Heat exchanger for flat heat pipe

A heat pipe heat exchanger, flat technology, applied in the field of flat heat pipe heat exchanger, to achieve the effect of improving heat exchange efficiency, small wind resistance, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

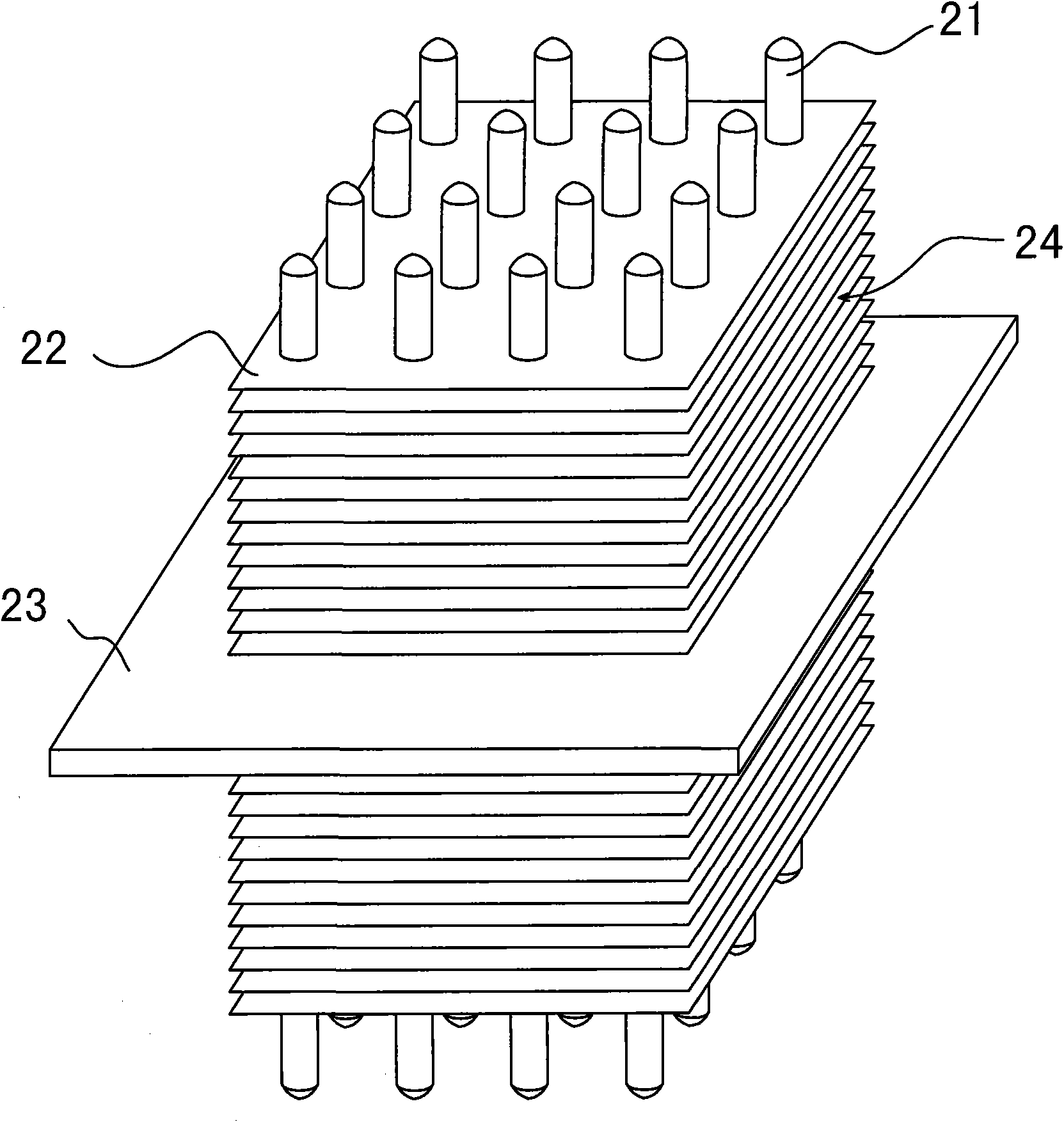

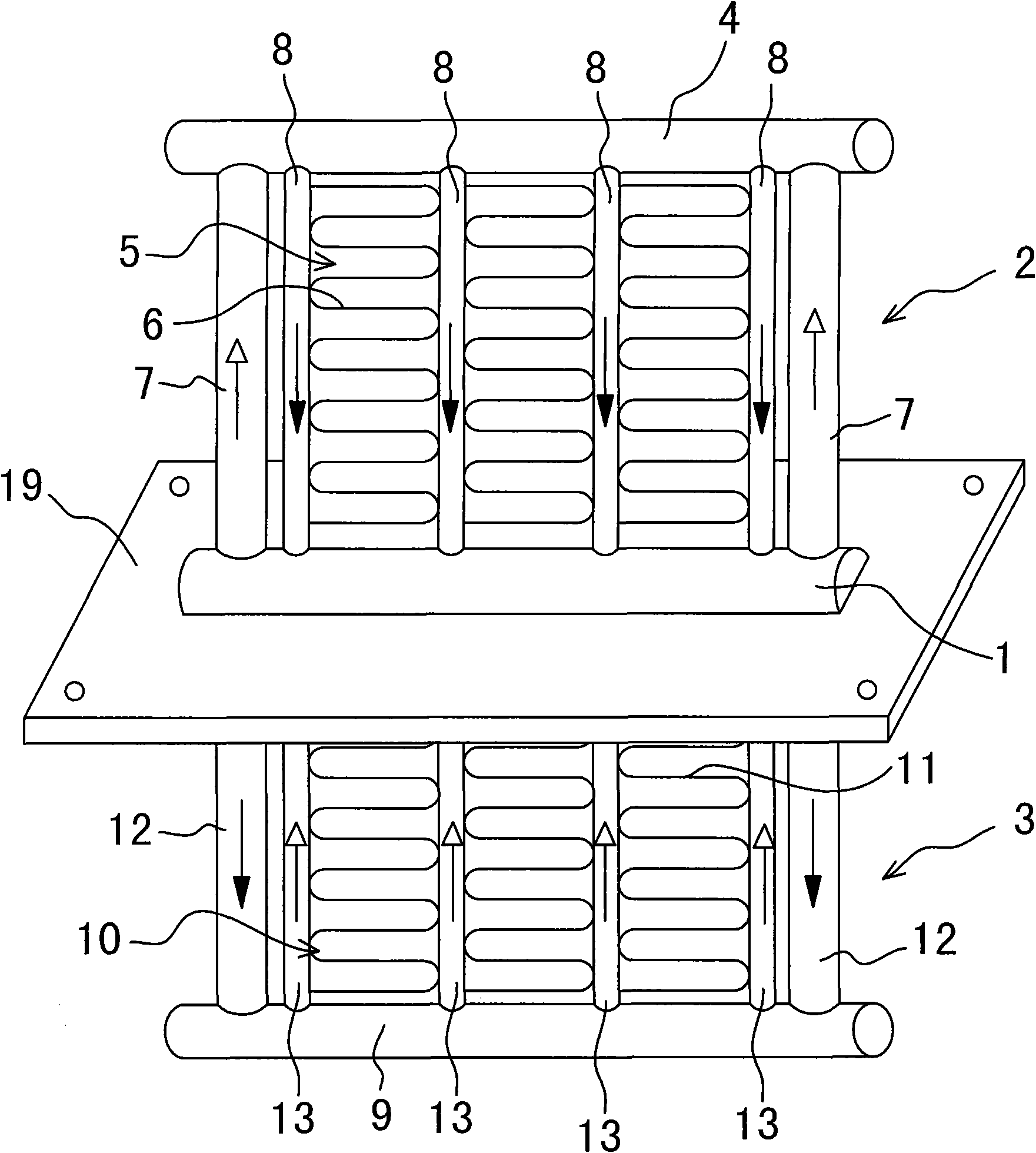

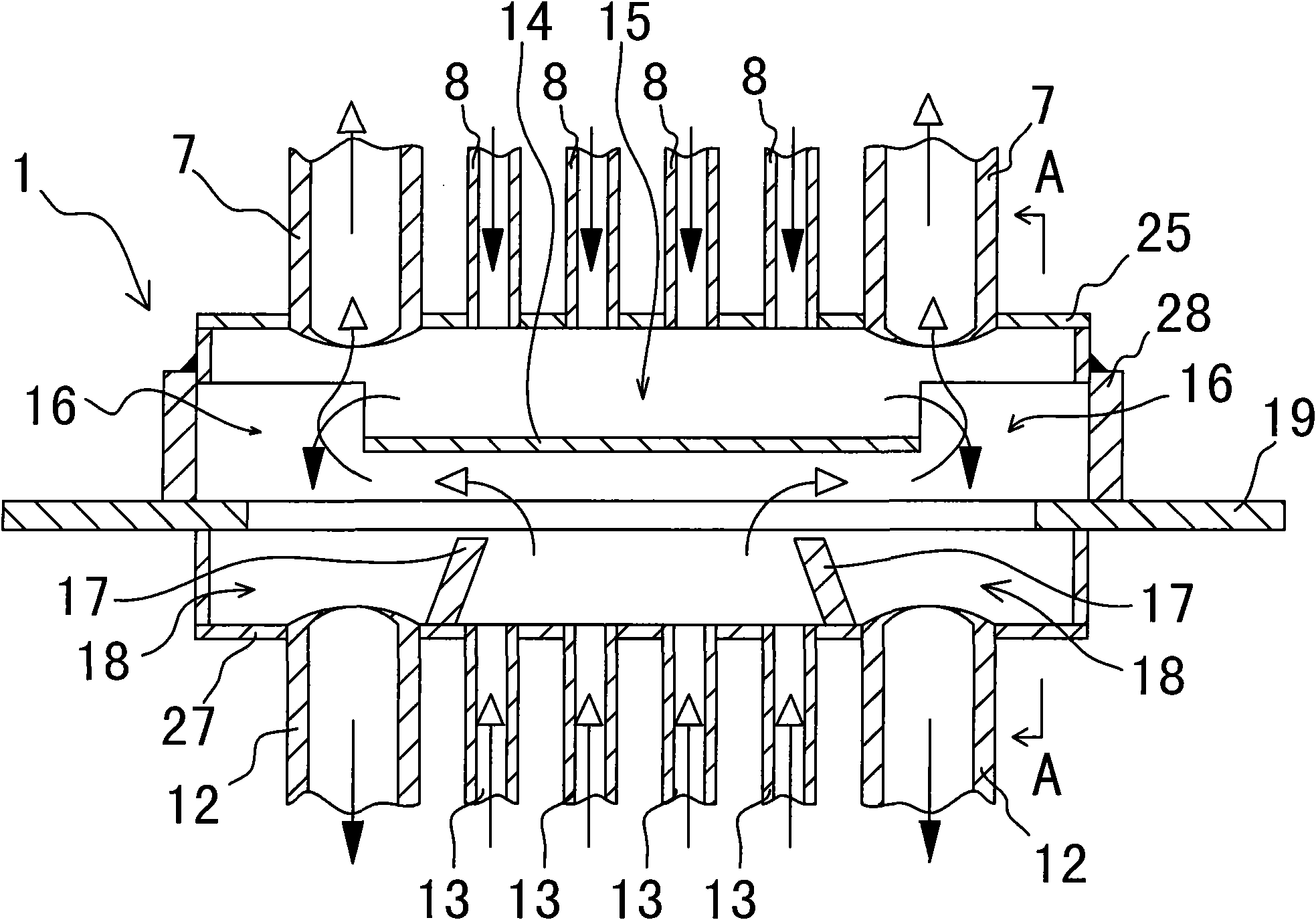

[0032] Example: see attached figure 2 ~ attached Figure 4 As shown, a flat heat pipe heat exchanger includes an intermediate gas-liquid separation chamber 1 , a condensation unit 2 located on the upper side of the intermediate gas-liquid separation chamber 1 , and an evaporation unit 3 located on the lower side of the intermediate gas-liquid separation chamber 1 .

[0033] The condensing unit 2 is composed of a gas collecting pipe 4, a condensing flat tube group 5, a heat exchange fin 6 and two gas delivery pipes 7, and the gas collecting pipe 4 is arranged on the upper side of the middle gas-liquid separation chamber 1 in parallel; the condensing The flat tube group 5 is composed of a plurality of metal flat tubes 8 formed in a row and vertically connected between the gas collecting pipe 4 and the top of the intermediate gas-liquid separation chamber 1 (four in the figure). The heat exchange fins 6 are connected between the relatively flat surfaces to form a cold-end multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com