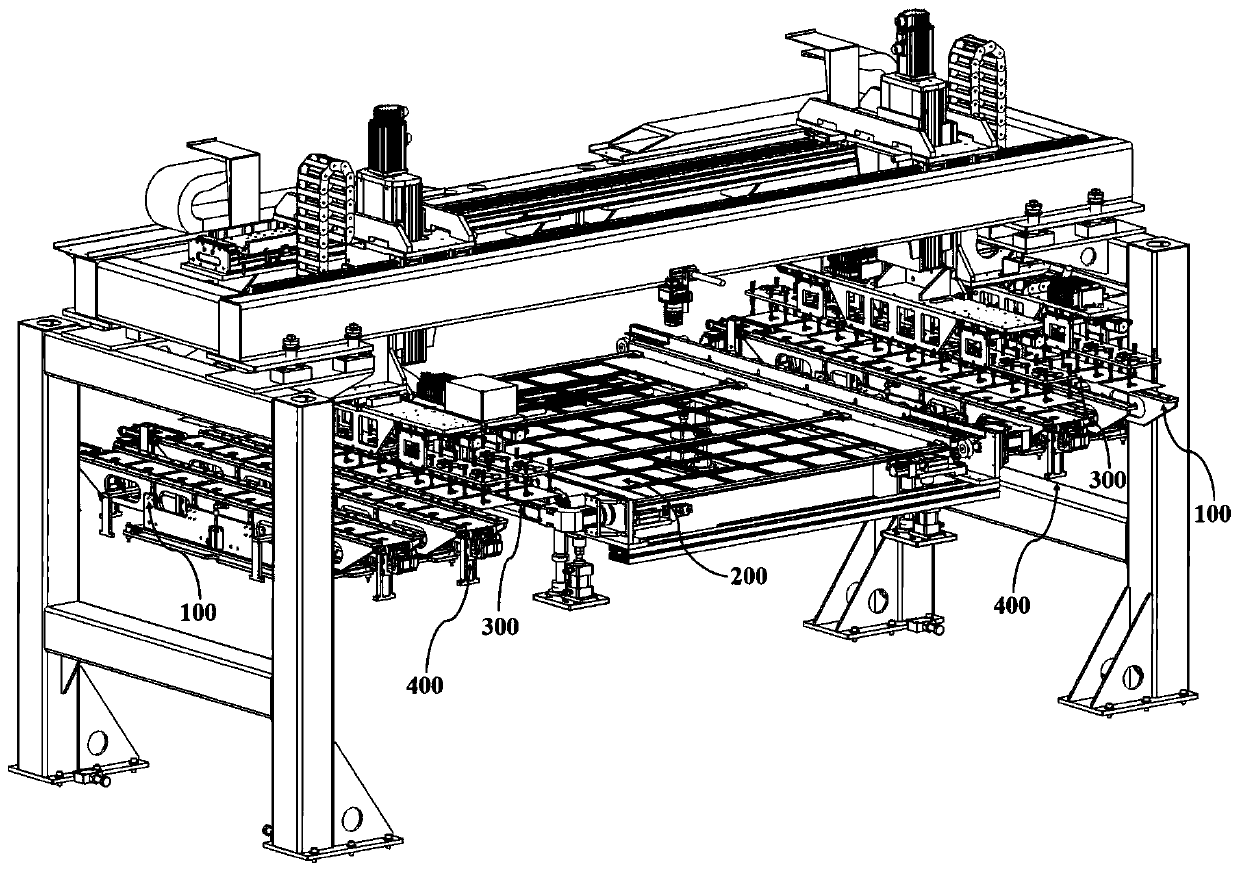

Silicon wafer feeding and discharging transmission system

A technology of transmission system and silicon wafer, which is applied in the field of solar cells, can solve the problems of low efficiency, achieve the effect of improving transmission efficiency, improving the efficiency of variable distance adjustment, and realizing accurate docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

