Coaxial multi-beam laser synthesis axis powder feeding ultrahigh-speed laser cladding head and cladding method thereof

A technology of laser cladding and laser synthesis, applied in metal material coating process, coating and other directions, can solve the problems of low utilization rate of powder, low cladding efficiency, insufficient energy required for melting powder, etc., to improve efficiency and speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further explained in detail in conjunction with the accompanying drawings.

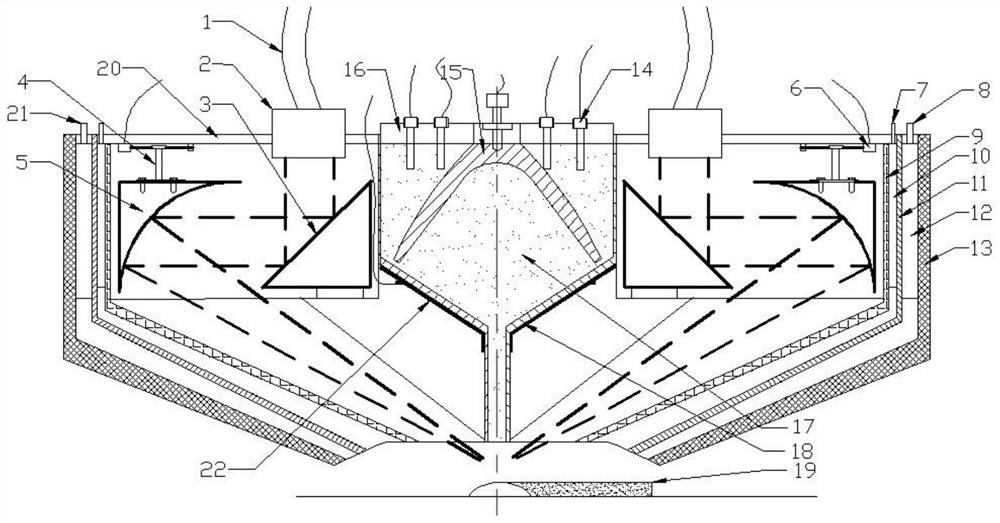

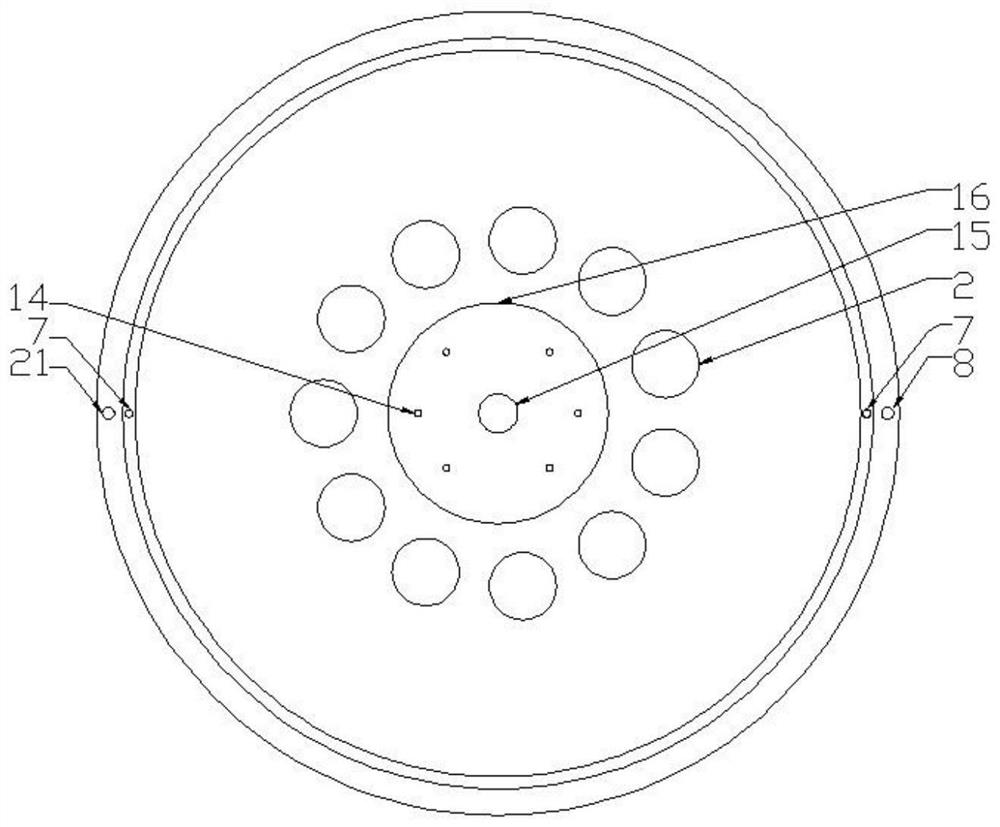

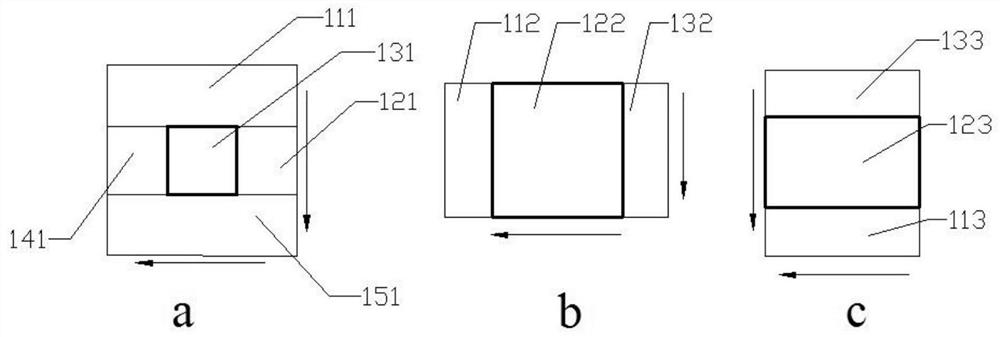

[0042] figure 1 A schematic cross-sectional structure diagram of a coaxial multi-beam laser synthesis axial powder feeding ultra-high-speed laser cladding head is shown; figure 2 It shows the top view of a coaxial multi-beam laser synthesis axis powder feeding ultra-high-speed laser cladding head; image 3 A schematic diagram showing the design of three square laser spots to synthesize a large spot; Figure 4 A schematic diagram of the design of two circular laser spots to synthesize a large spot is shown.

[0043] The structure of a coaxial multi-beam laser synthesis axial powder feeding ultra-high-speed laser cladding head in the embodiment of the present invention mainly includes: transmission optical fiber 1, laser collimator 2, 45-degree reflector 3, parabolic mirror fixing device 4, separation Axial parabolic mirror 5, mini slide rail 6, air inlet 7, wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com