Vertical U-shaped gasification heating equipment

A kind of heating equipment, U-shaped technology, applied in the field of heating and gasification, can solve the problems of poor economic and environmental protection, low air heat capacity, high cost, etc., achieve the effect of convenient gas-water separation, high thermal efficiency, and reduce heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

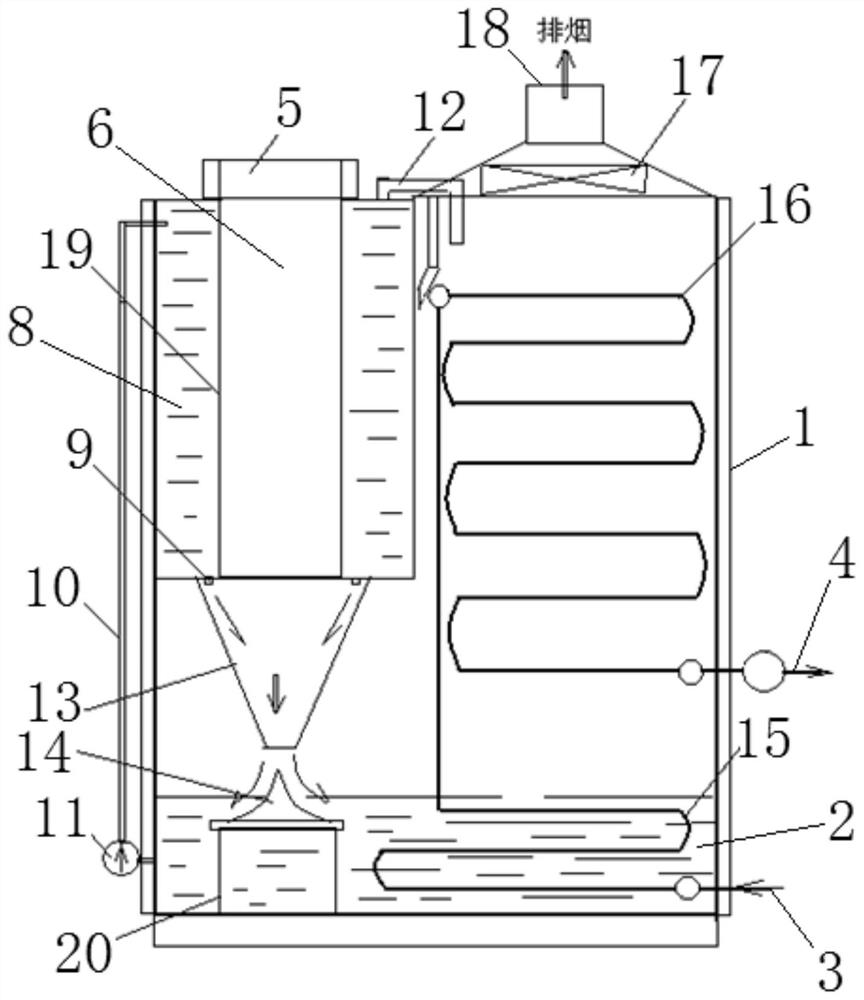

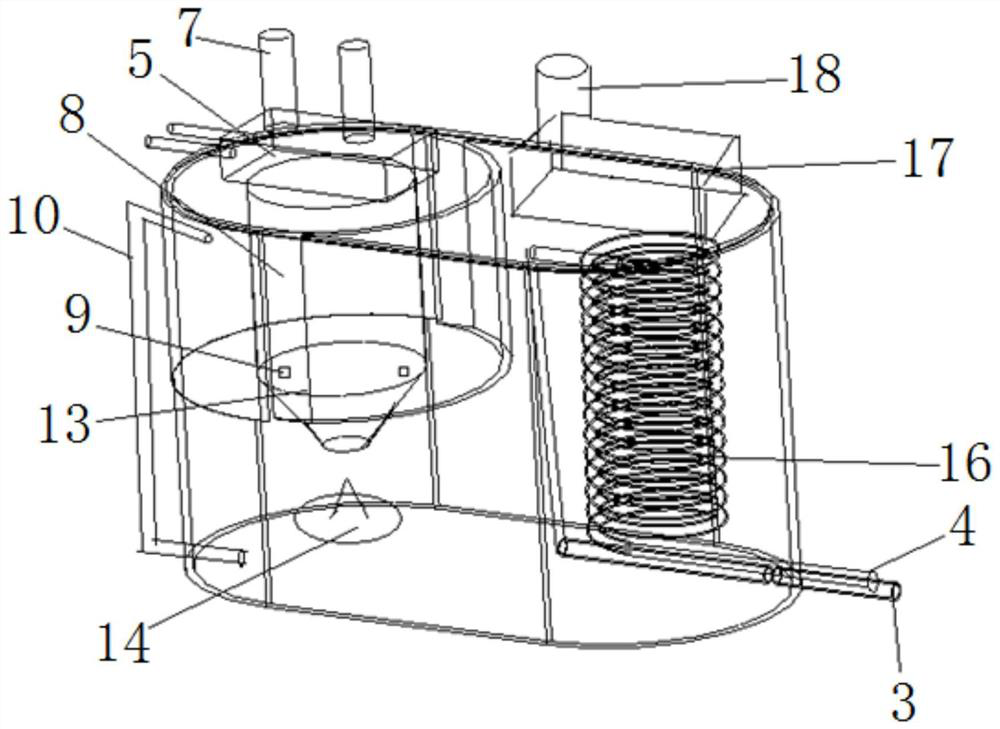

[0031] Such as figure 1 , figure 2In the shown vertical peak-shaving U-shaped gasification heating equipment, the fuel enters the burner 5 through the fuel inlet 7, the burner 5 is started, the fuel is fully burned in the combustion chamber 6, and a large amount of smoke is generated. And spray out at the nozzle 13, the water chamber 8 protects the combustion chamber 6, and prevents the equipment from being damaged due to too high temperature. The water in the water chamber 8 absorbs the waste heat of the combustion chamber 6, reaches the water nozzle 9, the water at the water nozzle 9 enters the nozzle 13, mixes the high-temperature flue gas to become water smoke, and reaches the guide plate 14, the guide plate 14 It plays the role of buffering the flue gas, and also has the function of drainage to increase the contact area. The water in the bottom pool 2 is successfully gasified, and the gasified water vapor reaches the heated pipe 16 on the right side together with the fl...

Embodiment 2

[0033] The utility model relates to a vertical U-shaped gasification heating device, which is used for heating industrial gas or industrial liquid. The equipment includes a housing 1, a bottom pool 2 arranged in the housing 1, and a heat source unit and a heated unit arranged side by side in the housing 1. The bottoms of the heat source unit and the heated unit are located in the bottom pool 2. The heat source unit includes The combustion mechanism and the injection guide mechanism are respectively arranged one above the other. The side of the housing 1 is provided with a fluid inlet 3 and a fluid outlet 4. The heated unit is connected with the fluid inlet 3 and the fluid outlet 4 respectively. Smoke extraction unit.

[0034] Wherein, the combustion mechanism includes a burner 5 arranged on the top of the housing 1 and a torch 19 arranged below the burner 5, the inside of the torch 19 is provided with a combustion chamber 6, the burner 5 is provided with a fuel inlet 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com