Laser bonding temperature acquisition system for photoelectric device packaging and method for photoelectric device packaging

A technology of temperature acquisition system and photoelectric device, which is applied in the direction of thermometers using electric/magnetic elements directly sensitive to heat, electric devices, electric solid devices, etc., which can solve the problems of high design and manufacturing costs, complex structure of temperature acquisition devices, The temperature measurement effect is not ideal enough to achieve the effect of ensuring the packaging quality, good temperature detection effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

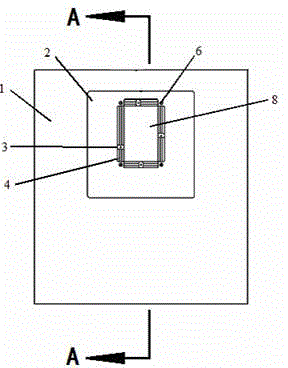

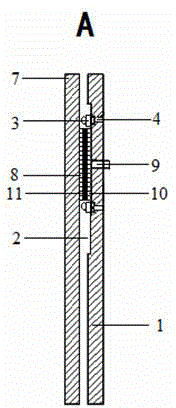

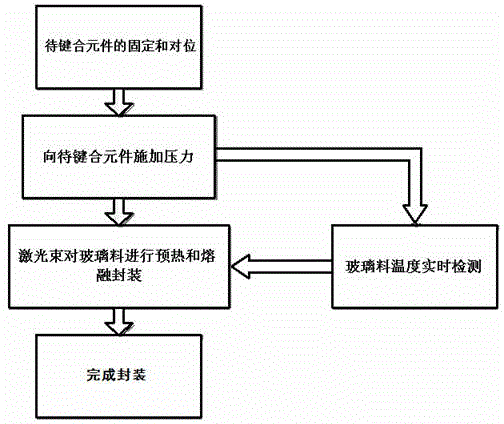

[0027] see figure 1 and figure 2 , a laser bonding temperature collection system for optoelectronic device packaging, including a temperature sensor and its positioning member, different temperature sensors are respectively arranged around the periphery of the glass substrate 10 used for optoelectronic device packaging, the temperature sensor can be set by the positioning member The position of the temperature collection point, so that different temperature sensors are arranged along the glass sealing strip 11 used for optoelectronic device packaging to carry out the temperature collection point layout, and the corresponding positions of the glass sealing strip 11 are respectively used for fixed-point temperature measurement, and the glass substrate 10 is fixedly installed on the support base plate 1, and there is an annular reserved gap between the outer edge of the glass substrate 10 and the notch edge of the positioning groove 2, and the positioning member is arranged in t...

Embodiment 2

[0039] The technical solution of this embodiment is basically the same as that of Embodiment 1, especially in that:

[0040] see Figure 4 , In this embodiment, an indicating scale 5 is also provided near the slideway 4, and the indicating scale 5 measures the current position of the indicating slide body on the slideway 4, and accurately positions the temperature sensor installed on the slideway. The indicator scale 5 of the sliding member can provide precise scales to facilitate precise positioning of the movement coordinates of the sliding body, thereby realizing more precise adjustment and positioning of the temperature sensor, and can accurately measure the temperature of different points of the glass sealing strip 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com