Preparation device and preparation process of power lithium ion battery pole piece

A technology for lithium-ion batteries and preparation devices, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of poor consistency of batteries, increased internal resistance of batteries, and poor cycles, and achieves uniform thickness, winding cores, etc. even size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation process for a pole piece of a power lithium-ion battery, comprising the steps of:

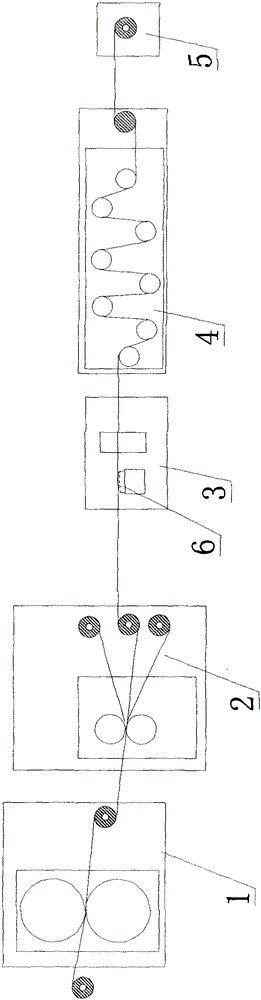

[0022] Step 1: Place the coated pole piece in the roller machine 1 with a winding device at the end, and wind the pole piece after the roller into the winding device at the end of the roller machine 1;

[0023] Step 2: Make the pole piece reeled to the winding device at the end of the roller machine 1 described in step 1 pass through the slitting machine 2 with a slitting and winding device for slitting, and wind the pole piece after slitting To the slitting and winding device;

[0024] Step 3: Make the pole piece reeled into the slitting and winding device described in step 2 pass through the film making machine 3, and the pole piece is welded and pasted with high-temperature adhesive tape in the film making machine 3;

[0025] Step 4: Make the pole piece described in step 3 after the pole piece is welded and pasted with high-temperature adhesive tape pass through the ove...

Embodiment 1

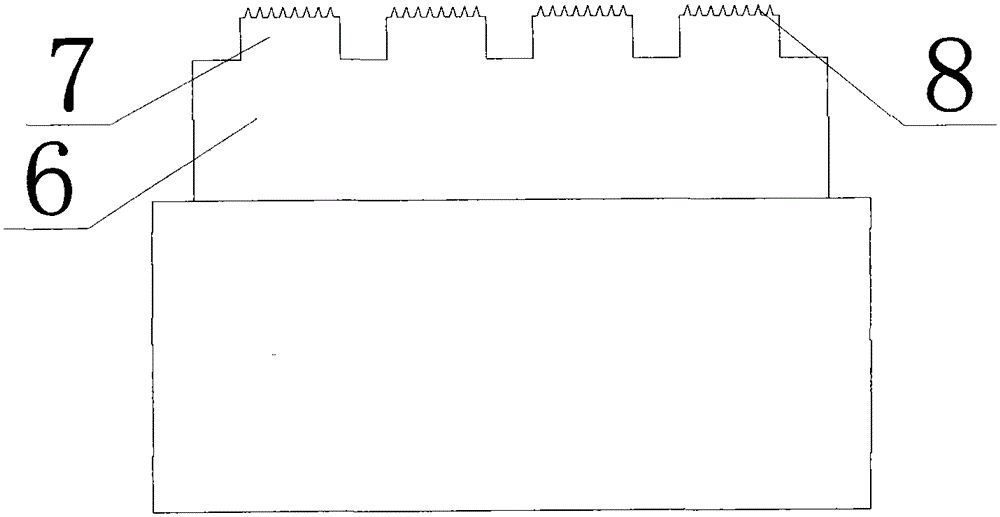

[0030] A power lithium-ion battery pole piece preparation device, comprising a roller machine 1 with a winding device at the end, the tail end of the roller machine 1 with a winding device at the end is sequentially installed with a cutting and winding device A slitting machine 2, a film making machine 3, an oven 4 with a post-baking rewinding device and a battery pole sheet winding machine 5; the inside of the oven 4 with a post-baking rewinding device is provided with a conveying device. The conveying device is a conveying belt. The tablet machine 3 is provided with an ultrasonic welding machine, the ultrasonic welding machine is provided with a welding head 6, the top of the welding head 6 is provided with a welding point 7, and the top of the welding point 7 is provided with several lines 8 , the height of the lines 8 is less than 0.10mm. The sum of the bottom areas of the several lines 8 is less than half of the top area of the solder joint 7 . The material of the wel...

Embodiment 2

[0039] A power lithium-ion battery pole piece preparation device, comprising a roller machine 1 with a winding device at the end, the tail end of the roller machine 1 with a winding device at the end is sequentially installed with a cutting and winding device A slitting machine 2, a film making machine 3, an oven 4 with a post-baking rewinding device and a battery pole sheet winding machine 5; the inside of the oven 4 with a post-baking rewinding device is provided with a conveying device. The conveying device is a conveying roller. The tablet machine 3 is provided with an ultrasonic welding machine, the ultrasonic welding machine is provided with a welding head 6, the top of the welding head 6 is provided with a welding point 7, and the top of the welding point 7 is provided with several lines 8 , the height of the lines 8 is less than 0.10mm. The sum of the bottom areas of the several lines 8 is less than half of the top area of the solder joint 7 . The material of the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com