Lightweight self-compacting concrete and preparation method thereof

A self-compacting concrete, lightweight technology, applied in the field of high-strength lightweight concrete and its preparation, self-compacting, can solve the problems of economic loss affecting the progress of the project, low concrete strength, poor concrete uniformity, etc., to achieve good anti-segregation performance, Stable and efficient production, far-reaching effects of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: by mass ratio cement: limestone powder: calcined expansive clay: sintered shale ceramic sand: sodium lauryl sulfate: polyacrylamide: polyacrylate: polycarboxylate water reducer: water=490:50: 798: 243: 20: 15: 1: 9: 180 Proportion of each component; add the wet and saturated calcined expanded clay, cement, sintered shale pottery sand, and 75% of the weighed water into the mixer in sequence , Stir for 2 minutes, then add 25% of the weighed water, limestone powder, air-entraining agent, thickener, viscosity regulator, and water reducer into the mixer, and stir for 2 minutes to get ready.

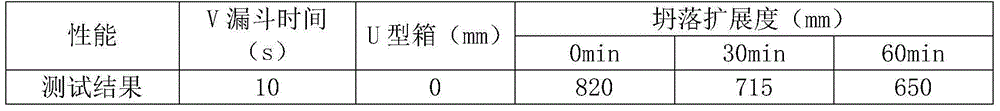

[0017] After mixing, test the performance of the freshly mixed concrete to evaluate its segregation resistance and self-compacting performance. The test results are listed in the following table:

[0018]

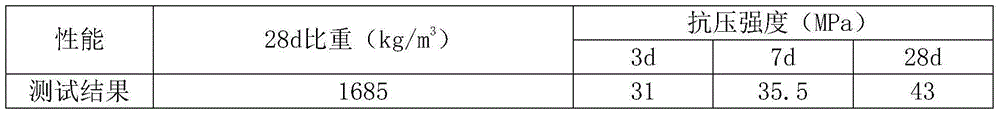

[0019] The concrete is made into a shaped cube test block, maintained at 20°C and the relative humidity is greater than 95%, and the compressive strength of the corr...

Embodiment 2

[0021] Embodiment 2: by mass ratio cement: limestone powder: calcined expansive clay: sintered shale pottery sand: sodium lauryl sulfate: hydroxymethyl cellulose ether: polyvinyl alcohol: aliphatic water reducer: water=460: 70: 798: 243: 20: 15: 1: 13: 185 ratio of each component; wet and saturated calcined expansive clay, cement, sintered shale pottery sand, and 75% of the weighed water, in order Add to a mixer, stir for 2 minutes, then add 25% of the weighed water, limestone powder, air-entraining agent, thickener, viscosity regulator, and water reducer into the mixer, and stir for 2 minutes to get ready.

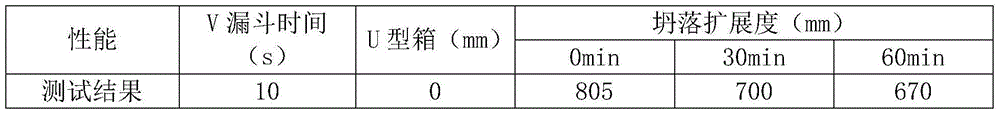

[0022] After mixing, test the performance of the freshly mixed concrete to evaluate its segregation resistance and self-compacting performance. The test results are listed in the following table:

[0023]

[0024] The concrete is made into a shaped cube test block, maintained at 20°C and the relative humidity is greater than 95%, and the compressive strength of the cor...

Embodiment 3

[0026] Embodiment 3: by mass ratio cement: limestone powder: calcined expanded clay: sintered shale pottery sand: sodium lauryl sulfate: hydroxymethyl cellulose ether: polyacrylic acid: aliphatic water reducing agent: water=490:50 : 798: 243: 20: 15: 1: 13: 170 Proportion of each component; add wet and saturated calcined expansive clay, cement, sintered shale pottery sand, and 75% of the weighed water in sequence Mixer, stir for 2 minutes, then add 25% of the weighed water, limestone powder, air-entraining agent, thickener, viscosity regulator, and water reducer into the mixer, stir for 2 minutes, and it is ready.

[0027] After mixing, test the performance of the freshly mixed concrete to evaluate its segregation resistance and self-compacting performance. The test results are listed in the following table:

[0028]

[0029] The concrete is made into a shaped cube test block, maintained at 20°C and the relative humidity is greater than 95%, and the compressive strength of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com