Composite low-carbon free-cutting steel and production method thereof

A technology of free-cutting steel and production method, which is applied in the field of low-carbon composite free-cutting steel and its production, can solve the problems of low-carbon free-cutting steel such as poor mechanical properties and stability, limited application range, and high production difficulty, and achieve The effect of reducing laziness, reducing anisotropy, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

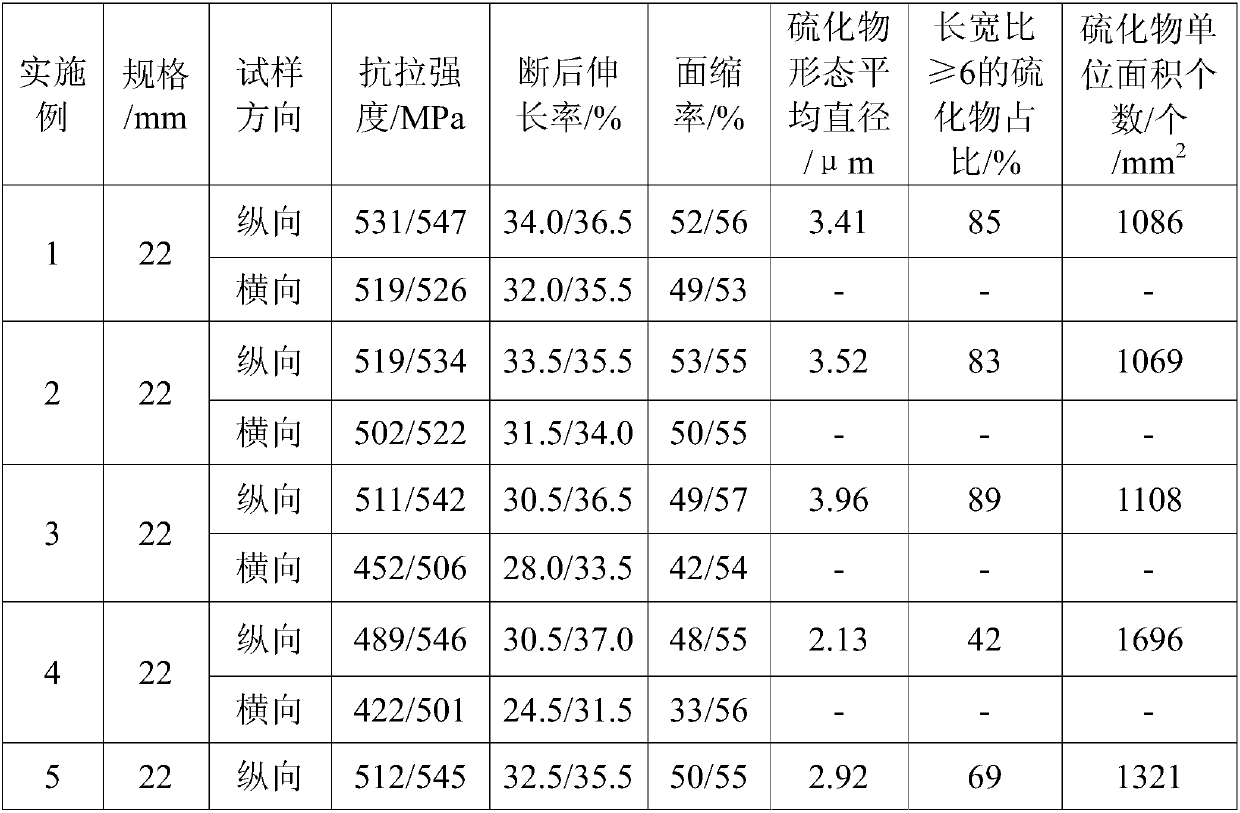

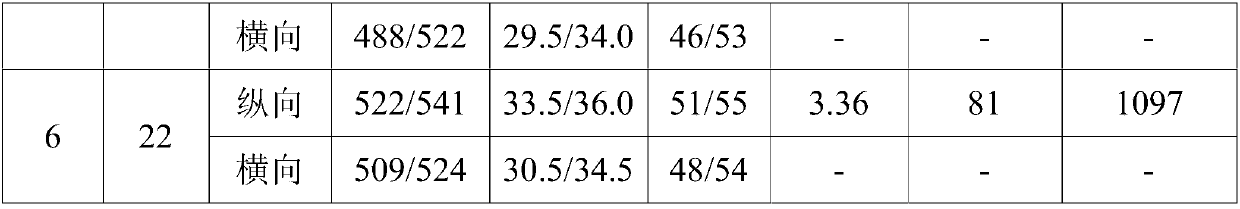

Examples

Embodiment 1

[0034] The process route of EAF-CONVERTER electric converter smelting→LF furnace refining→CCM continuous casting is adopted to produce low-carbon free-cutting steel.

[0035] Composition control of smelted products: C: 0.13~0.16%, Si: ≤0.05%, Mn: 0.90~1.05%, P: 0.035~0.050%, S: 0.15~0.20%, Cr: 0.20~0.28%, Cu: 0.10~ 0.15%, B: 0.0040~0.0055%, N: 0.014~0.018%, Al: ≤0.005%, O: 0.0045~0.0075%, the balance is Fe.

[0036] The electric converter uses molten iron, pig iron and high-quality scrap steel as raw materials. The total loading is controlled at 109 tons, the ratio of molten iron is 89%, the amount of pig iron added is 5.5 tons, and the rest is high-quality scrap. End-point composition C: 0.07%, P: 0.016%, tapping temperature T: 1661°C, tapping volume 93.5 tons, using eccentric bottom tapping, no slagging; the tapping process is followed by adding appropriate amounts of aluminum, iron, silicon manganese, Low-carbon ferromanganese, low-carbon ferrochrome, ferrophosphorus, ferrosulf...

Embodiment 2

[0042] The process route of EAF-CONVERTER electric converter smelting→LF furnace refining→CCM continuous casting is adopted to produce low-carbon free-cutting steel.

