Production line of ultrathin flexible graphite paper

A flexible graphite and production line technology, applied in the direction of inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of overall consideration and optimization of the production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following provides a specific implementation manner expressed by the drawings in the description.

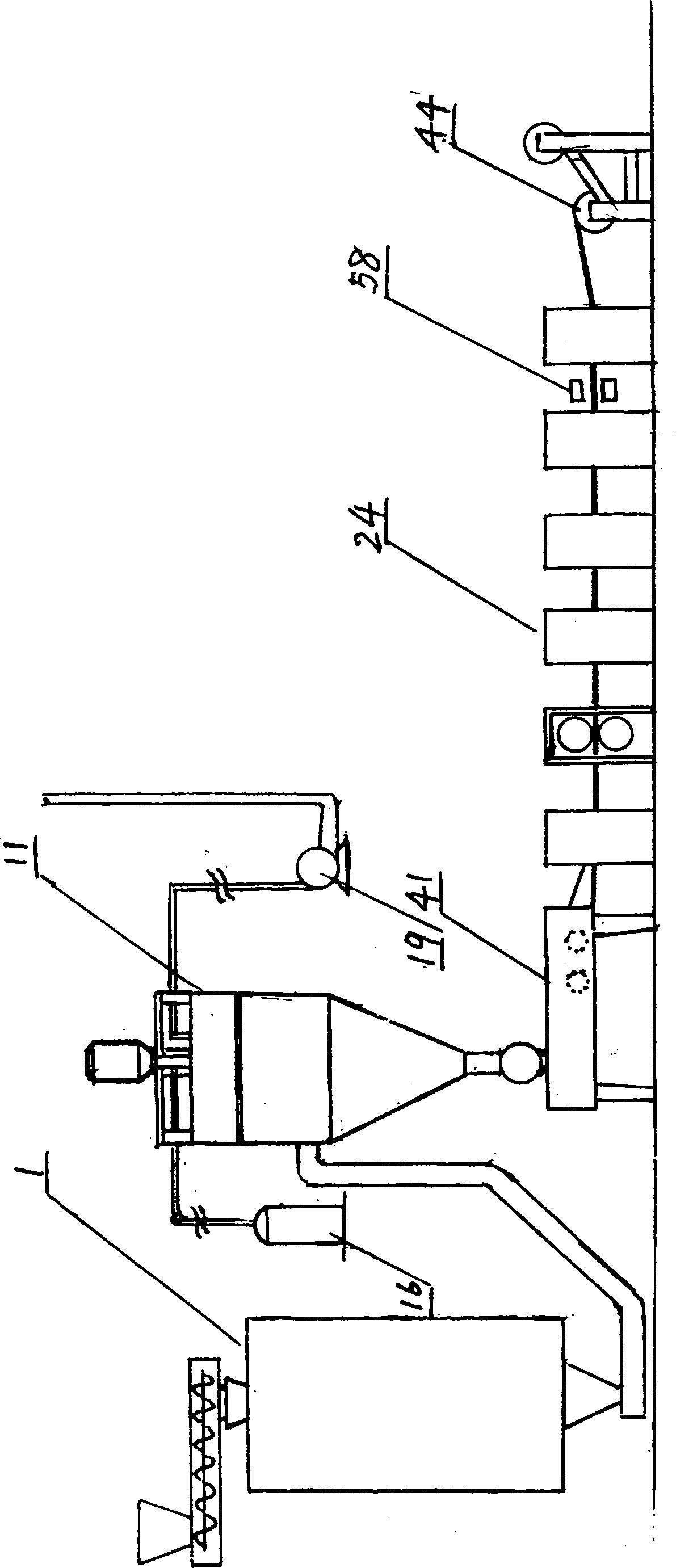

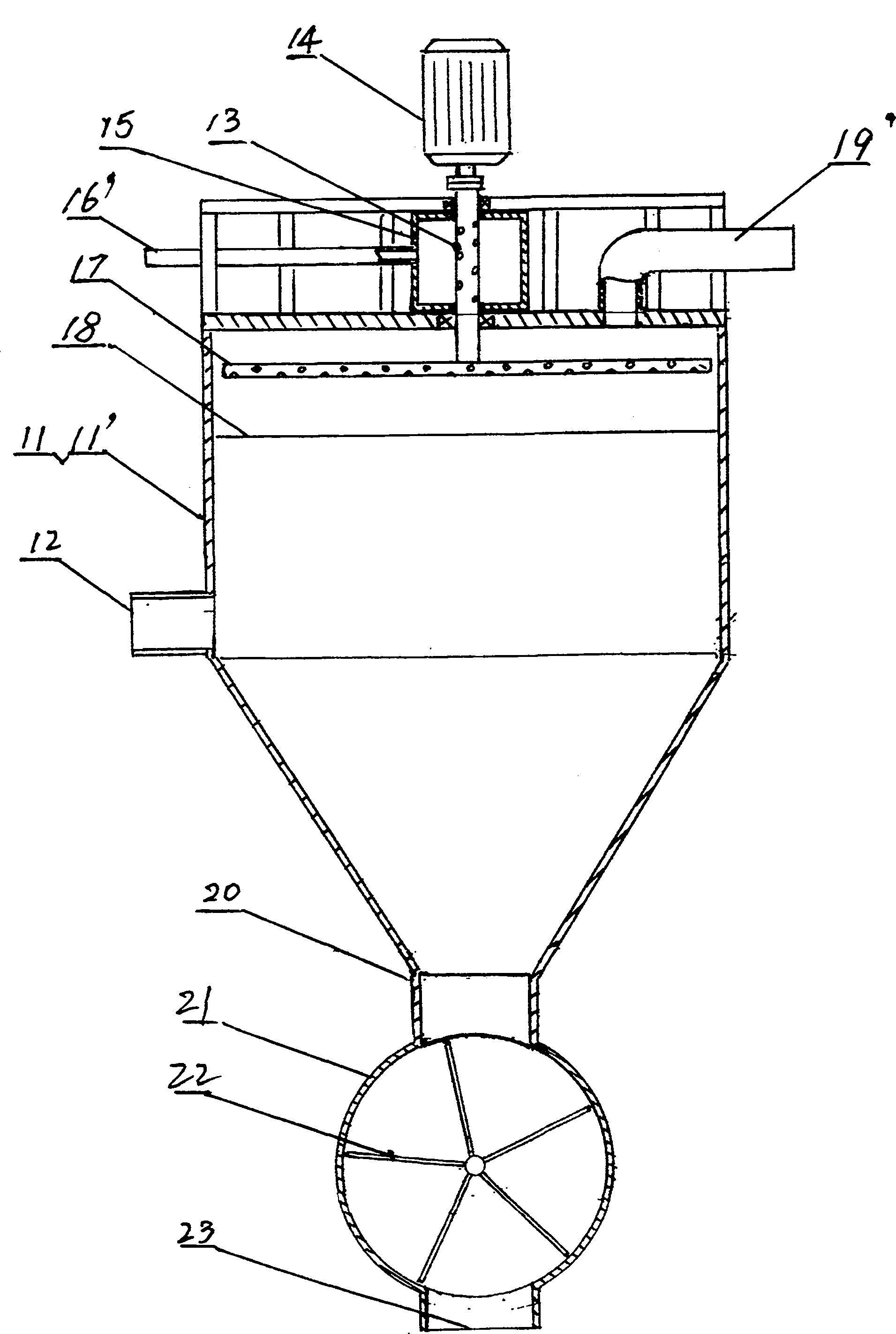

[0026] A production line for ultra-thin flexible graphite paper, comprising five major parts: a graphite expansion device 1, a desulfurization device 11, a material distribution device 41, a calendering device 24 and a paper rolling device 44.

