Empty cigarette detecting and eliminating device

A technology of a rejecting device and a detection device, which is applied in the detection and removal device of a single cigarette short end, can eliminate single cigarette short end detection and removal devices, and can solve the problems of low packaging efficiency, waste, and increased workload of operators, etc. To achieve the effect of convenient maintenance, waste reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

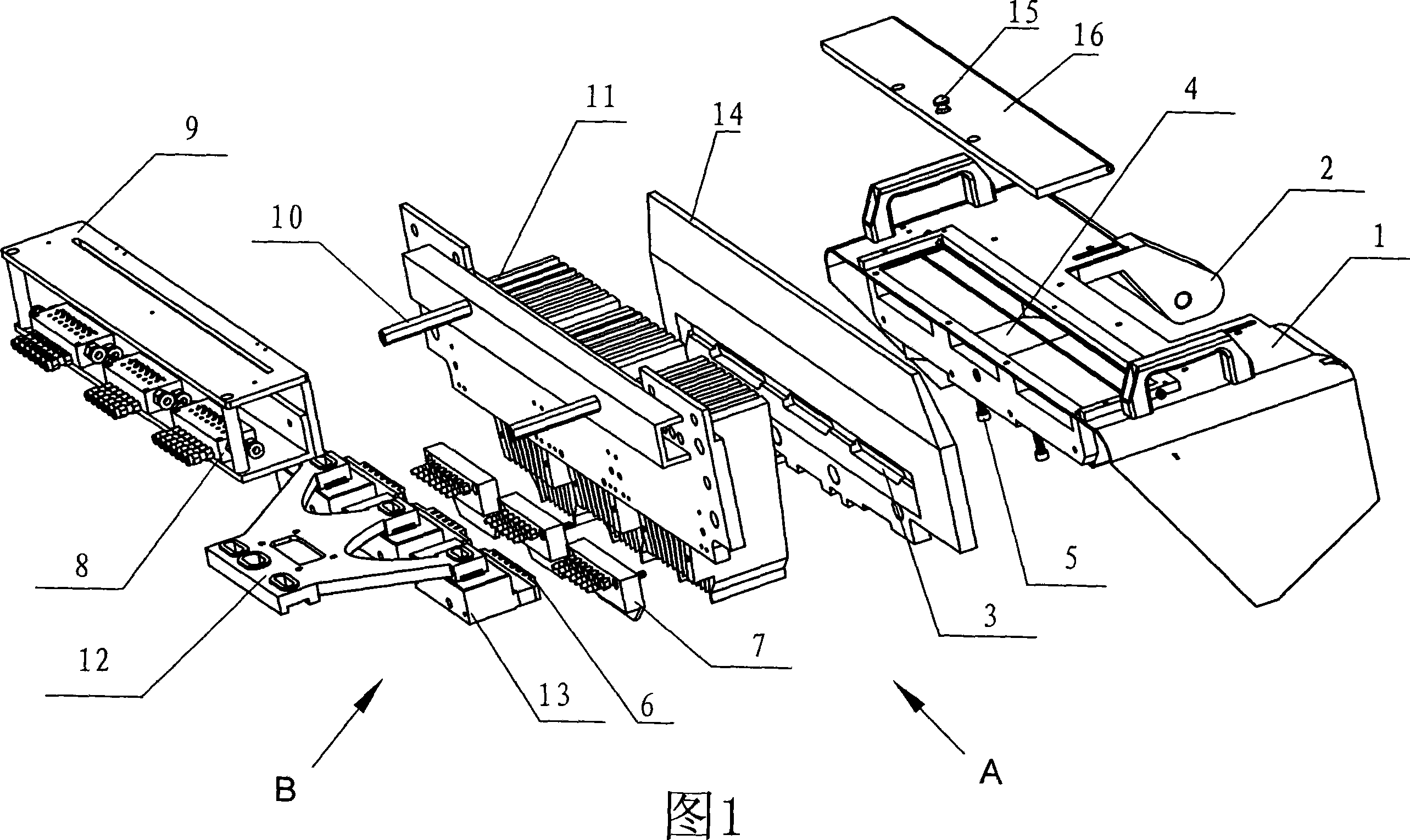

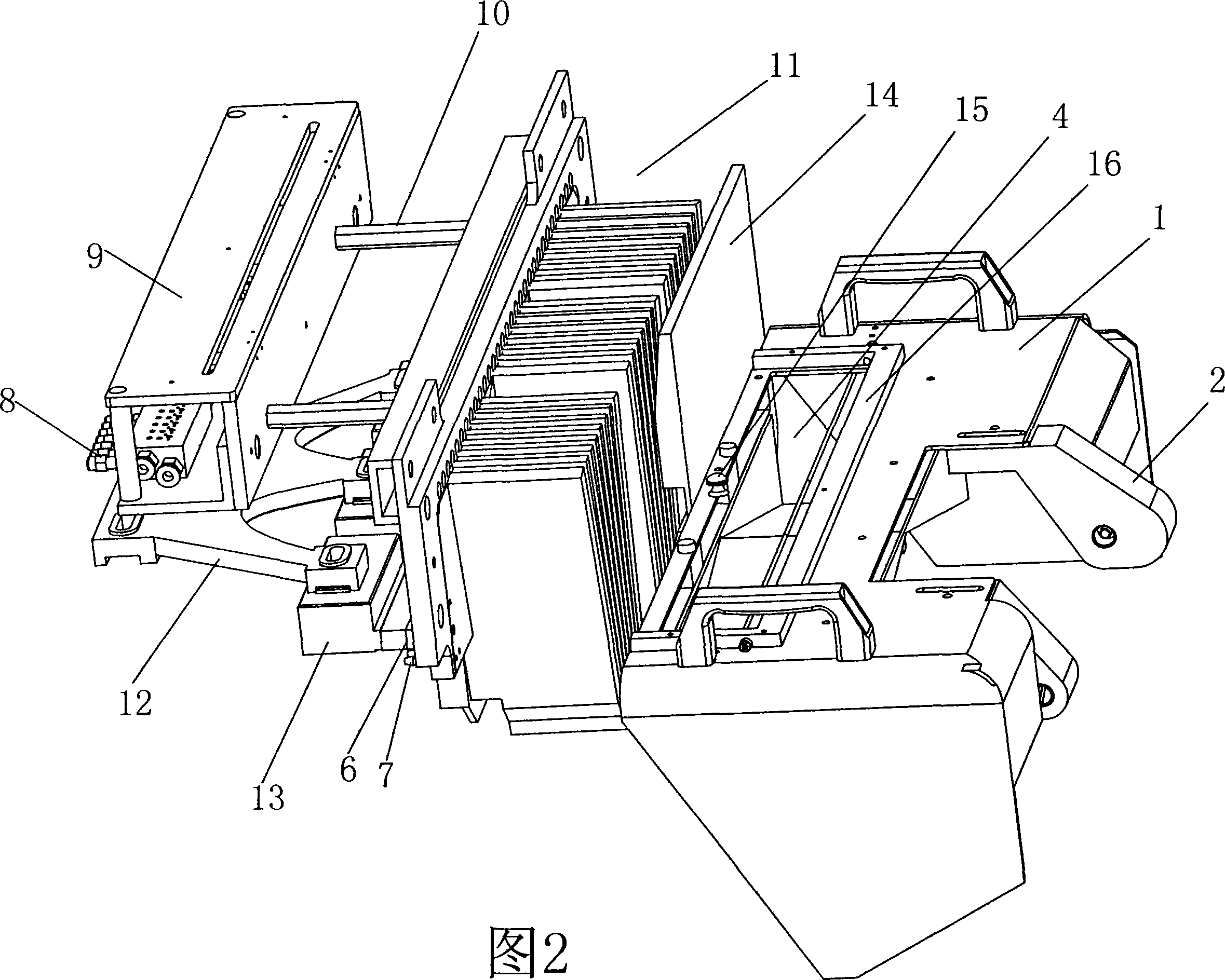

