Packaging machine

A packaging machine and lifting mechanism technology, applied in packaging machines, packaging, packaging protection and other directions, can solve the problems of economic loss, products that are easy to bump, and the packaging effect of wrapping film is not good, so as to ensure the quality of packaging, prevent products from being crushed, Good packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

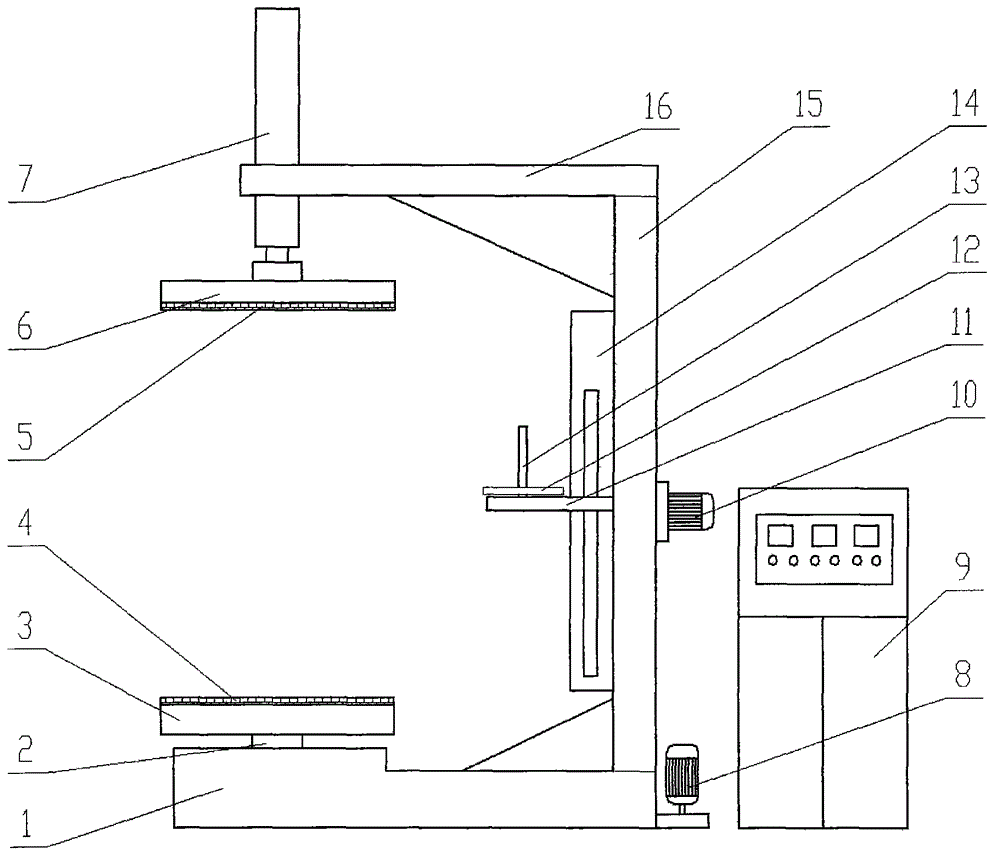

[0011] see figure 1 A kind of winding wrapping machine of the present invention shown, comprises base 1, column 15, crossbeam 16, elevating mechanism 14 and control cabinet 9, and one end of described base 1 is connected column 15, and is fixed by oblique tie bar, and the upper end of column 15 The connecting crossbeam 16 is also fixed by oblique tendons, and a lifting mechanism 14 is also installed on the column 15. The rear end of the base 1 is equipped with a turntable motor 8, and the main shaft 2 and the driving turntable 3 are connected above, and the lower turntable 3 is also installed. Disk rubber pad 4, a lifting mechanism 14 and a lifting motor 10 are installed on the column 15, a lifting platform 11 is installed on the lifting mechanism 14, a tray 12 and a rotating shaft 13 are also connected to the lifting platform 11, and one end of the beam 16 is installed A cylinder 7 is connected with a follow-up pressure plate 6 on the cylinder 7, and an upper disc rubber pad ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com