System and method for pressing walnuts into cracks based on precise self-positioning

A self-positioning, walnut technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of walnut kernel whole kernel rate and manual shelling gap, incomplete walnut shell breaking, and imperfect development of related devices, etc. The production effect is considerable, the effect of increasing the pre-shell process and reducing the size and classification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

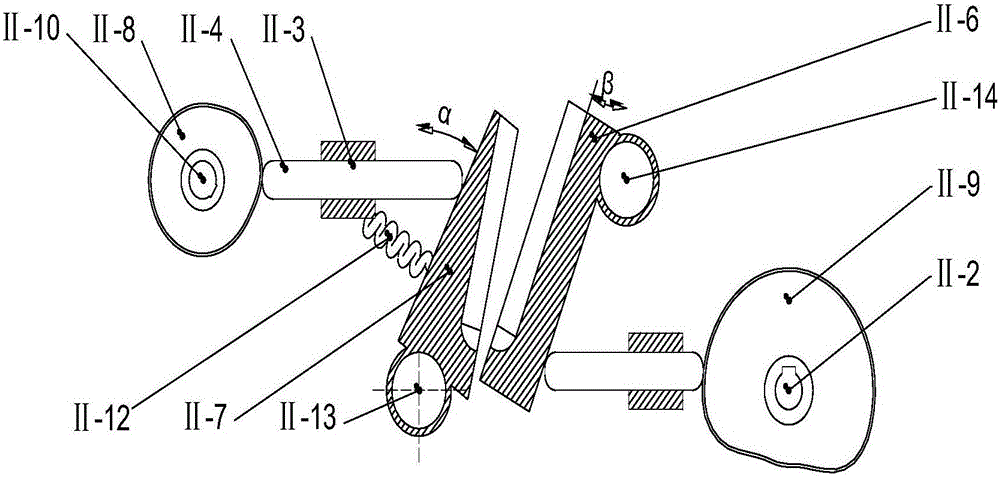

[0057] In this embodiment, the blanking block and the extruding block are V-shaped blocks as an example. However, it can also be a blanking plate, an extruding plate, or other shapes such as trapezoids, which can be realized through simple deformation. The scope of protection of the present invention is not limited to the illustrated shape of the present invention; in the same way, in the blanking V-shaped block and the extruded B-shaped block in the embodiment, there are holes for preventing walnuts from slipping in the horizontal direction and applying force evenly when extruding. Groove, the shape of the groove is not limited to the shape of the groove mentioned in this embodiment.

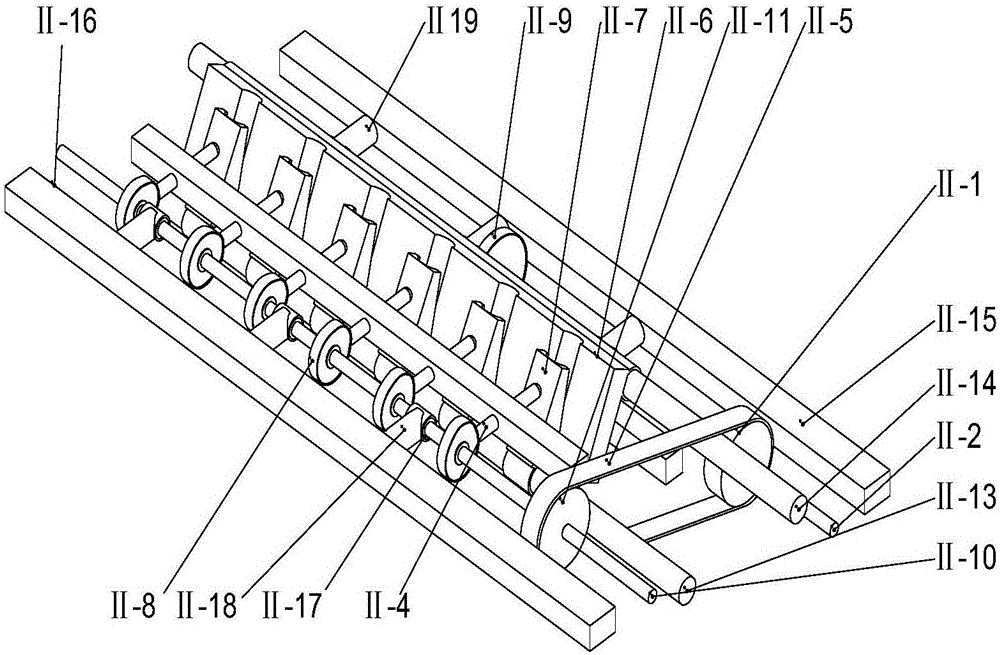

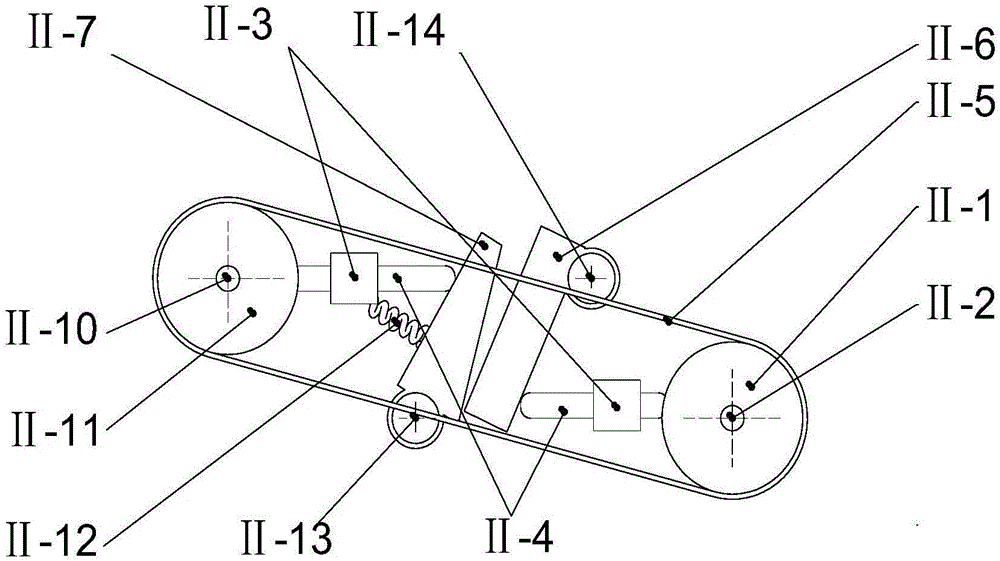

[0058] Such as figure 1 , figure 2 As shown, multiple extrusion cams Ⅱ-8 are staggered at a certain angle, and are fixedly connected to shaft ⅢⅡ-10 through key connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com