Patents

Literature

31results about How to "Small reaction space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

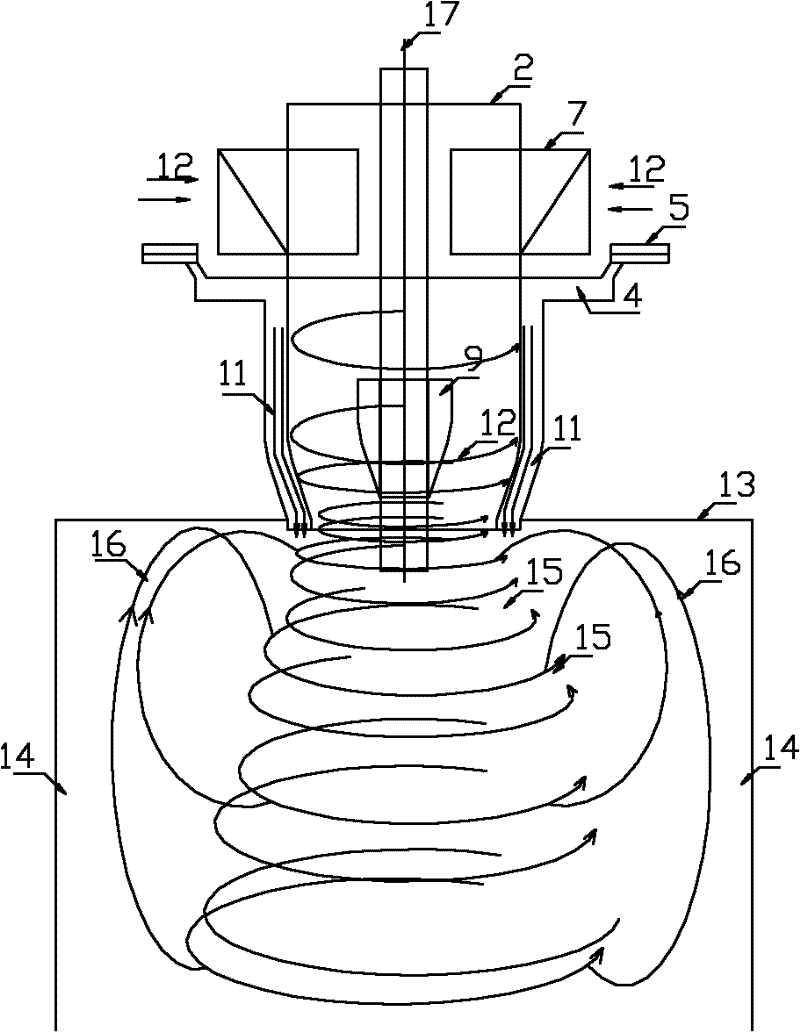

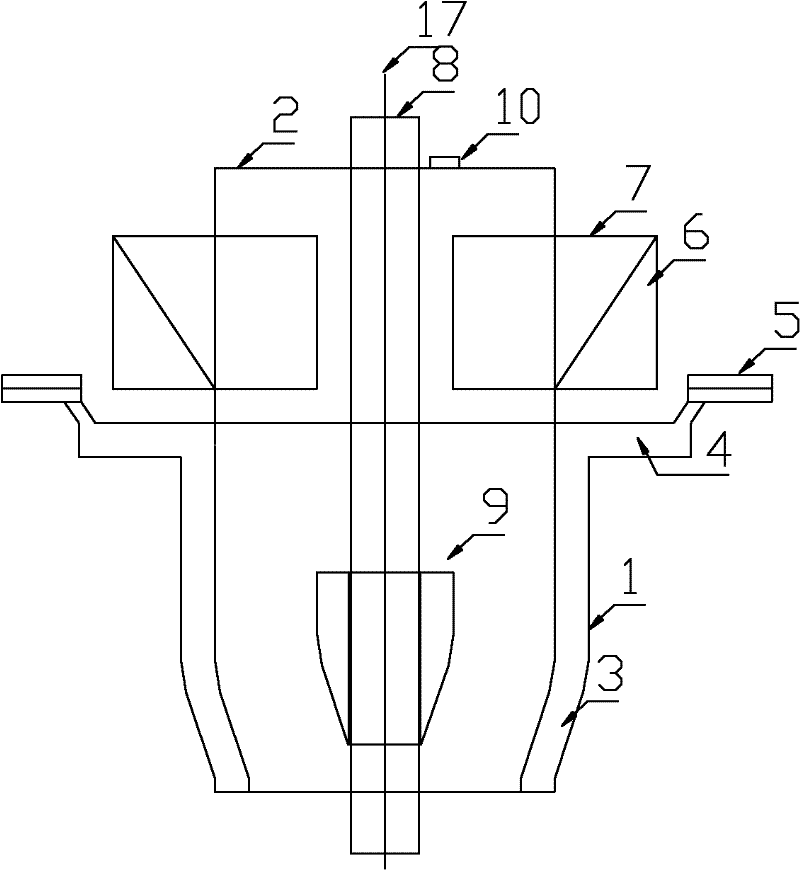

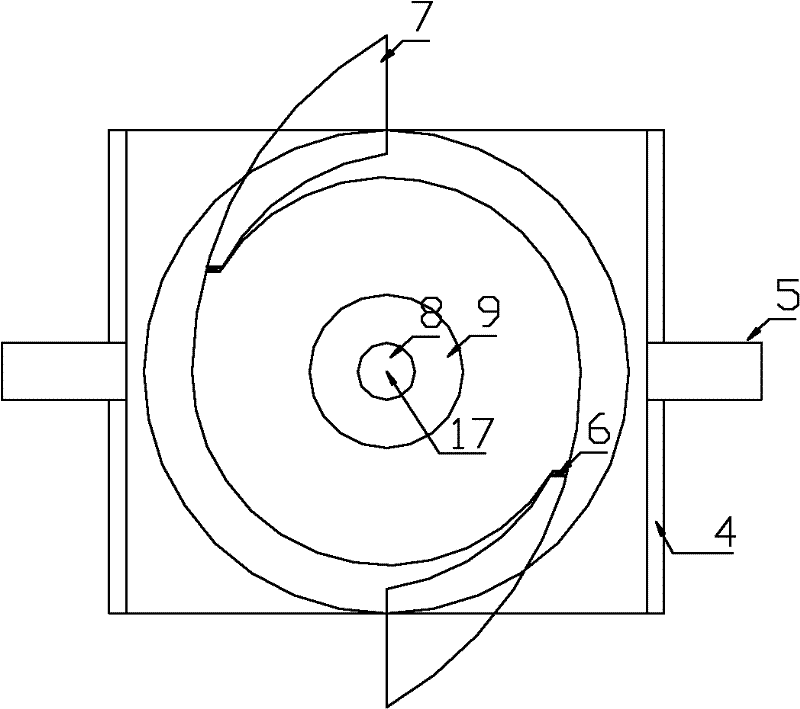

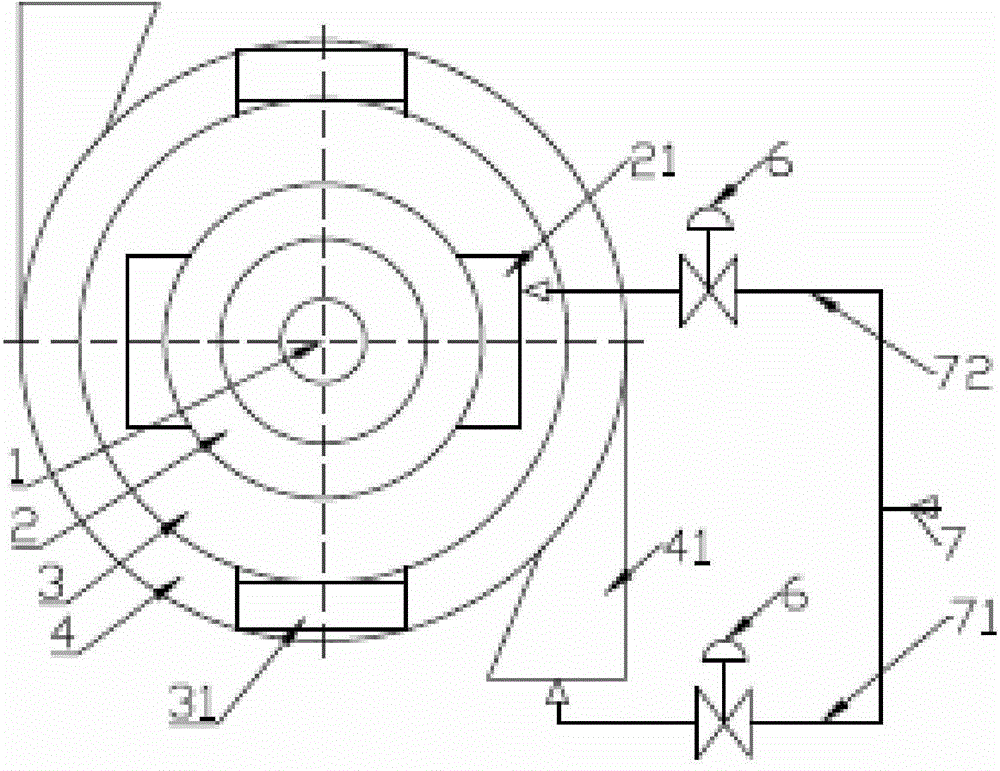

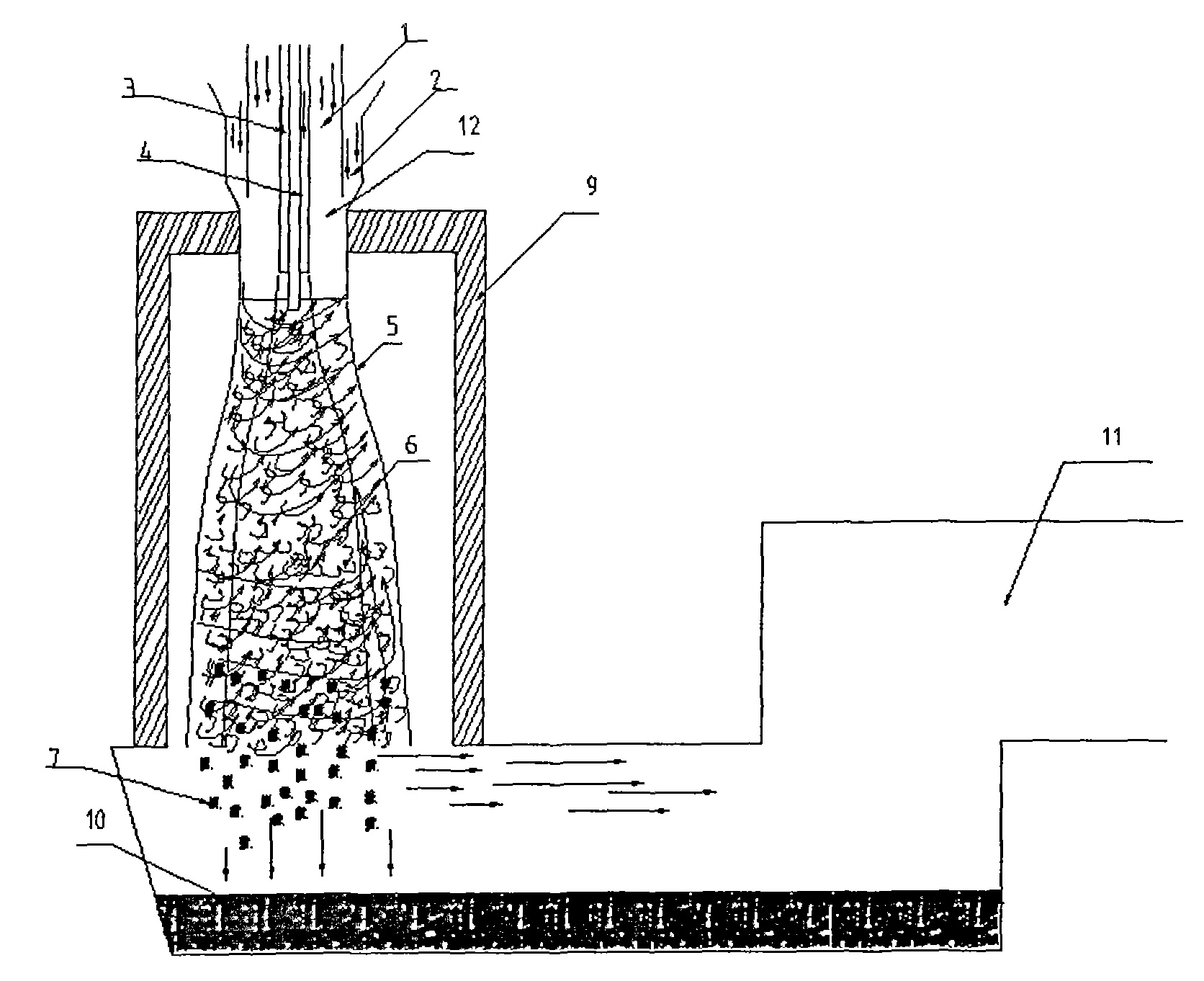

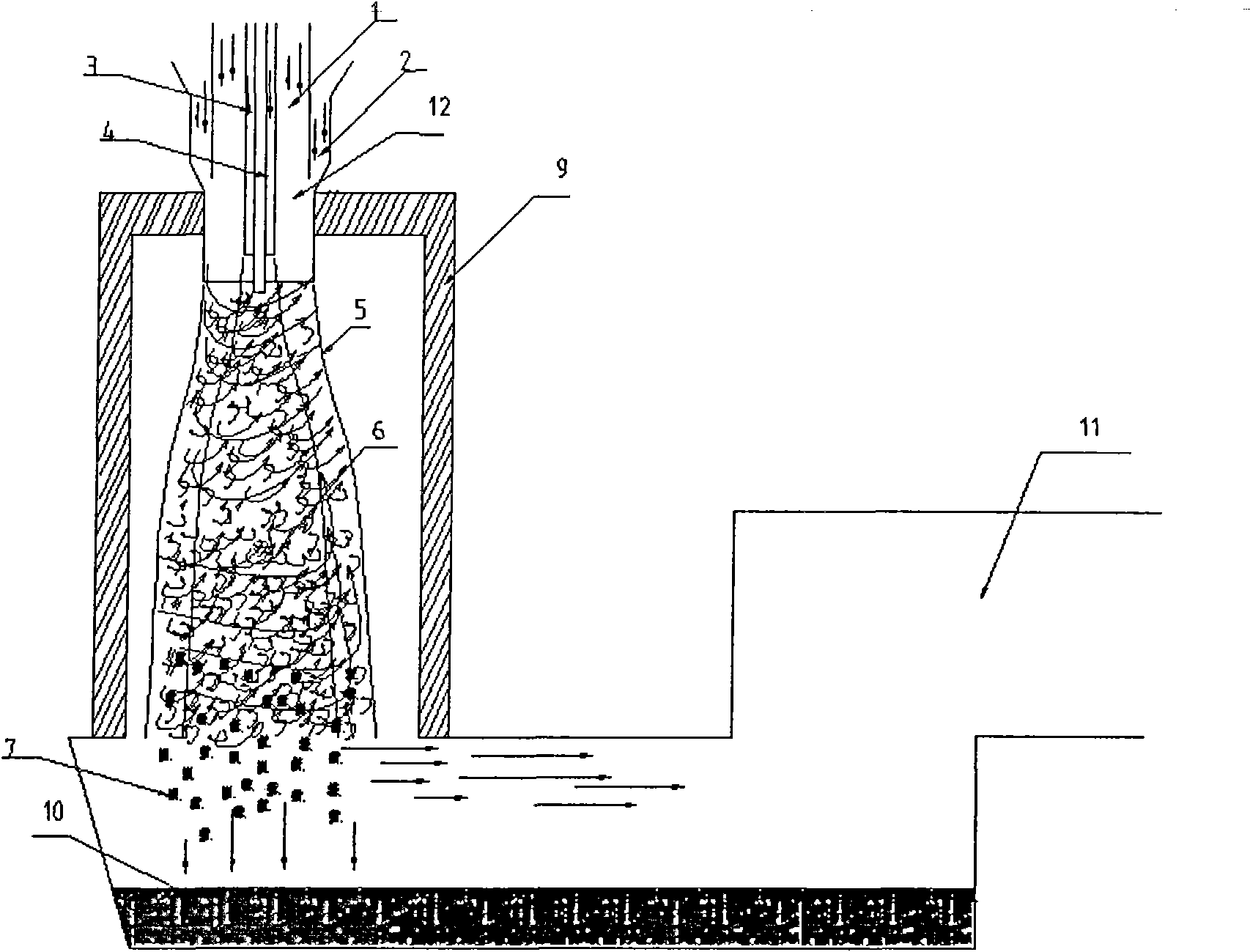

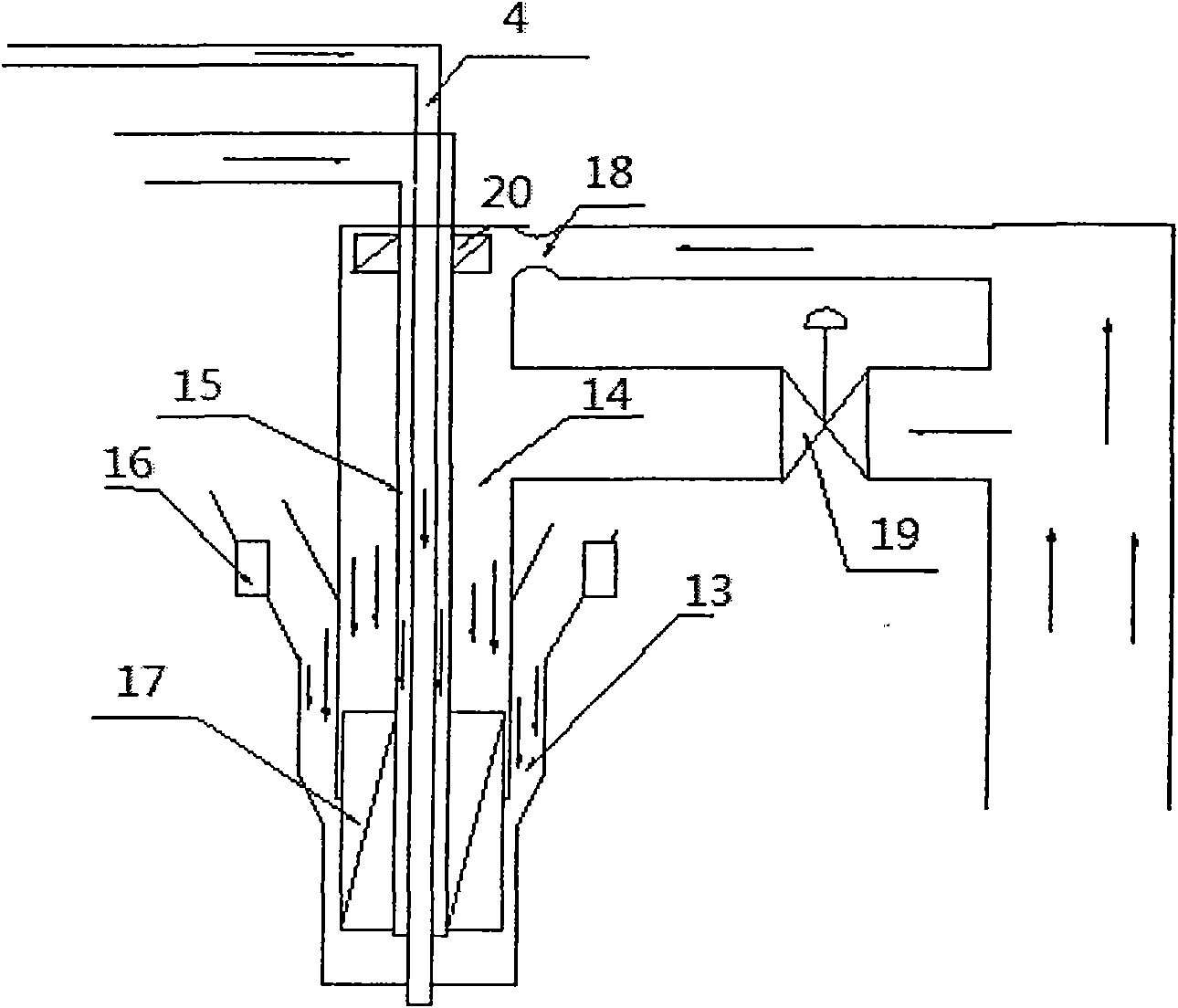

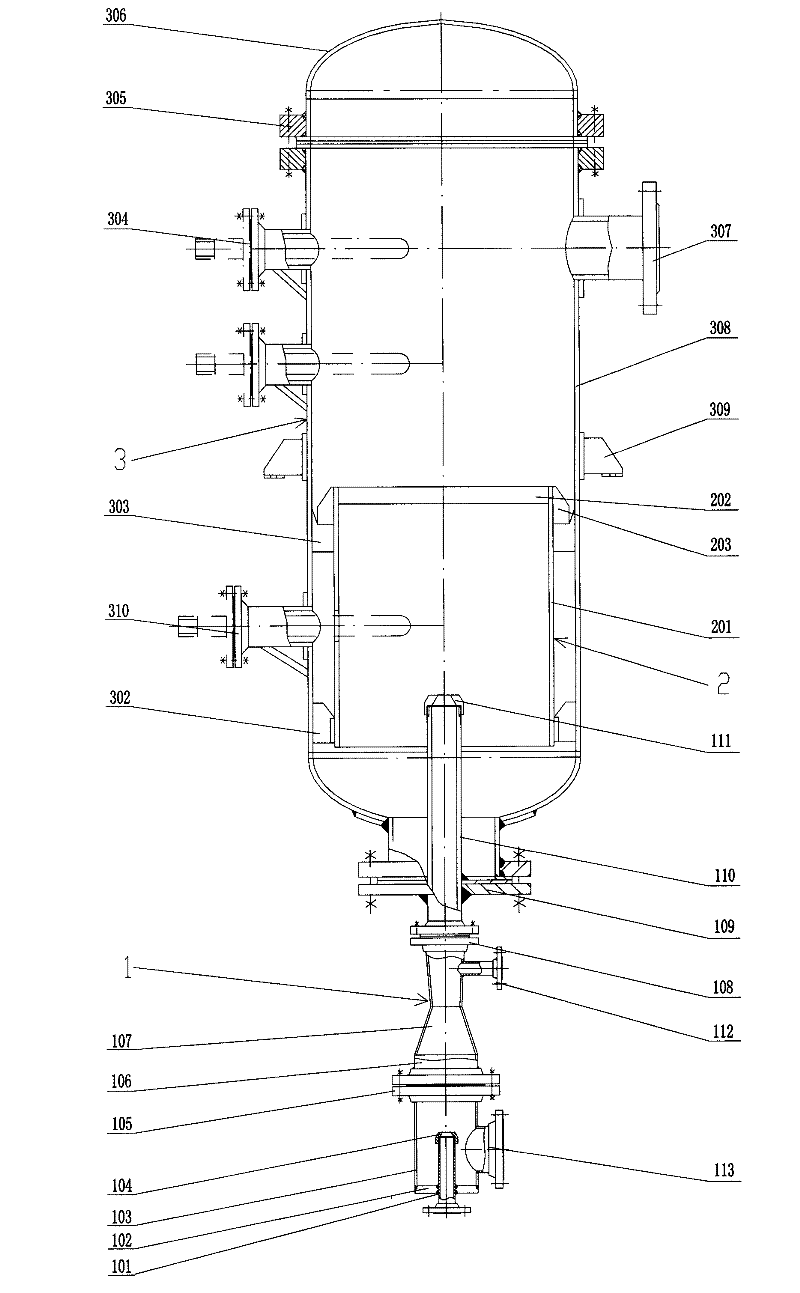

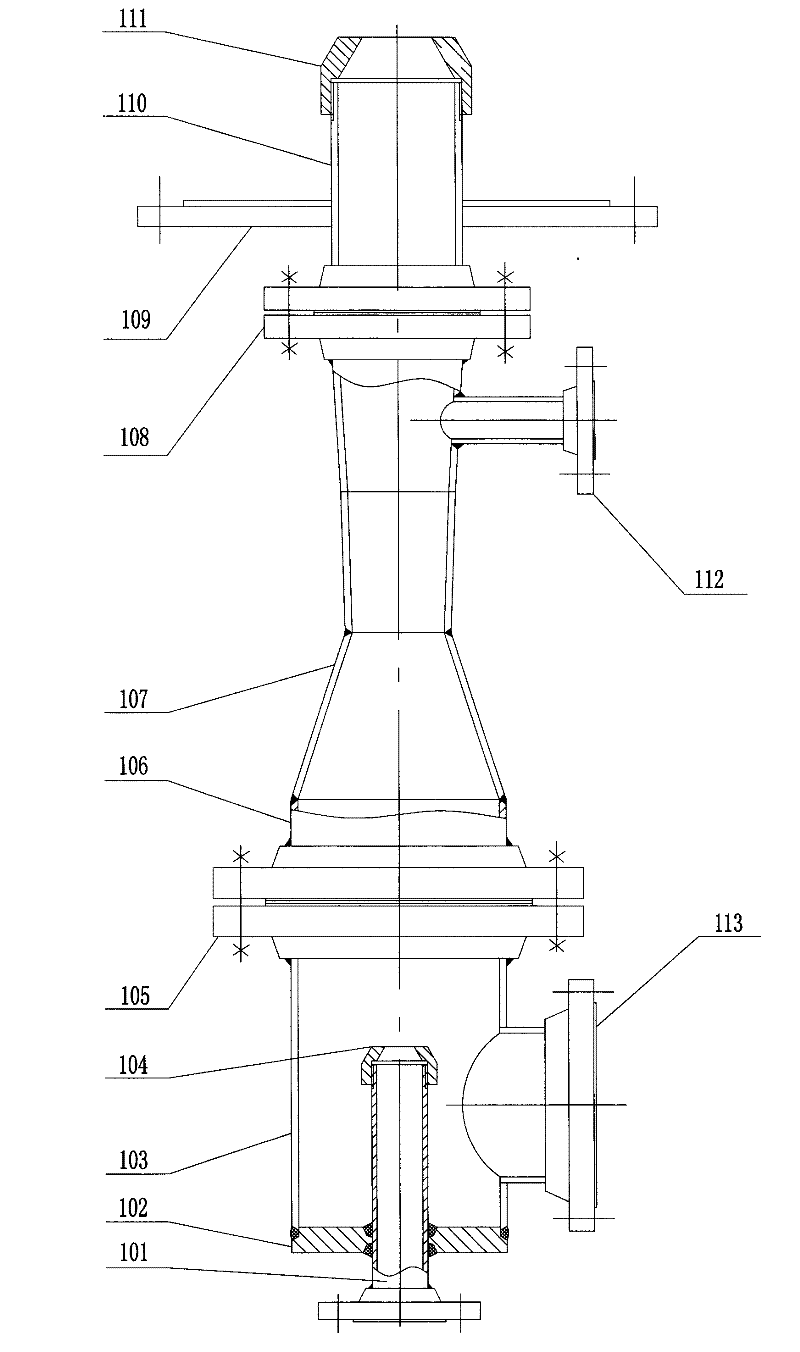

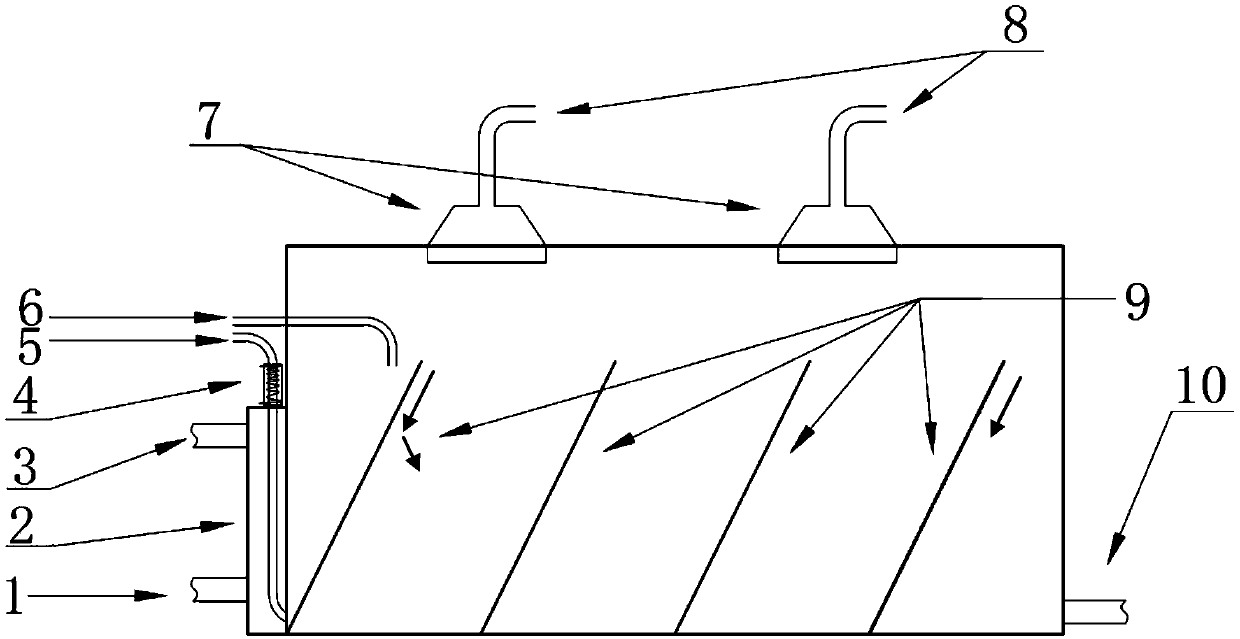

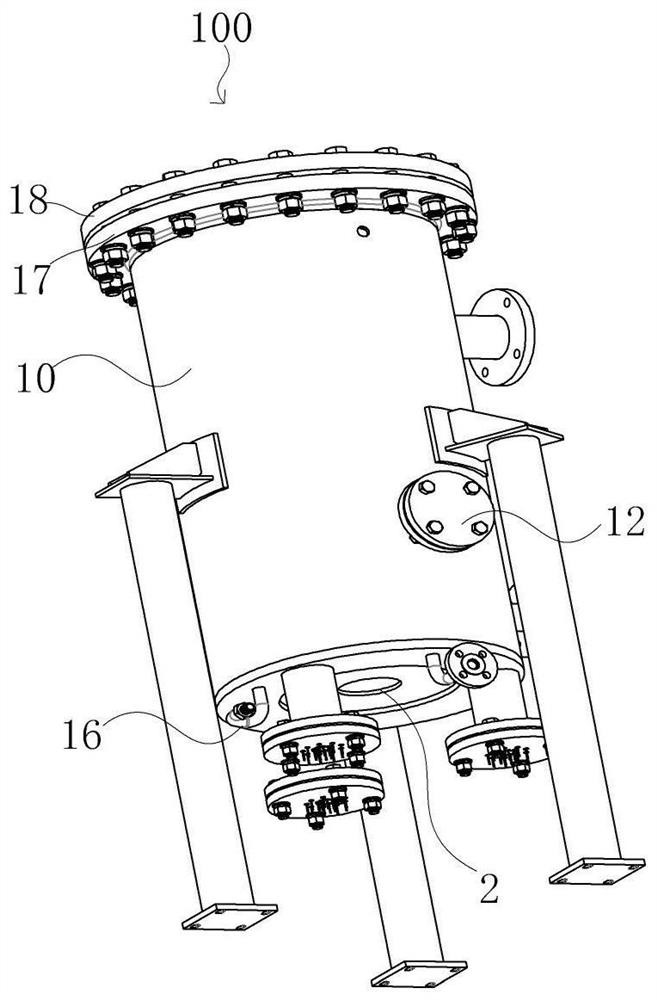

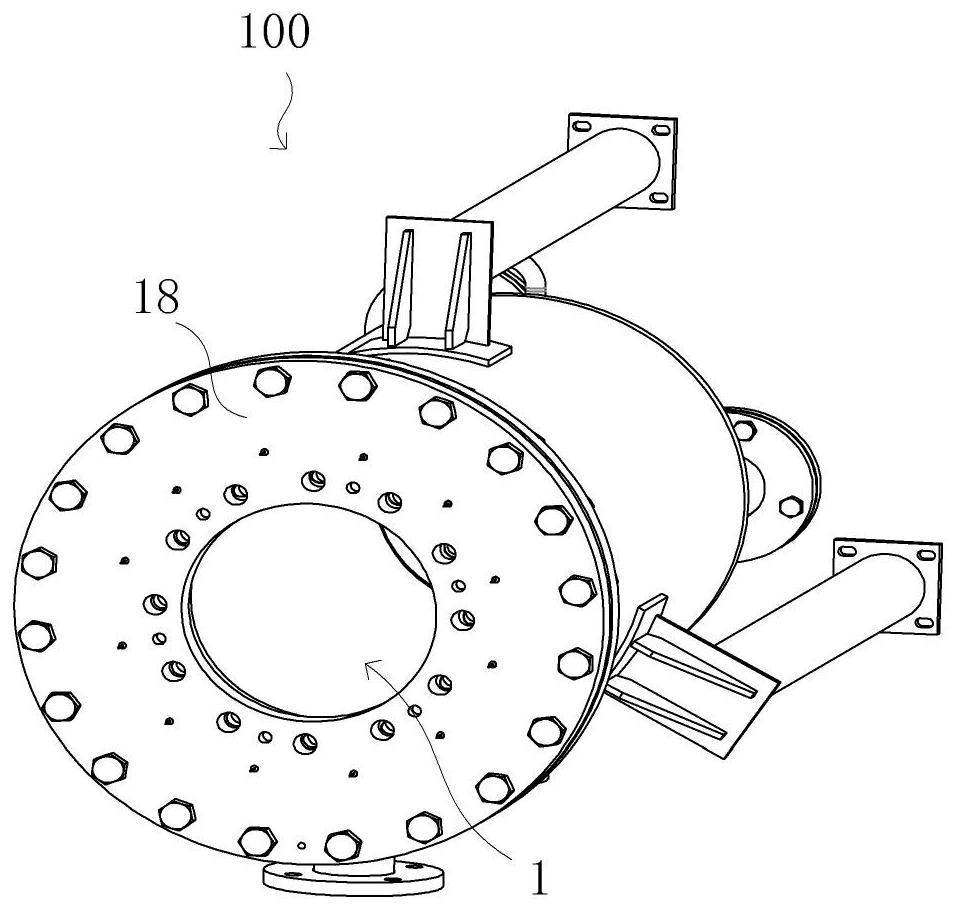

A spin-floating entrainment metallurgical process and its reactor

The invention relates a floating entrainment metallurgical process. In this process, the reaction gas and the powdery materials are injected into the reaction furnace, aiming to obtain a controllable highly rotating and floating state and reach the ignition point under the high-temperature radiation of the reaction furnace to combust intensely. Meanwhile, the rotating fluid injected in the reaction furnace will drive the furnace gas, and forms a relatively low-temperature circular backflow protection