Laser quasi-synchronous scanning method and system

A quasi-synchronized, laser technology, applied in the field of laser quasi-synchronized scanning and systems, to avoid repeated heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

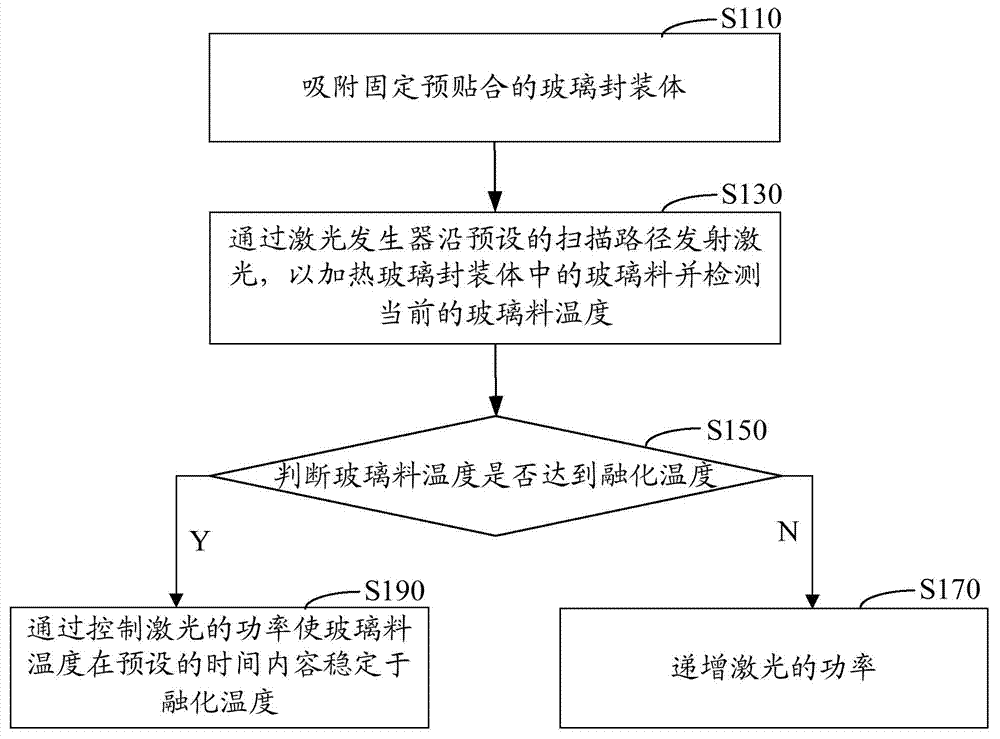

[0032] Such as figure 1 Shown, in one embodiment, a kind of laser quasi-synchronous scanning method comprises the steps:

[0033] Step S110, absorbing and fixing the pre-laminated glass package.

[0034] In this embodiment, the glass package includes an aligned upper glass substrate and a lower glass substrate, and glass frit placed between the upper glass substrate and the lower glass substrate, wherein the glass frit will surround the upper glass substrate and the lower glass substrate. edge placement.

[0035] First vacuumize the sealed chamber to ensure the yield rate of the laser quasi-synchronous process, then place the pre-laminated glass package on the adsorption platform in the sealed chamber, and drive the push rod to the pre-laminated glass package through the cylinder set around the adsorption platform. The bonded glass package is fixed by adsorption.