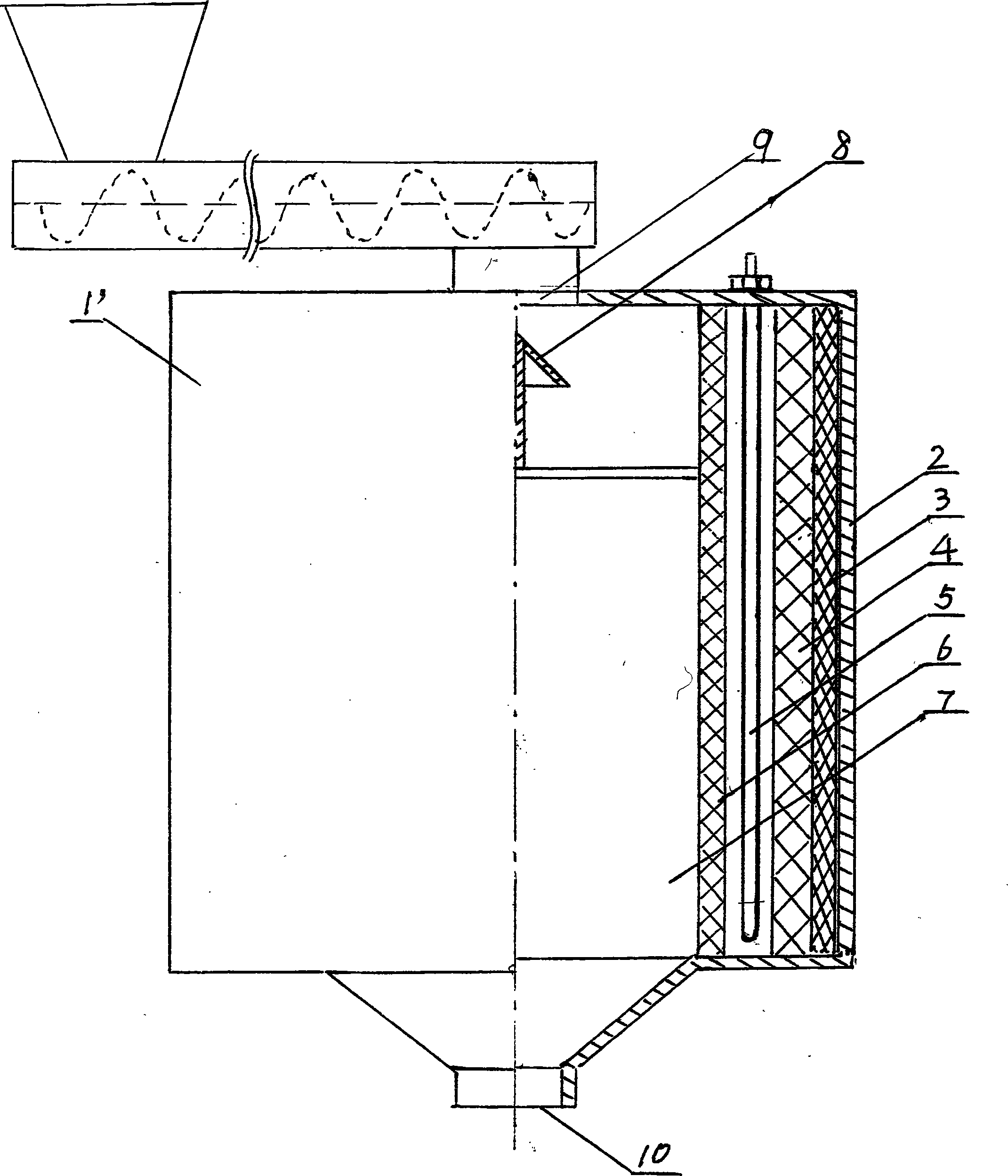

[0027] Graphite expansion device 1 as attached figure 2 As shown, a cylindrical cylinder vertical expansion furnace 1' is adopted, which is composed of a shell 2, which is composed of an insulating cotton layer 3, an insulating brick layer 4, an electric heating tube 5, and an electrode material expansion tube 6. The lumen of the expansion tube is Graphite Expansion Channel 7. The top of the expansion furnace is provided with a feed port 9, which is connected to the feed hinge, and the bottom is provided with a discharge port 10, which is connected to the feed port of the desulfurizer through a pipeline. Mullite bricks are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com