area around the rotating fluid. The reaction gas is tangentially fed into the rotating generator along numbers of rotary channels to form a controllable rotating airflow, in addition, a conical exit air controller that can be moved up and down is adopted to control the exit area of the rotating generator, thus controlling the velocity of the reaction gas into the reaction furnace; the powdery materials fall freely around the reaction gas and are involved in the high-speed rotating airflow, forming a rotating fluid, of which the powdery materials are highly dispersed into the reaction gas, moving downwards along the radial high-speed rotating axle. For the purpose of this invention, a steplessly adjusted reactor is as well referred to in this invention.

Owner:YANGGU XIANGGUANG COPPER

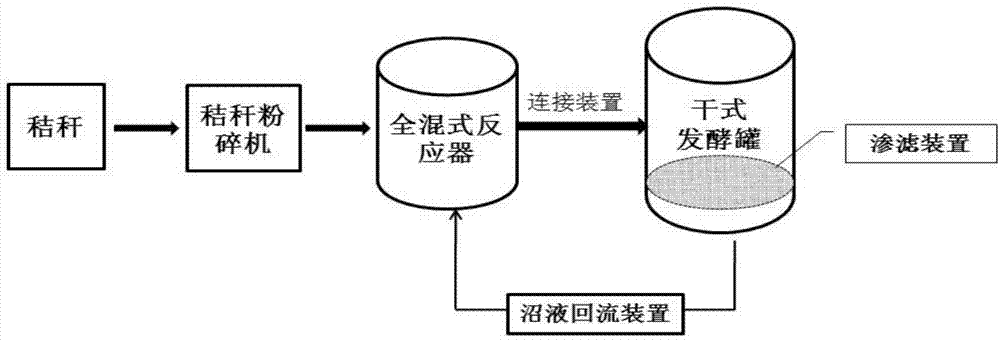

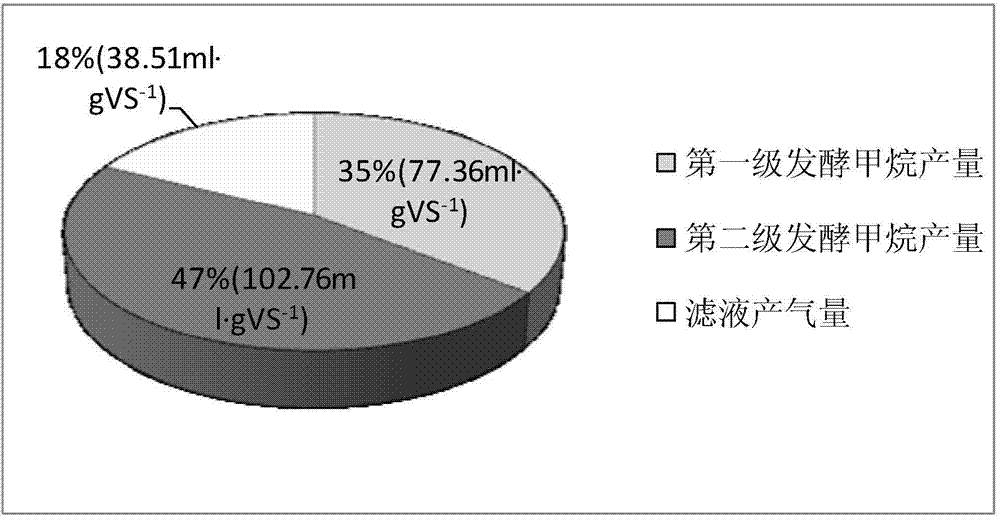

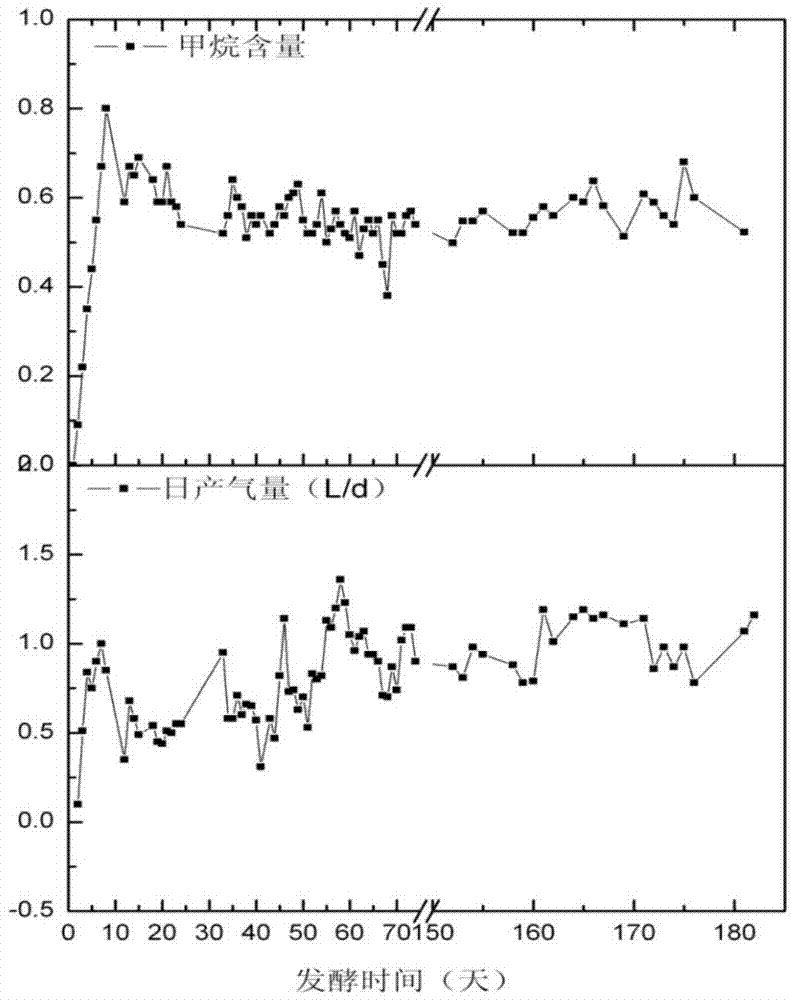

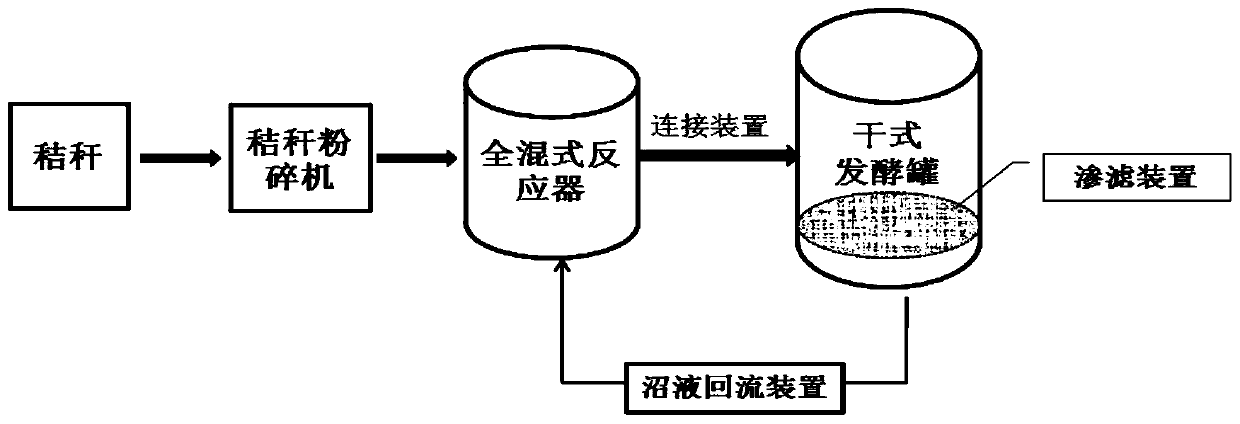

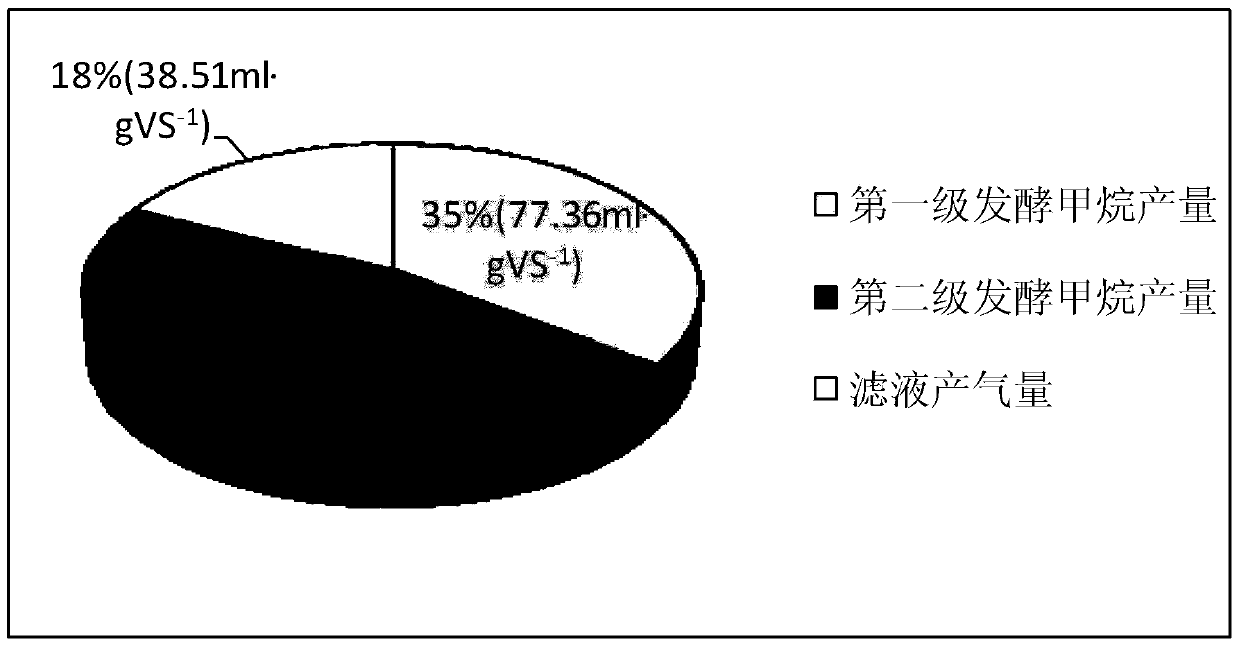

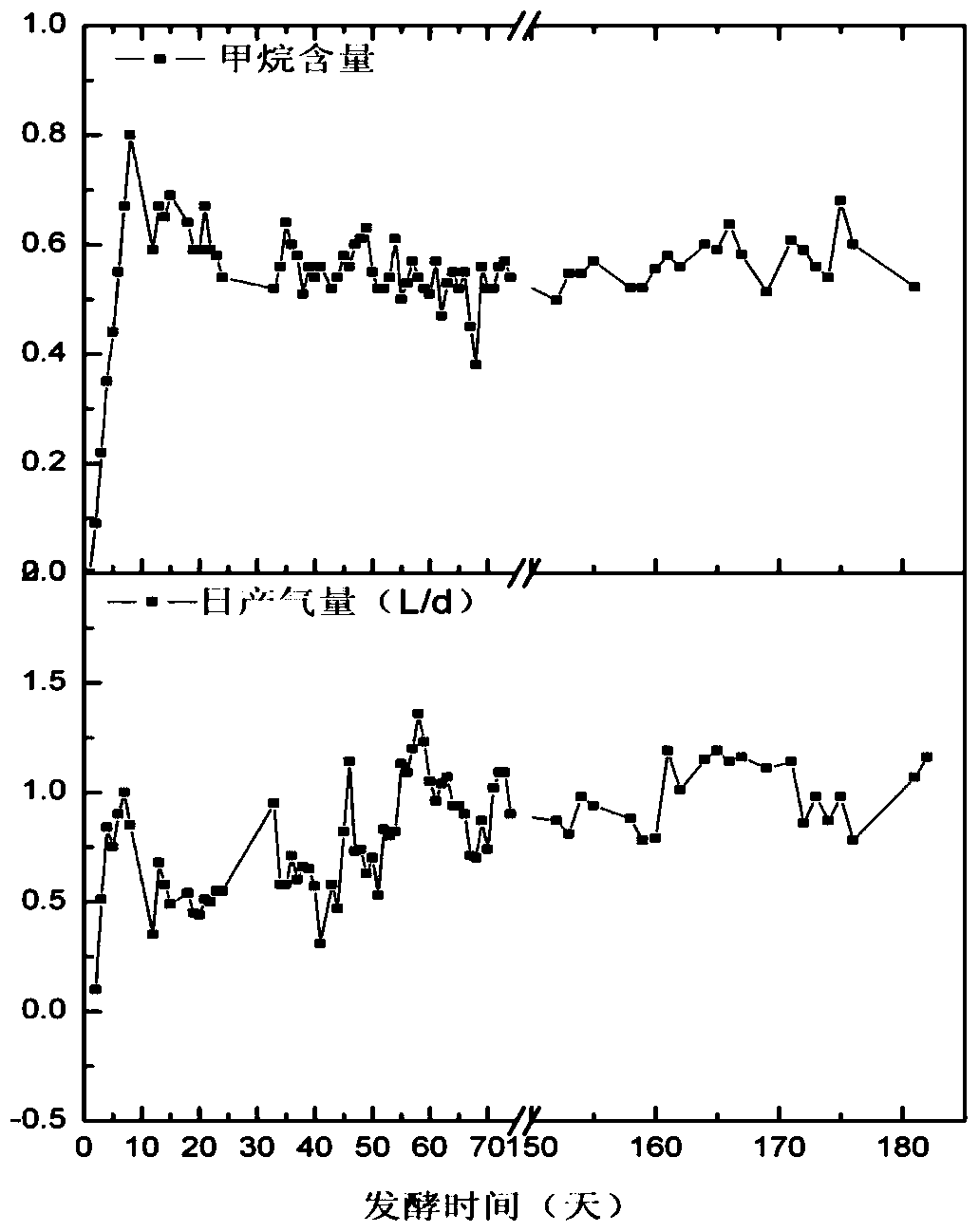

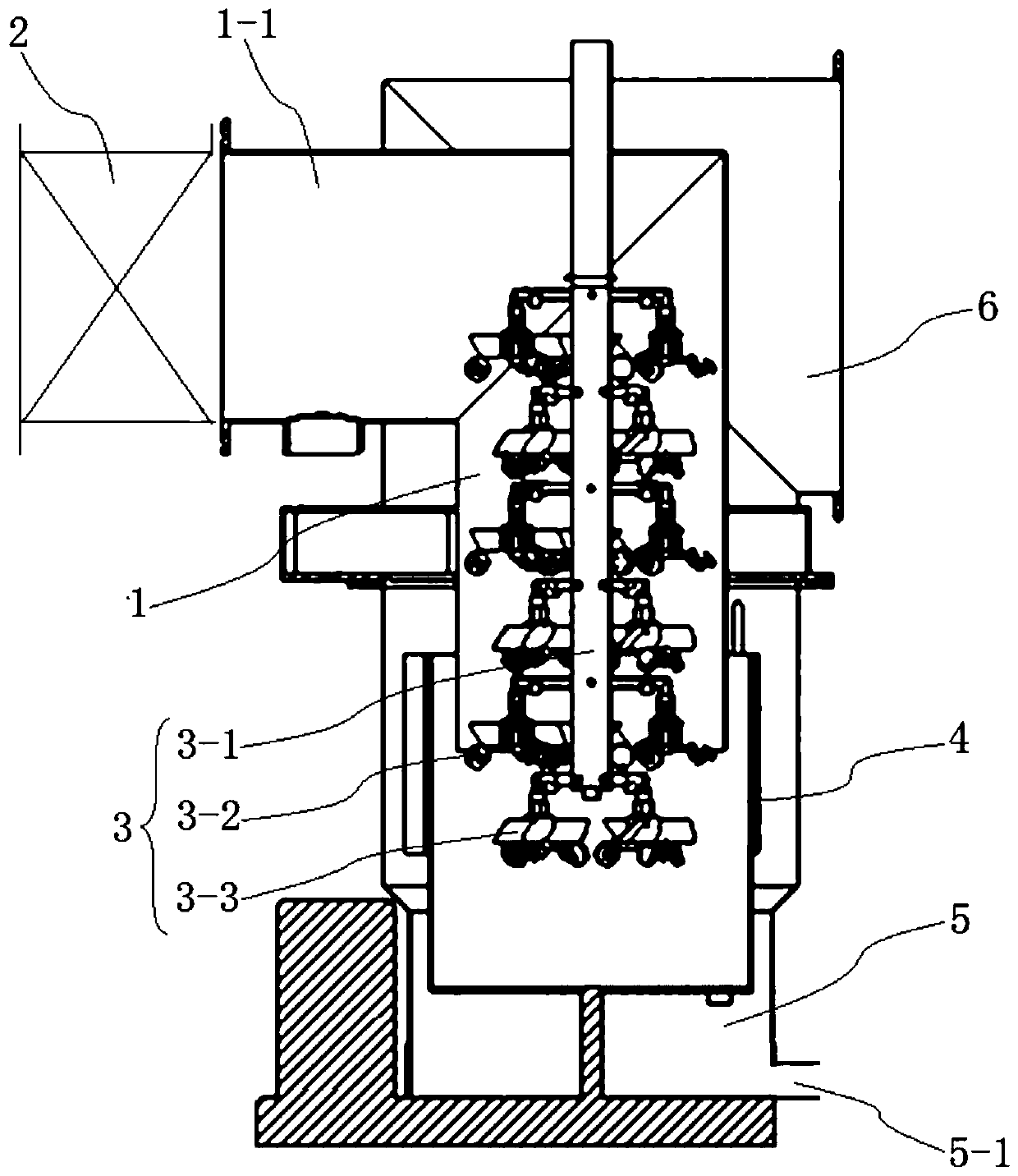

Process for production of biogas by wet method-dry method combined two-stage anaerobic fermentation

