Foldable scraper blade type conveying arm for cutting type sugarcane harvester

A harvester and scraper-type technology, which is applied in the field of foldable scraper-type conveying arms, can solve the problems of inaccurate throwing position, offset center of gravity, large size of the conveying arm, etc. The effect of becoming smaller and the length of the whole machine is smaller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples.

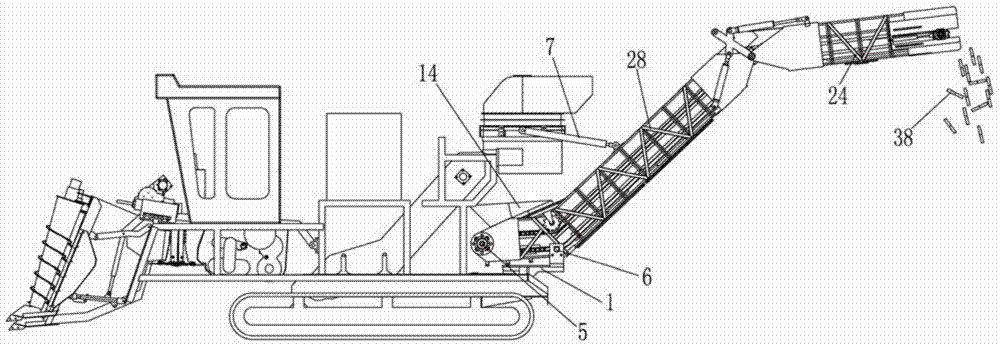

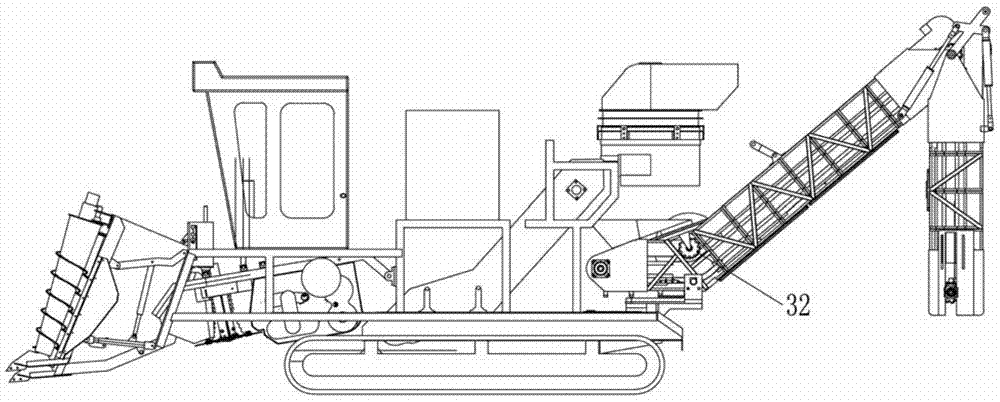

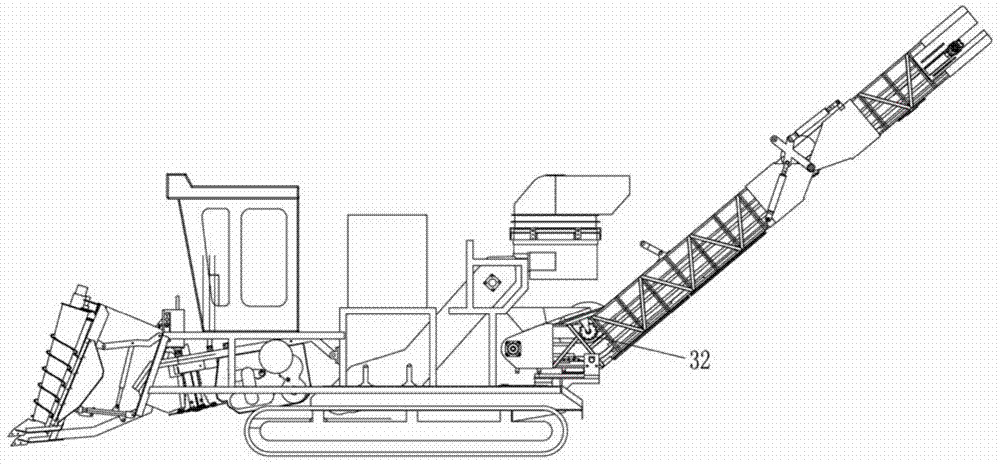

[0033] Such as Figure 1 to Figure 13 As shown, the foldable scraper-type conveying arm described in this embodiment is mounted on a segment-cut sugarcane harvester, and a horizontal angle turntable 1 is installed on the segment-cut sugarcane harvester for controlling the entire foldable scraper-type conveying arm. The arm rotates 180° horizontally. The foldable scraper conveyor arm includes an upper arm section, a lower arm section, a folding drive part and a chain scraper mechanism for conveying materials; one end of the upper arm section is hinged on the first driven sprocket shaft 2, and the other One end is equipped with a driving sprocket shaft 4 driven and rotated by a hydraulic motor 3 (through a throttle valve to control the speed of the hydraulic motor); one end of the lower arm section is hinged on the first driven sprocket shaft 2, and the other end is installed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com