A continuous thermal transfer process and special equipment suitable for single glass

A special equipment and thermal transfer printing technology, which is applied in transfer printing, rotary printing machine, printing, etc., can solve the problems of inability to realize continuous operation, poor transfer printing quality, complicated sealing device, etc., and achieve easy automatic operation and control, Effects of energy saving and equipment process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

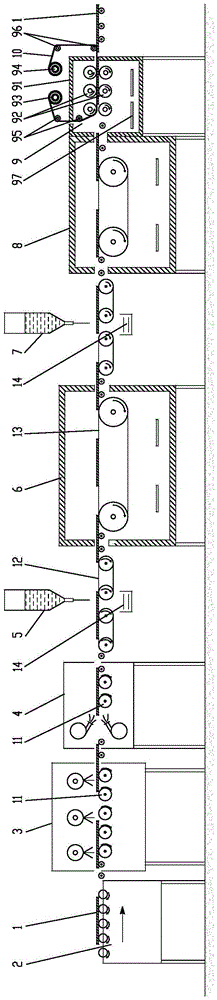

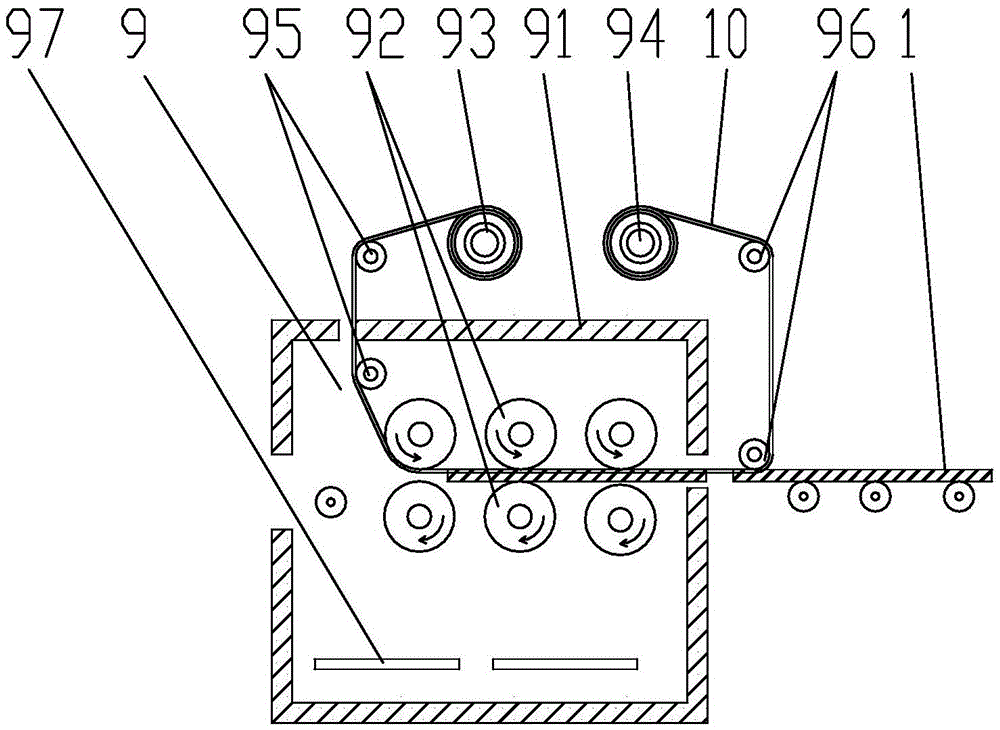

[0031]Referring to the accompanying drawings, the present invention is applicable to the continuous thermal transfer operation of a single piece of glass. The equipment of the present invention sequentially includes a feeding device 2 for flat glass 1, a cleaning device 3, an air drying device 4, and a transparent varnish processing device 5 according to the sequence of the flow operation. , heating surface drying device 6, solid color paint processing device 7, heating curing device 8 and roller type continuous thermal transfer device 9; cleaning device 3 is a spray cleaning machine, and a spray gun head is arranged above the flat glass 1, and the flat glass The bottom of 1 is the conveying roller 11; the air-drying device 4 includes a pair of hot air blowers relatively arranged on the upper and lower sides of the flat glass 1, and the lower part of the flat glass 1 is the conveying roller 11; the transparent paint processing device 5 and the solid color paint processing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com