ActiveCN104745639ASolve the difficulty of fermentation inoculationSolve the problem of slow startupWaste based fuelFermentationResource utilizationDecomposition

The invention belongs to the field of solid waste disposal and resource utilization, and in particular relates to a process for production of biogas by wet method-dry method combined two-stage anaerobic fermentation. Broken solid waste and an inoculum are mixed in a full wet type reactor for wet anaerobic fermentation, the wet anaerobic fermentation period hydraulic retention time (HRT) is 5-20 days, after fermentation processing, a fermentation material can be delivered to a dry method fermentation reactor with an infiltration device at the bottom for dry solid fermentation for production of the biogas, and the process combines the dual advantages of wet method fermentation and dry method fermentation. The fermentation process integrating the advantages of fast mass transfer and easy start-up characteristics of the wet method fermentation and reaction space saving of the dry method fermentation, and the like is disclosed. By combination of biomass multistage decomposition and transformation in the fermentation process and methane producing bacteria group enrichment principle, the wet fermentation process advantage is used, the wet fermentation process is used as a homogeneous inoculation stage of the dry method fermentation process, and the problems of difficult inoculation and slow start of the dry method fermentation can be solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

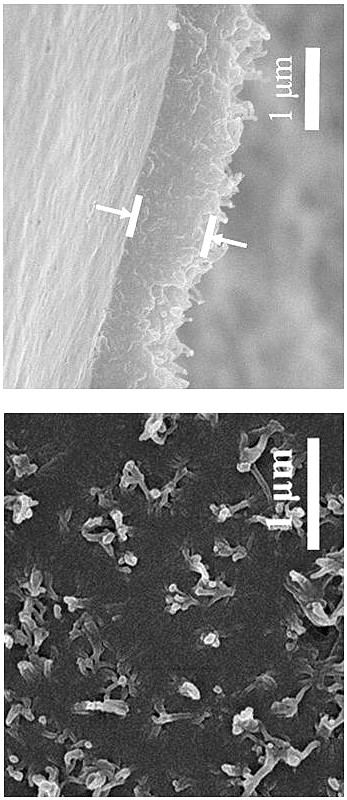

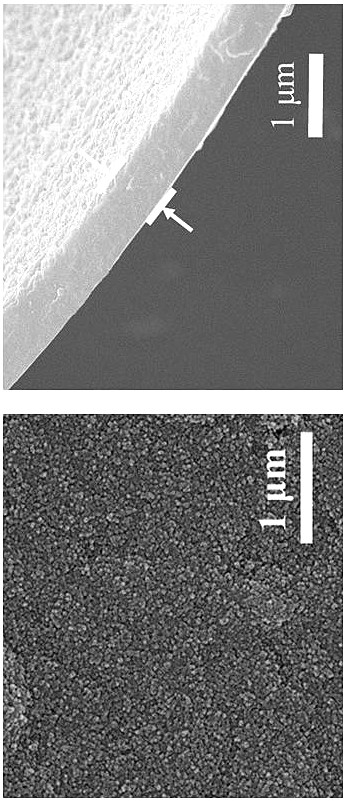

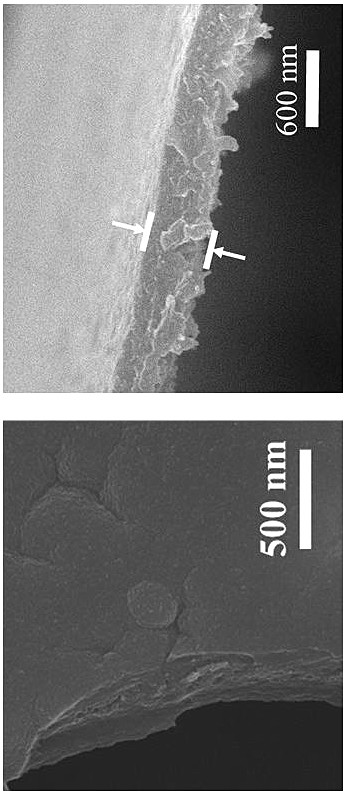

Method for preparing high-crystallinity covalent organic framework film by using ionic liquid-water interface

PendingCN113603912AImprove film qualityAvoid pollutionSemi-permeable membranesPtru catalystP-Toluenesulfonic acid

The invention discloses a method for preparing a high-crystallinity covalent organic framework membrane by using an ionic liquid-water interface. The method comprises the following steps of: dissolving an aldehyde monomer in a hydrophobic ionic liquid to obtain a solution A; dissolving an amine monomer and an acid catalyst p-toluenesulfonic acid in deionized water to obtain a solution B; transferring the solution A into a reactor, adding deionized water to the surface of the solution A, layering, adding the solution B to the upper part of the deionized water layer, and performing a reaction for more than 3 days in the reactor under the condition of still standing at room temperature, so as tosynthesize the covalent organic framework membrane by using a double-diffusion control mechanism that the hydrogen-bond interaction of the acid catalyst and the amine monomer and the high viscosity of hydrophobic ionic liquid are utilized and the diffusion rates of the two monomers are limited at the same time. The covalent organic framework membrane prepared by the method has very high crystallinity, the specific surface area of themembrane is increased by 4 times compared with that of a covalent organic framework membrane synthesized on a traditional dichloromethane-water interface, and the solvent flux is also increased by 2 times under the condition that dye interception is not influenced.

Owner:HENAN NORMAL UNIV

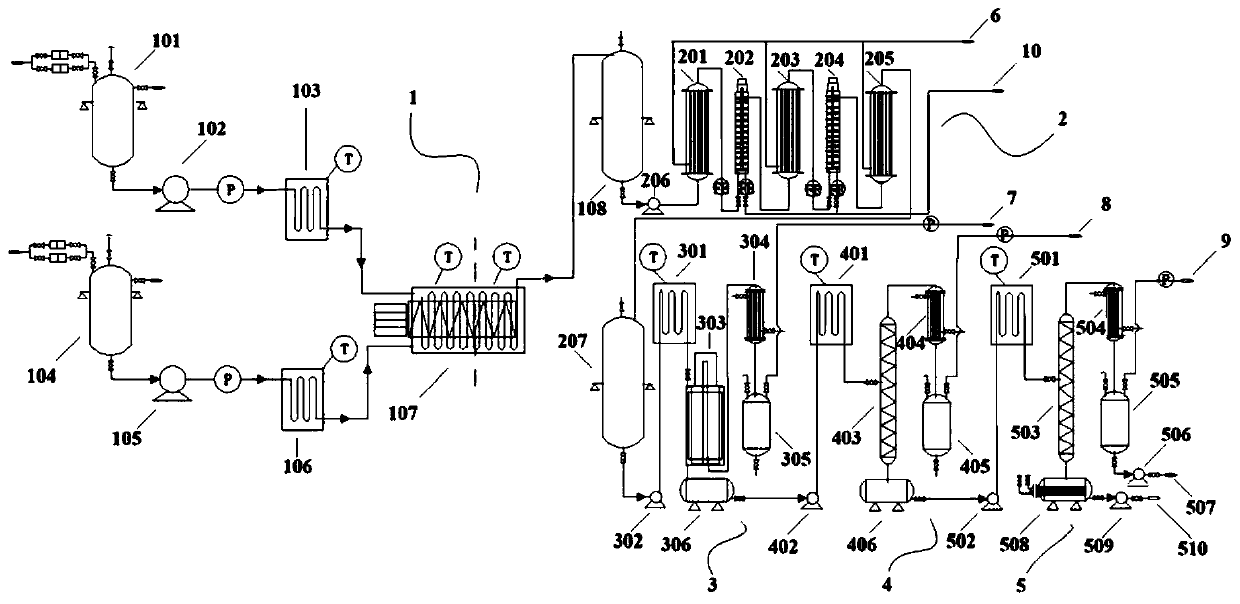

Whole-process continuous phenylacetonitrile production device and process

ActiveCN111253284AShorten the production cycleThe production process is safe, stable and environmentally friendlyChemical industryPreparation by cyanide reactionProcess engineeringOil water

The invention provides a whole-process continuous phenylacetonitrile production device and process. The whole-process continuous phenylacetonitrile production device comprises a reaction unit, a washing unit, an evaporation dehydration unit, a light component removal unit and a product rectification unit which are connected in sequence. The reaction unit comprises a tangential flow reactor. The washing unit comprises an oil-water film separator and a pipeline mixer. The evaporation dehydration unit comprises a falling film evaporator. The light component removal unit comprises a first rectification tower. The product rectification unit comprises a second rectification tower. A continuous production method is adopted in the whole production process of the phenylacetonitrile, the productionperiod is greatly shortened, the production process is safer, more stable and more environmentally friendly, and the production efficiency is remarkably improved. As the tangential flow reactor has the structural characteristics of small reaction space, large specific surface area and arrangement of a stirring device, mass transfer and heat transfer in the reaction process can be enhanced, and thewhole reaction system is small in occupied area, smooth in reaction process and free of channel blockage.

Owner:青岛雪洁助剂有限公司

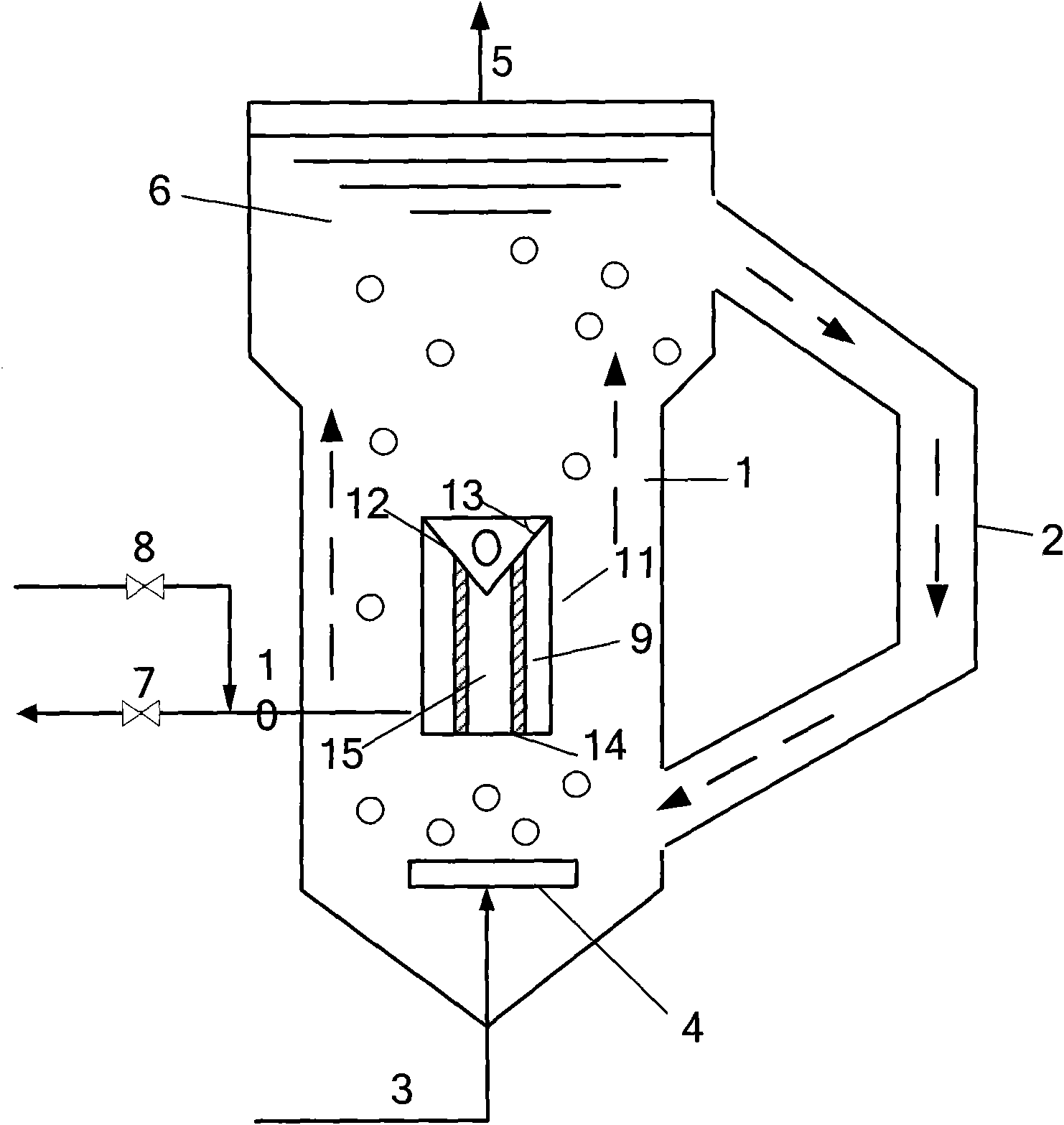

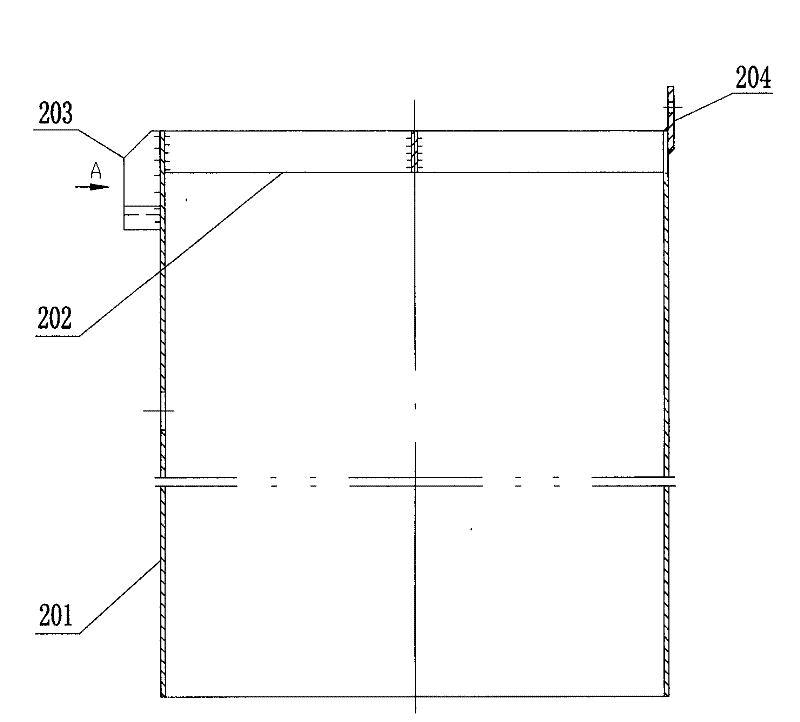

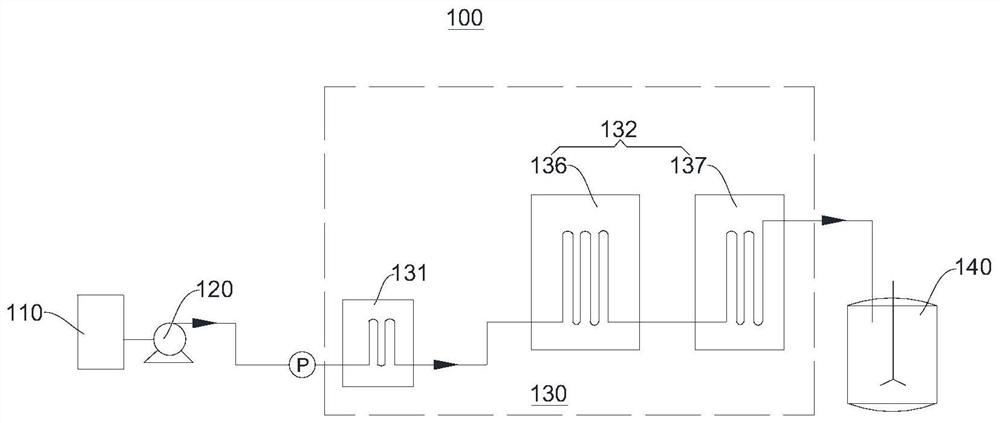

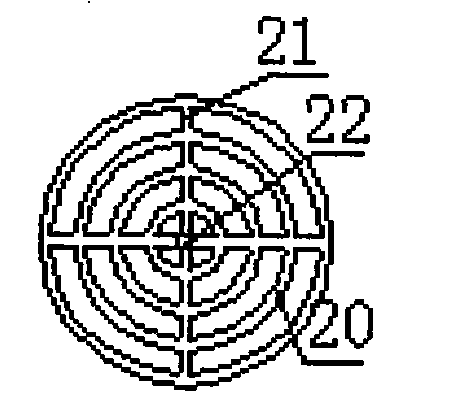

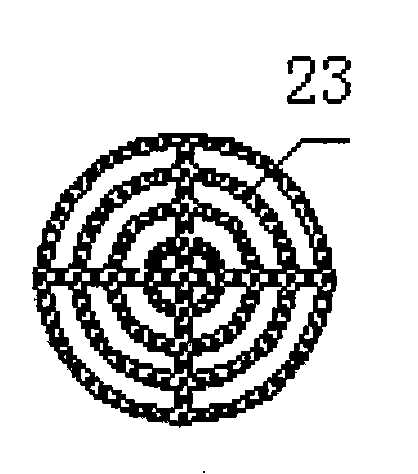

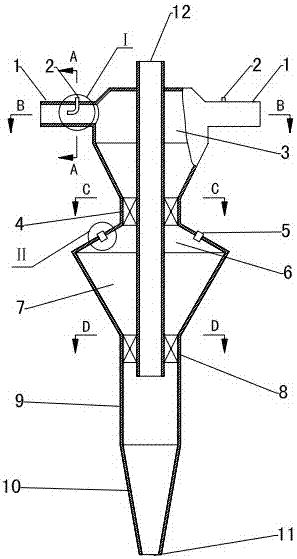

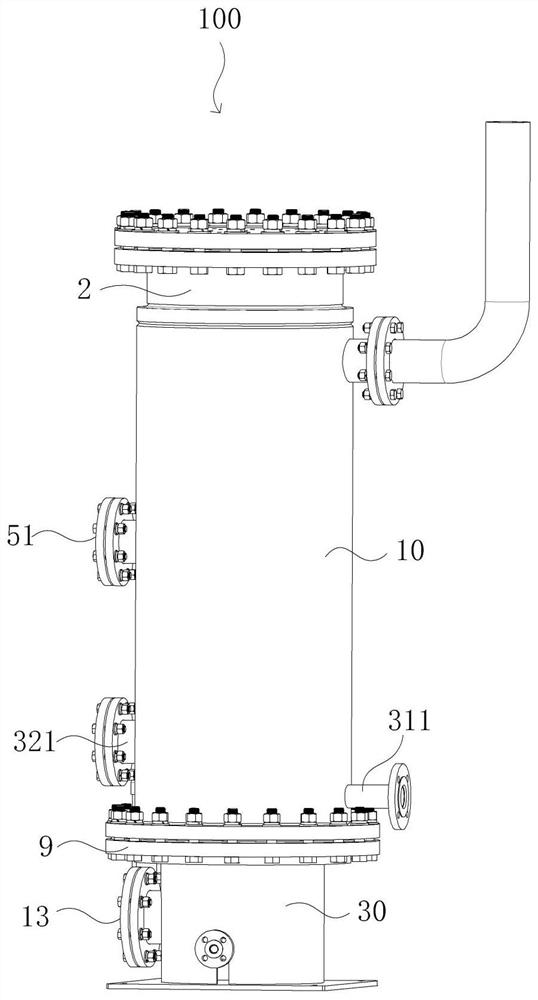

Application method of loop slurry reactor adopting novel filtration module

The invention discloses an application method of a loop slurry reactor adopting a novel filtration module. In the method, synthesis gas firstly enters a riser of the loop slurry reactor from the bottom of the reactor, and then is mixed with the slurry in the riser for reaction, wherein the interior of the riser is provided with the filtration module, and the upper end of an internal flow passage of the filtration module is of a reverse conical structure with a cone angle of 20 degrees to 70 degrees; the slurry flows upwardly along the riser, part of the slurry flows into the internal flow passage of the filtration module, and clear solution penetrates through the wall of a filter tube and serves as a product to be discharged out of the slurry reactor through a discharge hole; and the filtered and condensed slurry continuously flows upwardly and then enters a settlement zone with an enlarged pipe diameter at the top; and the slurry, most bubbles of which are removed in the settlement zone, enters a downcomer, and then is circulated to the riser through the downcomer so as to be subjected to reaction continuously. The method provided by the invention has the advantages of long working cycle of the filtration module and high liquid-solid separation efficiency; and simultaneously, the method provided by the invention is favorable for uniform distribution of the gas flow and liquidflow in the reaction zone of the riser, thus the utilization efficiency of the reactor is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

