Core-shell iron-based catalyst for directly producing aromatic hydrocarbon from synthesis gas as well as preparation method and application of the core-shell iron-based catalyst

A core-shell iron-based, synthesis gas technology, applied in the preparation of liquid hydrocarbon mixtures, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low aromatics selectivity and yield, low CO utilization rate, and low selectivity , to achieve high aromatics selectivity, high CO conversion rate, particle size and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

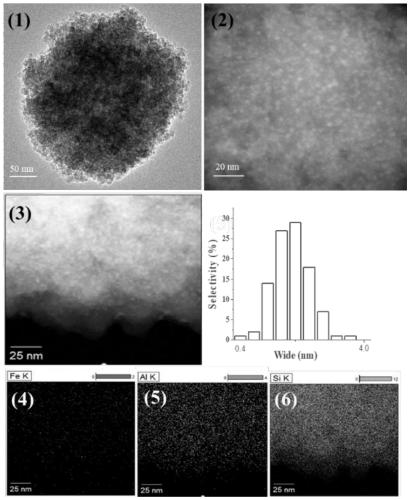

Image

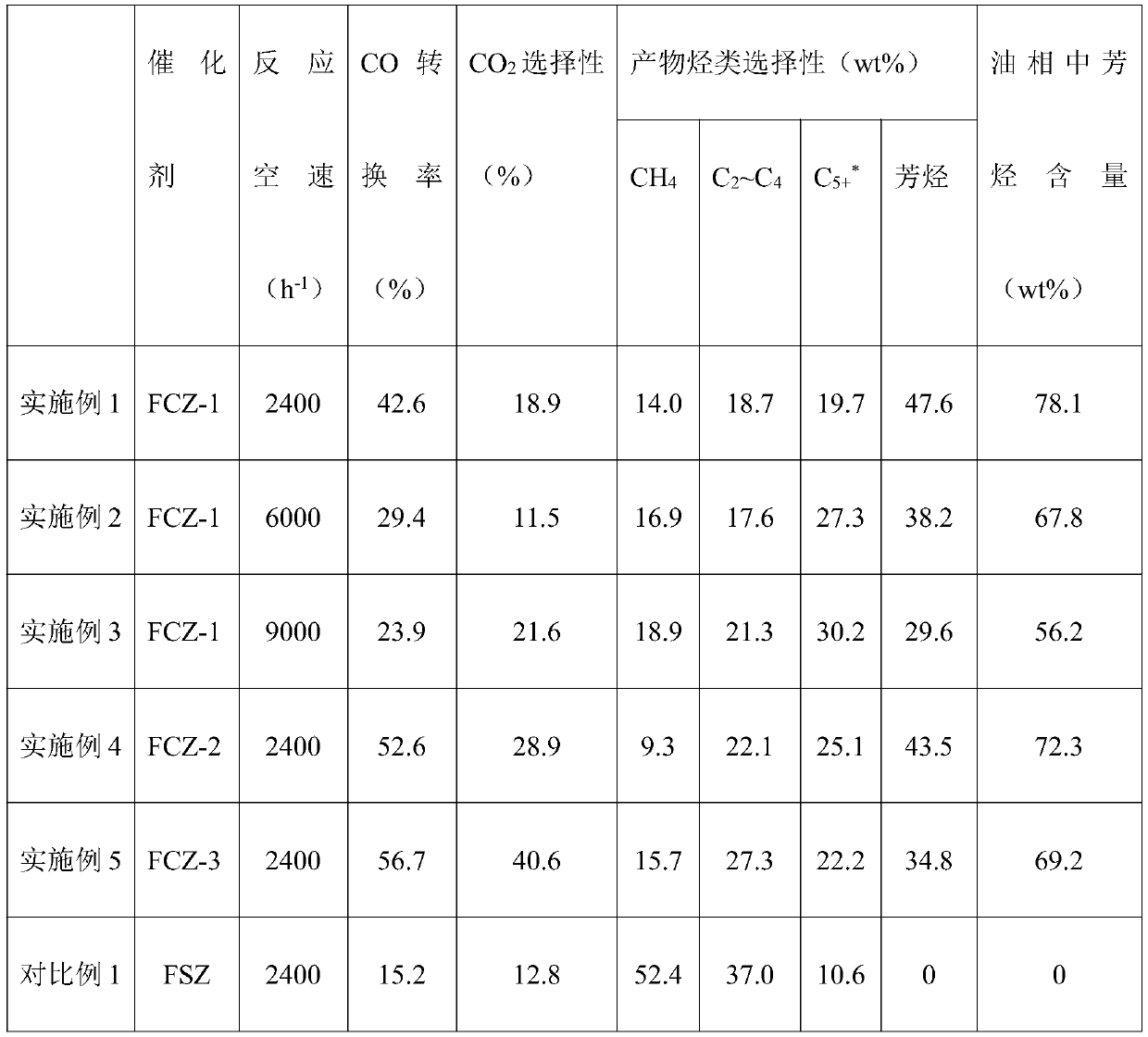

Examples

Embodiment 1

[0036] (1) Catalyst preparation:

[0037] ①Preparation of nanometer Fe with uniform size by hydrothermal synthesis 3 O 4 Granules: The molar ratio of ferric chloride, sodium acetate, ethylene glycol, ethylenediamine and polyvinylpyrrolidone (PVP10, average molecular weight 58000) is: 1:2.9:32:4:0.8, and stirred at 40°C To completely dissolve, the obtained mixed solution was transferred to a hydrothermal kettle, sealed and hydrothermally reacted at 200°C for 12 hours, and washed with deionized water and absolute ethanol after being cooled to room temperature. The separated solid was vacuumed at 60°C. Dry overnight to obtain nano-Fe with uniform size 3 O 4 Particles.

[0038] ②Using organosilane agent for nano-Fe 3 O 4 Pre-modification of particle surface: take the nano-Fe obtained in step ① 3 O 4 The particles were dispersed in a mixed solution of ethanol and deionized water and treated with ultrasound for 30 minutes. The volume ratio of ethanol to deionized water in the mixed solut...

Embodiment 2

[0045] The preparation of the catalyst is the same as in Example 1, the difference is that the gas volumetric space velocity of the feed gas in the carbon monoxide hydrogenation reaction in the application of the catalyst is adjusted to 6000h -1 , The remaining steps are the same as in Example 1.

Embodiment 3

[0047] The preparation of the catalyst is the same as in Example 1, the difference is that the gas volumetric space velocity of the feed gas in the carbon monoxide hydrogenation reaction in the application of the catalyst is adjusted to 9000h -1 , The remaining steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com