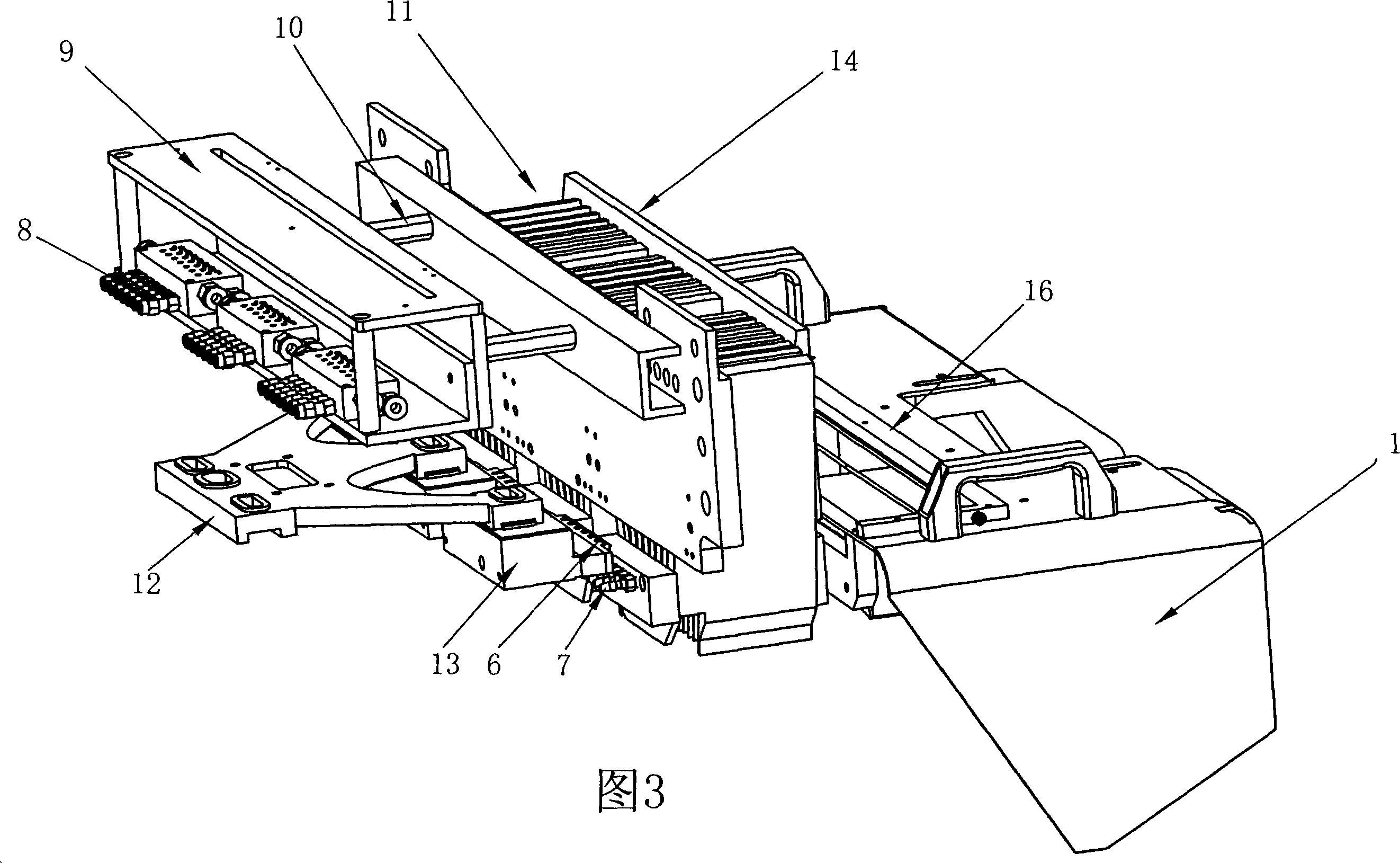

[0025] The following structural drawings and embodiments further illustrate the present invention.

[0026] As shown in Figure 1-3.

[0027] A device for detecting and rejecting short ends of a single cigarette for a GD-type cigarette packaging unit, which is composed of a detection device and a rejecting device; The outer side of the rear guard plate, its height from the inner bottom of the lower smoke channel 11 is at least greater than the diameter of two cigarettes, so as to ensure that when the sensor 6 detects an empty cigarette, the cigarette has enough time to fall to make the air nozzle 7 move to ensure When the empty cigarette falls to the air nozzle 7, the empty cigarette can be removed in time. The sensor 6 is installed on the sensor seat 13, and the sensor seat 13 is connected with the telescopic plate 12. The telescopic plate 12 drives the sensor seat 13 to reciprocate, thereby Drive the sensor 6 to reciprocate, the quantity of the sensor 6 installed on each sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com