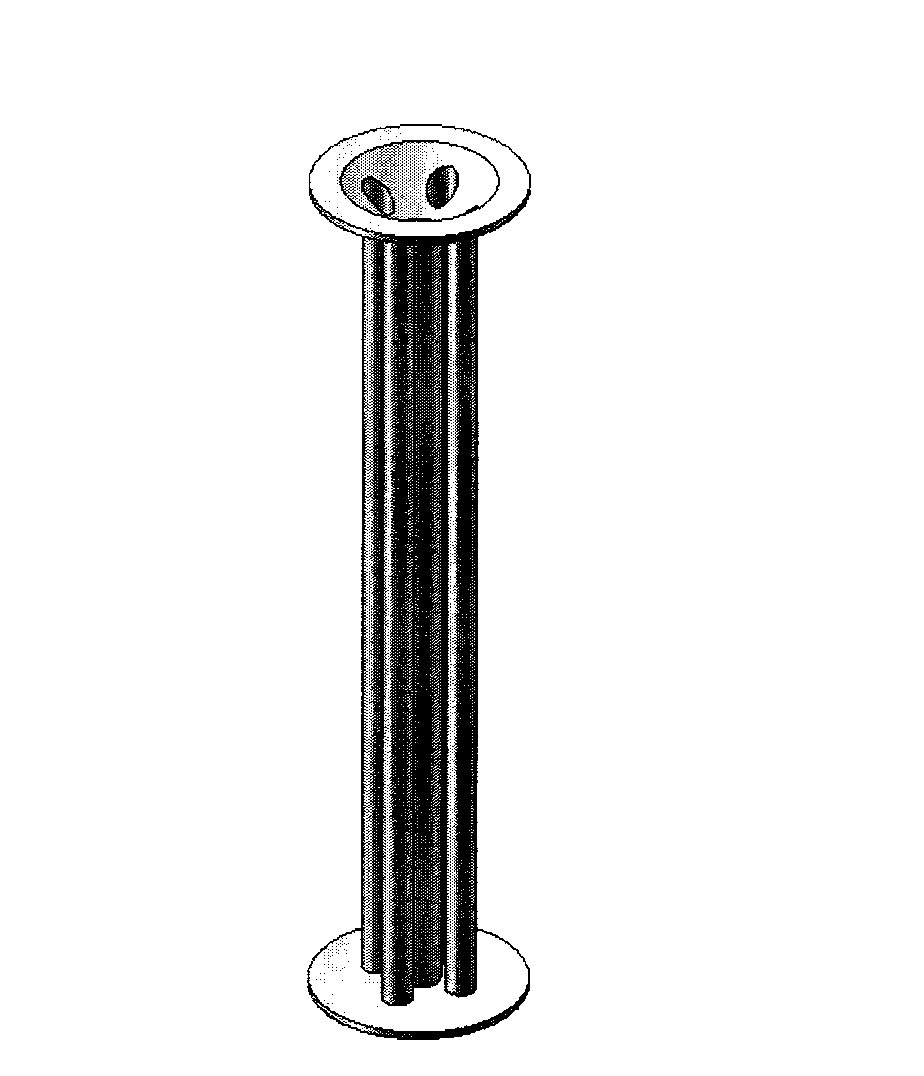

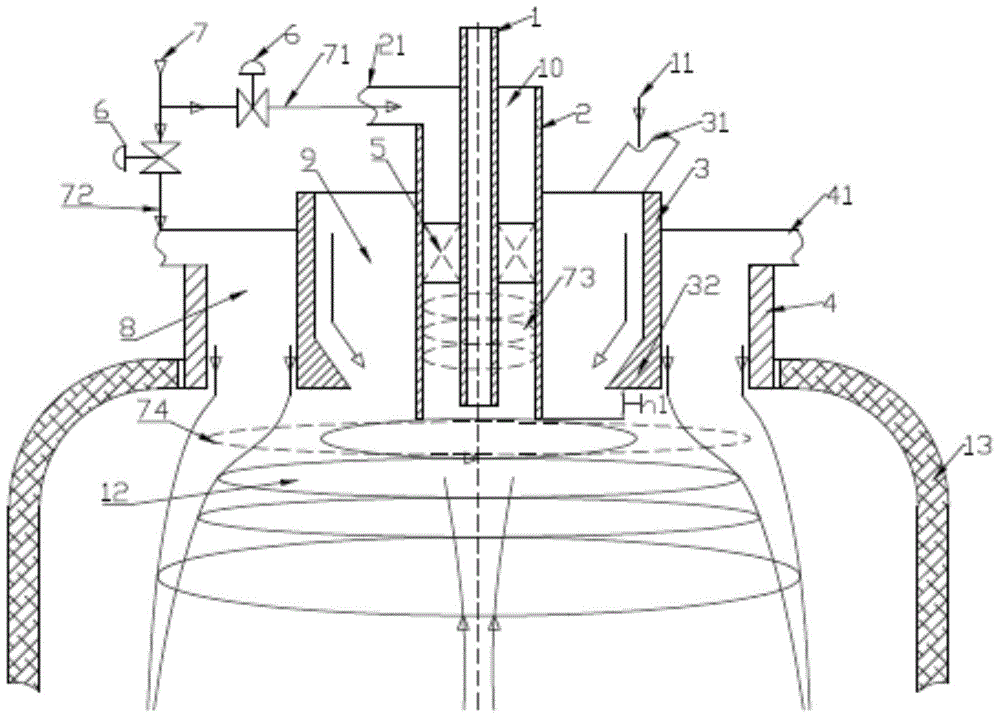

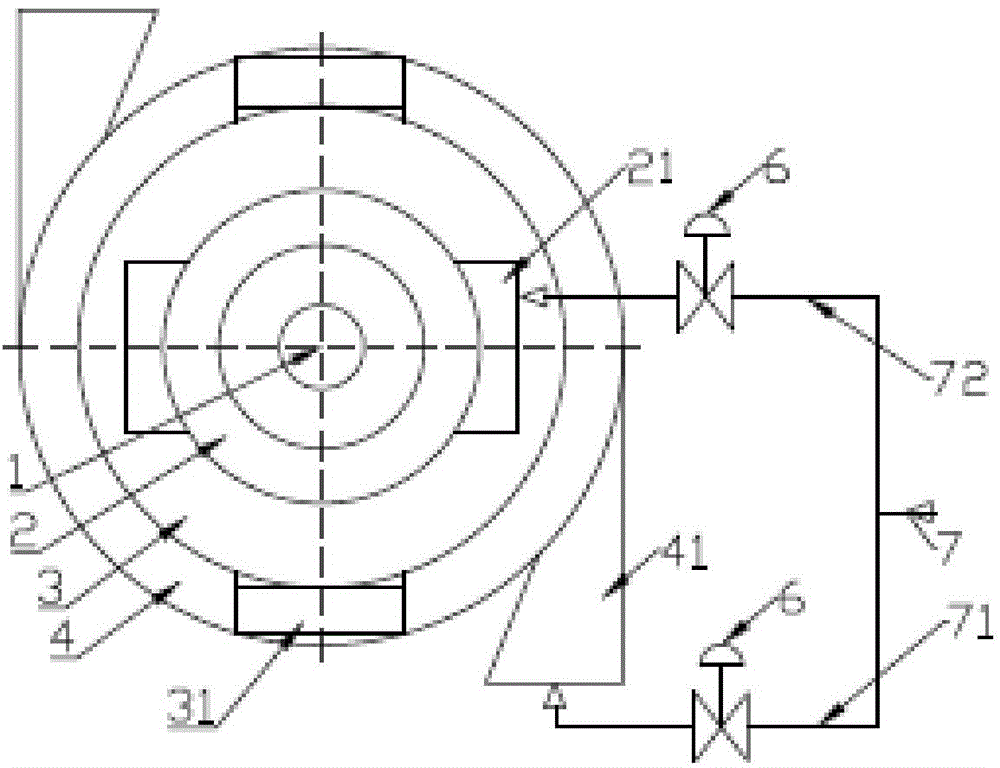

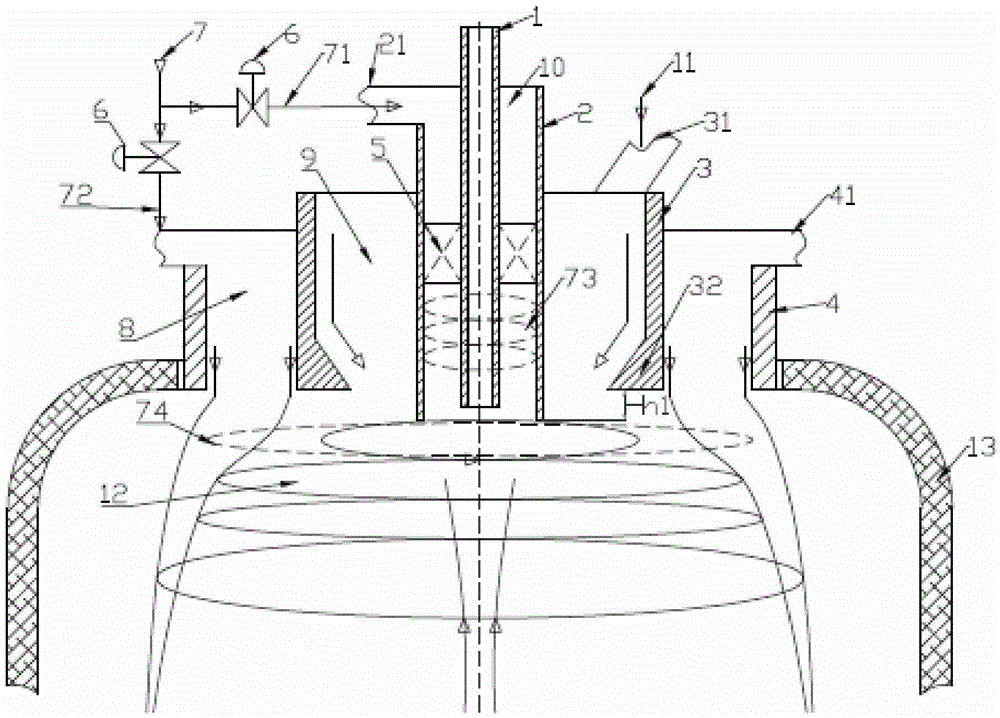

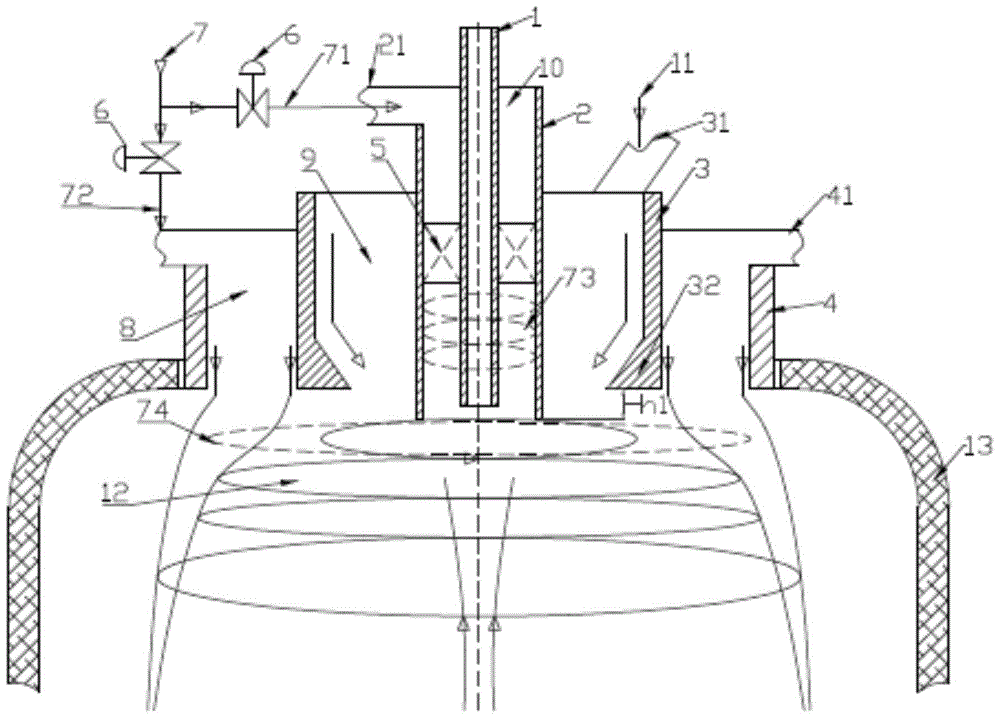

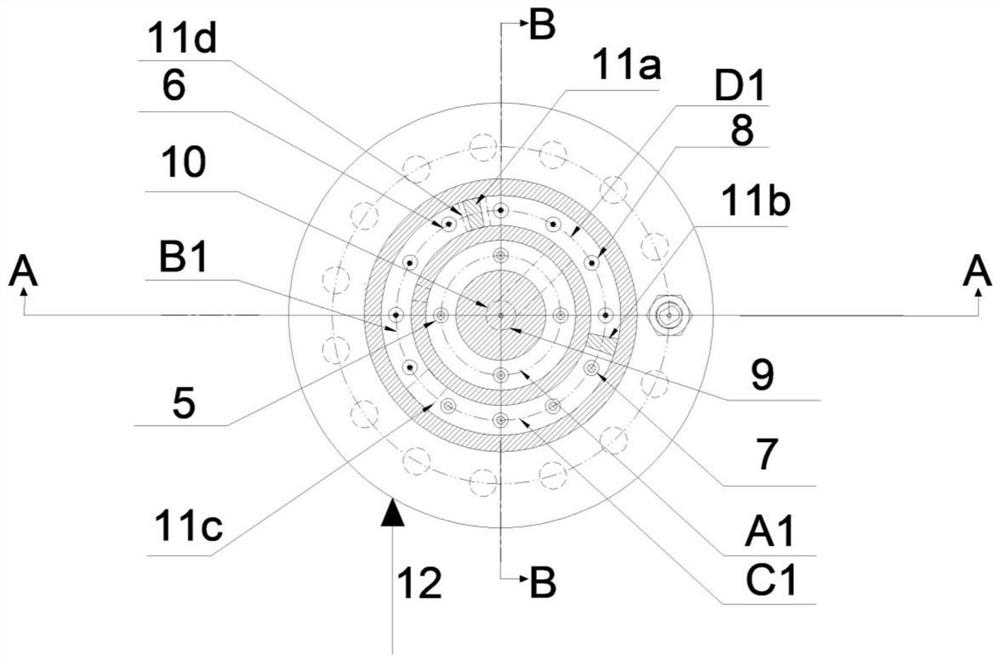

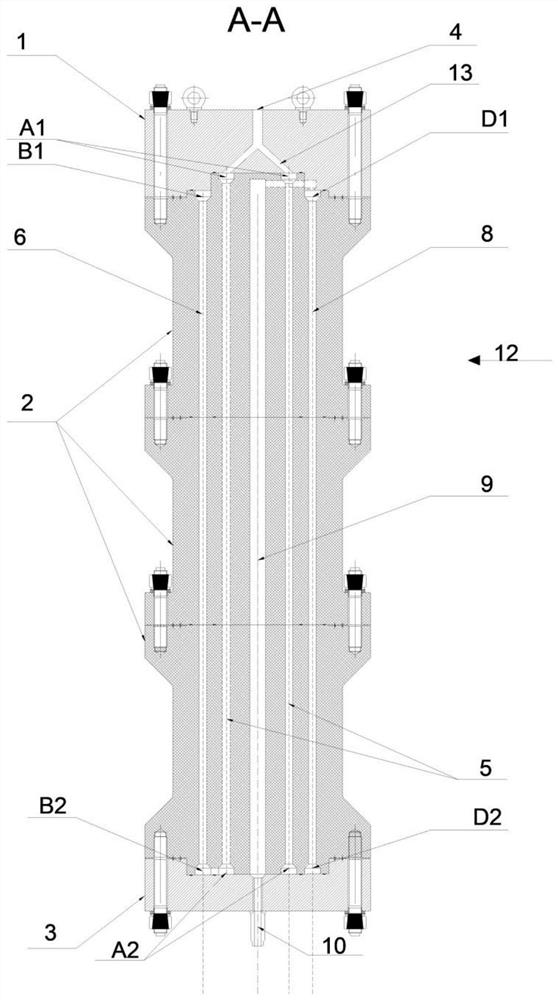

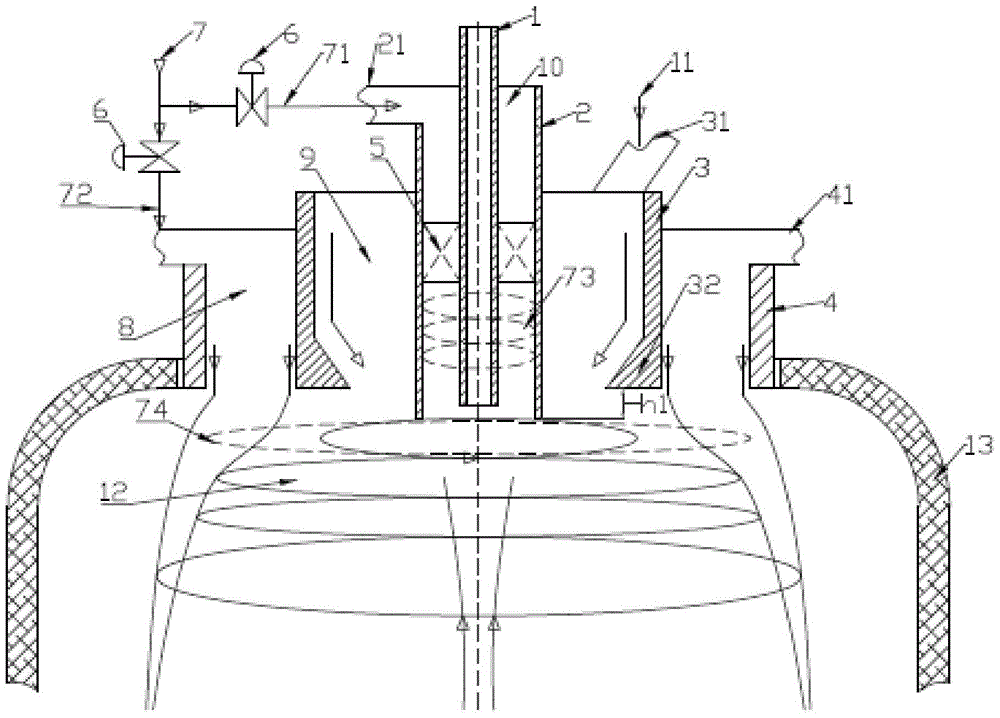

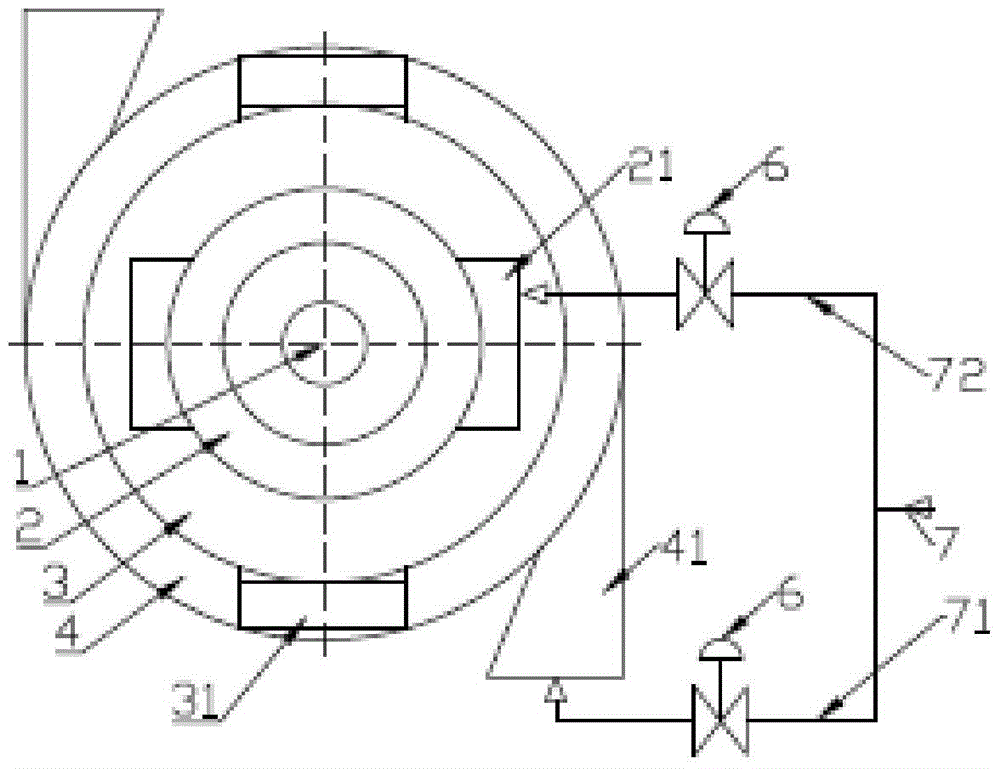

Same-direction rotary-floating smelting method, nozzle and metallurgical equipment

ActiveCN104634101AThorough responseHigh oxygen utilizationCharge manipulationFurnace typesSlagSpray nozzle

The invention discloses a same-direction rotary-floating smelting method. The method includes that powdery sulphide concentrate and oxygen-containing gas are sprayed into space of a high-temperature reaction tower through equipment; the oxygen-containing gas is divided into two parts before entering the equipment, and second oxygen-containing gas is sprayed into the reaction tower by means of annular rotational flow to form a bell-shaped rotating air curtain; first oxygen-containing gas is converted into rotary jet flow through the equipment and injected at the center of the rotating air curtain; in an annular space between two branches of the rotating air flow, the concentrate enters in a direction deflecting to the center, is drawn into by the oxygen-containing gas and sucks high-temperature smoke on the lower portion of the reaction tower to form two-phase rotating jet flow with gas and particle mixed; when being ignited by high temperature, the sulphide concentrate is in drastic burning reaction with oxygen and releases SO2-enriched smoke and forms mixed melt containing sulfonium (or metal) and slag, and sulfonium (or metal) and slag are separated at the bottom of the reaction tower to complete metallurgical process. The invention further provides metallurgical equipment and a same-direction rotary floating smelting nozzle thereof.

Owner:YANGGU XIANGGUANG COPPER

Reverse spin floating smelting method, nozzle and metallurgical equipment

The invention discloses a reverse spin floating smelting method. Powdery sulfide concentrate and oxygen-containing gas are sprayed into a space of a high-temperature reaction tower through equipment. The oxygen-containing gas is divided into two parts before entering the equipment; the second oxygen-containing gas is sprayed into the reaction tower in an annular rotary flow mode to form a bell-shaped rotary air curtain; the first oxygen-containing gas is converted into rotary jet via the equipment and is injected from the center of the rotary air curtain. In the annular space between the two rotary gas flows, the concentrate enters in the direction deflecting to the center, and is drawn in by the oxygen-containing gas while high-temperature flue gas from the lower portion of the reaction tower is sucked to form two-phase rotary jet of gas-particle mixing. When the sulfide concentrate is lighted at high temperature, the sulfide concentrate generates severe combustion reaction with oxygen and releases flue gas rich in SO2, meanwhile, sulfonium (or metal) and slag containing mixed melt is formed, and finally the sulfonium (or metal) is separated from the slag at the bottom of the reaction tower so as to complete the metallurgy process. The invention further provides the metallurgical equipment and a reverse spin floating smelting nozzle thereof.

Owner:YANGGU XIANGGUANG COPPER

Porous ceramic as well as preparation method and application thereof

ActiveCN111874866AMiniaturizationImprove hydrogen production performanceHydrogenPhysical/chemical process catalystsCarbide siliconPtru catalyst

The invention discloses a porous ceramic which comprises a silicon carbide porous ceramic matrix, wherein a silicon carbide film is attached to the surface of the hole wall of the silicon carbide porous ceramic substrate; nanometer nickel particles are embedded in the silicon carbide film. The invention also discloses a catalytic micro-reactor and a catalytic micro-reaction system comprising the porous ceramic, and a preparation method of the catalytic micro-reactor. The porous ceramic can reduce the reaction space and contribute to realizing miniaturization of a reforming hydrogen productionsystem; in addition, the nano nickel particles are embedded in the silicon carbide film to improve the bonding strength of catalyst loading and contribute to realizing vehicle-mounted online hydrogenproduction.

Owner:HUNAN UNIV

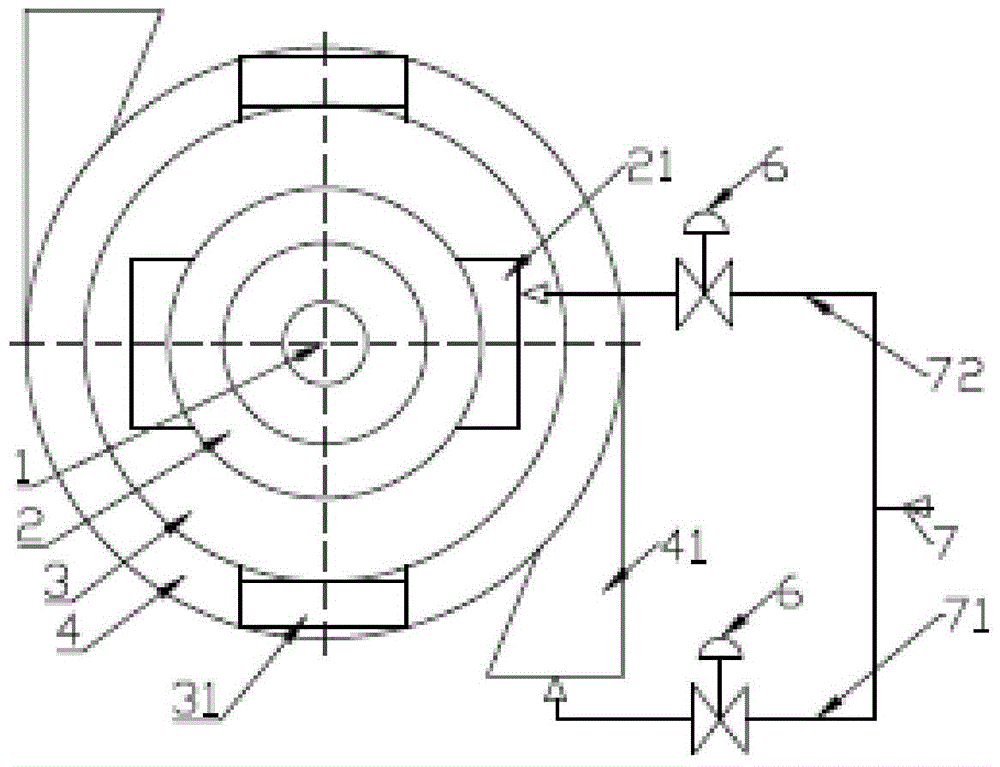

Process and device for smelting copper by pulsation vortex method

ActiveCN101705369BIncreased chance of collisionHigh oxygen utilizationRotary drum furnacesCrucible furnacesMelting tankSlag

Owner:YANGGU XIANGGUANG COPPER

A co-rotational flotation smelting method, nozzle and metallurgical equipment

ActiveCN104634101BThorough responseHigh oxygen utilizationCharge manipulationFurnace typesSlagVia device

The invention discloses a same-direction rotary-floating smelting method. The method includes that powdery sulphide concentrate and oxygen-containing gas are sprayed into space of a high-temperature reaction tower through equipment; the oxygen-containing gas is divided into two parts before entering the equipment, and second oxygen-containing gas is sprayed into the reaction tower by means of annular rotational flow to form a bell-shaped rotating air curtain; first oxygen-containing gas is converted into rotary jet flow through the equipment and injected at the center of the rotating air curtain; in an annular space between two branches of the rotating air flow, the concentrate enters in a direction deflecting to the center, is drawn into by the oxygen-containing gas and sucks high-temperature smoke on the lower portion of the reaction tower to form two-phase rotating jet flow with gas and particle mixed; when being ignited by high temperature, the sulphide concentrate is in drastic burning reaction with oxygen and releases SO2-enriched smoke and forms mixed melt containing sulfonium (or metal) and slag, and sulfonium (or metal) and slag are separated at the bottom of the reaction tower to complete metallurgical process. The invention further provides metallurgical equipment and a same-direction rotary floating smelting nozzle thereof.

