Low-temperature pyrolysis device for coal

A low-temperature pyrolysis and coal block technology, which is applied in the field of coal heating and cracking, can solve problems such as pipeline blockage and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

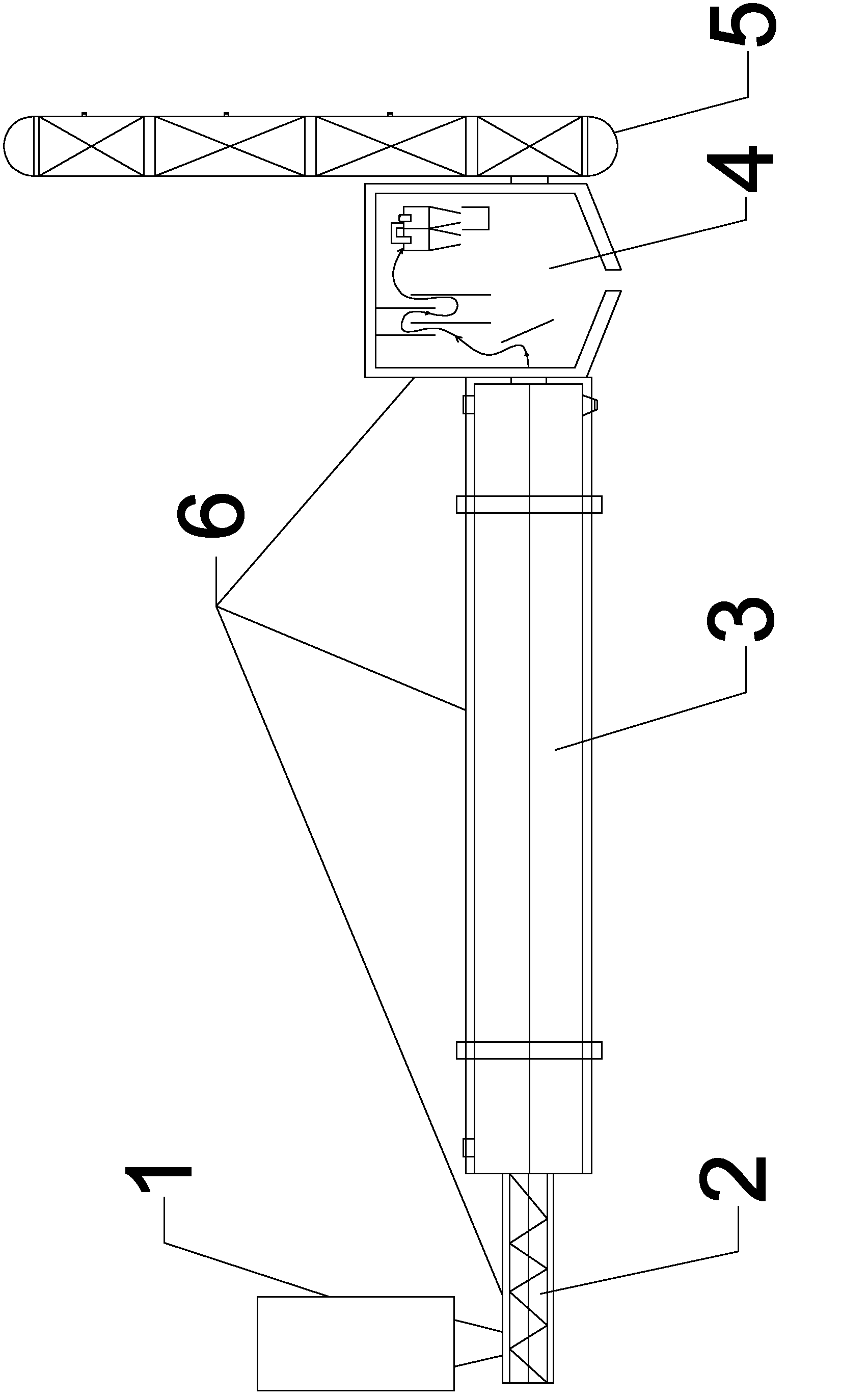

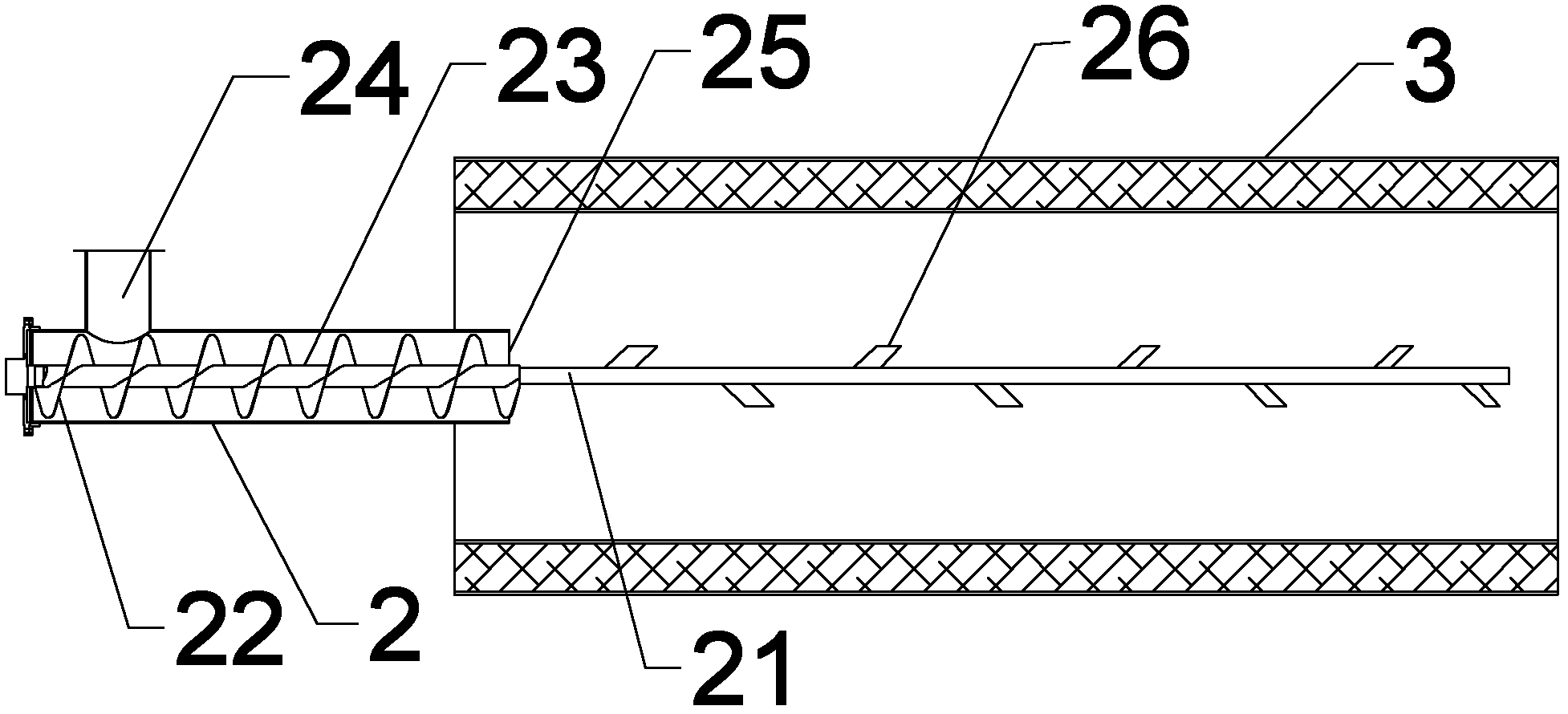

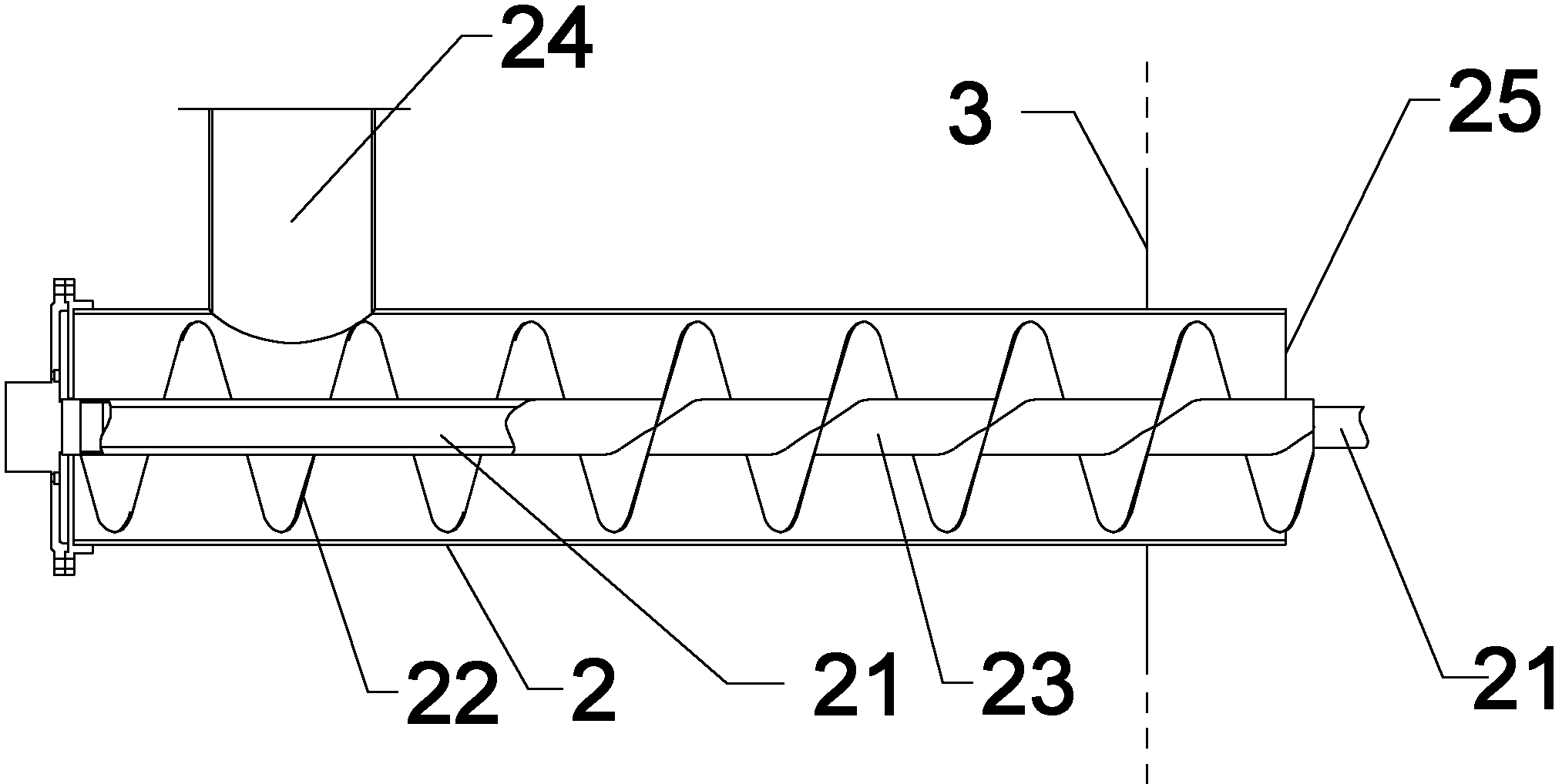

[0039] Figure 1-9 A specific embodiment of the coal low-temperature pyrolysis device of the present invention is shown, such as figure 1 As shown, according to the reaction sequence, the coal low-temperature pyrolysis device sequentially includes: a coal storage tank 1 , a feeder 2 , a reactor 3 , a dust collector 4 , and a separation tower 5 .

[0040] The coal storage tank 1 is used to quantitatively add raw coal lumps to the feeder 2 . The feeder 2 is used to supply raw coal lumps and catalysts to the reactor 3 . The reactor 3 is used for pyrolysis treatment of the raw coal block. The deduster 4 is used to dedust the volatile matter generated by the pyrolysis of the reactor 3 . The separation tower 5 is used to separate the volatile matter that has undergone dust removal treatment. Such as figure 1 As shown, the feeder 2, the reactor 3, and the oute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com