Method for preparing ultra-clean high-purity hydrochloric acid

A hydrochloric acid and net high technology, applied in chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, etc., can solve the problems of shortened service life, shedding of resin groups, large volume and low concentration, etc., to prolong service life, reduce oxidation and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

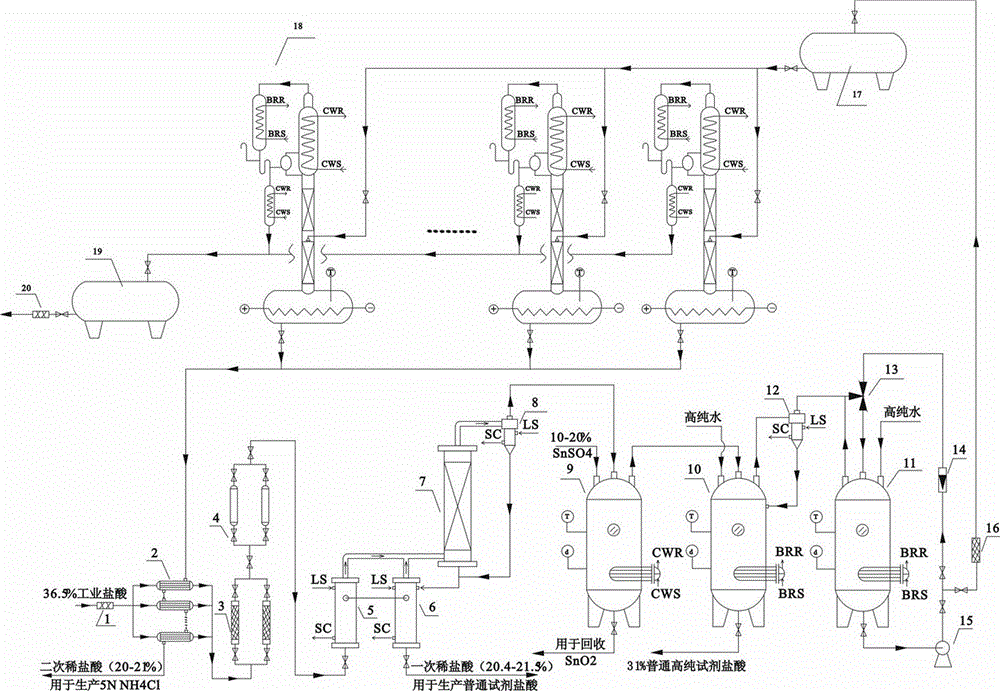

[0024] A. Pretreatment and primary distillation:

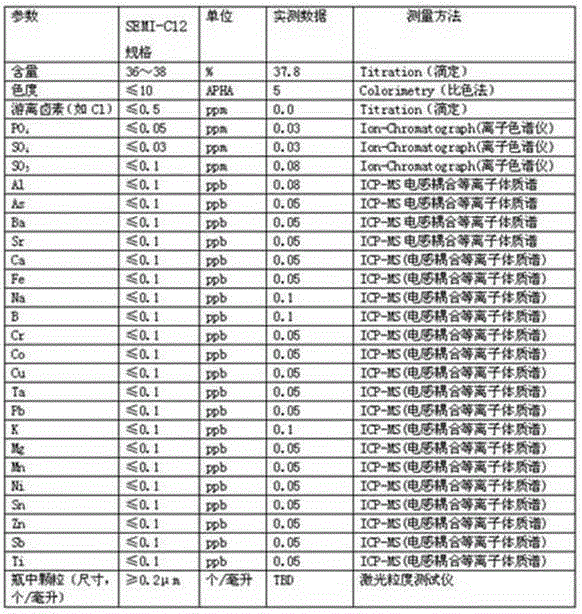

[0025] 36.5% industrial hydrochloric acid (single metal ion content is about 1-80ppm, free Cl concentration is 60ppm) is continuously filtered through ultra-pure polytetrafluoroethylene microfilter 1 with a pore size of 0.45μm at a speed of 500L / h, and high-purity quartz The glass heat exchanger group 2 is initially heated, the pretreated cellulose-based activated carbon fiber column 3 is dechlorinated, and the 201×7 strong basic anion resin column 4 is ion-exchanged, and the graphite heater impregnated with high-purity tetrafluoroethylene is used 5, 6 Heating and evaporating, controlling the steam pressure to about 0.12Mpa, the gas phase fraction passes through the ultra-pure polytetrafluoroethylene-impregnated graphite packing tower 7 to remove high boiling point substances (stripping and rectification), and then enters the thermal insulation and high-efficiency aerosol separator 8 to remove mist droplets and particles. The...

Embodiment 2

[0039] A. Pretreatment and primary distillation:

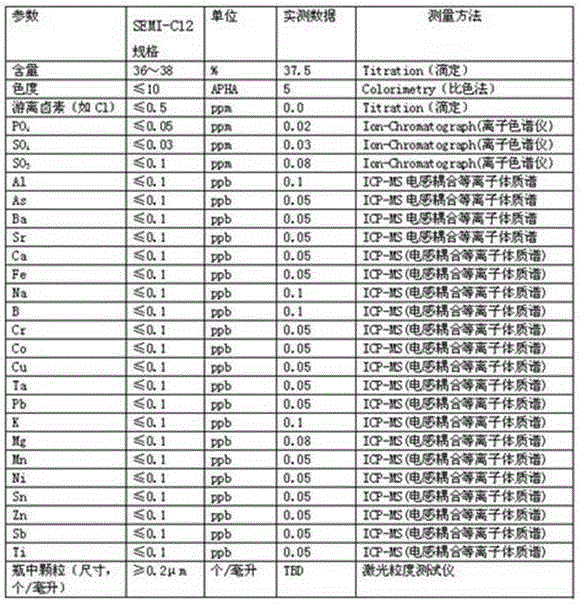

[0040] 31% industrial hydrochloric acid (single metal ion content is about 1-80ppm, free Cl concentration is 50ppm) is continuously filtered through ultra-pure polytetrafluoroethylene microfilter 1 with a pore size of 0.45μm at a speed of 500L / h, and high-purity quartz The glass heat exchanger group 2 is initially heated, the pretreated cellulose-based activated carbon fiber column 3 is dechlorinated, and the 201×7 strong basic anion resin column 4 is ion-exchanged, and the graphite heater impregnated with high-purity tetrafluoroethylene is used 5, 6 Heating and evaporating, controlling the steam pressure to about 0.15Mpa, the gas phase fraction passes through the ultra-pure polytetrafluoroethylene-impregnated graphite packing tower 7 to remove high-boiling point substances (stripping and rectification), and then enters the thermal insulation and high-efficiency aerosol separator 8 to remove mist droplets and particles. The g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com