Pre-cooling type rotating wheel humidity adjusting fresh air processing device

A technology of fresh air treatment and rotary wheel, applied to air treatment details, heating methods, air conditioning systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

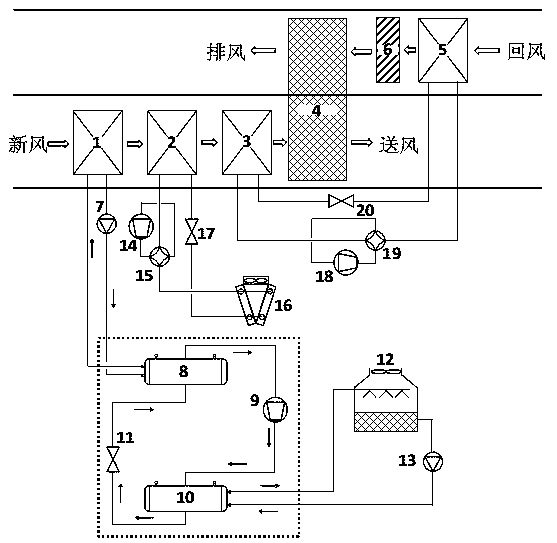

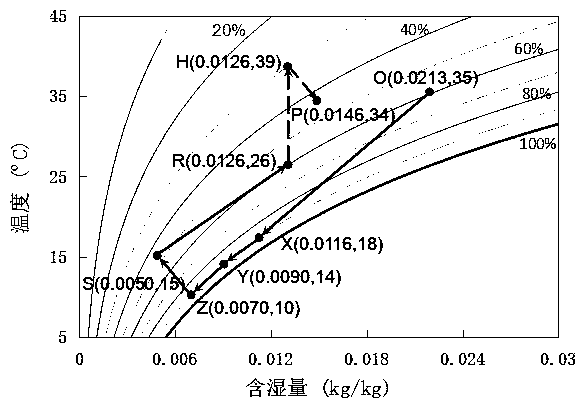

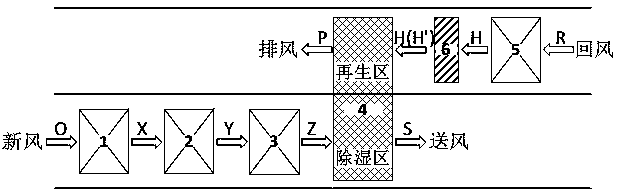

[0030] figure 1 The schematic diagram of the system during the humidity adjustment process of the pre-cooling wheel is shown. The device includes a water-cooled chiller unit, an air-cooled heat pump unit, a sensible heat recovery unit, a rotary solid adsorption dehumidification equipment and an electric heater. The summer fresh air passes through the water-cooled chiller fan coil unit 1, The evaporator 2 of the air-cooled heat pump unit, the evaporator 3 of the sensible heat recovery unit, and the dehumidification area of the rotary solid adsorption dehumidification equipment 4 are sent into the room, and the return air passes through the condenser 5 of the sensible heat recovery unit in the process of being processed. , the electric heater 6 and the regeneration zone of the rotary solid adsorption dehumidification equipment 4 are discharged outside.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com