[0043] Composition control of smelted products: C: 0.13~0.16%, Si: ≤0.05%, Mn: 0.90~1.05%, P: 0.035~0.050%, S: 0.15~0.20%, Cr: 0.20~0.28%, Cu: 0.10~ 0.15%, B: ≤0.0030%, N: ≤0.0120%, Al: ≤0.005%, O: 0.0045~0.0075%, the balance is Fe.

[0044] The electric converter uses molten iron, pig iron and high-quality scrap steel as raw materials. The total loading is controlled at 108 tons, the molten iron ratio is 91%, the pig iron addition is 5.1 tons, and the rest is high-quality scrap steel. End-point composition C: 0.07%, P: 0.016%, tapping temperature T: 1659°C, tapping volume 93.6 tons, eccentric bottom tapping, slagging is strictly prohibited; the tapping process is followed by adding appropriate amounts of aluminum, iron, silicon manganese, Low-carbon ferromanganese, low-carbon ferrochrome, ferrophosphorus, ferrosulf...

Embodiment 3

[0050] The process route of EAF-CONVERTER electric converter smelting→LF furnace refining→CCM continuous casting is adopted to produce low-carbon free-cutting steel.

[0051] Composition control of smelted products: C: 0.13~0.16%, Si: ≤0.05%, Mn: 0.90~1.05%, P: 0.035~0.050%, S: 0.20~0.35%, Cr: 0.20~0.28%, Cu: 0.10~ 0.15%, B: ≤0.0030%, N: ≤0.0120%, Al: ≤0.005%, O: 0.0080~0.0120%, the balance is Fe.

[0052] The electric converter uses molten iron, pig iron and high-quality scrap steel as raw materials. The total loading is controlled at 109 tons, the ratio of molten iron is 86%, the amount of pig iron added is 4.5 tons, and the rest is high-quality scrap. End-point composition C: 0.06%, P: 0.013%, tapping temperature T: 1659°C, tapping volume 93.8 tons, eccentric bottom tapping, slagging is strictly prohibited; the tapping process is followed by adding appropriate amounts of aluminum iron, silicon manganese, Low-carbon ferromanganese, low-carbon ferrochrome, ferrophosphorus, ferros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com