Atmospheric vacuum distillation method and apparatus with vacuum flash vaporizer

A technology of atmospheric and vacuum distillation and flash tower, which is applied in the field of atmospheric and vacuum distillation methods and equipment, which can solve the problems of no significant change in energy consumption of the device and large investment in the device, and achieve the reduction of the scale of the main equipment, small investment in equipment, Effect of reducing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

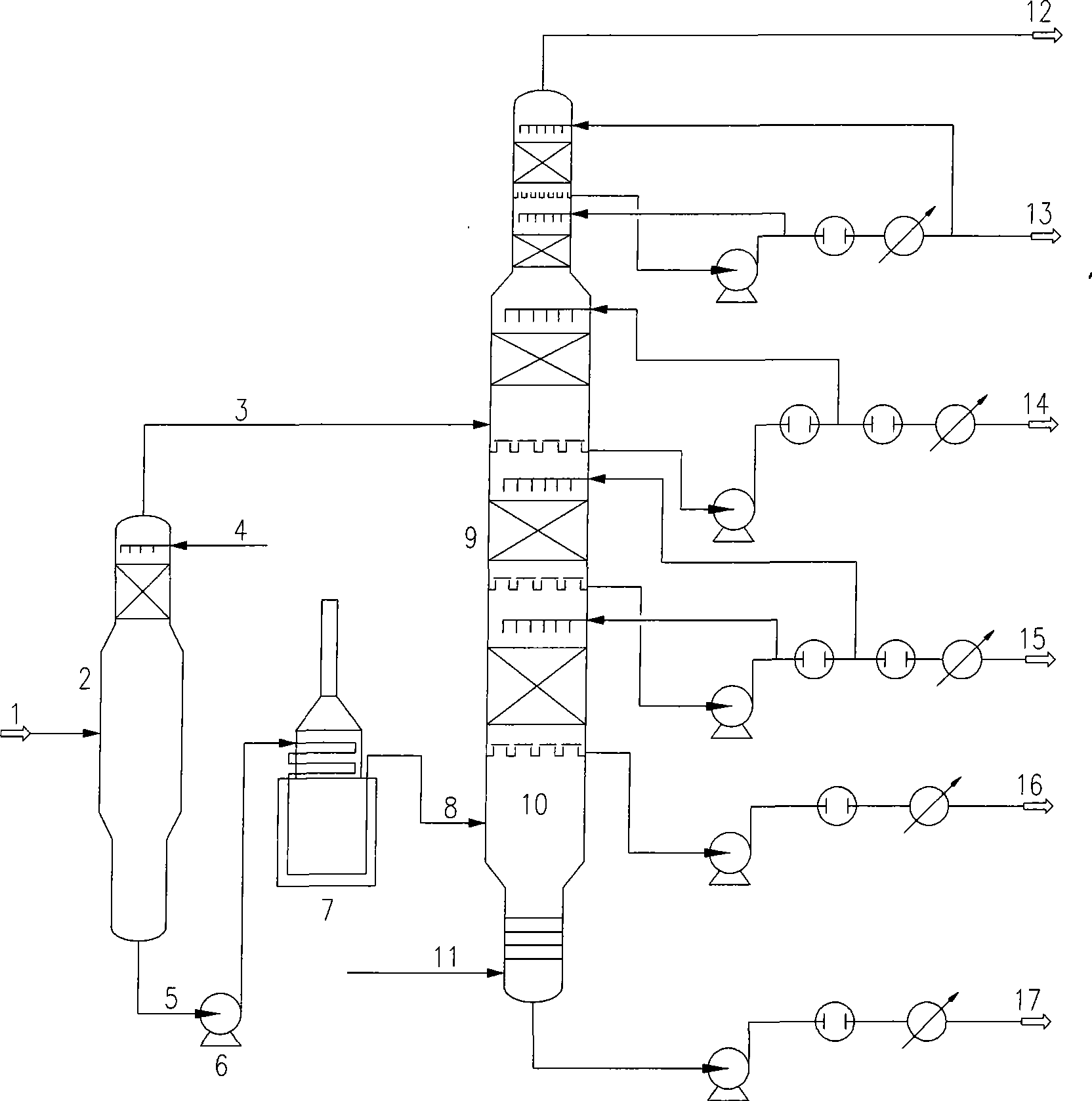

[0027] The method of the present invention is used for the transformation of a certain atmospheric pressure reducing device, and the atmospheric pressure part is the same as that of a common ordinary pressure reducing device, and the pressure reducing part adopts such as: figure 1 As shown in the decompression process of the atmospheric and vacuum distillation apparatus with a vacuum flash column, the main equipment of the decompression part includes a vacuum flash column 2, a vacuum furnace 7, and a vacuum column 9. The normal bottom oil 1 first enters the vacuum flashing tower 2 for flashing, the flash top gas 3 enters the upper or middle part of the vacuum tower 9 through the pipeline, and the flash bottom oil 5 enters the vacuum furnace 7 for heating through the flash bottom oil pump 6, and is heated in the vacuum furnace 7. Partial vaporization in the pressure furnace obtains the vacuum tower feed in a gas-liquid mixed state, and enters the flash section 10 of the vacuum t...

Embodiment 2

[0032] The method of the present invention is used in the design of a new atmospheric and vacuum unit, except that no washing oil is introduced into the upper part of the vacuum flash tower, the rest of the process is the same as the appendix. figure 1 same as shown.

[0033] The processing capacity of the unit is 5 million tons / year of crude oil. The vacuum process mainly includes vacuum flash column, vacuum furnace and vacuum tower. The decompression tower is a fuel type, with a slightly wet operation, with a total of four side-line products. No scrubbing oil is added to the upper part of the vacuum flash tower.

[0034] The operating pressure at the top of the vacuum flash tower is 35 mmHg, and the amount of flash top gas accounts for 32% of the feed amount of the flash tower. The operating pressure at the top of the vacuum tower is 15mmHg, and the flash top gas enters the vacuum tower from above the extraction outlet of the second line; the flash bottom oil is heated to...

Embodiment 3

[0037] The method of the present invention is used for the design of a new atmospheric and vacuum unit, the upper part of the vacuum flash tower does not introduce washing oil, the number of products in the side line of the vacuum is 6, and the side line is added with a stripper, and the rest of the process is the same as the appendix. figure 1 same as shown.

[0038] The processing capacity of the unit is 8 million tons / year of crude oil. The vacuum process mainly includes vacuum flash column, vacuum furnace and vacuum tower. The decompression tower is lubricating oil type, wet operation, and there are 6 side line products in total. No scrubbing oil is added to the upper part of the vacuum flash tower.

[0039]The operating pressure at the top of the decompression flash tower is 200mmHg, and the amount of flash top gas accounts for 4.7% of the feed amount of the flash tower. The operating pressure at the top of the decompression tower is 25mmHg, and the flash top gas enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com