Resin adhesive vacuum encapsulation device and process thereof

A resin glue and vacuum technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of convenient potting operation, ensuring packaging quality, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1. Resin glue vacuum potting device There are four small cases in total

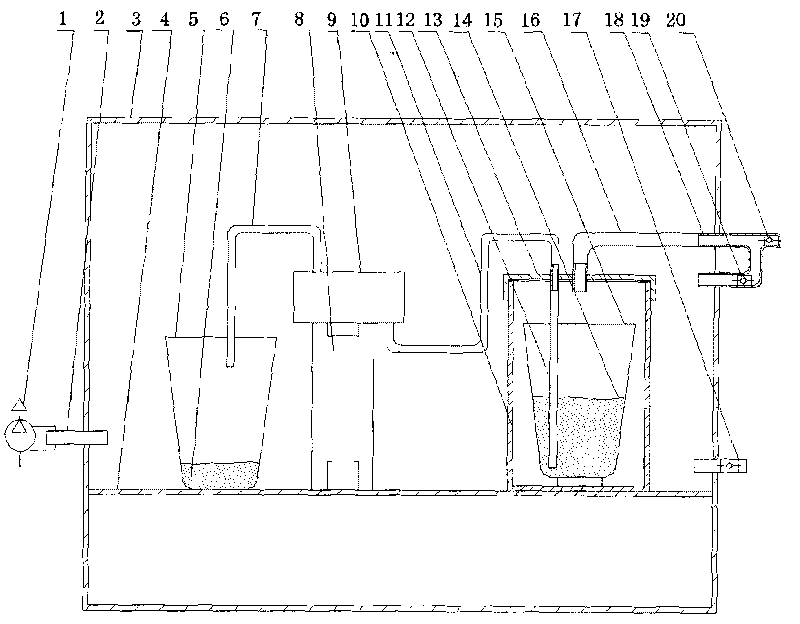

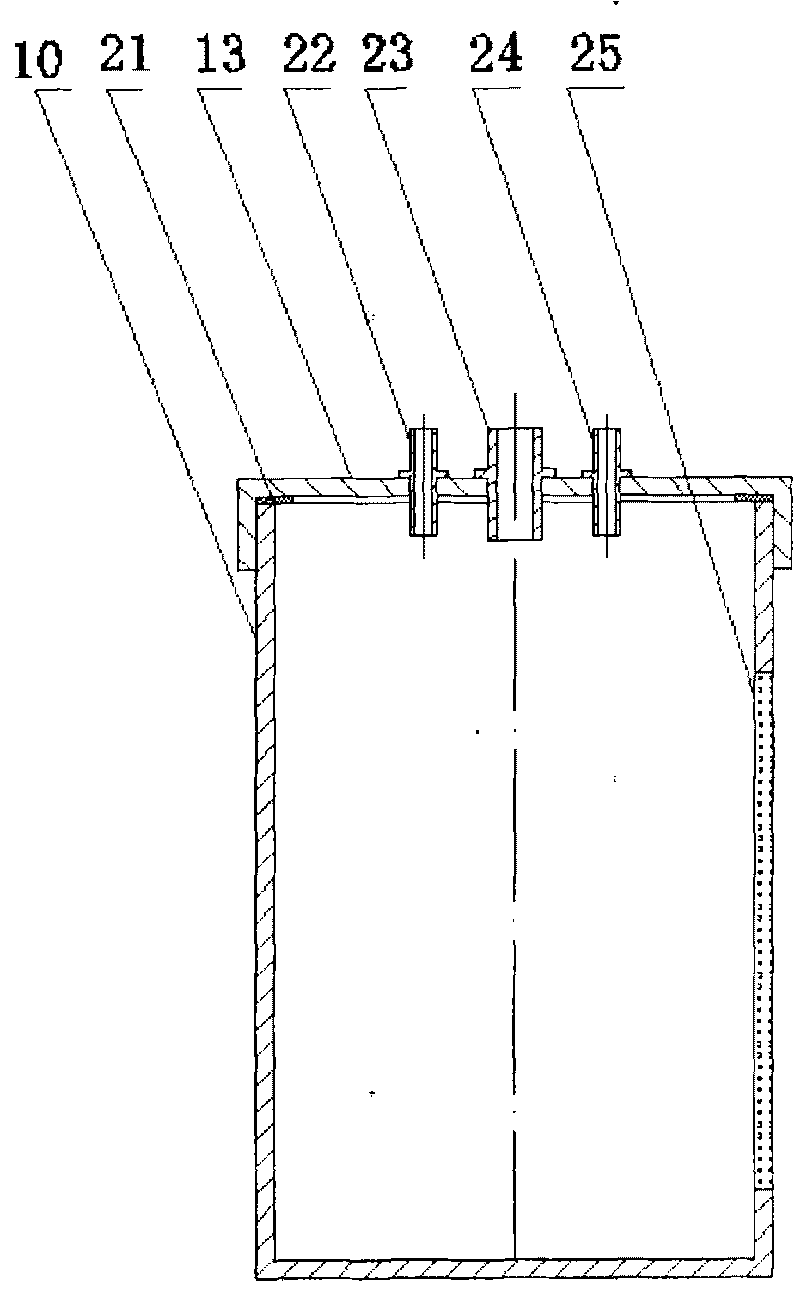

[0025] Example 1. The specific structure of the resin glue vacuum potting device of this example is as follows: figure 1 , figure 2 Jointly shown, figure 1 A structural diagram of the resin glue vacuum potting device is shown. The potting device includes a vacuum drying box 3, a vacuum pump 1, cup and tube utensils, connecting pipes, valves and the like. Described vacuum oven 3 is purchased in the market, and its model, specification, size are selected according to needs, need to be transformed before use. Set the pump interface 2 on the vacuum drying box 3 and connect the vacuum pump 1, set or install the partition 4 in the vacuum drying box 3, set or place the overflow glue cup 5, the circuit barrel 9, and place the potting on the partition 4 in sequence For the sealing cylinder 10 of the rubber cup, use the rubber inlet tube 11 and the suction tube 12 to connect the potting rubb...

