A pair-roll continuous thermal transfer device suitable for steel plates

A technology of thermal transfer printing and thermal transfer paper, applied in transfer printing, rotary printing machines, printing, etc., can solve the problems of poor transfer printing quality, insecure quality, and easy to run out of air, etc., and achieve simplified equipment processes and easy Effects of automated operations and controls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

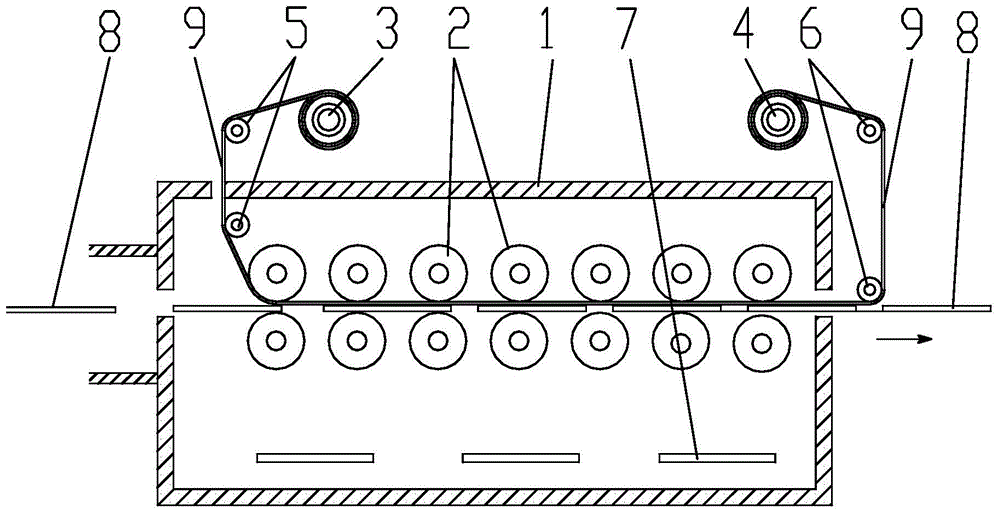

[0021] Combine below figure 1 , the present invention will be further described.

[0022] A double-roll continuous heat transfer device suitable for steel plates, comprising a heat box 1 and a paper release shaft 3 for heat transfer paper 9 arranged outside the heat box 1, which are respectively arranged at two opposite side ends of the heat box 1 There are steel plate imports and steel plate exits, and a steel plate clamping and conveying device arranged in the hot box 1 is also included. A heater 7 is arranged in the hot box 1, and a thermal insulation layer is arranged on the wall of the hot box 1.

[0023] From the entrance of the steel plate to the exit of the steel plate, there are many sets of heat transfer rollers 2; The gap between the steel plate 8 and the thermal transfer paper 9 and through which the steel plate 8 and the thermal transfer paper 9 pass is covered with a silicone layer on the outer circumferences of the upper and lower rotating shafts. On the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com