Owner:YANGGU XIANGGUANG COPPER

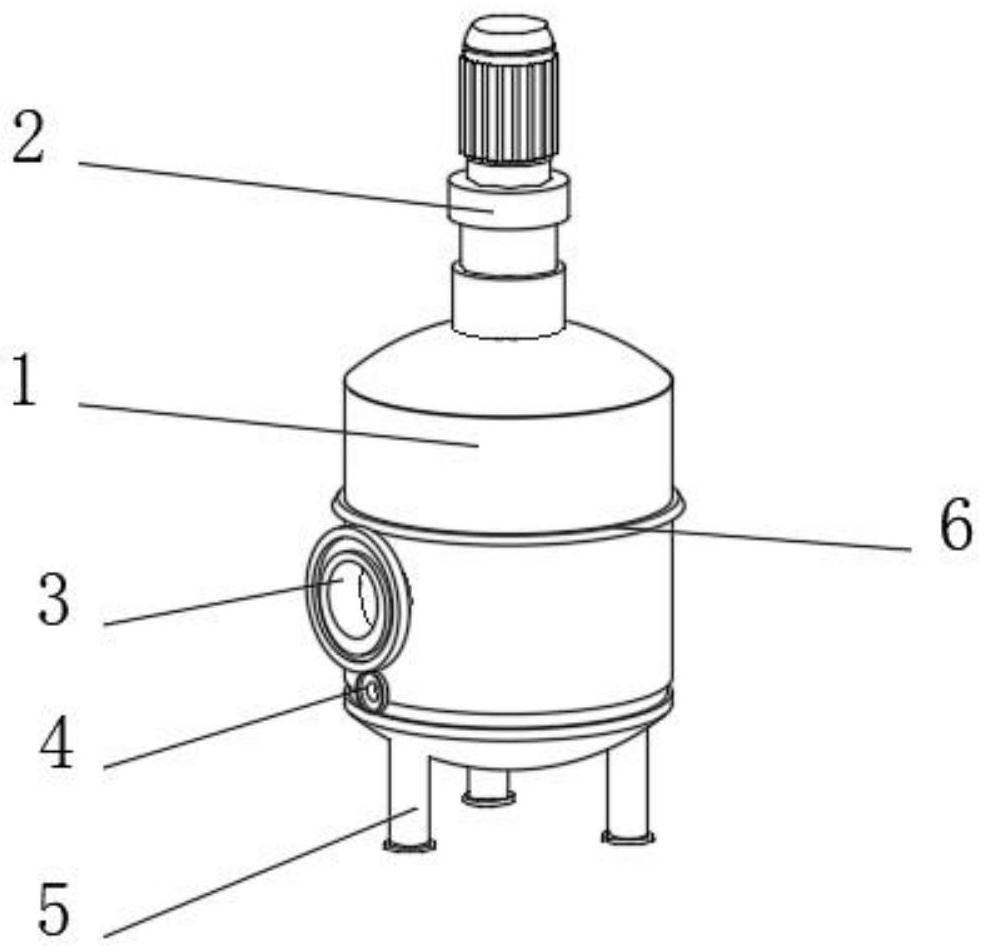

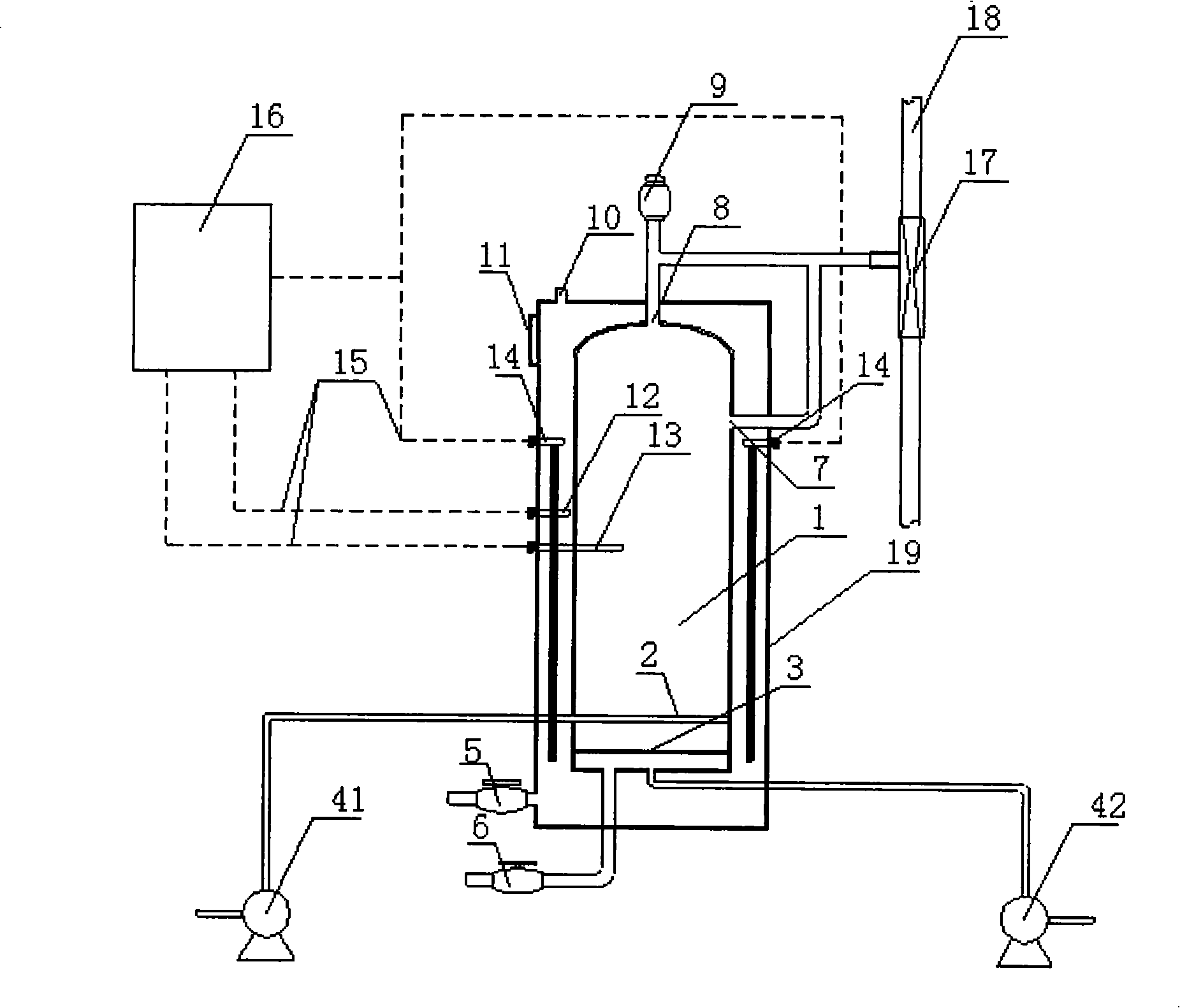

Efficient biological fermentation reaction device

PendingCN113493732AGuaranteed stabilityConvenient Compatible ProcessingBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyDrive shaft

The invention discloses an efficient biological fermentation reaction device which comprises a fermentation device body, a stirring motor is fixedly mounted at the top of the fermentation device body, a stirring reinforcing sleeve is fixedly mounted at the bottom of the stirring motor, an output shaft on the stirring motor penetrates through the stirring reinforcing sleeve, and an adjusting device for adjusting the internal use space of the fermentation device main body is fixedly mounted at the position, corresponding to the outer side of the stirring reinforcing sleeve, of the inner top of the fermentation device main body. According to the biological fermentation reaction device, the reaction rate of the device is increased to a certain extent by adjusting the use space in the fermentation device main body, meanwhile, the stability of a base plate and machine base part is ensured by utilizing pushing adjustment of a driving shaft rod and an electric push rod, compatible processing of different parts of reaction materials is facilitated, and the safety of the device is improved.

Owner:张剑

Chlorination reaction device

ActiveCN101623614BIncrease the reaction areaPromote internal circulationFlow mixersChemical/physical/physico-chemical processesCarbon ChlorideEngineering

The invention relates to a chlorination reaction device adopting the following technical scheme: the chlorination reaction device is composed of an injection mixer, an inner draft tube and a chlorination reactor, wherein the injection mixer is connected with the chlorination reactor, and the inner draft tube is arranged in the chlorination reactor; the injection mixer is characterized in that a material cavity is composed of a chlorination inlet pipe, a flat cover, a cylinder body, a nozzle and a mixed gas inlet pipe, a short section is respectively connected with the cylinder body and a reducer section which is connected with an injecting pipe, and the injecting pipe passes through the chlorination reactor to extend into the inner draft tube; the inner draft tube comprises a tube body, areinforcing rib, a supporting plate, a lifting lug and a stop block; the inner draft tube is matched with the chlorination reactor by the supporting plate and the stop block; the chlorination reactoris characterized in that an end socket and the cylinder body form a device body, the lower end of the cylinder body is provided with a man hole, a connecting plate and the supporting plate are used for fixing and limiting the inner draft tube, and the cylinder body is provided with a temperature measuring port, a material outlet and a support. The invention has favourable energy saving and loss reduction and obvious environment protection effect, and the production scale of carbon tetrachloride can be controlled from around 40% at present to 2%.

Owner:沈阳东方钛业股份有限公司

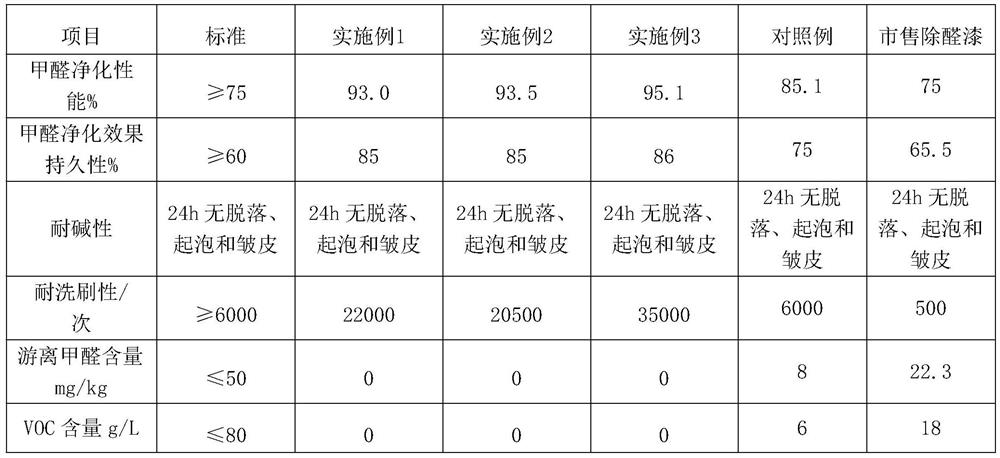

Graphene inorganic coating with pearlescent effect and preparation method

InactiveCN113736295AImprove permeabilityImprove adhesionAlkali metal silicate coatingsPolymer scienceGraphite

The invention discloses a graphene inorganic coating with a pearlescent effect and a preparation method, and belongs to the field of building material coatings, the graphene inorganic coating comprises the following components: inorganic resin, a graphene modified anti-formaldehyde auxiliary agent, a multifunctional auxiliary agent, deionized water, a polymer emulsion, a defoaming agent, a dispersing agent, a rheological auxiliary agent, a thickening auxiliary agent, a pigment filler and pearl powder slurry; and the problems that a coating is insufficient in formaldehyde removal effect, unstable in performance and prone to fading are solved, and the technical problems that the coating contains free formaldehyde and is insufficient in adhesive force and poor in environment-friendly effect are solved.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

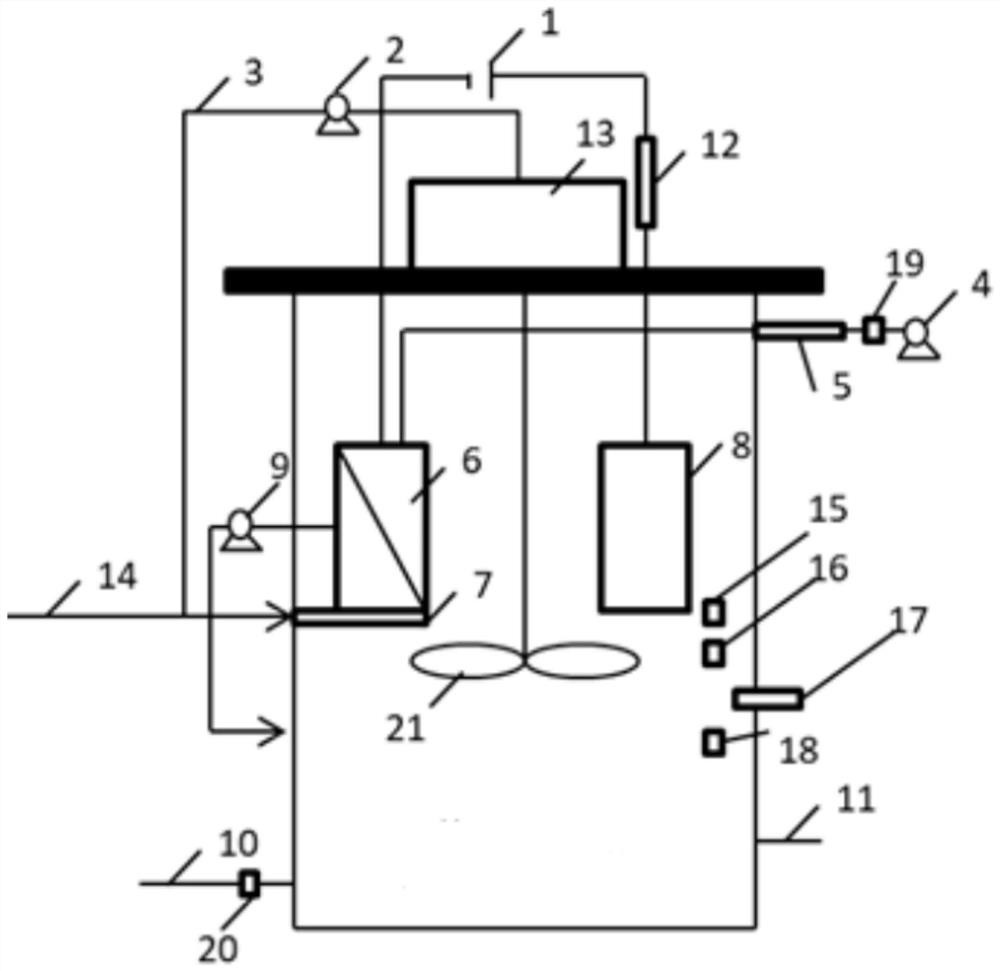

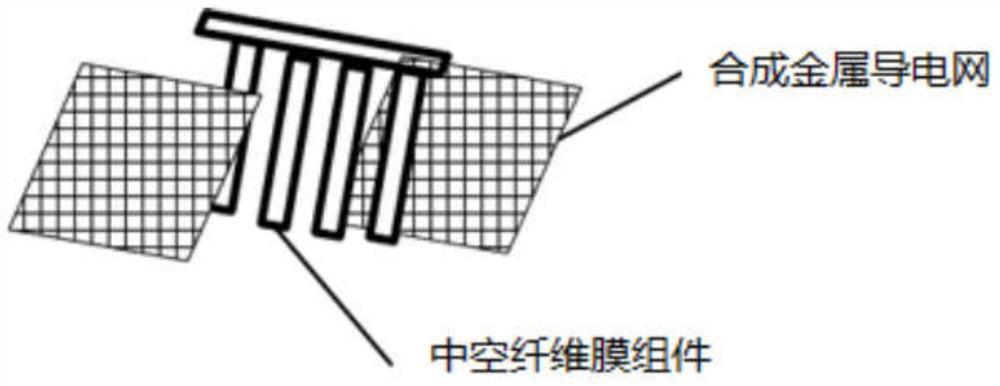

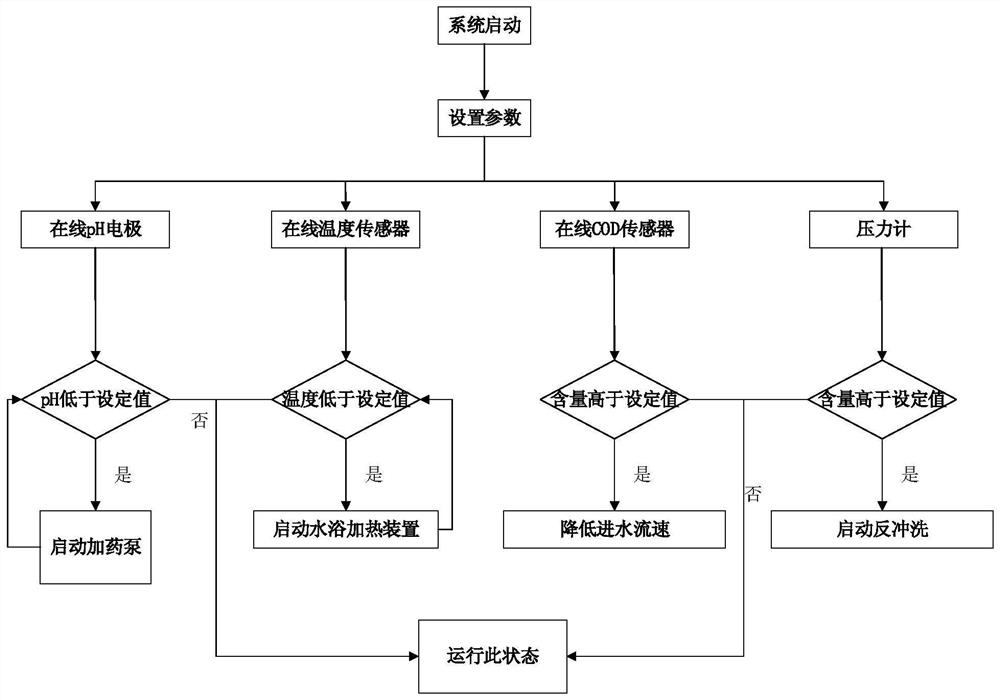

Anti-fouling and anti-blocking system of anaerobic membrane bioreactor

InactiveCN112811731AImprove biological activityImprove processing efficiencyWater treatment parameter controlSemi-permeable membranesProcess engineeringEnvironmental engineering

The invention discloses an anti-fouling and anti-blocking system of an anaerobic membrane bioreactor, and belongs to the field of anaerobic processes. The device comprises a bioreactor, wherein a biological carrier is arranged in the bioreactor, a cathode and an anode are respectively arranged in the bioreactor, an external power supply and a sliding resistor are arranged outside the bioreactor, the external power supply, the sliding resistor, the cathode and the anode form a closed circuit, and a backwashing assembly is further arranged outside the bioreactor; a methane collecting device is further arranged outside the bioreactor, one end of the methane collecting device is communicated with a biogas reflux pump through a pipeline, the output end of the biogas reflux pump is communicated with a biogas reflux pipe, and one end of the biogas reflux pipe is communicated with a backwashing assembly which is further arranged outside the bioreactor. According to the anti-fouling and anti-blocking technology for the anaerobic bioreactor provided by the invention, membrane pollution in the bioreactor is relieved and the treatment efficiency of the bioreactor is improved by adding the biological carrier into the bioreactor and the like.

Owner:SHANGHAI BI ZONE ENVIRONMENTAL EQUIP & ENG

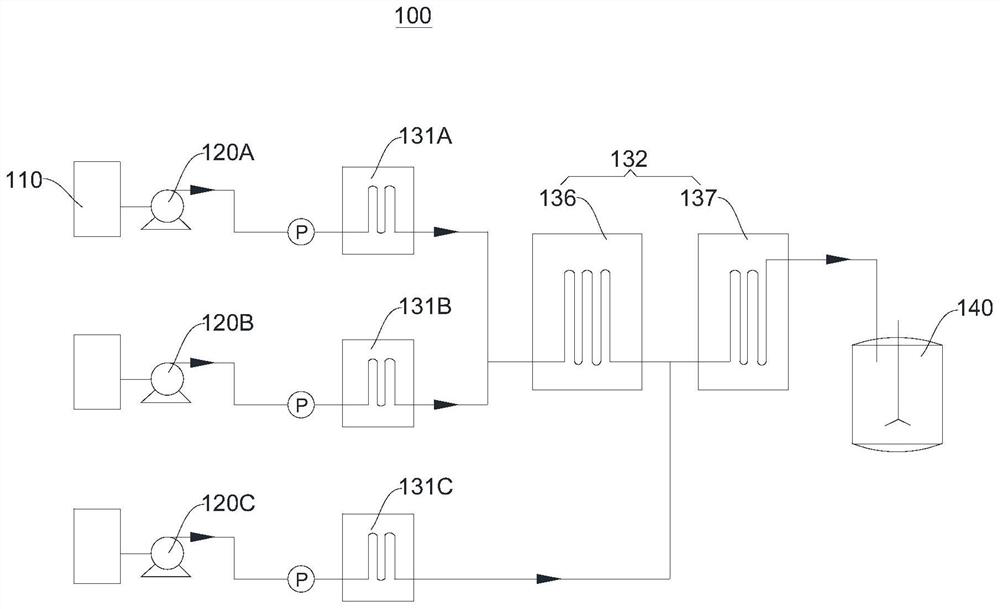

An alkyl polyether co-modified polysiloxane and its continuous synthesis device and method

ActiveCN111013522BSmall reaction spaceHigh selectivityChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsReaction temperatureProcess engineering

The invention discloses polysiloxane co-modified by alkyl polyether and its continuous synthesis device and method, and relates to the technical field of preparation technology of organosilicon polyether copolymer. The device includes a microchannel reactor and a tank reactor, wherein the microchannel reactor includes a preheating pipeline and a mixing pipeline communicated with the preheating pipeline, and the mixing pipeline communicates with the tank reactor. The device can effectively solve the mass transfer problem at the initial stage of the synthesis reaction of the alkyl polyether co-modified polysiloxane, so that the liquid-liquid heterogeneous reaction liquid is fully mixed, and the selectivity of the product is improved. At the same time, the reaction temperature and reaction time can be precisely controlled to prevent the occurrence of "flying temperature" phenomenon and the generation of by-products during the synthesis process, and improve the safety of production. The method provided by the present application uses the above-mentioned device for synthesis, which can realize continuous operation, effectively shorten the reaction time, shorten the production cycle, make the reaction process more stable, and significantly improve the reaction efficiency.