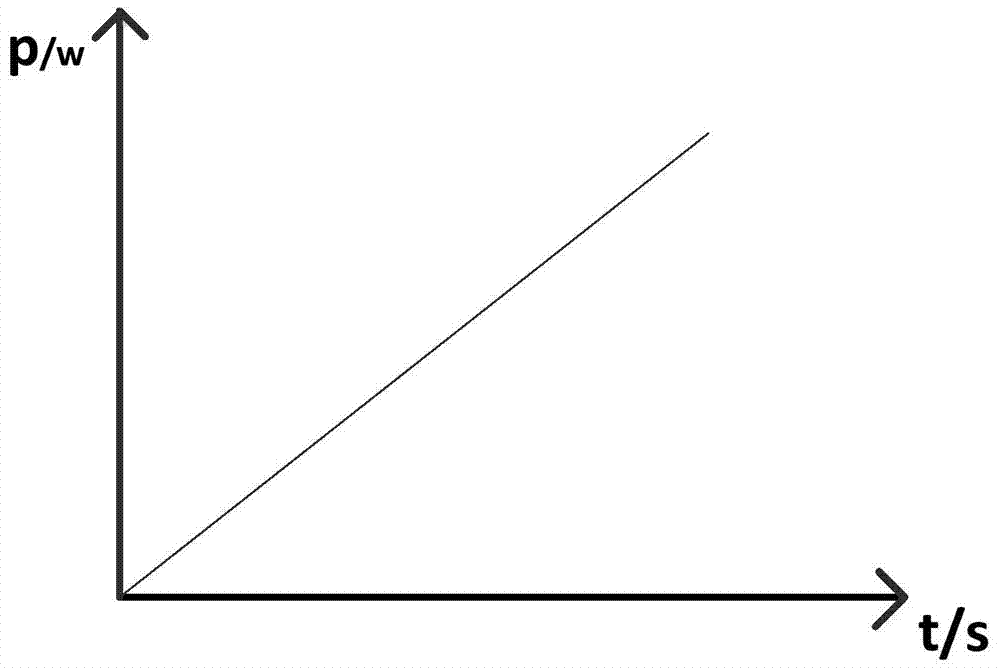

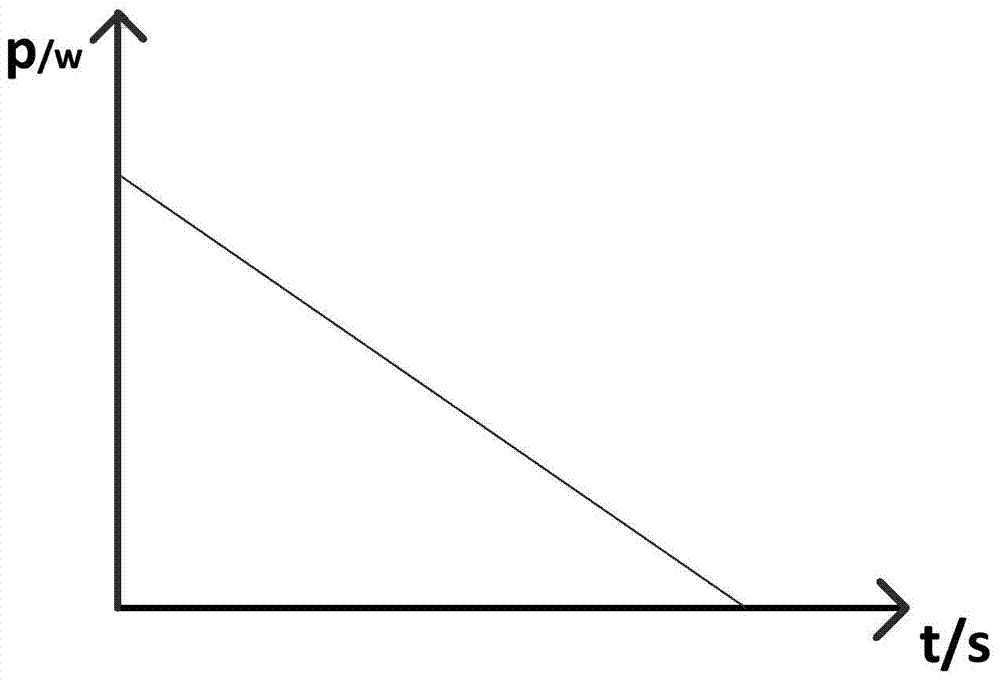

[0036] In step S130, the laser generator emits laser light along a preset scanning path to heat the glass frit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com