Horizontal type oblique nozzle bag full-automatic packaging technology

A fully automatic packaging and fully automatic packaging machine technology, applied in packaging, packaging protection, multiple packages, etc., can solve the problems of occupying a large production site, low production efficiency, and a large number of equipment, so as to improve production efficiency and product packaging The effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

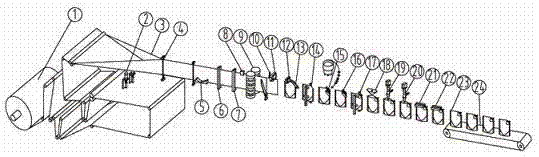

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The automatic packaging process of the horizontal type oblique mouth bag of the present invention comprises the following steps to manufacture the packaging bag:

[0031] 1. Make packaging bags.

[0032] (1) Forming of packaging film.

[0033] ①, such as figure 1 As shown, put the packaging material film roll of printed trademark and / or graphic characters into the film releasing device 1, and then start to release the film.

[0034] ②The film roll enters the packaging bag forming frame, and the packaging film is folded in half from the flat to the "V" shape, and at the same time, the bottom is punched 2 to make the packaging film fold flat.

[0035] ③ After the packaging film is formed 3, it is guided 4 by the packaging film, and the packaging film has been folded flat.

[0036] (2) Seal the bag.

[0037] ①. Send the half-folded forming fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com