Owner:JIANGSU MAYSTA CHEM

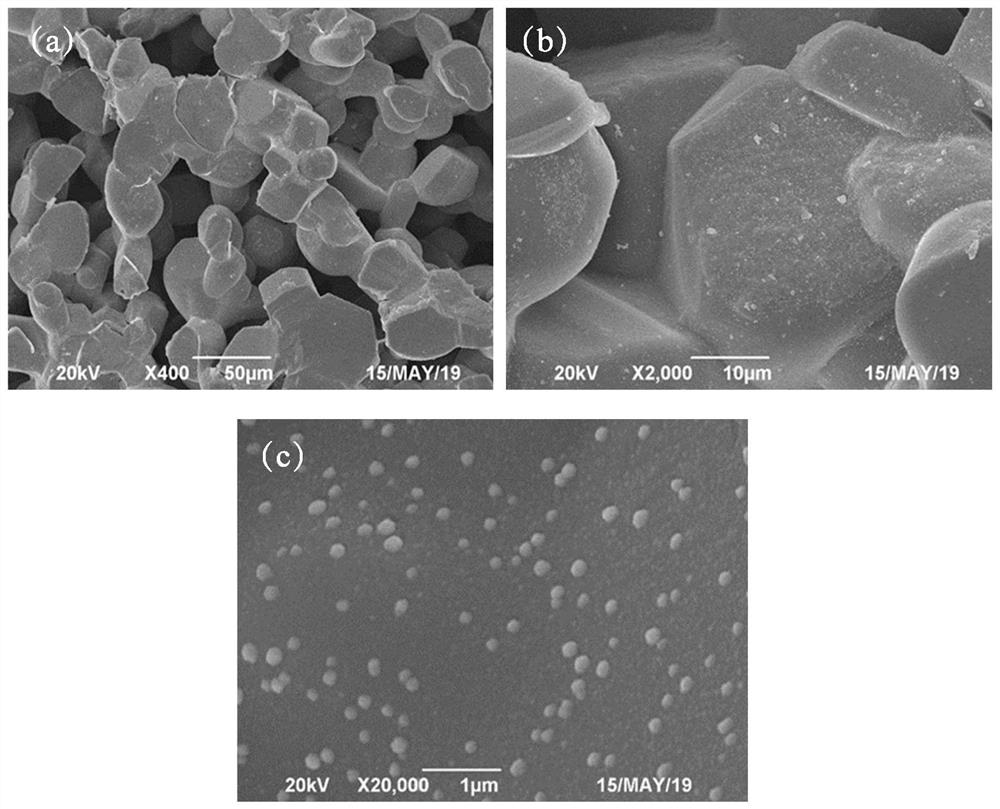

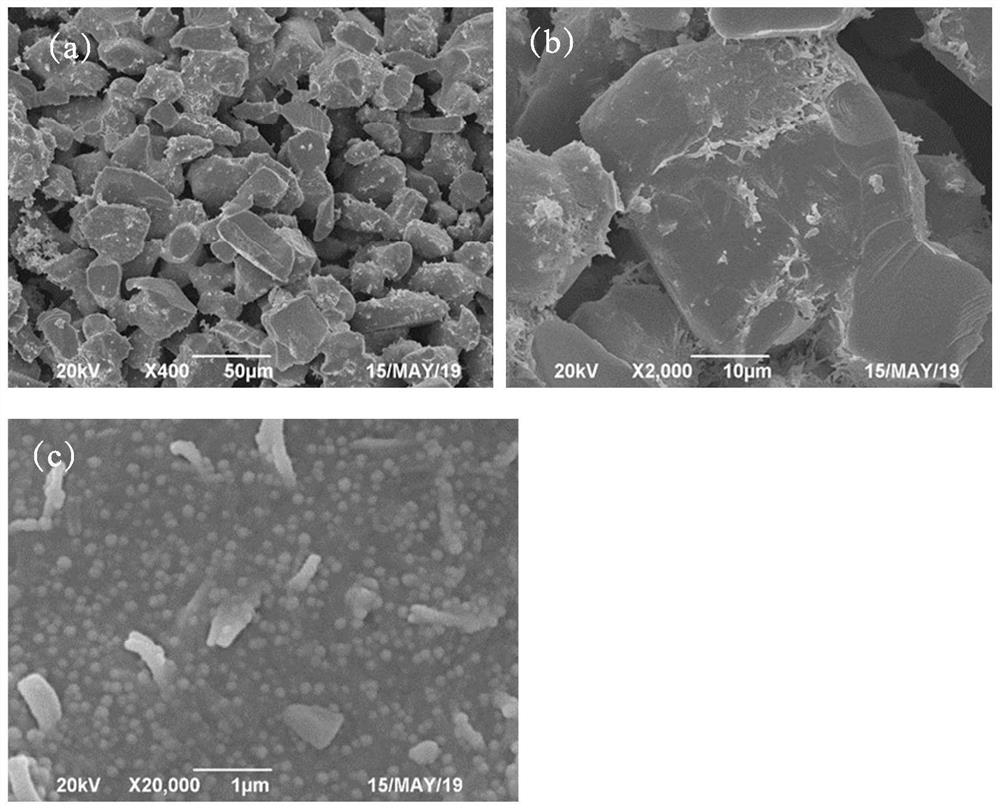

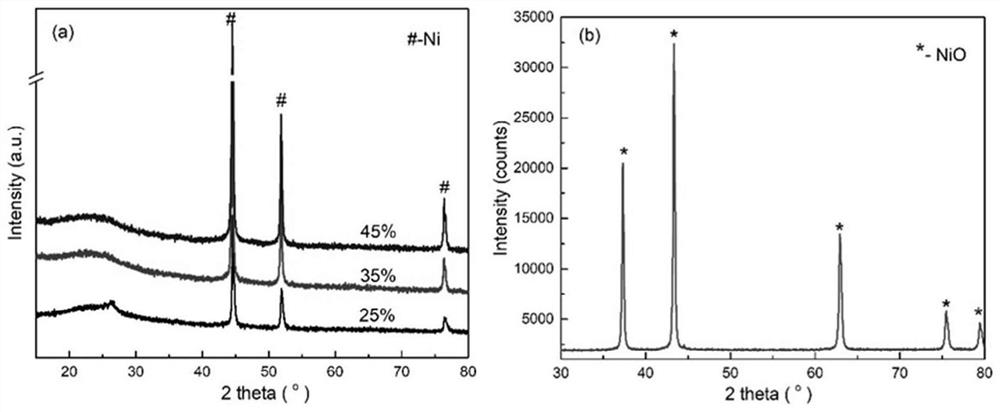

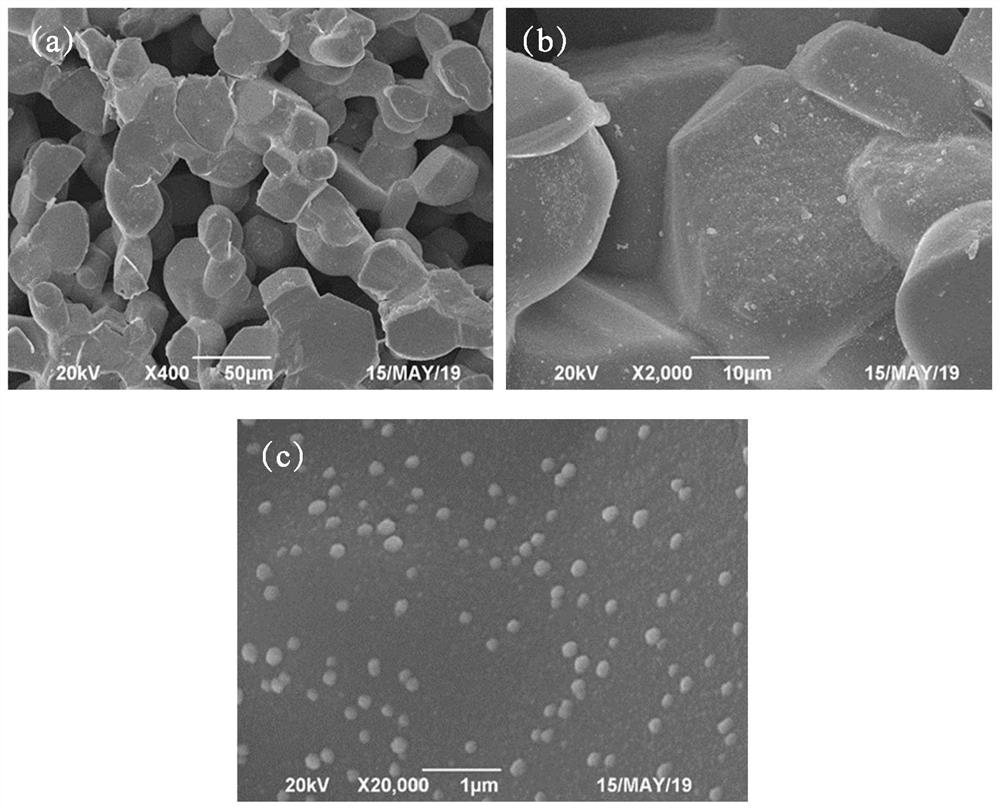

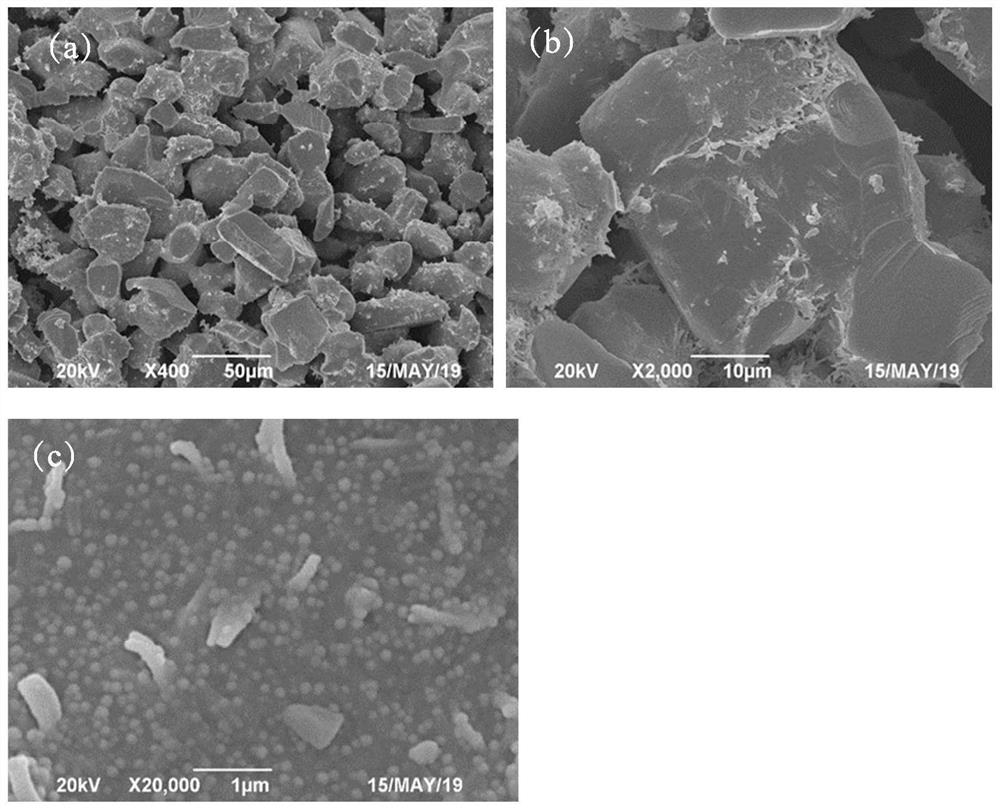

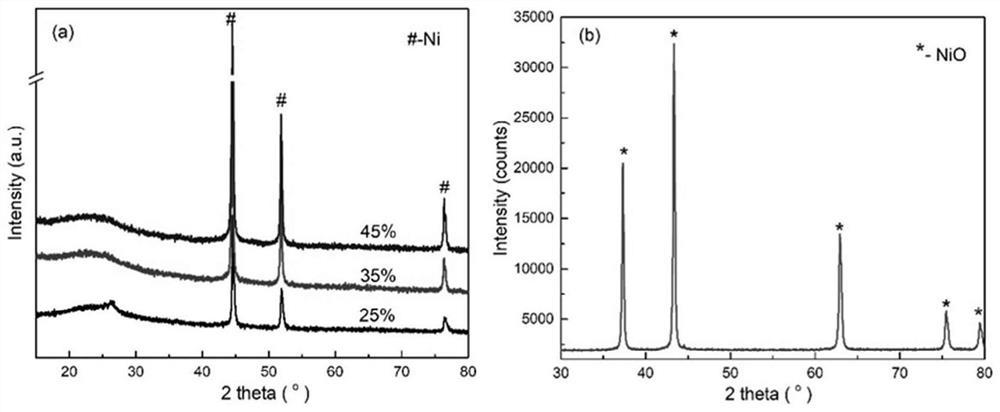

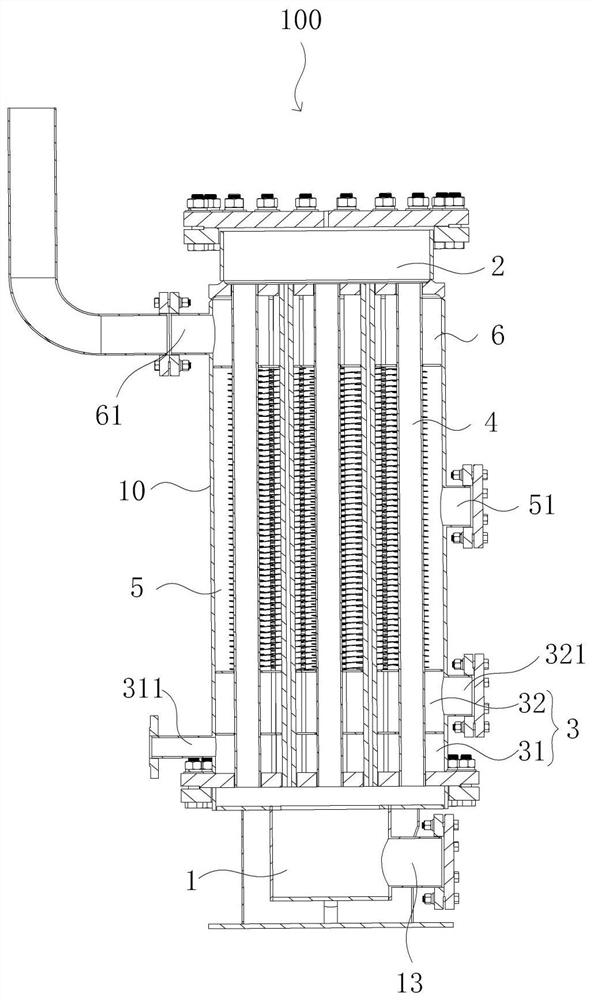

Integrated ultrasonic field-assisted microchannel reactor for supercritical hydrothermal synthesis of nanomaterials

ActiveCN113813897BFree increase or decrease quantityPrecise control of response timeChemical/physical/physico-chemical microreactorsNanoparticleHydrothermal synthesis

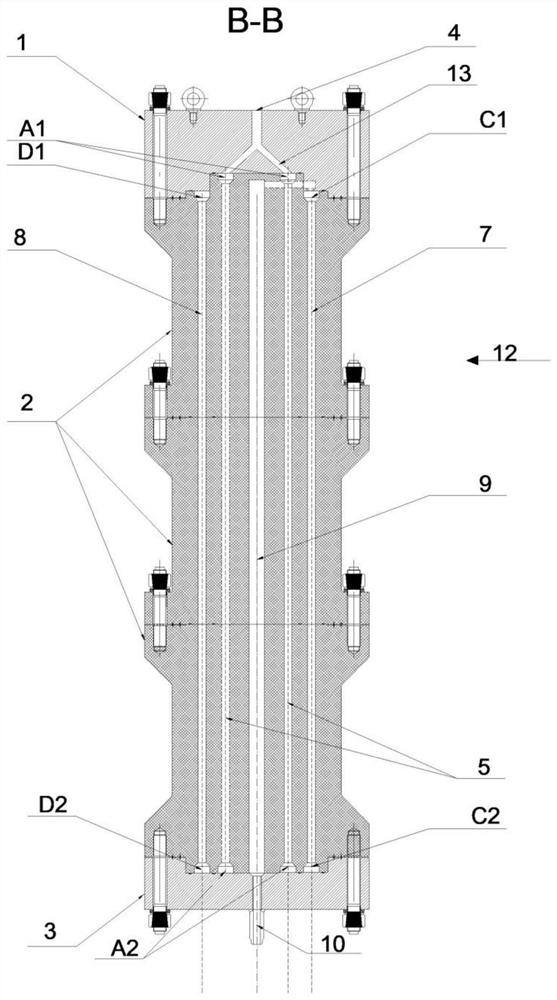

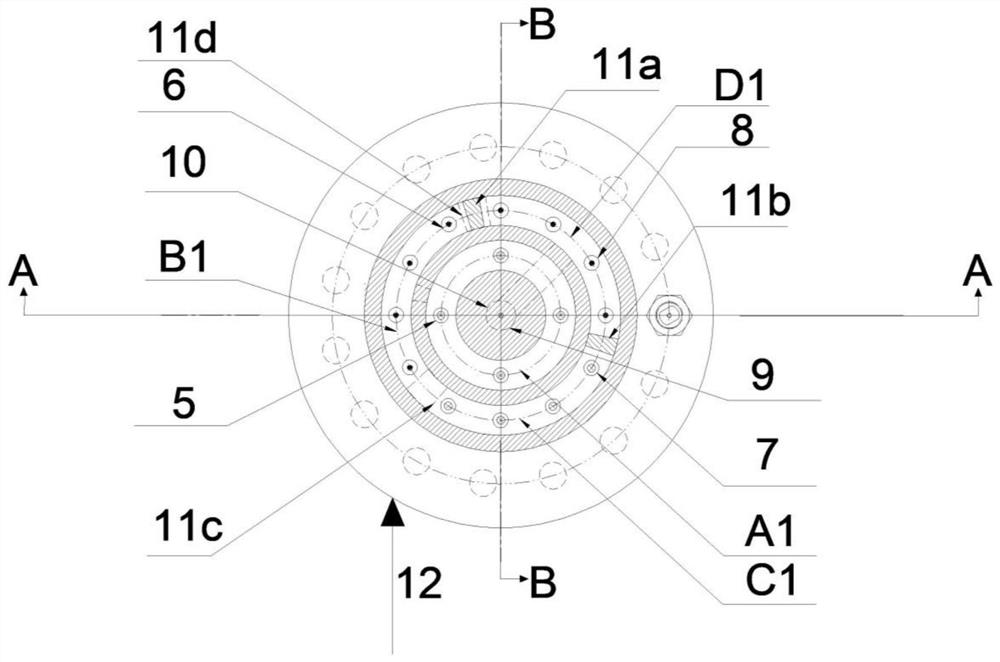

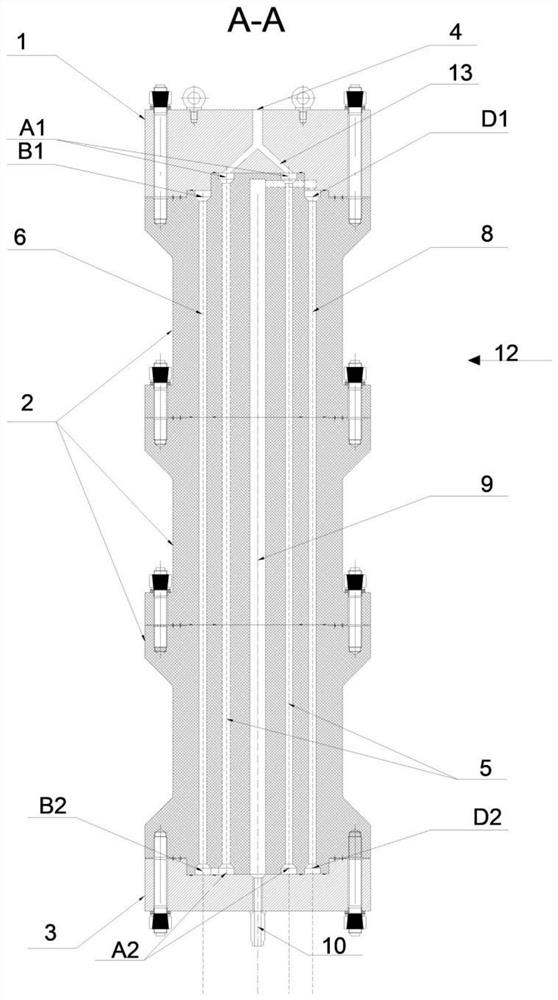

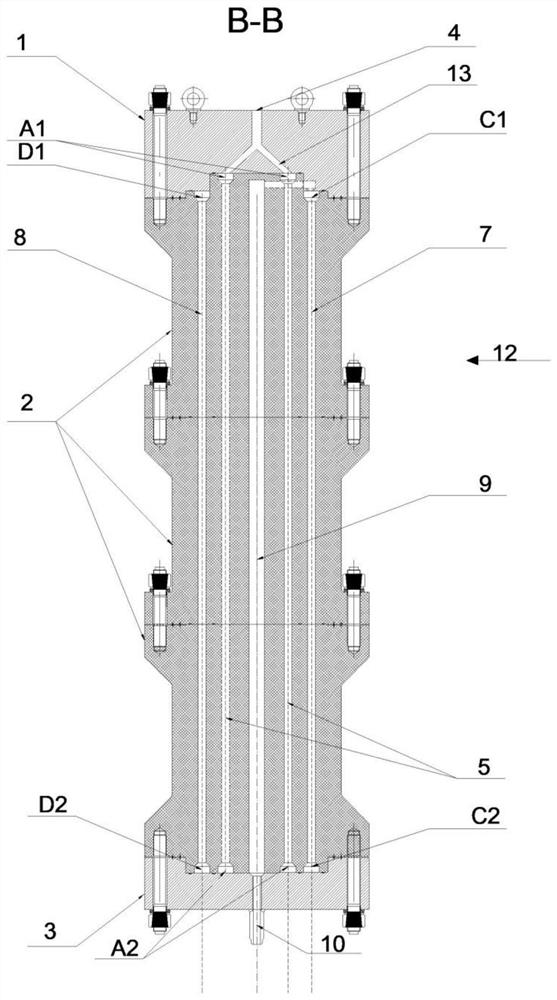

The invention discloses an integrated ultrasonic external field-assisted microchannel reactor for supercritical hydrothermal synthesis of nanomaterials, comprising a main body formed by axial docking of a plurality of supercritical microchannel reaction modules; A plurality of micro-reaction channels are arranged along the axial direction, and the micro-reaction channels are connected at the top or bottom end of the main body to form a material flow channel in the form of upper and lower turns. Turn up and down in the circumferential direction. The reactor can determine the number of supercritical microchannel reaction modules according to the reaction time of different types of nanoparticles, and precisely control the reaction time; multiple reaction processes are integrated inside the reactor, and the micro-scale multi-process supercritical hydrothermal synthesis reaction and the ultrasonic generator are coordinated. Under the action, metal and metal oxide nano-powders with small particle size and uniform distribution can be synthesized in a green and efficient manner, and at the same time, particle agglomeration can be effectively prevented and problems such as clogging of reaction channels can be avoided.

Owner:XI AN JIAOTONG UNIV

Integrated ultrasonic external field assisted microchannel reactor for supercritical hydro-thermal synthesis of nanomaterials

ActiveCN113813897AFree increase or decrease quantityPrecise control of response timeChemical/physical/physico-chemical microreactorsChemical physicsHydrothermal synthesis

The invention discloses an integrated ultrasonic external field assisted microchannel reactor for supercritical hydro-thermal synthesis of nanomaterials. The reactor comprises a main body formed by axial butt joint of a plurality of supercritical microchannel reaction modules, wherein the supercritical microchannel reaction modules are provided with a plurality of miniature reaction channels along an axial direction, the miniature reaction channels are connected at the top end or the bottom end of the main body to form a material flow channel in an up-and-down turn-back form, and the up-and-down turn-back form comprises an up-and-down turn-back track in different radial directions and an up-and-down turn-back track in the same radial direction and different circumferential directions. According to the reactor, the number of the supercritical microchannel reaction modules can be determined according to the reaction time of different types of nanoparticles, and reaction time is accurately regulated and controlled; a plurality of reaction processes are integrated in the reactor; under the synergistic effect of a micro-scale multi-process supercritical hydrothermal synthesis reaction and an ultrasonic generator, metal and metal oxide nanopowder with a small particle size and uniform distribution can be synthesized in a green and efficient manner; and meanwhile, particle aggregation is effectively prevented, and the problems of reaction channel blockage and the like are avoided.

