Slitting and feeding device for row straw

A technology of feeding device and blocking device, applied in packaging and other directions, can solve the problems of unguaranteed packaging quality, high labor intensity, low packaging efficiency, etc., and achieve the effect of saving labor, accurate cutting, and ensuring packaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

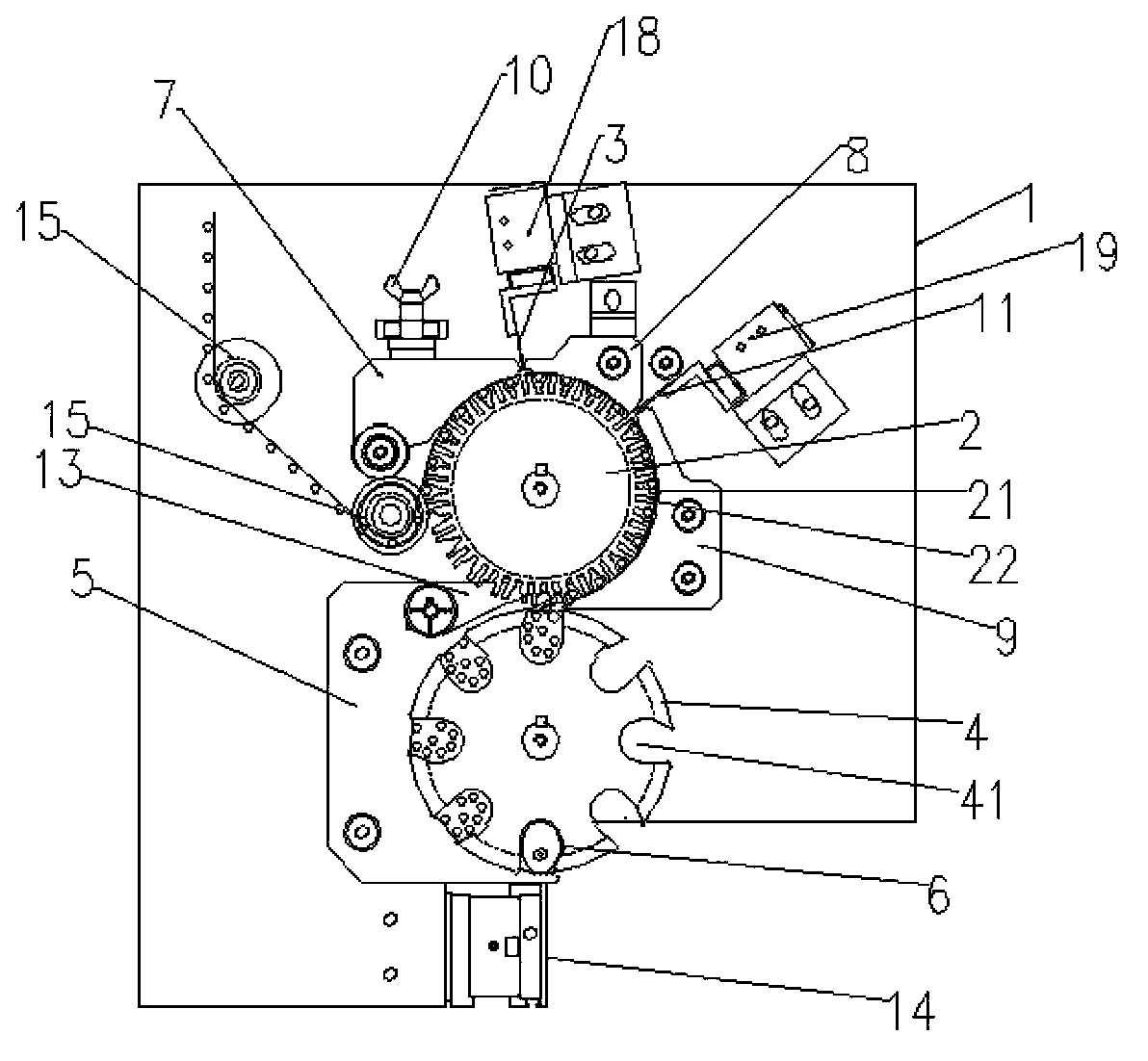

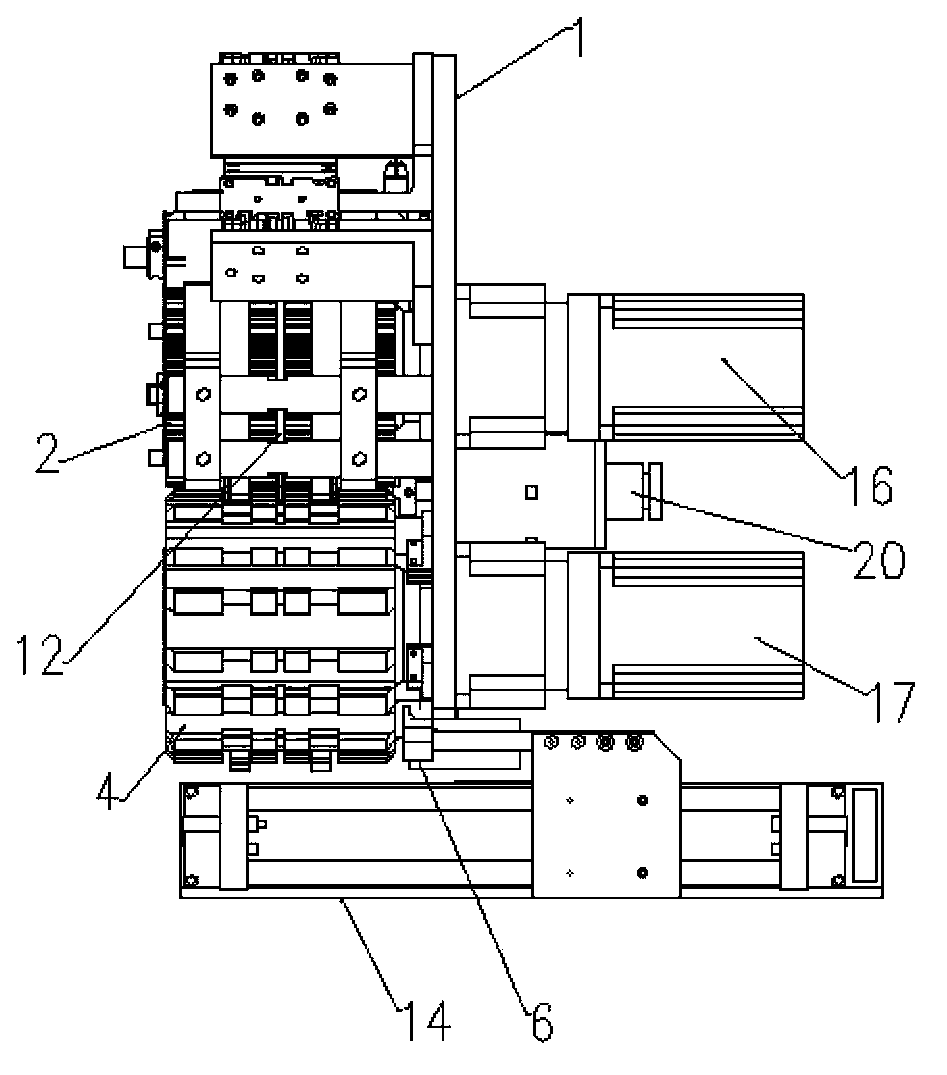

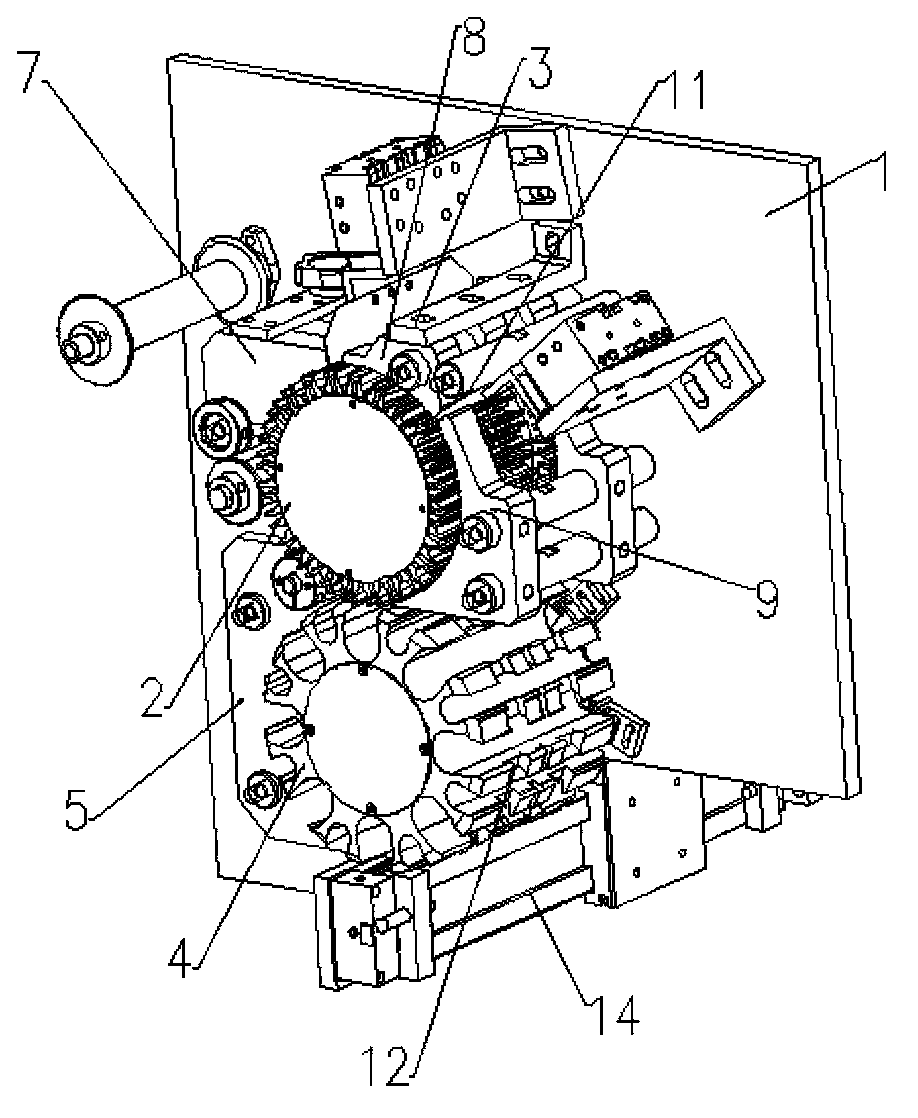

[0018] Embodiment: a kind of row suction pipe cutting, feeding device, comprises frame 1, pineapple head 2, stop material device, first cutting knife 3, collector 4, guide material device, push rod 6, controller and The first, second, third, and fourth power units 16, 17, 18, 14, the pineapple head 2 and the collector 4 can be rotated and positioned on the frame 1 respectively, and the outer surface of the pineapple head 2 circumference is provided with several axially extending The suction pipe receiving grooves 21 are provided with the knife grooves 22 extending in the axial direction between the two suction pipe containing grooves 21, and several suction pipe collecting grooves 41 are arranged at intervals on the outer surface of the circumference of the collector 4, and the material retaining device is positioned on the frame 1, the blocking device can cover the opening of the straw accommodating groove 21 between the feed end and the discharge end of the pineapple head 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com