Vertical continuous annealing furnace bluing device and bluing technology thereof

A continuous annealing furnace, vertical technology, applied in the direction of metal material coating process, furnace, furnace type, etc., can solve the problems of long production operation time, low production efficiency, complex process, etc., to increase energy consumption and high production efficiency , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

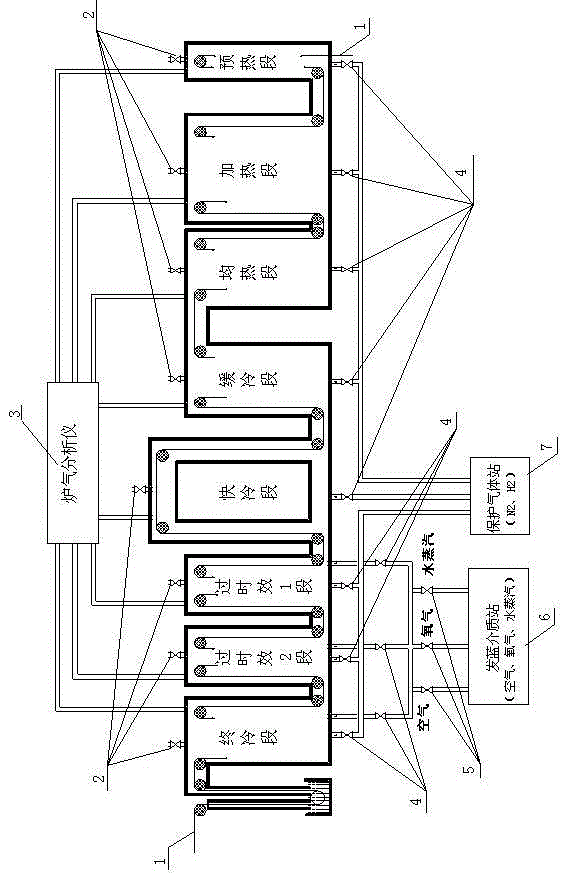

[0016] Example: see figure 1 , pickling-rolled chilled steel strip 1, in the vertical continuous annealing unit, after winding-leveling-cutting head and tail-welding-surface cleaning, drying-vertical looper, enter the vertical continuous annealing unit Annealing in the furnace. At this time, each section of the furnace is filled with 3.0% to 5.0% hydrogen and a protective gas with the balance being nitrogen. The residual oxygen content is controlled below 0.02% to prevent surface oxidation. The atmosphere in the furnace is controlled through the relief valve 2 installed on the top of each section of the furnace, the furnace gas analyzer 3 connected to the pipeline, and the regulating valve 4 on the protective gas pipeline to realize automatic detection and adjustment, maintain a slight positive pressure, and the detection data is displayed in the operating room real-time display on the screen. Steel strip 1 enters the furnace for preheating—heating—soaking (soaking temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com