Owner:XI AN JIAOTONG UNIV

Chlorine dioxide solution generator with sodium chlorate as reaction raw material

InactiveCN101492152BThe specifications and models are simple and clearLow costChlorine oxidesExhaust valveSodium chlorate

The invention belongs to the technical field of chemical equipment, and in particular relates to a chlorine dioxide solution generator taking sodium chlorate as a reaction raw material. The chlorine dioxide solution generator comprises a retort, an acid liquor metering pump, a sodium chlorate solution metering pump, a heating water jacket, a safety valve, a water ejector, and a control panel, wherein an acid liquor distributor and a sodium chlorate solution distributor are arranged on the lower part in the retort in turn; the lower end of the retort is provided with a retort exhaust valve; the upper part and the lateral surface of the retort are provided with a chlorine dioxide gas outlet and a chlorine dioxide solution outlet respectively; and the heating water jacket is also provided with a heating water jacket feed liquor and discharge air valve, an air communication valve, a heating water level display, a heating water temperature monitoring controller, and the like. The chlorine dioxide solution generator has the advantages of compact and small structure, simple operation, safe and reliable running, and convenient maintenance and use.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

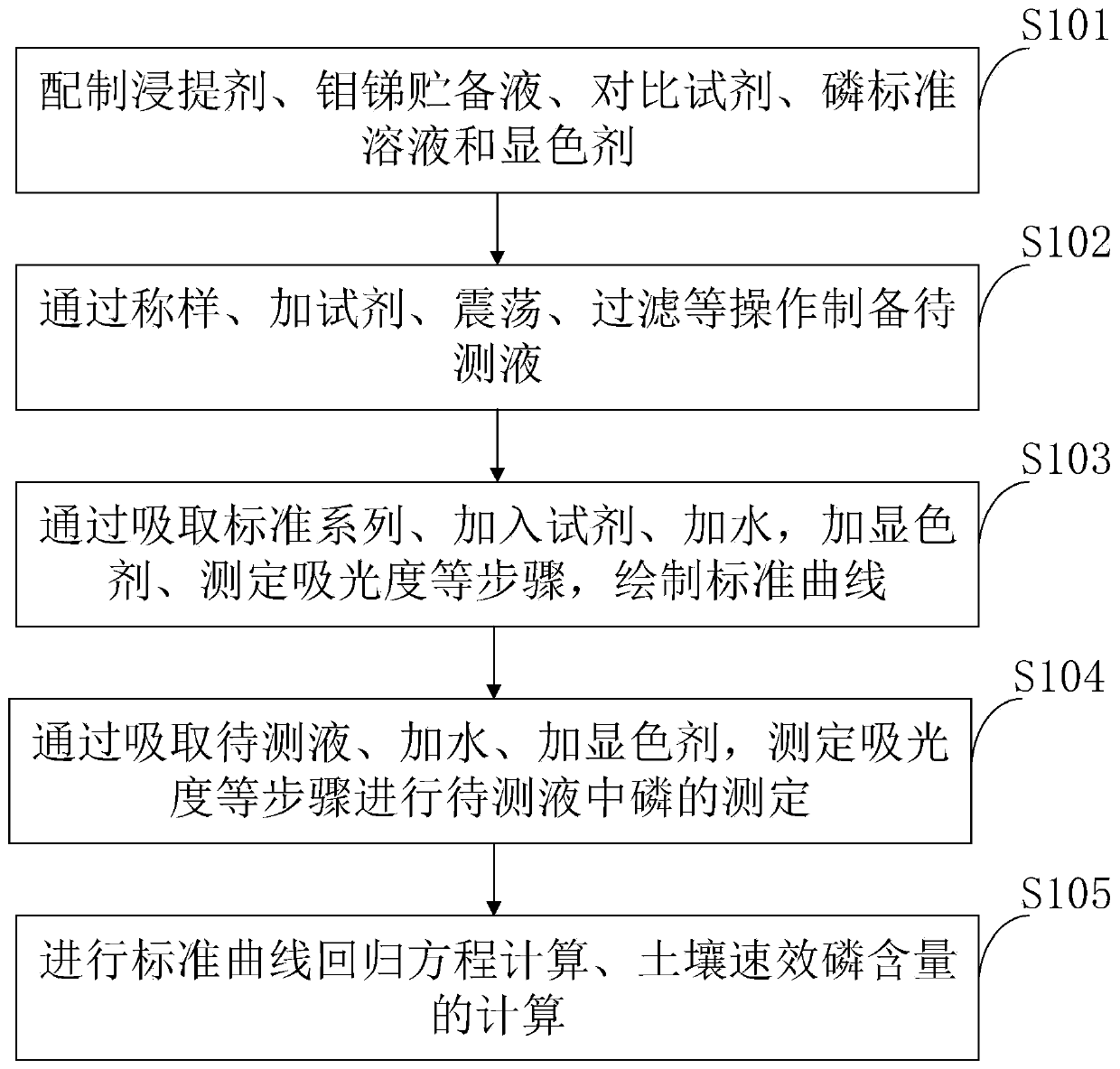

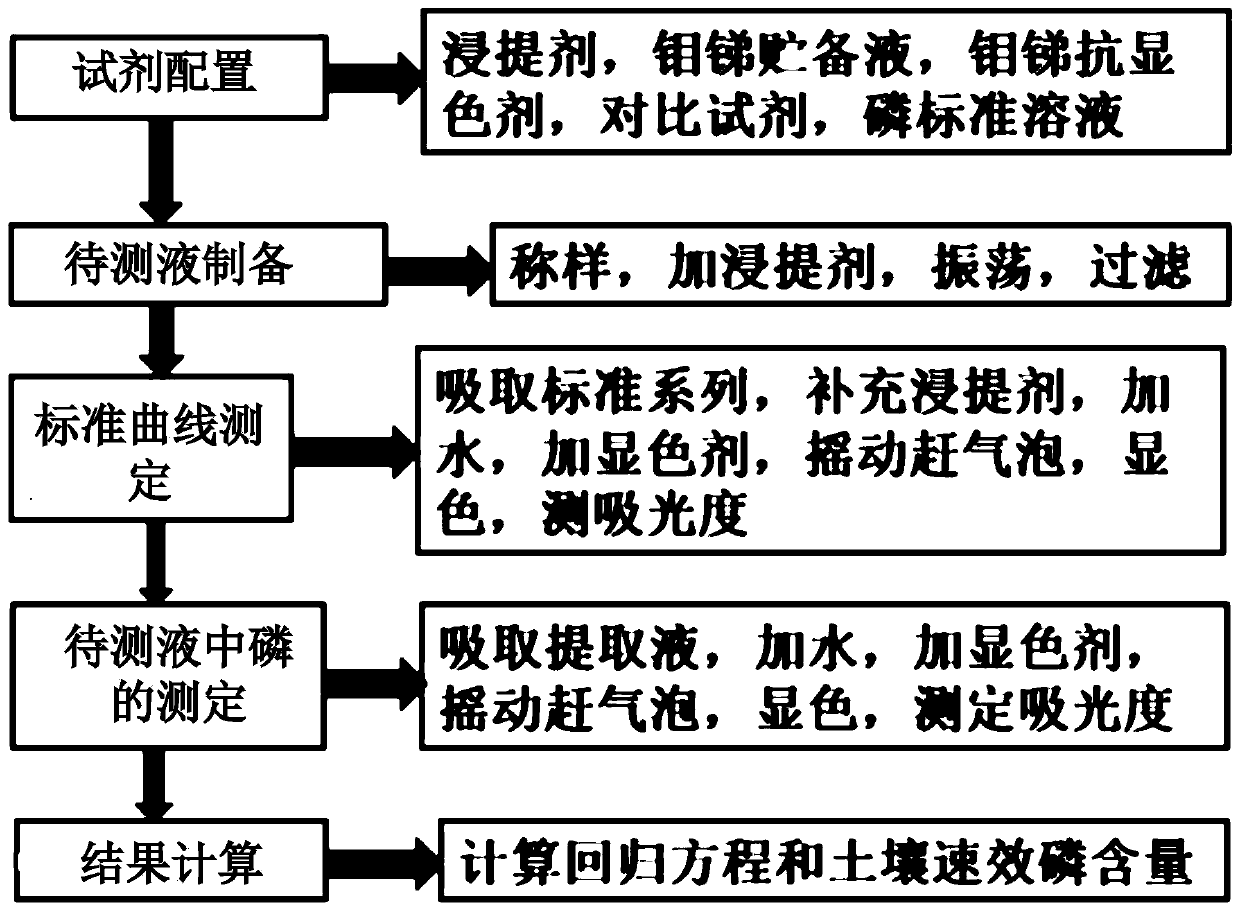

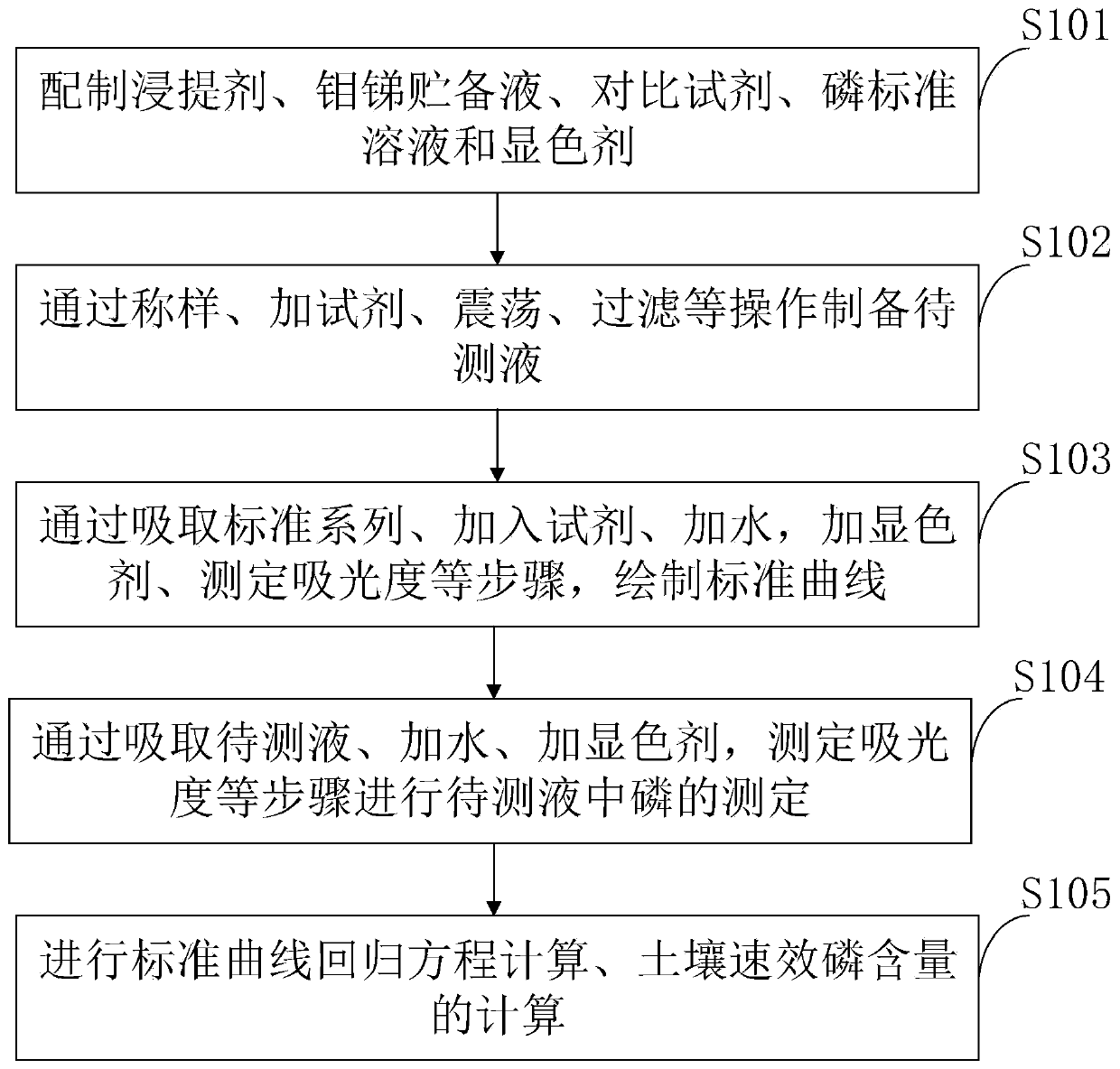

Soil rapidly-available phosphorus measuring method based on Olsen method

PendingCN110018129AEasy to prepareFast preparationPreparing sample for investigationColor/spectral properties measurementsForm analysisAbsorbance

The invention belongs to the field of technical operation of soil nutrient form analysis and measurement, and discloses a soil rapidly-available phosphorus measuring method based on the Olsen method.An extracting agent, a molybdenum-antimony stock solution, a comparison reagent, a phosphorus standard solution and a color developing agent are firstly prepared; a to-be-measured solution is preparedthrough sample weighing, reagent adding, oscillation, filtering and the like; a standard curve is drawn through the steps of standard-series suction, reagent adding, water adding, color developing agent adding, absorbance measurement and the like; phosphorus in the to-be-measured solution is measured through the steps of to-be-measured solution suction, water and color developing agent adding, absorbance measurement and the like; and a standard curve regression equation and the soil rapidly-available phosphorus content are calculated. By improving reagent preparation, a reaction system and comparison reaction, operation is simplified, error sources are reduced, operation time is shortened, the types and amount of reagents are reduced, operation is easy and rapid, and the cost is low and saved.

Owner:HUBEI UNIV

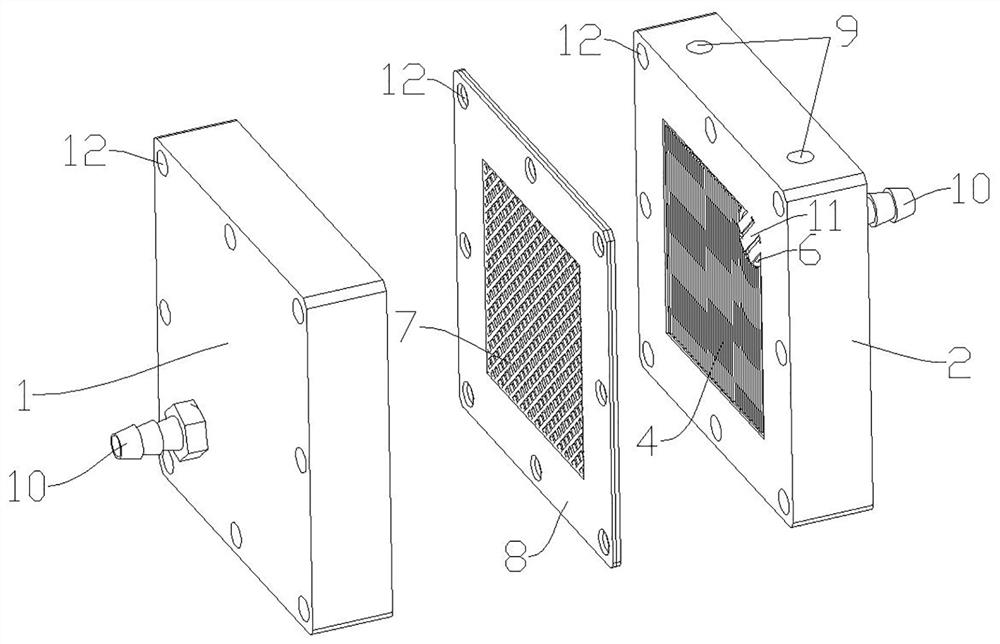

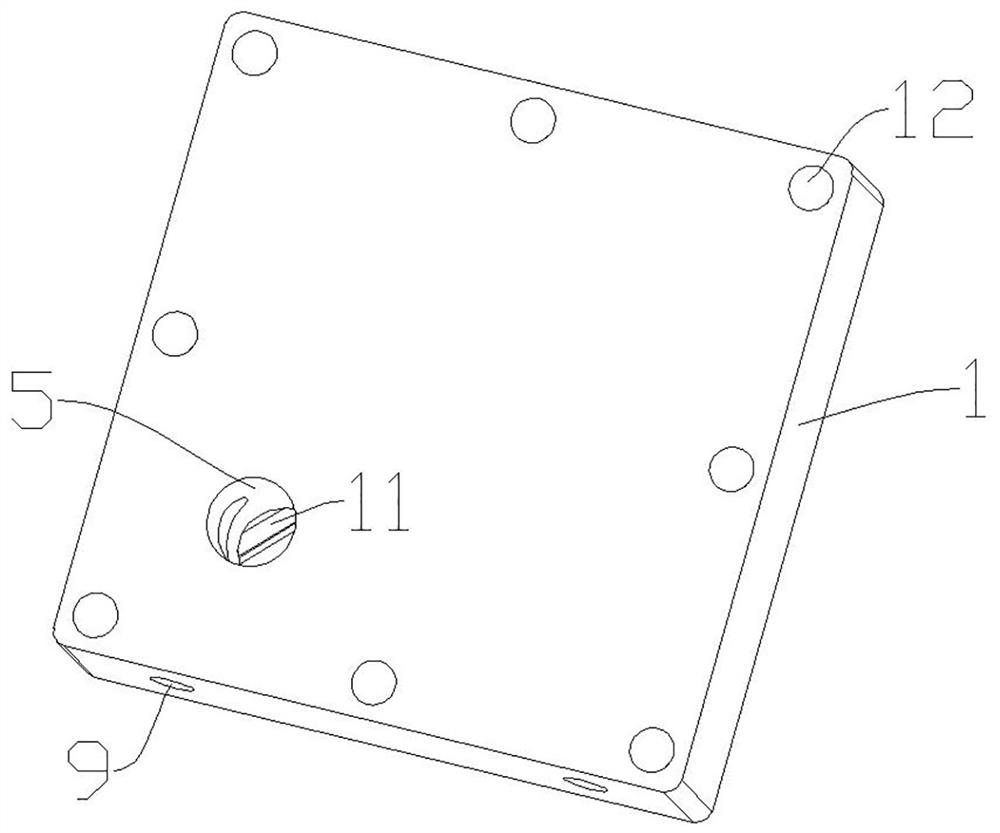

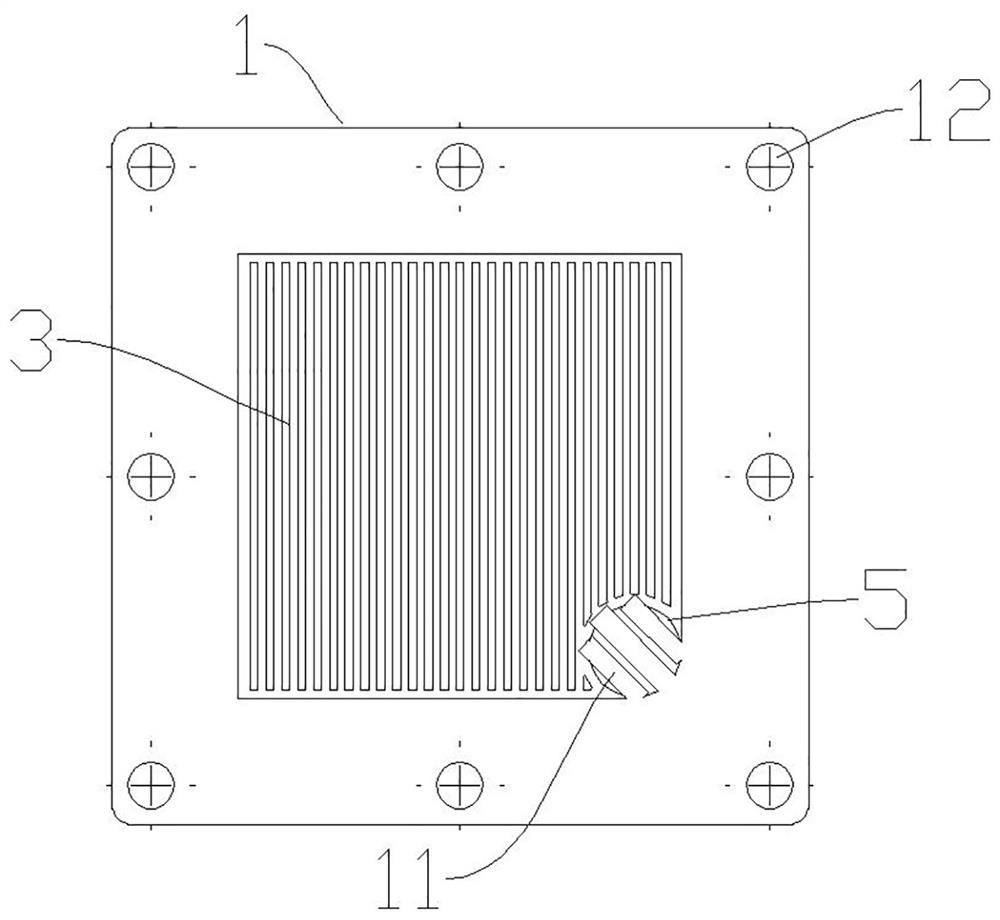

Novel chemical hydrogen production reactor

InactiveCN111620303AFully contactedIncrease profitHydrogen productionMass transfer resistancePtru catalyst

The invention belongs to the technical field of fuel cells, and specifically relates to a novel chemical hydrogen production reactor. The novel chemical hydrogen production reactor comprises two end plates and a catalytic assembly arranged between the two end plates, wherein a reaction space is arranged through flow channels formed in the end plates and a catalytic layer located between the flow channels; the flow channels can evenly disperse a flowing-in hydrogen production solution, so regional reaction difference is reduced; the catalyst layer is of a net-shaped structure and has a large specific surface area; reaction liquid can make full contact with the catalyst through the design of the flow channels, the utilization rate of the catalyst is remarkably increased, and the mass transfer resistance is also reduced through the net-shaped structure; and because the reaction space is small, the hydrogen can be quickly discharged by utilizing the characteristic of light weight of the hydrogen and an air outlet above a liquid inlet pressure flow channel. Compared with a traditional canning structure, the novel chemical hydrogen production reactor of the invention has the advantages of small size, simple structure, convenient installation and the like, continuous catalytic hydrogen production can be conducted on a sodium borohydride solution or other solution type hydrogen production agents, and reaction is rapid and efficient.

Owner:浙江高成绿能科技有限公司

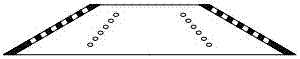

Absorption and separation integrated sulfur-containing gas desulfurization cyclone reaction device

ActiveCN105107355BIncrease mass transfer rateIncrease contact areaDispersed particle separationCycloneProcess engineering

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of preparation device and preparation method of high-purity chlorine dioxide

