Supersonic ejector

A technology of supersonic speed and ejector, which is applied in the directions of jet pumps, fluid mixers, machines/engines, etc., and can solve the problems of the ejected airflow not having time to expand, interfere, and waste pressure energy, etc., and achieve simple installation, easy processing, The effect of air mixing is sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention will be described in detail below in conjunction with the accompanying drawings.

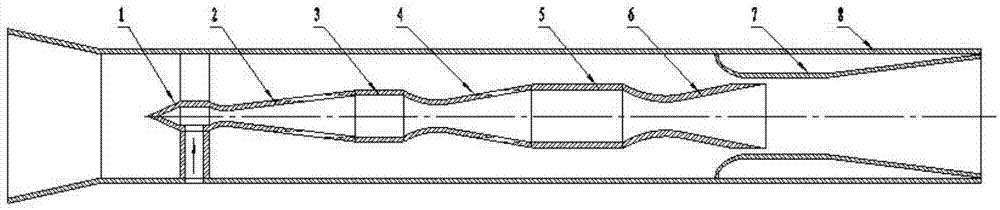

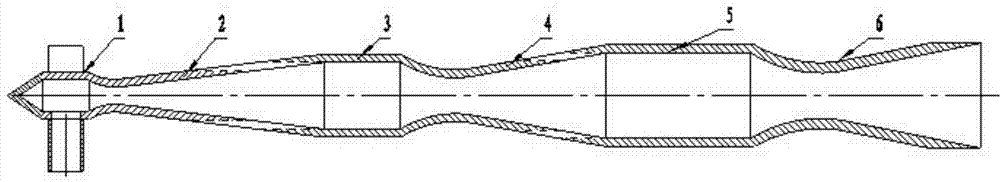

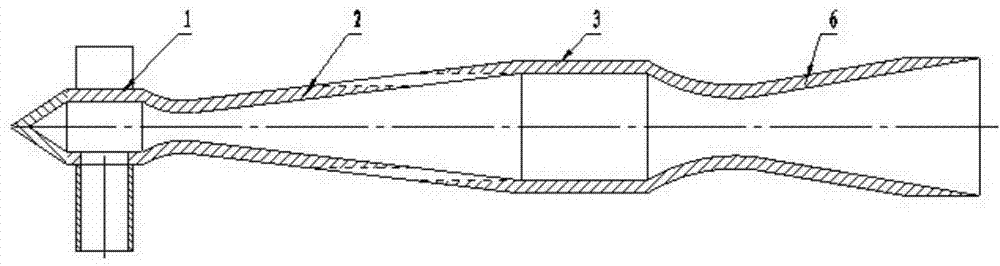

[0022] When the pressure of the gas source of the ejector is high, the nozzle is used to expand and compress the gas multiple times, and the serial staged air intake is adopted to improve the mixing efficiency and reduce the pressure loss. Reasonable distribution of intake air volume between stages is particularly important for improving ejection efficiency. figure 1 It is a structural diagram of a supersonic ejector, and the ejector includes: an intake pressure chamber 1, a nozzle 2, a mixing chamber 3, a nozzle 4, a mixing chamber 5, a tail nozzle 6, a supersonic diffuser section 7 and a shell cylinder 8. According to the design of the present invention, the above nozzles 2 and 4 are all Laval nozzles, and the peripheral walls of the expansion parts are provided with forward air inlet grooves. The nozzle 2, the mixing chamber 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com