Preparation method of TS-1 molecular sieve microspherical catalyst with magnetism and application

A TS-1, magnetic microsphere technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as no reaction process involved, save the cost of product purification, convenient operation, secondary less reactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

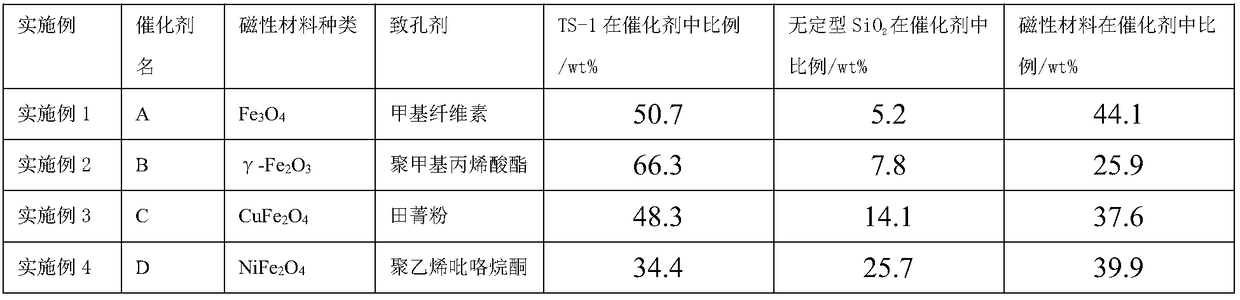

Examples

Embodiment 1

[0028] This example illustrates the preparation method of composite magnetic TS-1 molecular sieve catalyst microspheres

[0029] (1) 500g of superparamagnetic 0.5-1.0μm Fe 3 o4 Ultrasonic dispersion of powder into 5L of HNO with a concentration of 0.2mol / L 3 Pretreatment was carried out in the solution, the magnetic particles were fully washed with deionized water, and then ultrasonically dispersed into 5 kg of ethanol-water mixture (ethanol content: 32 wt%). Then add 750ml of 25% ammonia solution, add 50ml of ethyl silicate (TEOS) during stirring, continue to stir at 50°C for 6h, separate the product with a magnet, and then dry it in vacuum at 55°C for 16h to obtain amorphous SiO 2 Coated magnetic particles, denoted as Fe 3 o 4 @SiO 2 .

[0030] (2) The magnetic particle Fe in (1) 3 o 4 @SiO 2 It is mixed with silica sol (concentration 30wt%), TS-1 molecular sieve, and methylcellulose to form a 30wt% slurry, and then prepared into 30-60μm microspheres by spray-drying ...

Embodiment 2

[0032] This example illustrates the preparation method of composite magnetic TS-1 molecular sieve catalyst microspheres

[0033] (1) 500g of superparamagnetic 0.5-2μm γ-Fe 2 o 3 The powder is ultrasonically dispersed into 3L of 0.4mol / L acetic acid solution for pretreatment, fully washes the magnetic particles with deionized water, and then ultrasonically disperses it into a 3kg isopropanol-water mixture (isopropanol content: 25wt%) )middle. Then add 600ml of 28% ammonia water, add 57ml of methyl silicate (TMOS) during the stirring process, continue to stir at 60°C for 5h, separate the product with a magnet, and then vacuum dry at 60°C for 12h to obtain amorphous SiO 2 Coated magnetic particles, denoted as γ-Fe 2 o 3 @SiO 2 .

[0034] (2) The magnetic particle γ-Fe in (1) 2 o 3 @SiO 2 It is mixed with silica sol (concentration 30wt%), TS-1 molecular sieve, and polymethacrylate to form a 35wt% slurry, and then prepared into 30-60μm microspheres by spray-drying molding ...

Embodiment 3

[0036] This example illustrates the preparation method of composite magnetic TS-1 molecular sieve catalyst microspheres

[0037] (1) 500g superparamagnetic 0.5-2μm CuFe 2 o 4 The powder was ultrasonically dispersed into 4L of citric acid solution with a concentration of 0.25mol / L for pretreatment, the magnetic particles were fully washed with deionized water, and then ultrasonically dispersed into 4kg of ethanol-water mixture (ethanol content: 81wt%). Then add 800ml of 20% ammonia water, add 118ml of propyl silicate (TPOS) during the stirring process, keep stirring at 45°C for 8h, separate the product with a magnet, and then dry it in vacuum at 50°C for 20h to obtain amorphous SiO 2 Coated magnetic particles, denoted as CuFe 2 o 4 @SiO 2 .

[0038] (2) The magnetic particles CuFe in (1) 2 o 4 @SiO 2 It is mixed with silica sol (concentration: 30wt%), TS-1 molecular sieve, and turnip powder to form a 40wt% slurry, and then prepared into 40-70μm microspheres by spray-dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com