High-pressure water sand-spraying deflashing machine

A technology for removing flash and high-pressure water, applied in abrasives, spray guns, sedimentation separation, etc., can solve the problems of poor controllability, unreliable and stable feeding of strips, etc., and achieve the effect of stable and orderly transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

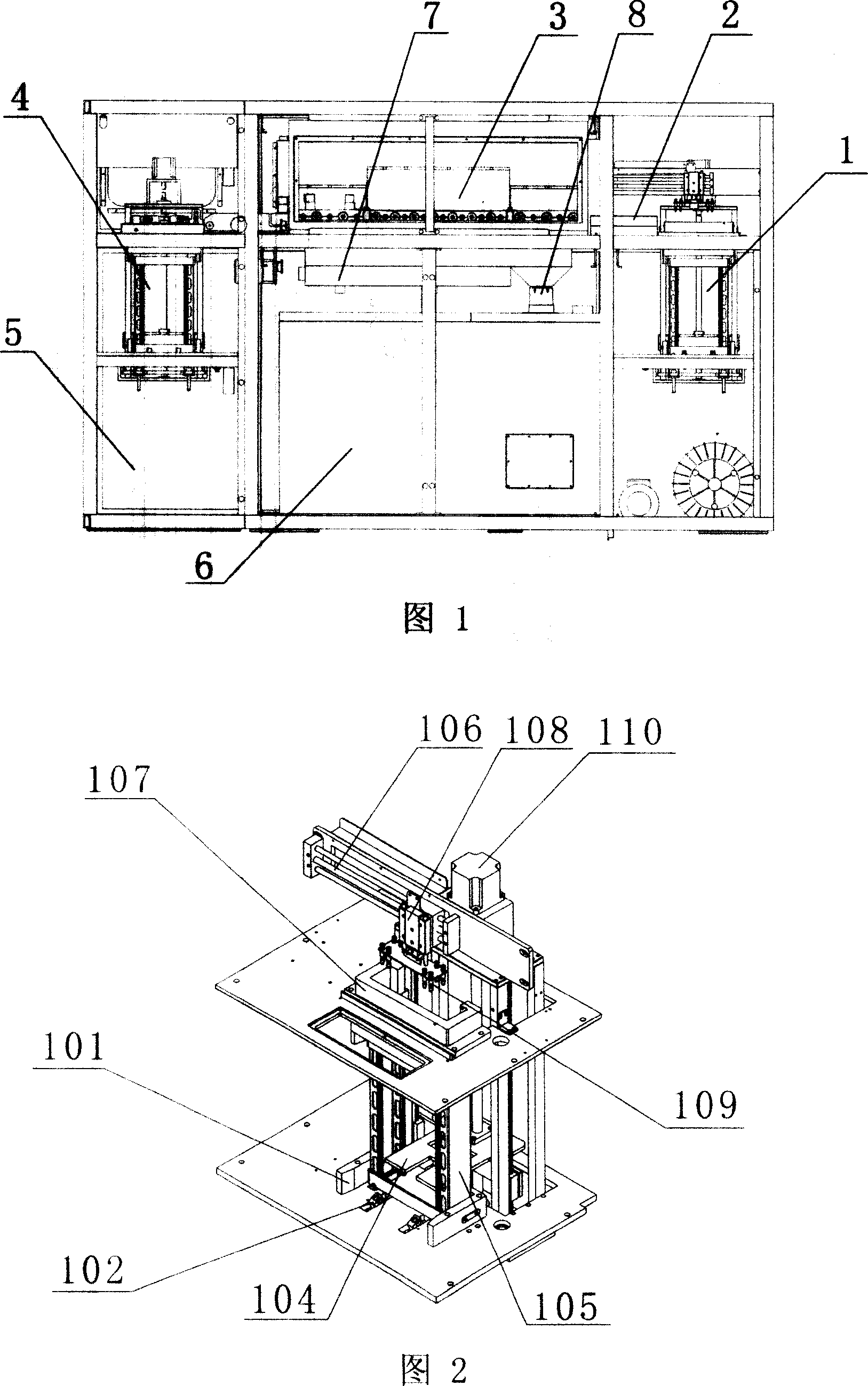

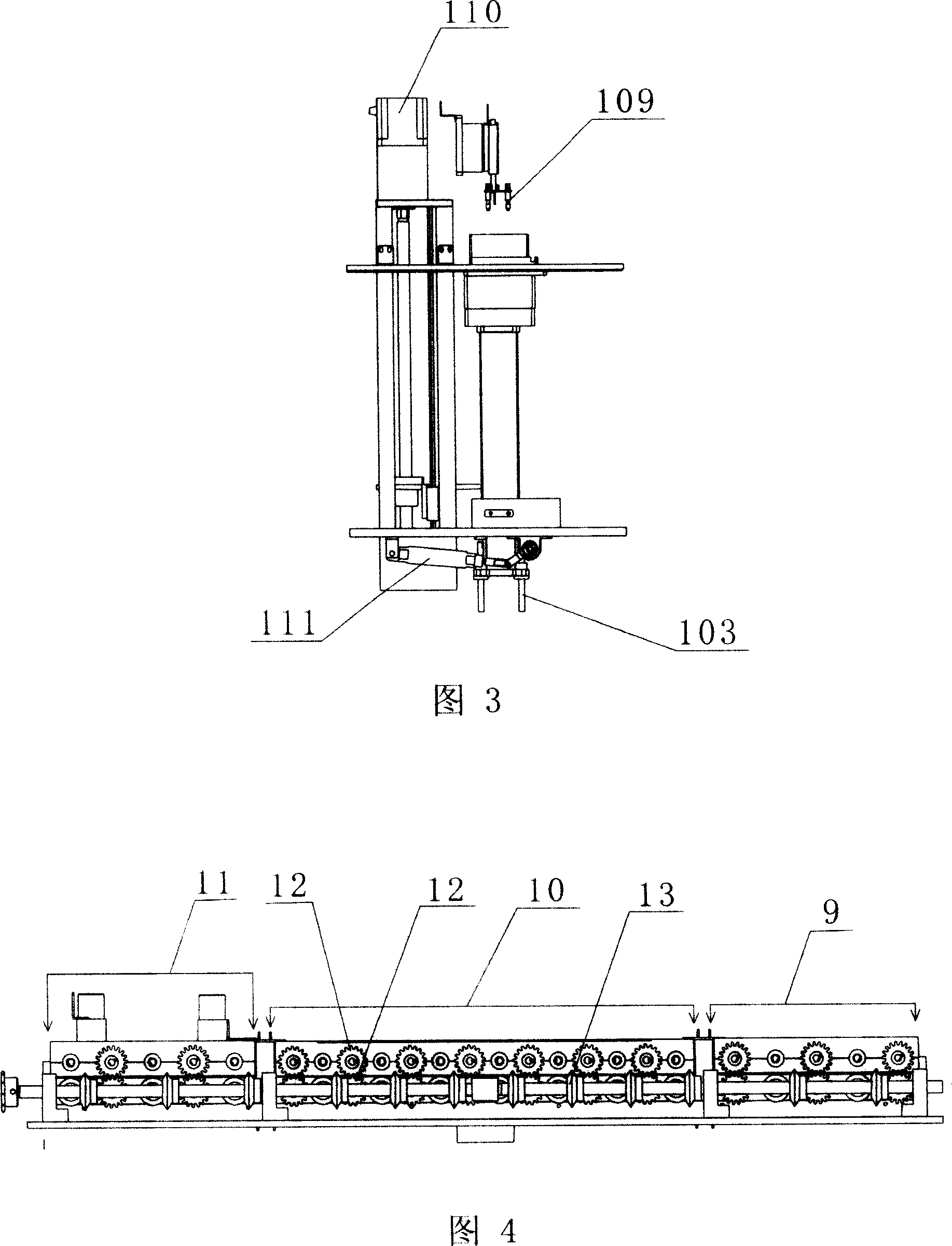

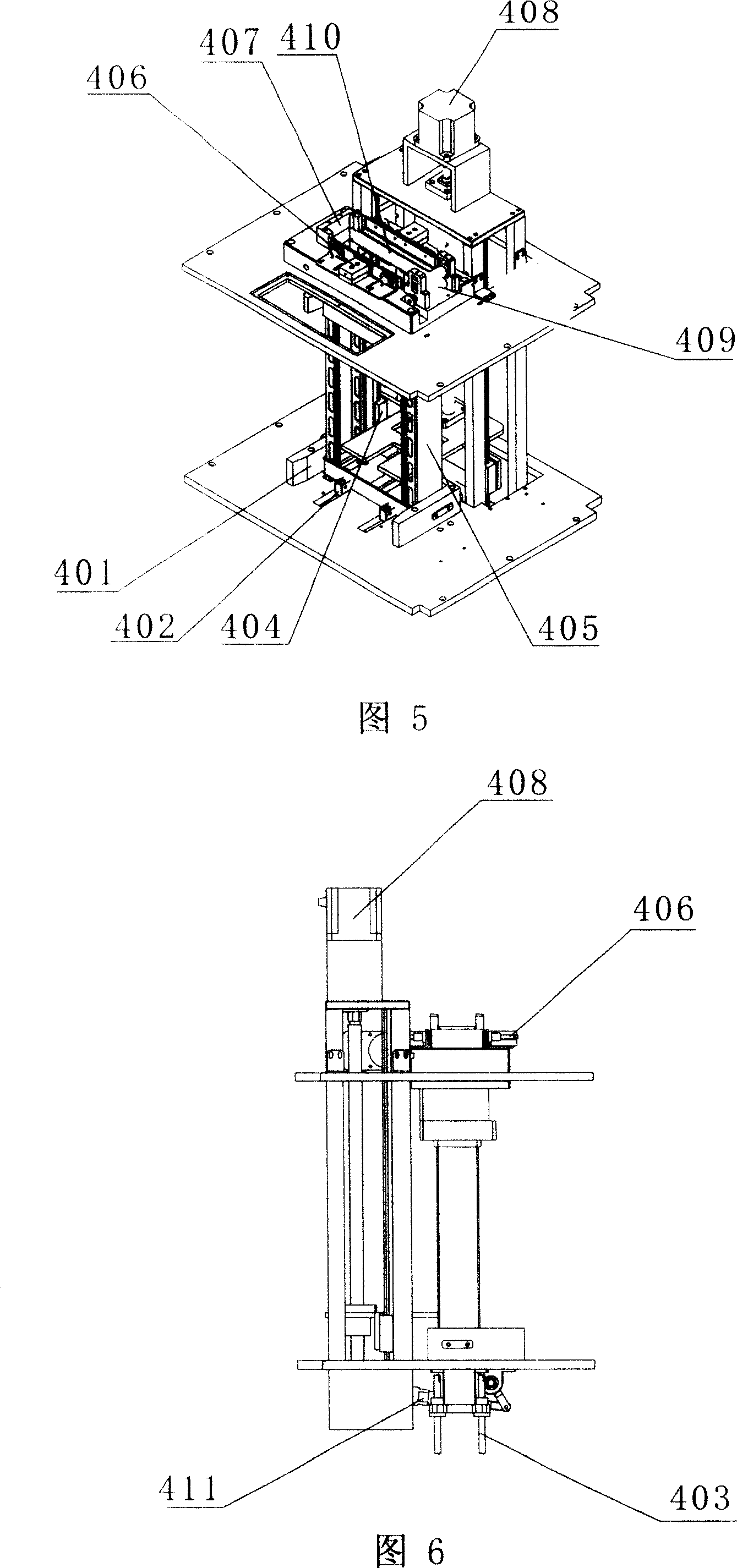

[0025] The present invention is a kind of high-pressure water sand blasting machine for removing overflow, as shown in Figure 1, it includes a feeding device 1, a material pushing device 2, a transmission and conveying mechanism, a material removing system 3, a feeding device 4 and an automatic control system. system, the de-overflow system includes a sand-collecting type water-sand separation box 6, several water-sand spray heads, some clear water spray heads, an air-drying device and a high-pressure water pump 5, and is characterized in that the feeding device 1 is The IC material strips are sent to the pusher into the warehouse by means of a transmission mechanism; the transmission and conveying mechanism drives the material strips forward through the upper and lower rows of roller shafts; the unloading device 4 uses the weight of the material strips to drop to the corresponding position through the blanking mechanism. According to the sequence of loading IC strips into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com