Production process and system applicable to steel plate heat transfer printing

A production process and production system technology, applied in transfer printing, rotary printing machine, printing and other directions, can solve the problems of insecure quality, complex sealing device, poor transfer quality, etc., achieve easy automatic operation and control, ensure thermal stability. Transfer effect, the effect of simplified equipment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

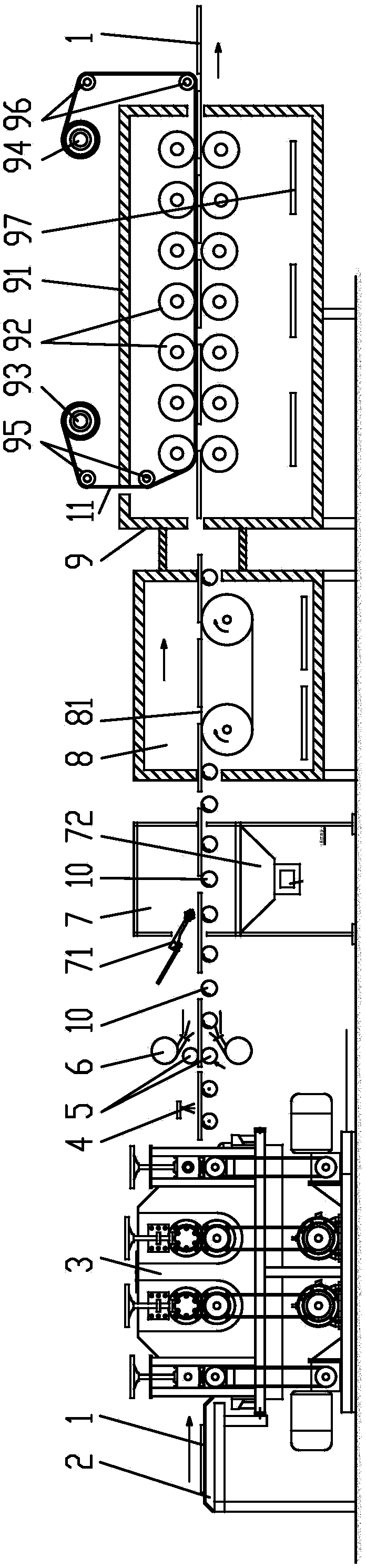

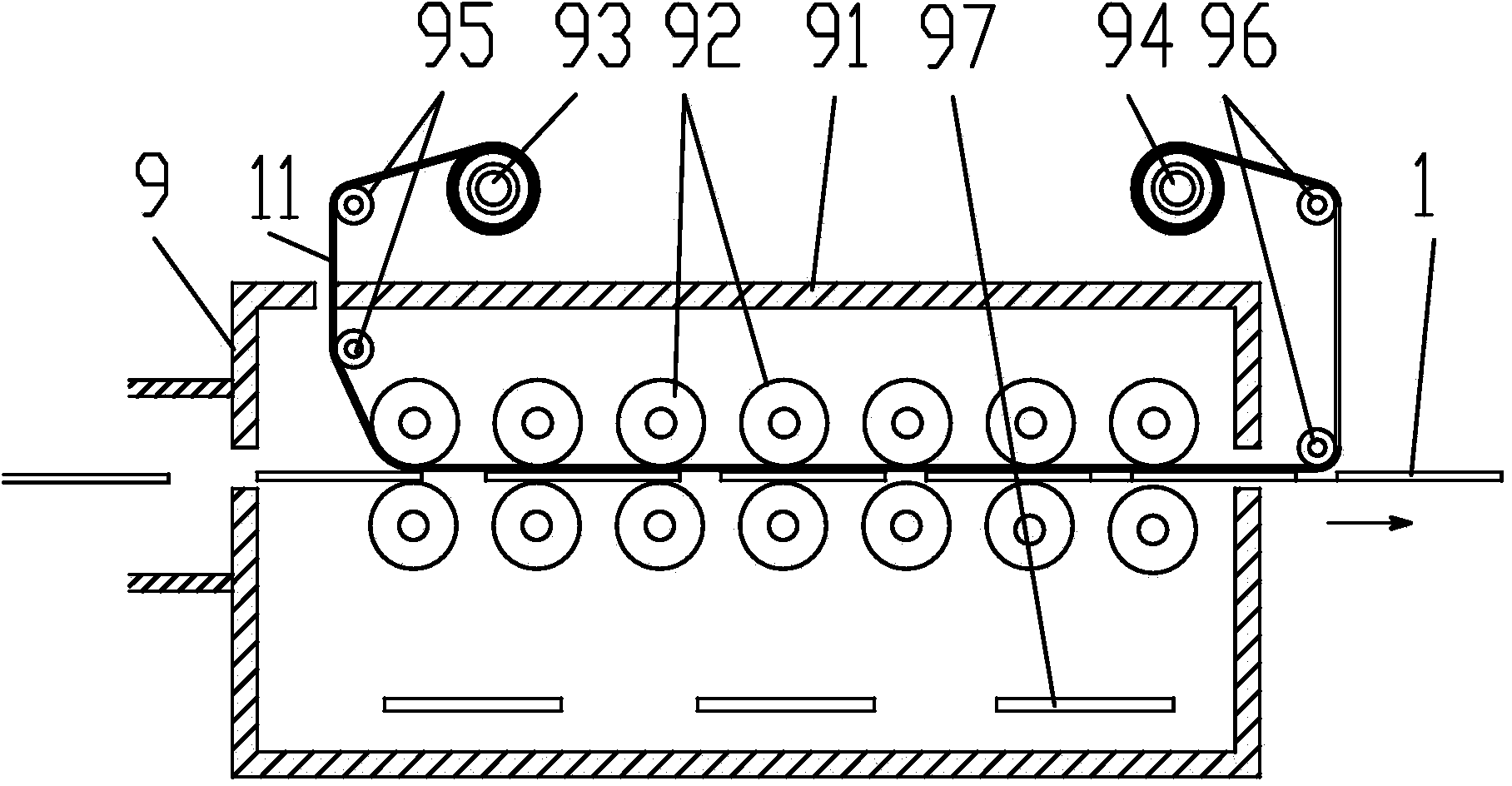

[0031] Referring to the accompanying drawings, the present invention is applicable to the continuous thermal transfer operation of a single steel plate, and the present invention includes the feeding device 2 of the steel plate 1, the cleaning and air-drying device, the powder spraying pretreatment device and the roller continuous thermal transfer operation in sequence. Printing device 9; the cleaning and air-drying device includes a rolling brush type cold-rolled steel plate cleaning chamber 3, a spray cleaning machine 4 arranged above the steel plate 1, and a counter-extrusion dewatering glue that removes excess water droplets on the steel plate 1 by counter-extrusion Roller 5 and air dryer 6, and the conveying roller shaft 10 that is arranged on steel plate 1 below; Powder spraying pretreatment device comprises powder spraying chamber 7 and curing chamber 8; Powder spraying gun head 71 is set above steel plate 1 in powder spraying chamber 7, The powder recovery device 72 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com