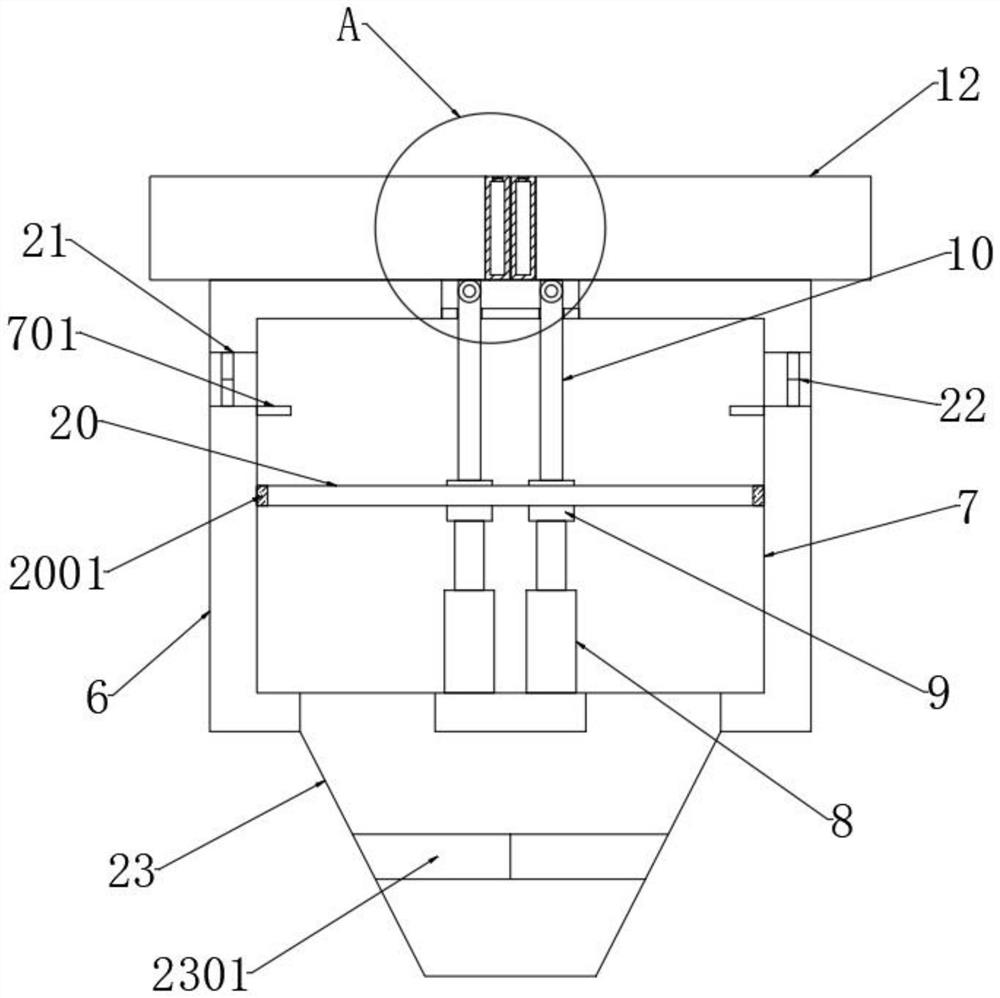

[0040] See Figure 1-4 An electronic product cutting equipment, including a table 1, and the upper end of the table 1 is fixedly connected to the cutting frame 2. The top of the cutting frame 2 is opened in the top of the top, and the slide 3 slides in the sliding groove 3. 4, the lower end of the electric slider 4 is rotated and the cutter assembly 5 is connected. The upper end of the table 1 is fixed to the platform base 6, and the platform base 6 is located under the lower side of the cutter assembly 5, and the platform base 6 is opened with a cavity 7. The bottom end of the cavity 7 is fixed to two relative electric telescoping rods 8, and the upper ends of the two electric telescoping rods 8 are fixedly connected to the connecting block 9, and the upper end of the connecting block 9 is fixedly connected to the support rod 10, the platform base 6 is opened. With through holes 11, the through hole 11 is in communication with the cavity 7, and the support rod 10 extends into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com