Phosgene production device and method

A carbonyl chloride and equipment technology, applied in the field of carbonyl chloride preparation, can solve the undisclosed problems of long-term continuous industrial production of carbonyl chloride, large gas pressure loss, large-scale implementation process, etc., to achieve simple implementation process and reduce loss , Guarantee the effect of production quality and production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

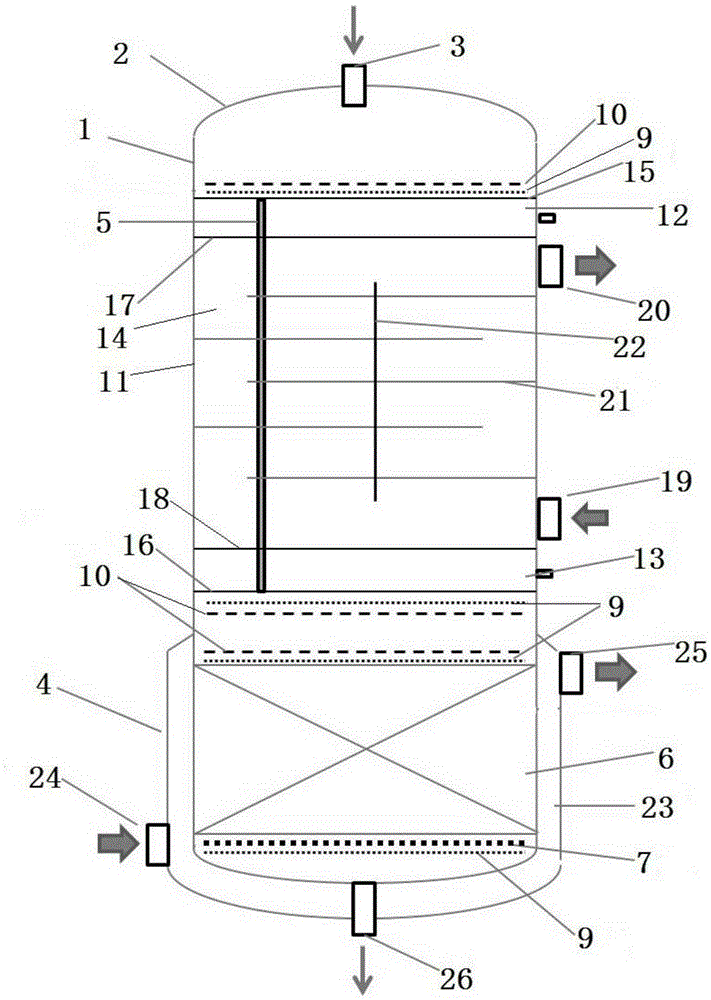

[0040] like figure 1 and figure 2 As shown, a device for producing phosgene includes a reactor shell 11, and the reactor shell 11 is provided with a primary reactor 1 and a secondary reactor 2. The upper end of the primary reactor 1 is connected with the raw material inlet 3 through the head 2, and the lower end is connected with the secondary reactor 4 through the connection section, and the other end of the secondary reactor 4 is connected with a phosgene outlet 26.

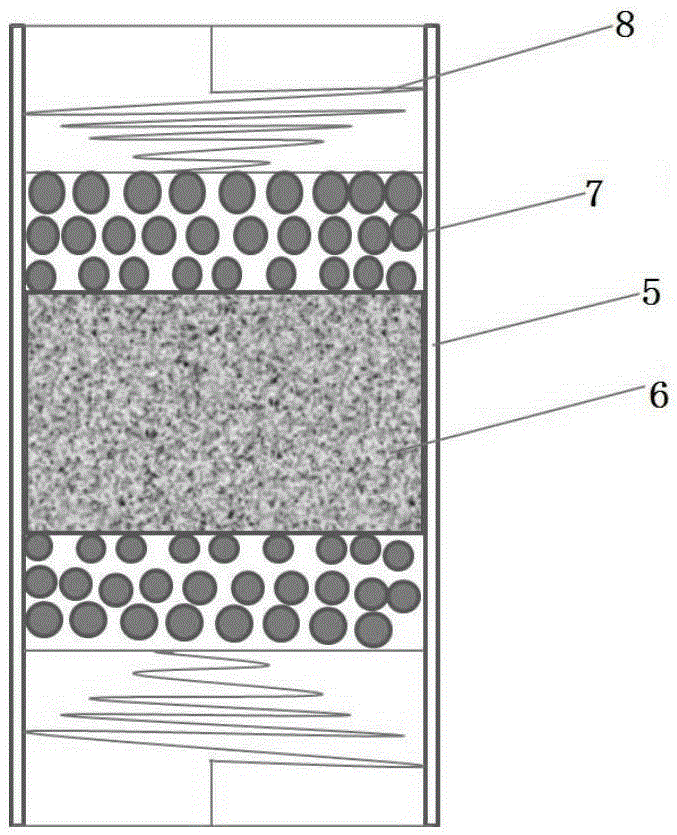

[0041] A tube-and-tube reaction tube bundle is arranged vertically in the primary reactor 1 , and the reaction tube bundle is composed of a plurality of reaction tubes 5 . The shell of the secondary reactor 4 is provided with a main body of the reaction zone, and the reaction tube 5 and the main part of the reaction zone of the secondary reactor 4 are filled with a fixed-bed catalyst 6 . For a clearer illustration, in figure 1 Only one reaction tube 5 is shown schematically.

[0042] The reactor housing 11...

Embodiment 2

[0059] Example 2 uses the same equipment as Example 1. In the method according to the present invention, the molar ratio of the raw materials CO and chlorine used is 1.07-1.10, and the residual chlorine is 40-60 ppm. The absolute pressure of the mixed gas is 0.48Mpa~0.52Mpa.

[0060] By properly selecting the coolant pressure and coolant temperature, the outlet product temperature is 65-80°C. The primary reactor 1 is cooled by means of the cooling chamber 14 and the loop, and the phosgene leaves the primary reactor 1 at a temperature of 80-90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com