Method and mold for packaging high-power LED (light emitting diode) liquid silicon rubber

A technology of liquid silica gel and packaging method, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as inability to effectively reduce production costs, inability to guarantee product quality, affecting product promotion, etc., to achieve simple and reasonable processes, consistent glue volume, The effect of ensuring package quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention provides a high-power LED liquid silica gel encapsulation method, which comprises the following steps:

[0032] A high-power LED liquid silicone encapsulation method, the method comprises the following steps:

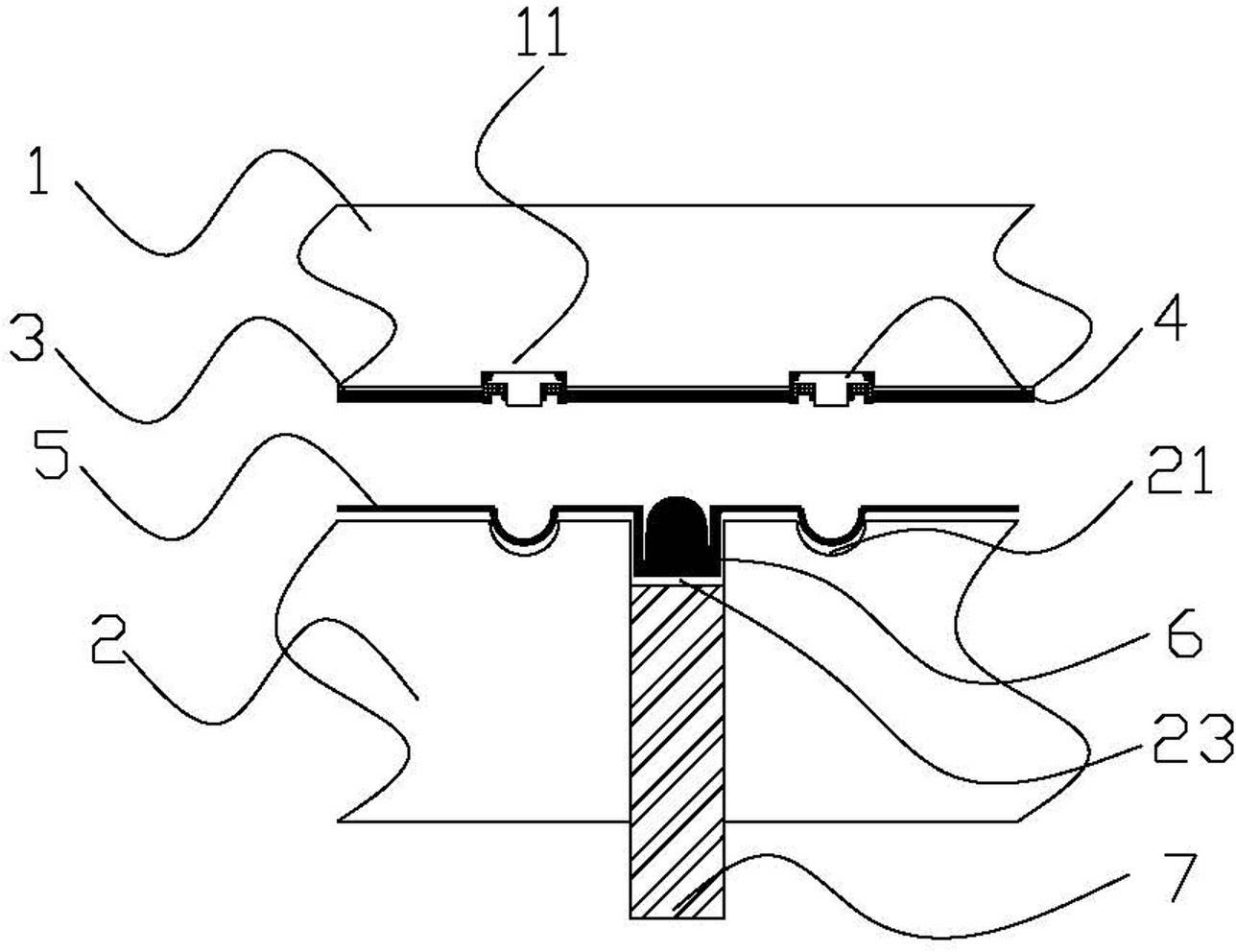

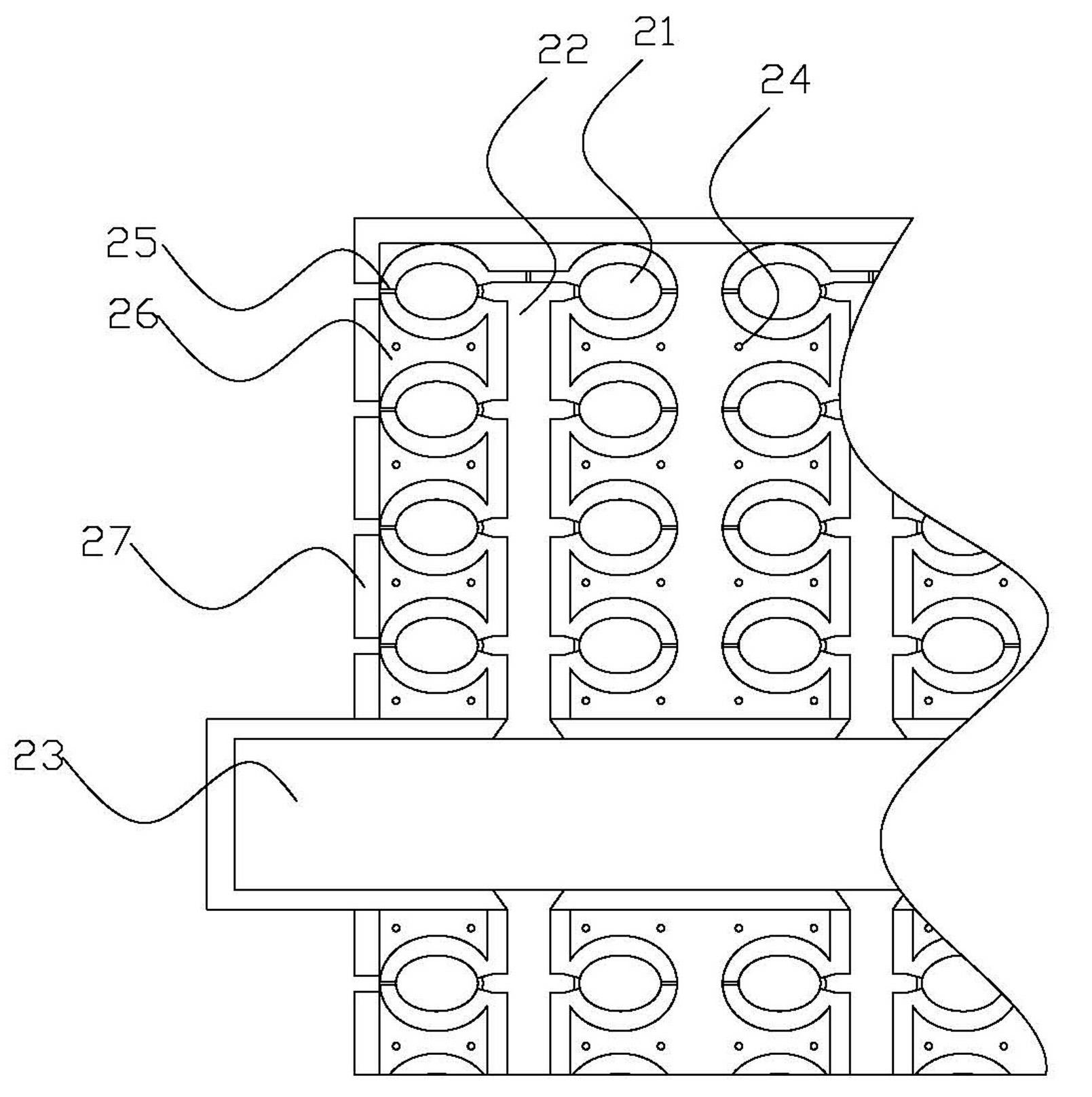

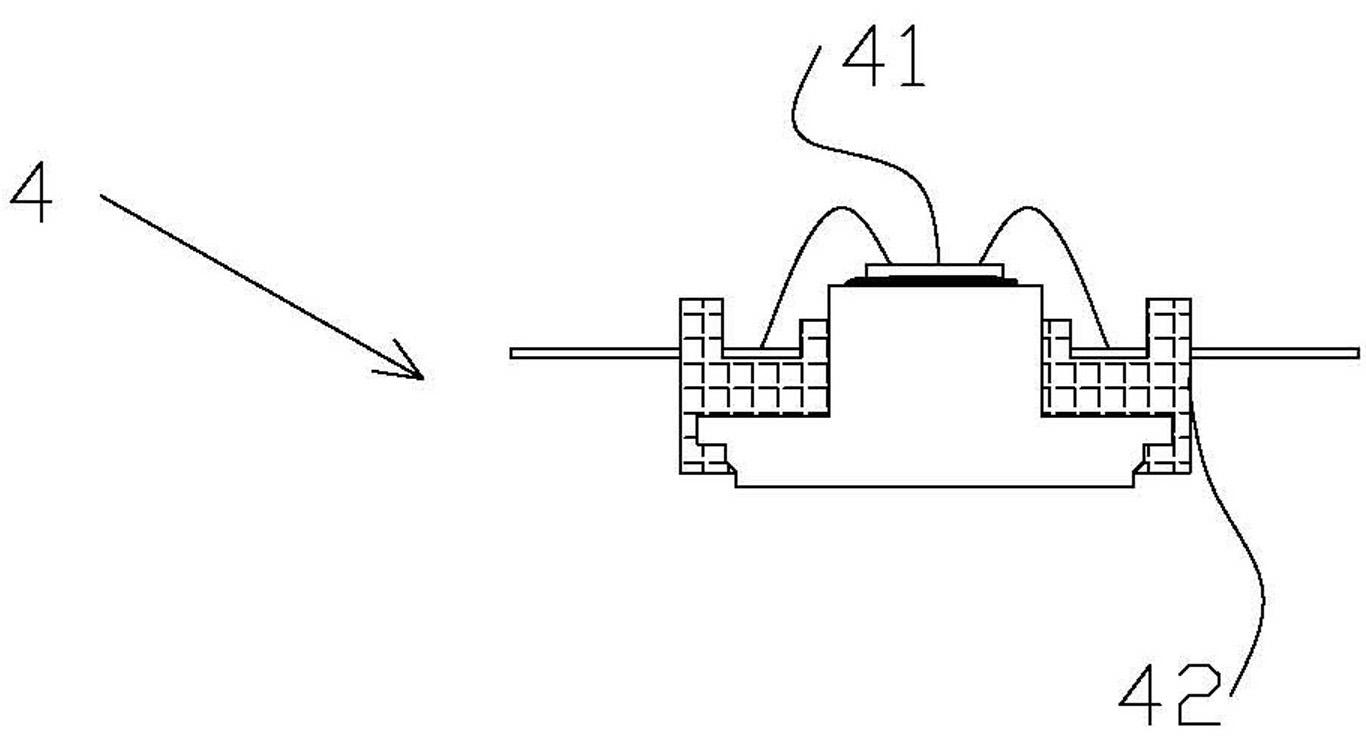

[0033] 1), prepare the upper and lower molds 1, 2 and the middle partition 3, wherein the lower mold 2 is provided with a concave cavity 21 corresponding to the shape of the upper part of the chip 41 of the LED bracket 4 to be packaged, and a glue injection into the cavity Road 22 and the glue storage groove 23 connected with the glue feeding channel 22; the upper mold 1 is provided with a positioning groove opposite to the concave cavity 21 of the lower mold 2, and the positioning groove corresponds to the lower shape of the LED bracket 4 to be packaged; Positioning holes are provided on the middle partition 3; the upper and lower molds 2 are installed in the working area of the machine for use;

[0034] 2) Put the LED bracket 4 to be packaged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com