Integrated forming technology of macromolecular sheet production and gluing

A technology of polymer sheet and molding process, which is applied to other household appliances, flat products, household appliances, etc., can solve the problems of discontinuous polymer sheet production and gluing process, and achieve simplified production process and continuous The effect of enhanced production and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Use the mixing feeder to stir and mix the plastics and transport them to the discharge tank;

[0026] (2) The raw material output from the storage tank enters the first extruder, the temperature is controlled at 160°C, and is extruded through a special die for sheet extrusion, and the die temperature is controlled at 160°C;

[0027] (3) The viscose raw material enters the second extruder, and the temperature is controlled at 140°C;

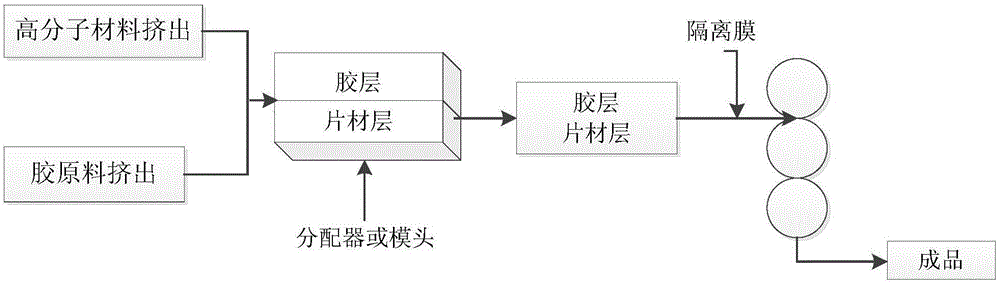

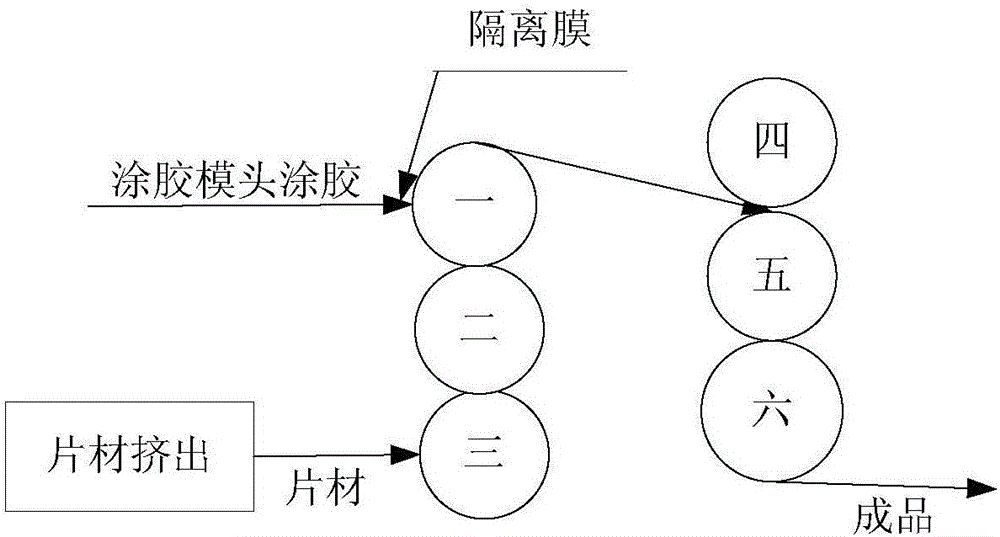

[0028] (4) The sheet polymer raw materials and viscose raw materials extruded from the first extruder and the second extruder respectively enter the distributor or multi-layer die for compounding, and finally extrude and form;

[0029] (5) The extruded material is directly covered with a high temperature resistant isolation film and then enters the 3-roll calendering device to control the thickness, and then is wound by the winding device.

Embodiment 2

[0031] (1) Stir and mix plastic and rubber uniformly with a mixing feeder and transport them to the discharge tank;

[0032] (2) The raw material output from the storage tank enters the first extruder, the temperature is controlled at 180°C, and it is extruded through a special die for sheet extrusion, and the die temperature is controlled at 170°C;

[0033] (3) The viscose raw material enters the second extruder, and the temperature is controlled at 155°C;

[0034] (4) The sheet polymer raw materials and viscose raw materials extruded from the first extruder and the second extruder respectively enter the distributor or multi-layer die for compounding, and finally extrude and form;

[0035] (5) The extruded material is directly covered with a high temperature resistant isolation film and then enters the 3-roll calendering device to control the thickness, and then is wound by the winding device.

Embodiment 3

[0037] (1) Use the mixing feeder to stir and mix the rubber evenly and transport it to the discharge tank;

[0038] (2) The raw material output from the storage tank enters the first extruder, the temperature is controlled at 200°C, and is extruded through a special die for sheet extrusion, and the die temperature is controlled at 180°C;

[0039] (3) The viscose raw material enters the second extruder, and the temperature is controlled at 170°C;

[0040] (4) The sheet polymer raw materials and viscose raw materials extruded from the first extruder and the second extruder respectively enter the distributor or multi-layer die for compounding, and finally extrude and form;

[0041] (5) The extruded material is directly covered with a high temperature resistant isolation film and then enters the 3-roll calendering device to control the thickness, and then is wound by the winding device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com