Full-automatic dough cake frying machine

An oil cake machine, a fully automatic technology, is applied in the utensils, household appliances, applications and other directions for frying things in oil, which can solve the problems of inability to effectively control the oil temperature, inconvenient control of the frying process, and slow production of oil cakes. Conducive to environmental protection, reduced fuel costs, and guaranteed health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

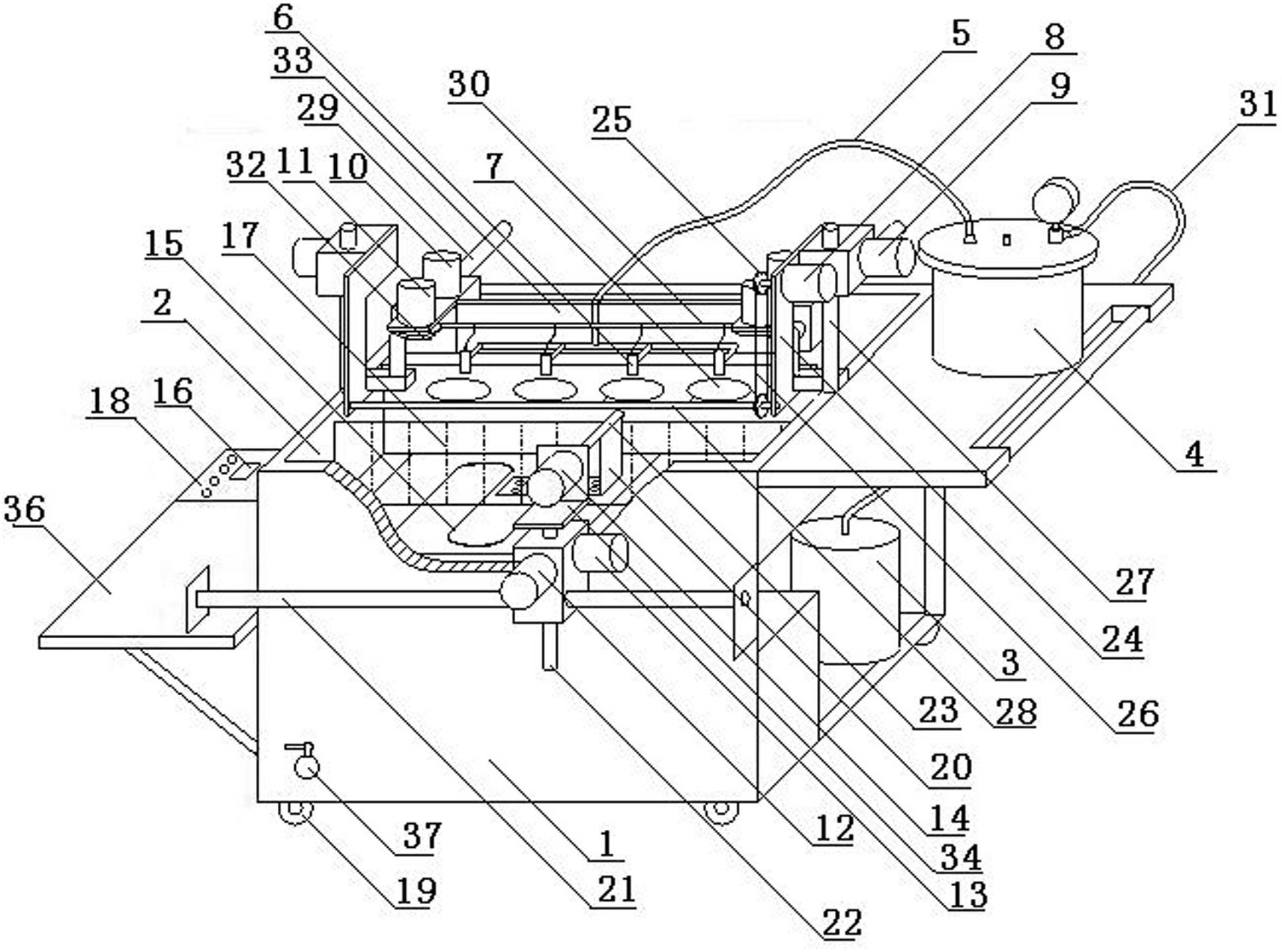

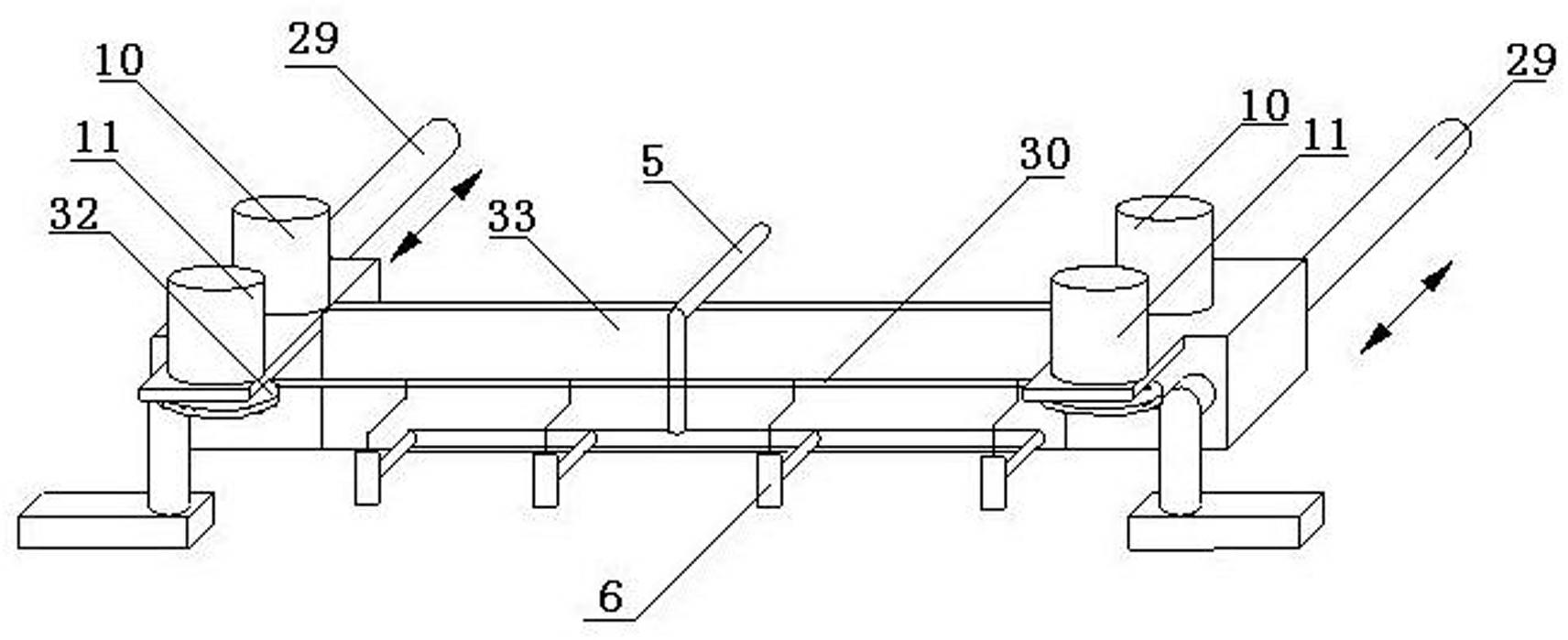

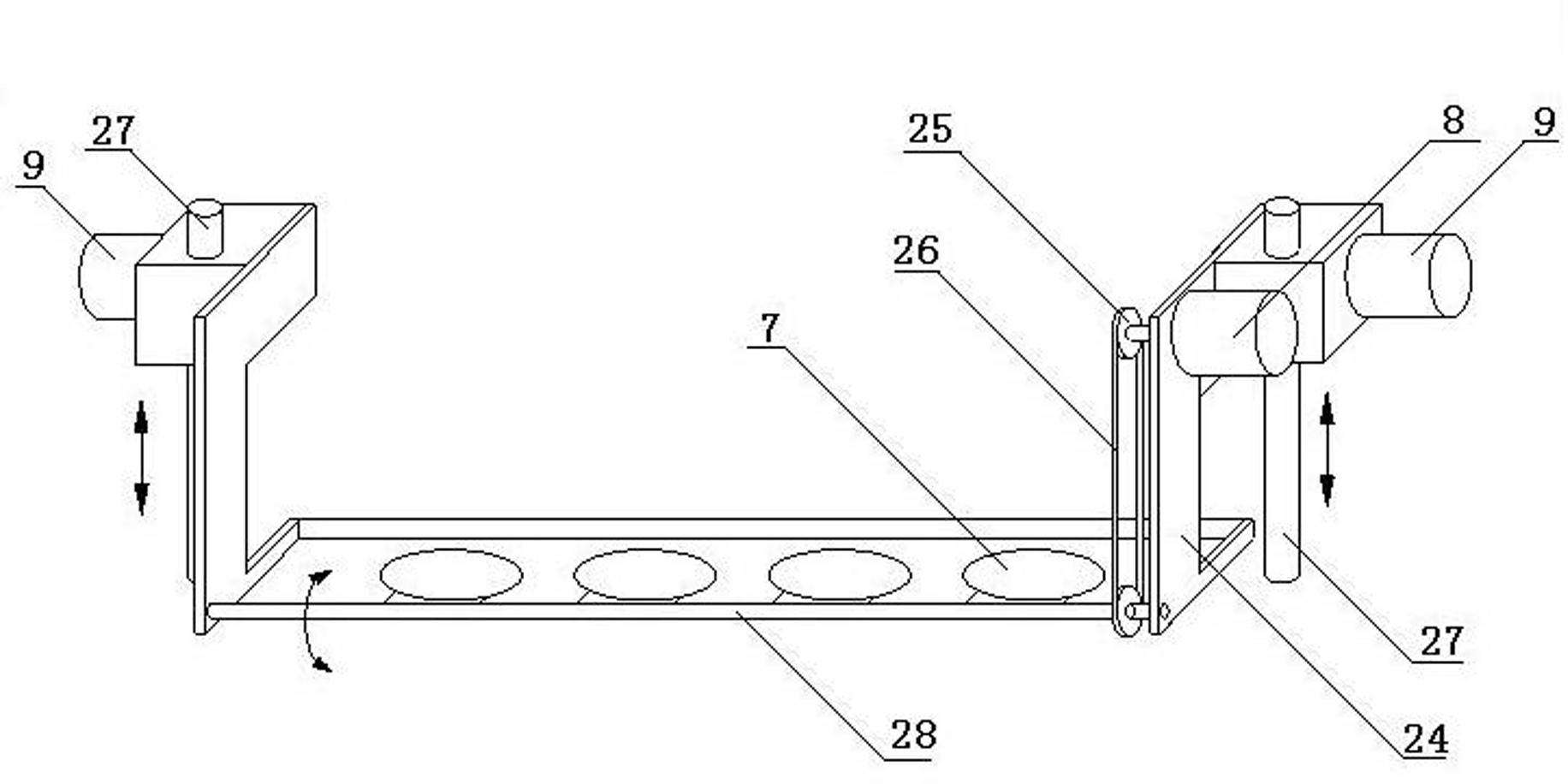

[0028] The embodiment structure of full-automatic deep-fried oil cake machine of the present invention, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, it includes frame 1, oil tank 2, raw material infusion device, material ladle 7 and material ladle driving device, heating device, oil cake collection device, electric control system, oil tank 2, raw material infusion device, material ladle 7 and material ladle The driving device, heating device, oil cake collecting device and electric control system are all arranged on the frame 1. Mobile wheels 19 are installed at the bottom of the frame 1, a cleaning box 35 is provided at the rear of the frame 1, and an oil discharge valve 37 is provided at the side of the frame 1; The raw material infusion device comprises an air compressor 3, a pressure barrel 4, a pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com