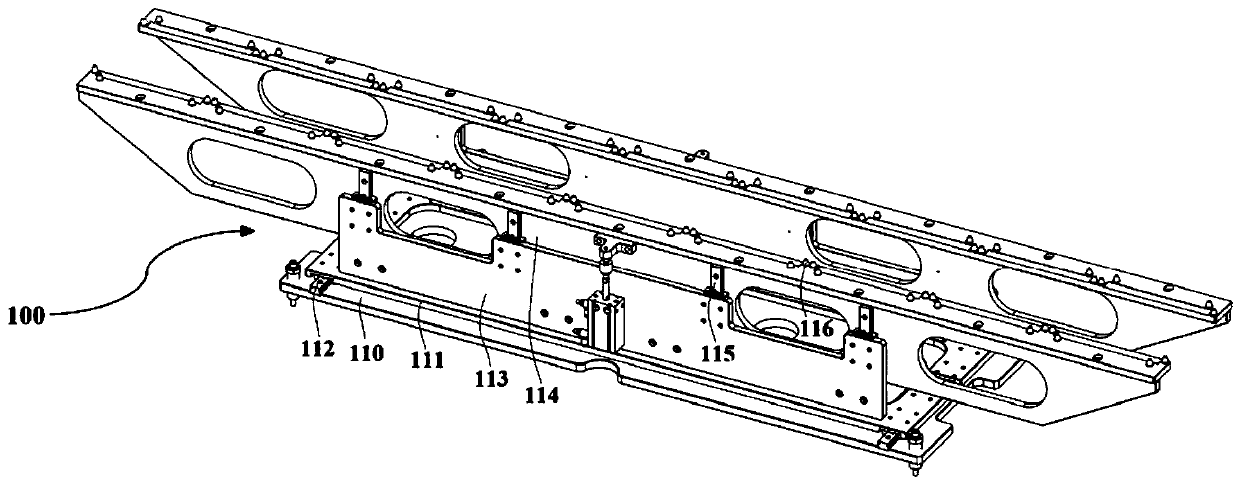

[0039] to combine Figure 5 , in the production of silicon wafers, it is necessary to take out the silicon wafers 500 piece by piece from the flower basket and put them on the silicon wafer carrier 200. Specifically, after the flower basket elevator is in place, it descends to send the silicon wafers 500 to the belt transmission mechanism 400, and the belt The transmission mechanism 400 includes a bracket 410 set at the bottom, on which is a drive shaft 411 for driving the conveyor belt 412 to move, the conveyor belt 412 picks up the silicon wafer 500 on the flower basket elevator and then is carried by the silicon wafer handling mechanism to carry it onto the wafer carrier 200.

[0040] The silicon wafer carrier 200 in the prior art can accommodate multiple silicon wafers 500 of the same specification at the same time, and the silicon wafers 500 are equidistantly arranged, and the silicon wafer handling mechanism only needs to carry the silicon wafers 500 in a certain directi...

