Absorption-separation integrated cyclone reactor for desulfurizing sulfur-containing gas

A swirl reaction and exhaust device technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of complex structure of packed towers, difficult installation and maintenance, and high cost, so as to speed up gas-liquid mass transfer Speed, small initial investment, and the effect of saving energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

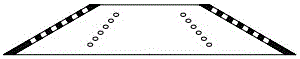

[0046] Refer to attached Figure 8~13 :Such as Figure 8 As shown, the liquid inlet structure includes an outer cylinder body 13, a liquid inlet port 14 and a liquid inlet hole 15. The outer cylinder body 13 is arranged on the upper part of the gradually expanding cone body 6 of the reaction section of the upper cavity, and the outer diameter is the same as that of the gradually expanding cone body of the reaction section. 6 have the same maximum outer diameter, a liquid inlet 14 is provided on the upper end surface of the outer cylinder 13, and a plurality of liquid inlet holes 15 are annularly provided on the inclined end surface of the upper cavity.

[0047] The inlet hole 15 can be as Figure 8~10 , a plurality of evenly distributed small holes shown in 12 can also be as Figure 11 with 13 The strip pores shown. The absorption liquid added in the gradually expanding cone 6 of the reaction section is sprayed through the liquid inlet 14 provided on the outer cylinder 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com