Owner:QINGDAO JUCHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

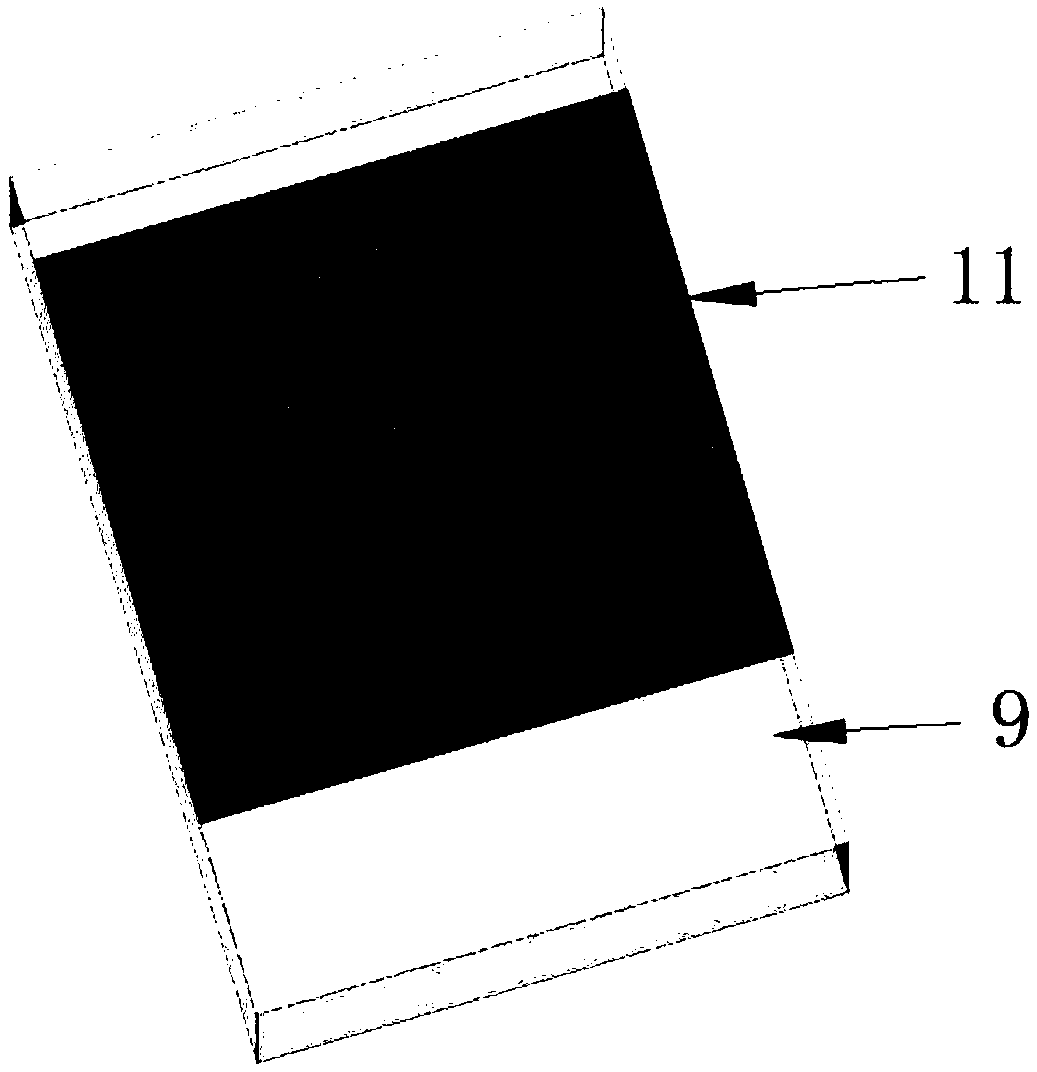

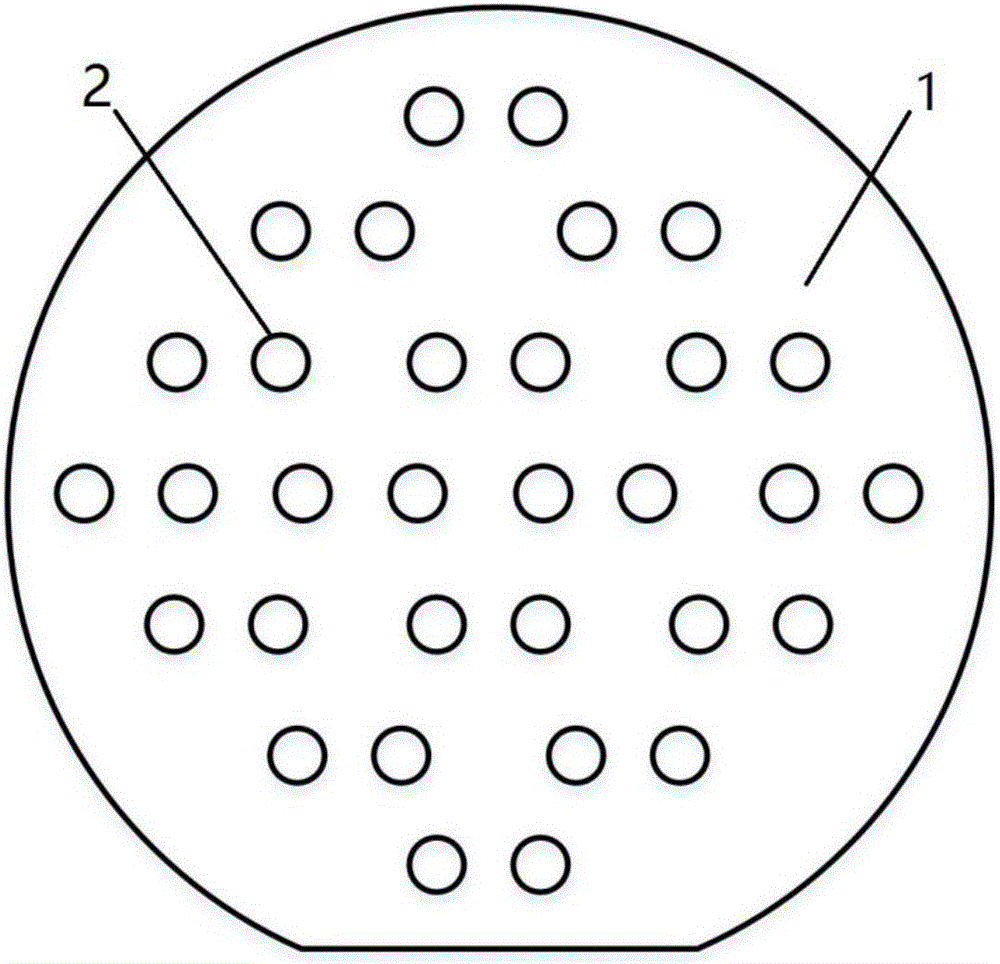

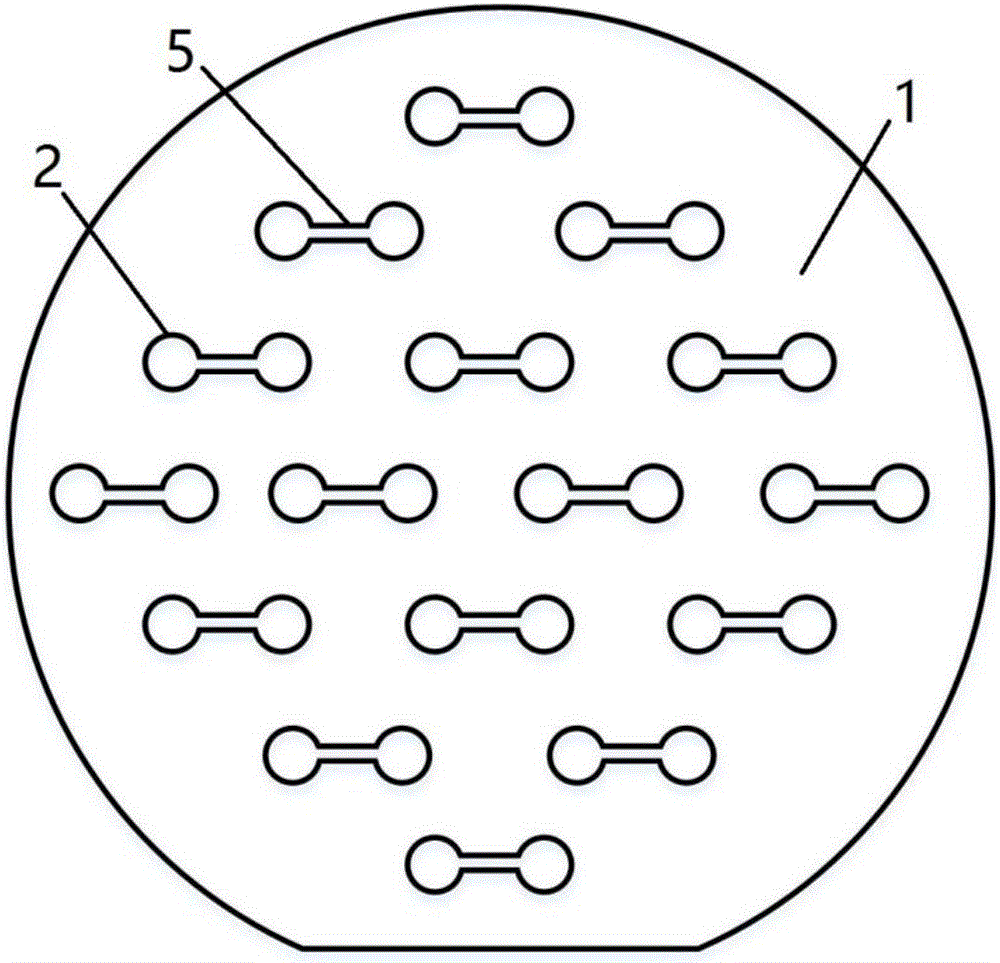

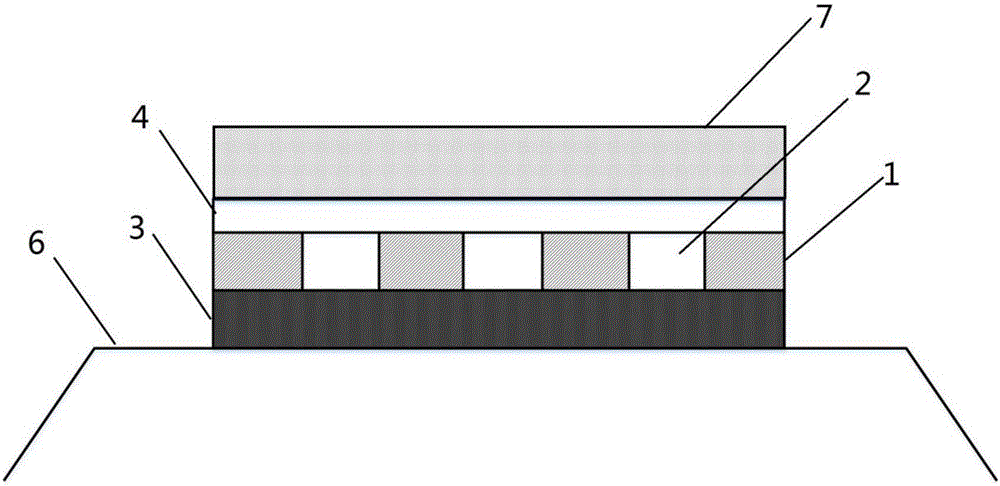

Vacuum film plating method

ActiveCN106498349AAchieve growthLow costVacuum evaporation coatingSputtering coatingOptoelectronicsMetal

The invention provides a vacuum film plating method and relates to a preparation technology for a diamond-like film and a metal film. The vacuum film plating method comprises the following steps that firstly, a laser is used for cutting or sculpturing a conductive wafer (1), and through holes (2) are formed in the conductive wafer (1); secondly, a target material wafer (3), the conductive wafer (1) and a substrate wafer (4) are sequentially stacked and put in vacuum to be heated until the temperature becomes stable; and thirdly, voltage is exerted onto the target material wafer (3) and the substrate wafer (4), the target material wafer (3) is connected with the positive electrode, the substrate wafer (4) is connected with the negative electrode, and under the action of the voltage, the substrate wafer (4) is plated with a target material film (8). According to the vacuum film plating method, the area, needing to be plated with the diamond-like film or the metal film, on the substrate wafer can be precisely controlled, and the diamond-like film or the metal film with the size being a millimeter level or even a submillimeter level can be prepared.

Owner:SOUTHEAST UNIV

A reverse smelting smelting method, nozzle and metallurgical equipment

ActiveCN104634102BThorough responseHigh oxygen utilizationCharge manipulationFurnace typesVia deviceEngineering

The invention discloses a reverse spin floating smelting method. Powdery sulfide concentrate and oxygen-containing gas are sprayed into a space of a high-temperature reaction tower through equipment. The oxygen-containing gas is divided into two parts before entering the equipment; the second oxygen-containing gas is sprayed into the reaction tower in an annular rotary flow mode to form a bell-shaped rotary air curtain; the first oxygen-containing gas is converted into rotary jet via the equipment and is injected from the center of the rotary air curtain. In the annular space between the two rotary gas flows, the concentrate enters in the direction deflecting to the center, and is drawn in by the oxygen-containing gas while high-temperature flue gas from the lower portion of the reaction tower is sucked to form two-phase rotary jet of gas-particle mixing. When the sulfide concentrate is lighted at high temperature, the sulfide concentrate generates severe combustion reaction with oxygen and releases flue gas rich in SO2, meanwhile, sulfonium (or metal) and slag containing mixed melt is formed, and finally the sulfonium (or metal) is separated from the slag at the bottom of the reaction tower so as to complete the metallurgy process. The invention further provides the metallurgical equipment and a reverse spin floating smelting nozzle thereof.

Owner:YANGGU XIANGGUANG COPPER

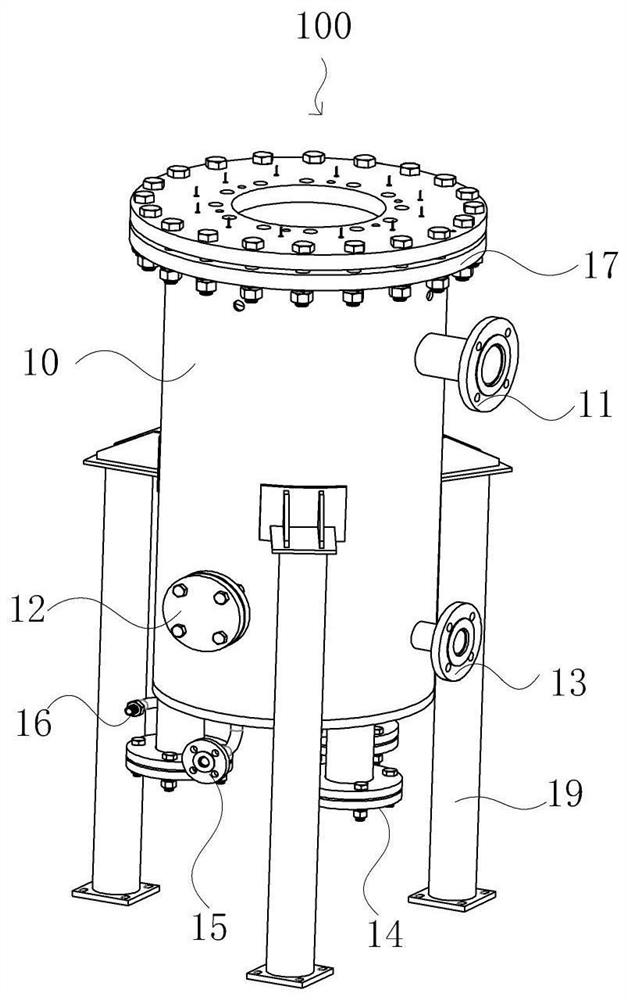

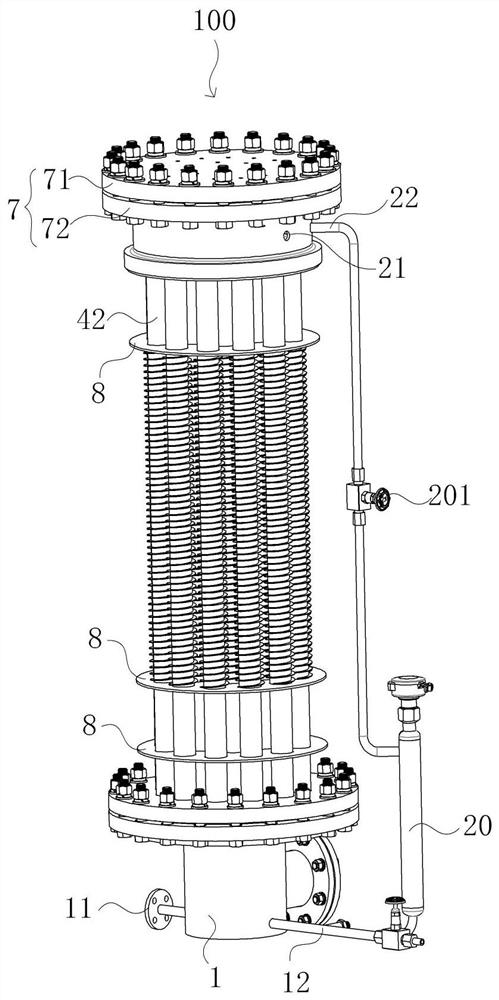

Hydrogen production device

The invention discloses a hydrogen production device. The hydrogen production device, for example, comprises: a vapor generator having a vapor space therein; a hydrogen reactor; at least one steam pipe; a heating part; and a steam output pipe. the hydrogen reactor is internally provided with a hydrogen production space, and the hydrogen production space is filled with a hydrogen production catalyst; wherein the steam generator is arranged outside the hydrogen reactor in a sleeving manner, and the steam space surrounds the hydrogen reactor to form an annular structure; the at least one steam pipe is arranged in the steam space; the heating part is used for heating the steam generator and the hydrogen reactor; and the steam output pipe is connected between the steam generator and the hydrogen reactor, and the steam generator can convey steam to the hydrogen reactor through the steam output pipe. The technical problems that the hydrogen production efficiency is low and the hydrogen production amount is low can be effectively solved.

Owner:广东醇氢新能源研究院有限公司

A kind of porous ceramic and its preparation method and application

ActiveCN111874866BMiniaturizationImprove hydrogen production performanceHydrogenPhysical/chemical process catalystsCarbide siliconPtru catalyst

The invention discloses a porous ceramic, which comprises a silicon carbide porous ceramic substrate; a silicon carbide film is attached to the surface of a hole wall of the silicon carbide porous ceramic substrate; and nanometer nickel particles are embedded in the silicon carbide film. The invention also discloses a catalytic microreactor and a catalytic microreaction system comprising the porous ceramic, and a preparation method of the catalytic microreactor. The porous ceramic can reduce the reaction space and help realize the miniaturization of the reforming hydrogen production system, and the nano-nickel particles embedded in the silicon carbide film can improve the binding strength of the catalyst load, and help realize the vehicle-mounted on-line hydrogen production.

Owner:HUNAN UNIV

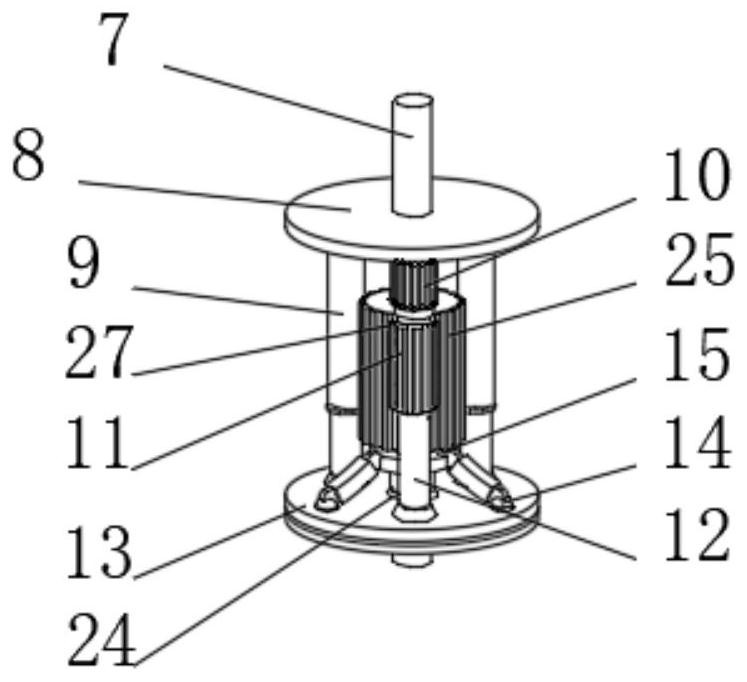

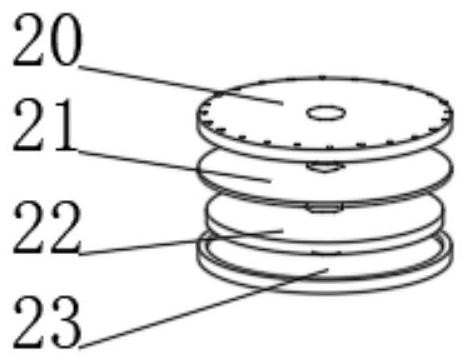

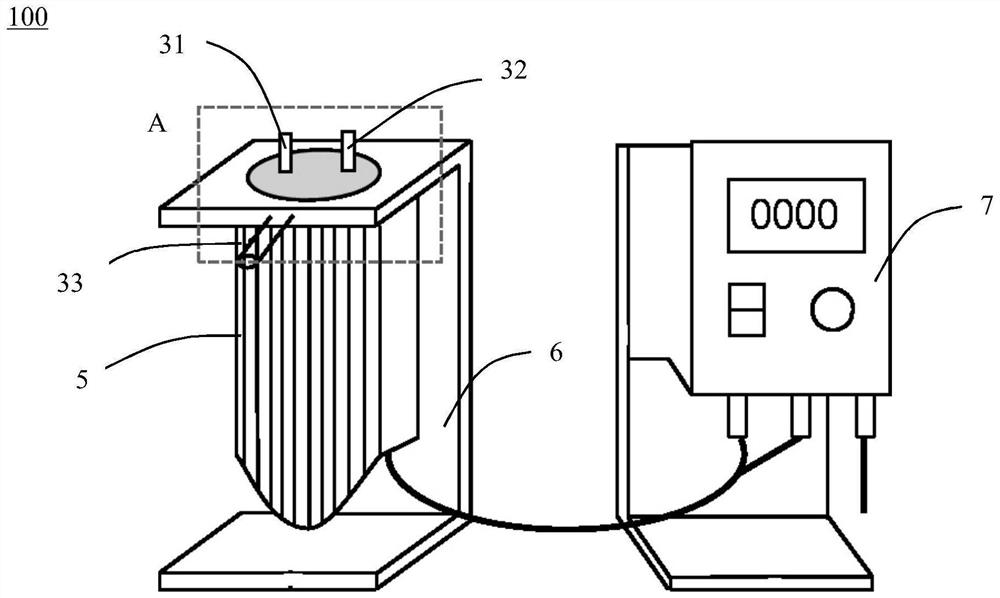

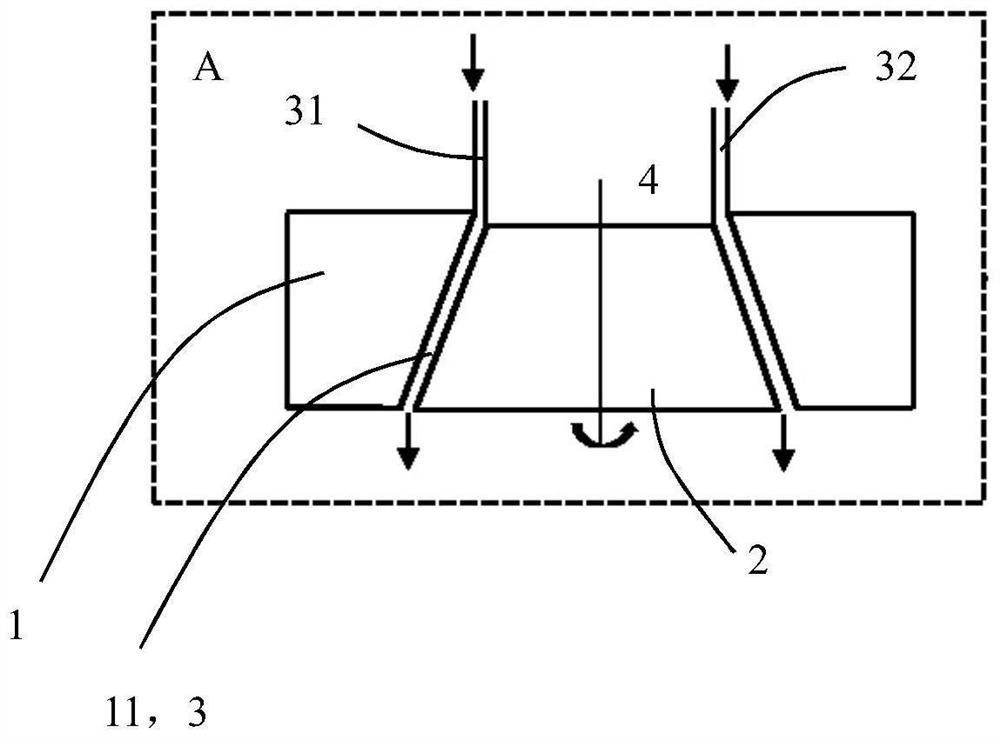

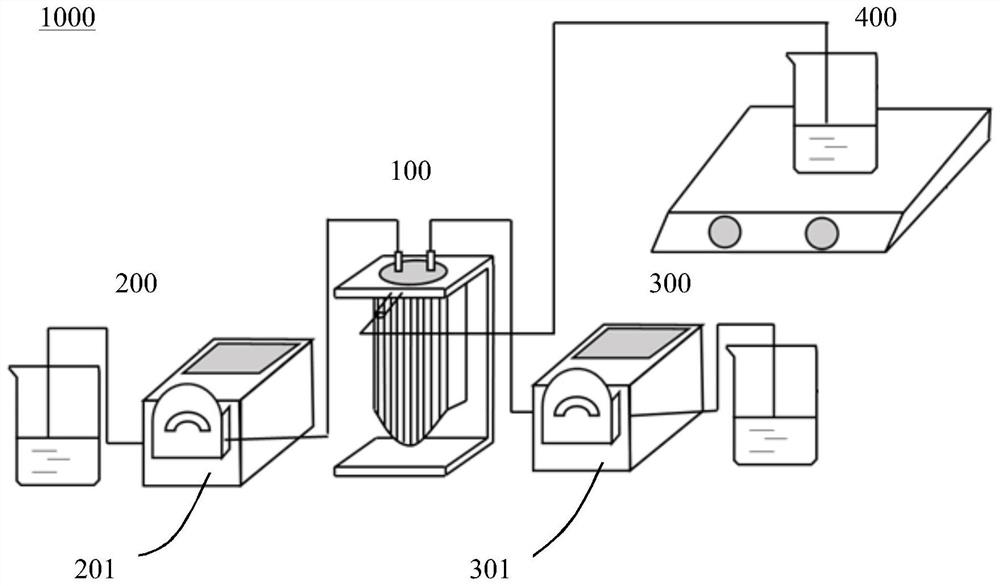

High-mixing type continuous rotary reactor and method for preparing aluminum salt lithium adsorbent by using high-mixing type continuous rotary reactor

PendingCN114832762AIncrease fluid velocityIncrease shear rateOther chemical processesChemical/physical/physico-chemical stationary reactorsMetallurgyPhysical chemistry

The invention discloses a high-mixing type continuous rotating reactor, which comprises a shell, a high-mixing type continuous rotating reactor and a high-mixing type continuous rotating reactor, wherein a containing cavity is limited in the shell, and the shell is used as a stator; the rotor is arranged in the containing cavity, the shape of the rotor is matched with the shape of the containing cavity, and a reaction gap is formed between the outer surface of the rotor and the surface of the containing cavity in a spaced mode; the at least one feeding hole is communicated with the reaction gap; the at least one sampling port is communicated with the reaction gap; the gasket placing position is arranged between the shell and the rotor and is used for placing a gasket with a certain thickness, and the reaction gap can be adjusted by adjusting the thickness of a single gasket or selecting the number of the gaskets. The invention also relates to a method for preparing the aluminum salt lithium adsorbent by using the high-mixing continuous rotary reactor.

Owner:EAST CHINA UNIV OF SCI & TECH

A wet-dry combined two-stage anaerobic fermentation biogas production process

ActiveCN104745639BSmall reaction spaceRealize a closed loopWaste based fuelFermentationResource utilizationDecomposition

The invention belongs to the field of solid waste disposal and resource utilization, and in particular relates to a process for production of biogas by wet method-dry method combined two-stage anaerobic fermentation. Broken solid waste and an inoculum are mixed in a full wet type reactor for wet anaerobic fermentation, the wet anaerobic fermentation period hydraulic retention time (HRT) is 5-20 days, after fermentation processing, a fermentation material can be delivered to a dry method fermentation reactor with an infiltration device at the bottom for dry solid fermentation for production of the biogas, and the process combines the dual advantages of wet method fermentation and dry method fermentation. The fermentation process integrating the advantages of fast mass transfer and easy start-up characteristics of the wet method fermentation and reaction space saving of the dry method fermentation, and the like is disclosed. By combination of biomass multistage decomposition and transformation in the fermentation process and methane producing bacteria group enrichment principle, the wet fermentation process advantage is used, the wet fermentation process is used as a homogeneous inoculation stage of the dry method fermentation process, and the problems of difficult inoculation and slow start of the dry method fermentation can be solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Speed-increase type concurrent flow rotating spraying type gas washing tower

PendingCN110270198ALow flow resistanceSpeed up the flowUsing liquid separation agentProcess engineeringEngineering

The invention discloses a speed-increase type concurrent flow rotating spraying type gas washing tower, and belongs to the technical field of washing towers. The speed-increase type concurrent flow rotating spraying type gas washing tower comprises a vertically-arranged air inlet flue and an induced draft fan, gas introduced in the air inlet flue by the induced draft fan is blown from top to bottom, a rotating spraying mechanism is arranged inside the air inlet flue, a rotating spin-drying mechanism is arranged at the lower portion of the air inlet flue, a gas-liquid separating channel is arranged at the bottom of a rotating spin-drying cylinder of the rotating spin-drying mechanism, the gas-liquid separating channel is communicated with an air outlet flue, and a spraying liquid collecting drainage opening is formed in the bottom of the gas-liquid separating channel. Due to the gas and spraying liquid concurrent flow design, the gas flowing resistance is lowered; on the basis of the atomization rotating spraying mode, effective contact between the spraying liquid and gas is increased, rapid gas-liquid separation is achieved by means of the rotating spin-drying mode, and a series of problems that an existing washing tower reaction is not sufficient, the gas flow speed is low, the gas exhaust humidity is high, and the tower structure is huge are solved fundamentally.

Owner:江苏龙冶节能科技有限公司

Hydrogen production device

PendingCN112607704ASmall reaction spaceReduce manufacturing costHydrogenHydrogen/synthetic gas productionPtru catalystEngineering

Owner:LUOYANG WODA MACHINERY TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com