Embodiment 2

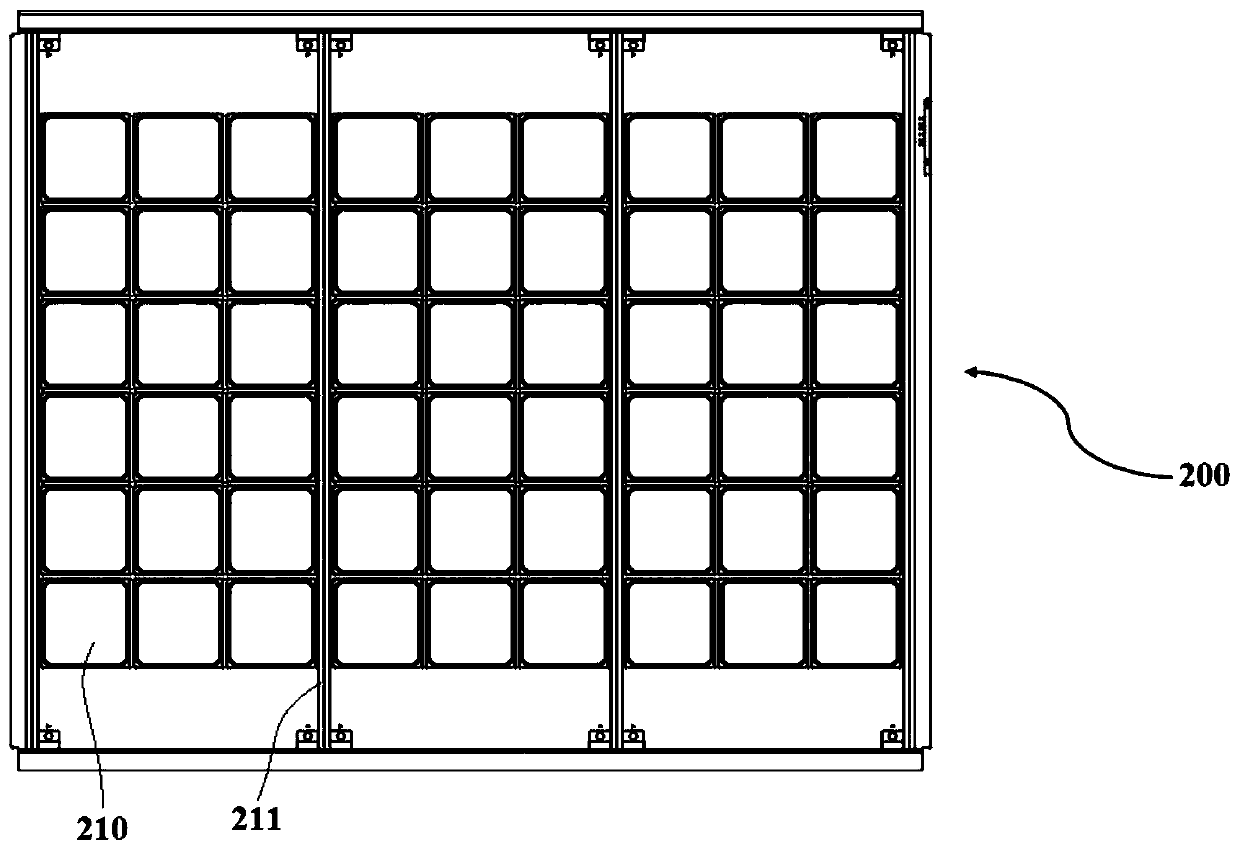

[0047] A silicon chip loading and unloading transmission system in this embodiment has basically the same structure as in Embodiment 1. Further, the grooves 210 in this embodiment are distributed in a rectangular array along the direction in which the support structure 211 is set, and two adjacent The grooves 210 between the support structures 211 are equidistantly distributed.

[0048] Specifically, in this embodiment, the silicon wafer carrier 200 is provided with grooves 210 in 6 rows*9 columns and four supporting structures 211, and a supporting structure 211 is provided every three columns, that is, the grooves on the silicon wafer carrier 200. The array of grooves 210 is divided into three groups of rectangular arrays by four support structures 211, and the grooves 210 between two adjacent support structures 211 are equally spaced, and the distance between every three columns of grooves 211 on the silicon wafer carrier 200 varies once.

[0049] In order to improve the p...

Embodiment 3

[0054] A silicon wafer loading and unloading transmission system in this embodiment has basically the same structure as that in Embodiment 2. Further, the distance changing mechanism 310 in this embodiment also includes a sensor 316, and the sensor 316 is arranged at the end of the distance changing slide rail 315 to It is used to detect the movement distance of the sliding seat 318 along the length direction of the suspension frame.

[0055] Specifically, in this embodiment, an induction sheet 317 is correspondingly provided on the side of the sliding seat 318 opposite to the sensor 316, and when the pitch-changing mechanism 310 drives the sucker assembly 320 to move to the sensor 316, the sensor 316 senses the induction on the sliding seat 318. Sheet 317, at this time, it shows that the distance variable mechanism 310 is in place, that is, the suction cup assemblies 320 connected to the bottom of the slide seat 318 are equidistantly distributed, and at this time, the sensor 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com