Device and method for separating light-colored C9 fraction of cracking

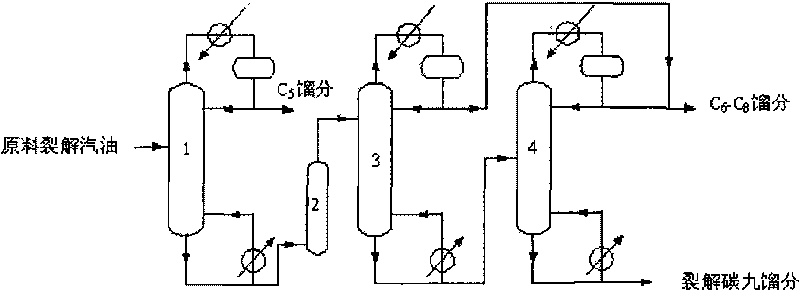

A cracked carbon, light-colored technology, applied in fractional distillation, hydrocarbon distillation, petroleum industry, etc., can solve the problems of low yield of light-colored cracked carbon 9, long process, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

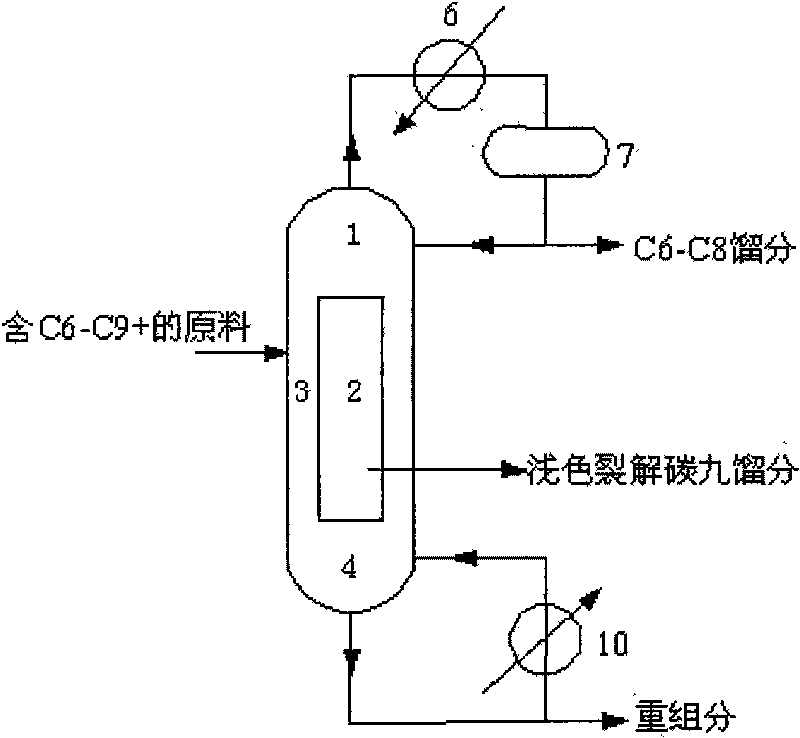

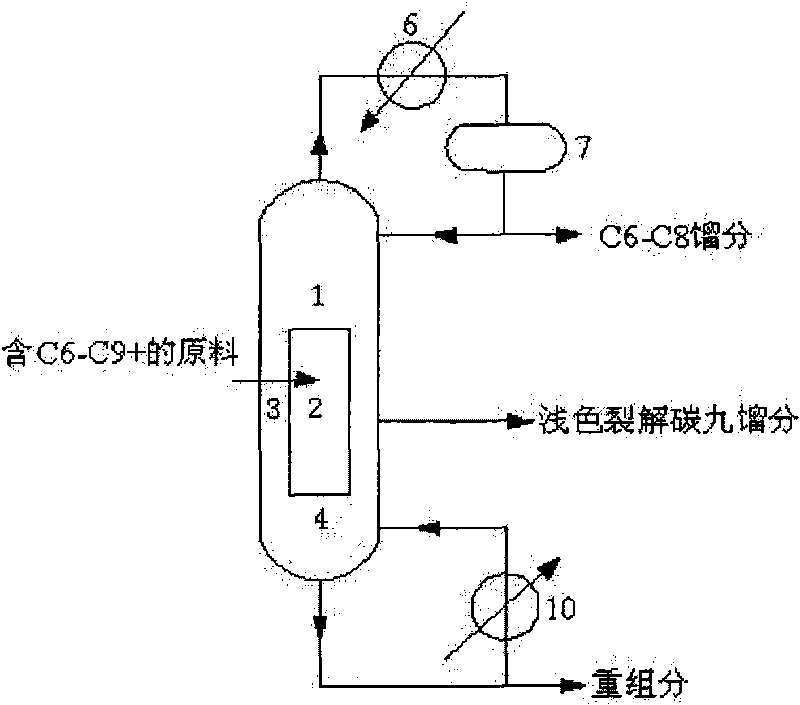

Embodiment 1

[0031] Embodiment 1: adopt sleeve tower separation cracking carbon nine, process condition is: processing capacity is 23905kg / h, C in the raw material 6 ~C 8 The mass fraction is 70.67%, the output at the top of the tower is 16646.1kg / h, and the C at the top of the tower is 6 ~C 8 The quality score is 99.2%. The output of light-colored pyrolysis carbon 9 is 5400kg / h, the outer tower feeds, the inner cylinder discharges, and the liquid distribution ratio (inner rectification cylinder 2: outer rectification tower body 3) is 1:2. The technical parameters of the sleeve tower are shown in Table 2.

[0032] Table 2 Sleeve column separation and cracking carbon nine process parameters list

[0033] project

sleeve tower

total

Tower top pressure (absolute pressure), KPa

21

Tower top temperature, °C

53

Tower kettle temperature, ℃

150

Number of theoretical plates

33

33

Reflux ratio

1.1

...

Embodiment 2

[0036] Embodiment 2: adopt sleeve tower separation cracking carbon nine, process condition is: processing capacity is 23905kg / h, C in the raw material 6 ~C 8 The mass fraction is 75.43%, the output at the top of the tower is 18000.1kg / h, and the C at the top of the tower is 6 ~C 8 The quality score is 99.3%. The output of light-colored pyrolysis carbon 9 is 4500kg / h, the outer tower feeds, the inner cylinder discharges, and the liquid distribution ratio (inner rectification cylinder 2: outer rectification tower body 3) is 1:2. The technical parameters of the sleeve tower are shown in Table 3.

[0037] Table 3 Separation and cracking carbon nine process parameters list of sleeve tower

[0038] project

sleeve tower

total

Tower top pressure (absolute pressure), KPa

25

Tower top temperature, °C

52.6

Tower kettle temperature, ℃

166

Number of theoretical plates

31

31

Reflux ratio

1.1

...

Embodiment 3

[0041] Embodiment 3: Under the same operating conditions as in Embodiment 2, only the position of feeding and discharging is changed, the inner cylinder is selected to feed, and the outer tower is discharged. The result obtained is the same as that of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com