Embodiment 2

[0029] Embodiment 2. Resin glue vacuum potting process There are five small examples

example 1

[0030] Example 1. The resin glue vacuum potting process of this example

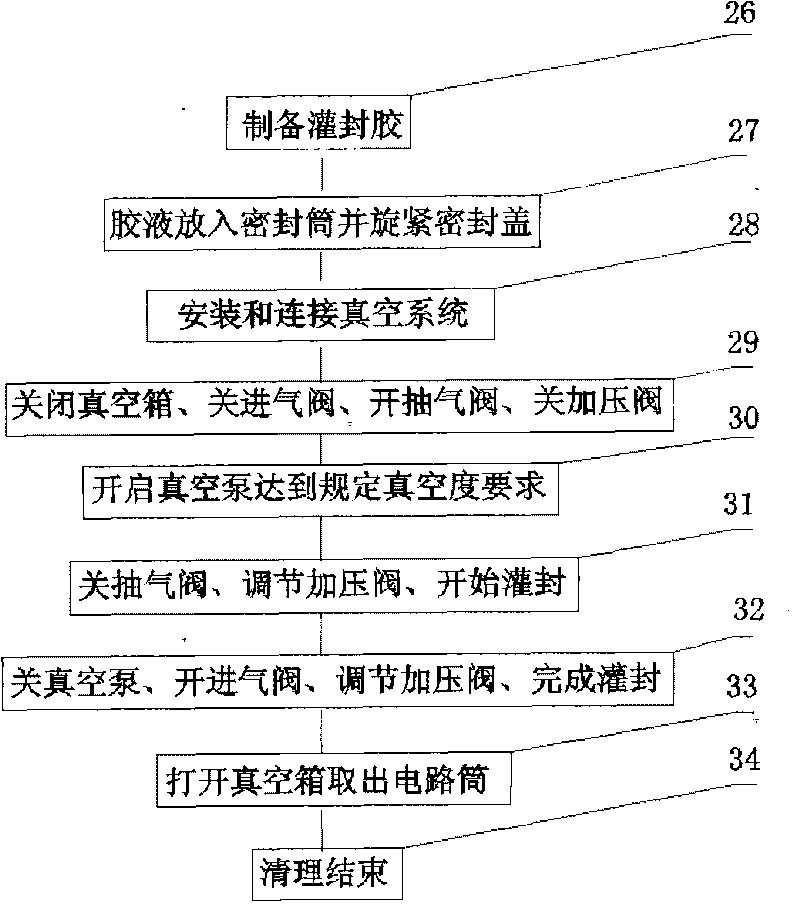

[0031] The resin glue vacuum encapsulation process of this example consists of image 3 show, image 3 The specific process steps shown include: 26 preparing vacuum potting glue, assembling or establishing a resin glue vacuum potting device or selecting a vacuum potting device for standby, taking potting glue liquid and pouring it into the potting glue cup in the sealing cylinder Adding and sealing the glue back cover the sealing tube cover, 27 to seal the sealing tube, take the circuit to be potted and put it into the circuit tube, put the circuit tube that needs to be potted into the resin glue vacuum potting device, 28 Connect all parts of the resin glue vacuum potting device, 29 control the potting device to vacuumize, 30 reach the vacuum standard and maintain the set time, observe that the potting glue basically has no volatile bubbles, 31 implement the resin glue vacuum potting circuit process and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com