Steel belt cleaning device

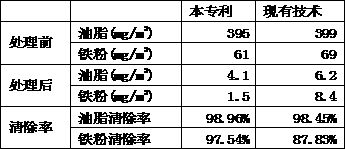

A cleaning device and technology for steel belts, applied in the directions of drying gas arrangement, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as affecting processing, general degreasing effect, and large footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

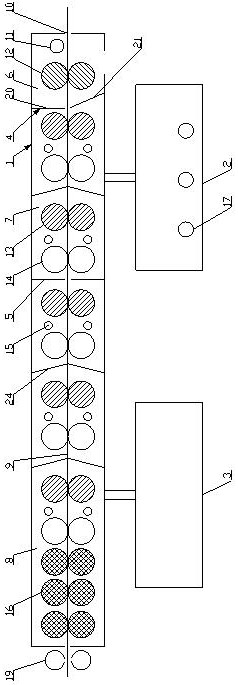

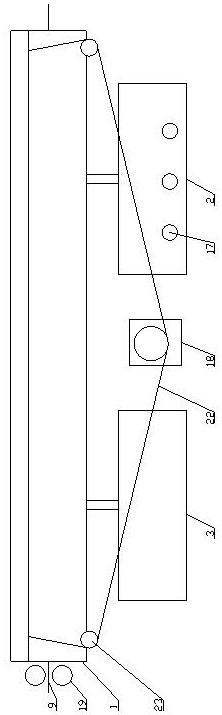

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] see figure 1 and 2, the embodiment of the present invention provides a steel strip cleaning device, which includes a cleaning chamber 1 arranged in the front and rear directions, an air-cooled structure on the rear side of the cleaning chamber 1 (for air-drying the steel strip 9 ) and a cleaning chamber 1 below and The degreasing agent circulation pool 2 arranged side by side (the degreasing agent is contained in it, the degreasing agent can be Xianghe brand CC776B (from Chengdu Xianghe Phosphating Co., Ltd.), the concentration is less than 5wt%) and the clear water circulation pool 3 (the degreasing agent is contained in it) clean water), etc. Among them, the front and rear partitions of the cleaning chamber 1 are provided with a front partition 4 (locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com