Fragile particle weighing filling machine

A filling machine and granule technology, which is applied in the field of weighing and filling machines for fragile granules, can solve the problem of high powderiness of fragile granule materials, and achieve the effects of ensuring packaging quality, convenient packaging operations, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

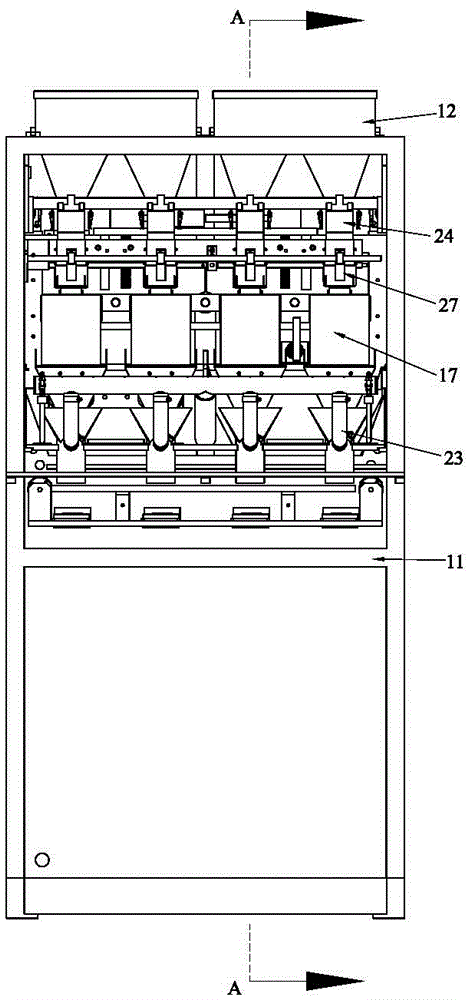

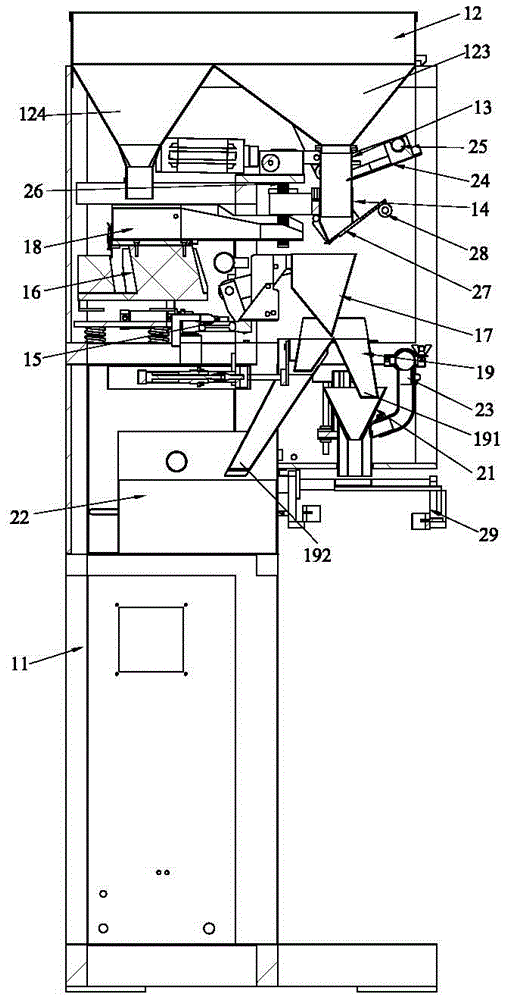

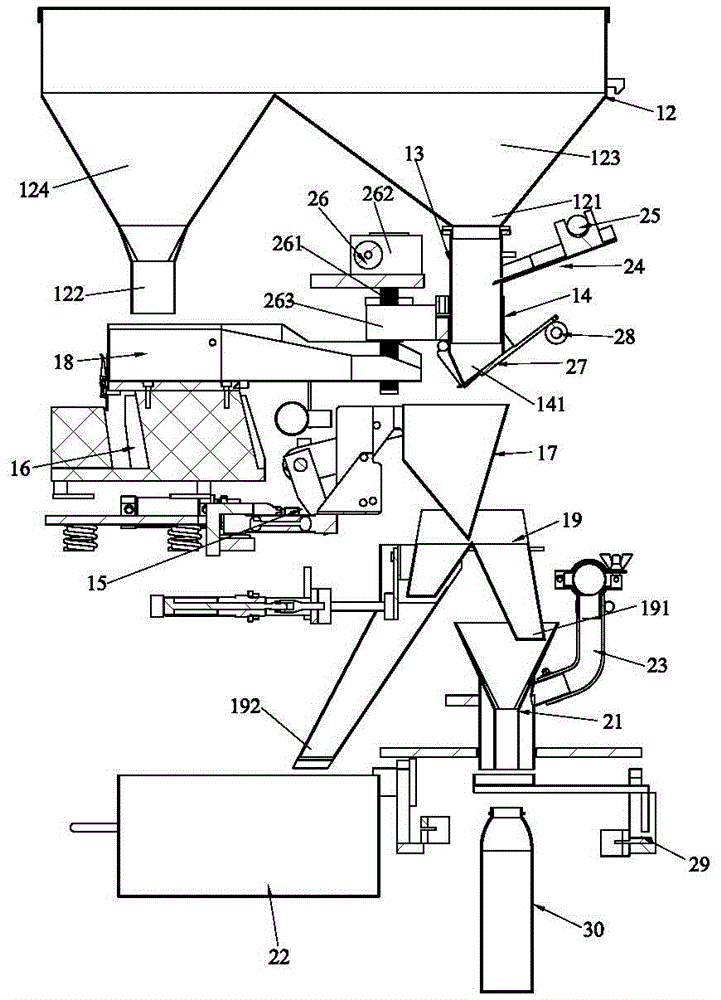

[0036] Please refer to Figure 1 to Figure 4 Shown, it has shown the concrete structure of preferred embodiment of the present invention, comprises frame 11, storage hopper 12, measuring cup 13, cup cover 14, weighing sensor 15, vibrator 16, weighing bucket 17, give Hopper 18, diverter hopper 19, filling hopper 21, recovery hopper 22 and dust suction mechanism 23.

[0037] The storage hopper 12 is arranged on the frame 11, and the storage hopper 12 has a first output port 121 and a second output port 122; in this embodiment, the storage hopper 12 has a front material tank 123 and a rear material tank 124. The first output port 121 is disposed at the bottom of the front material tank 123 , and the second output port 122 is disposed at the bottom of the rear material tank 124 .

[0038] The measuring cup 13 is fixedly connected with the storage hopper 12, the upper and lower ends of the measuring cup 13 run through, the upper end of the measuring cup 13 communicates with the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com