Whole-process continuous phenylacetonitrile production device and process

A technology of production device and production process, which is applied in the fields of organic chemistry, cyanide reaction preparation, and carboxylic acid nitrile purification/separation, etc., can solve the problems of incapable of continuous production and insufficient production efficiency, and achieves a safe, stable and environmentally friendly production process and a production cycle. The effect of shortening and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

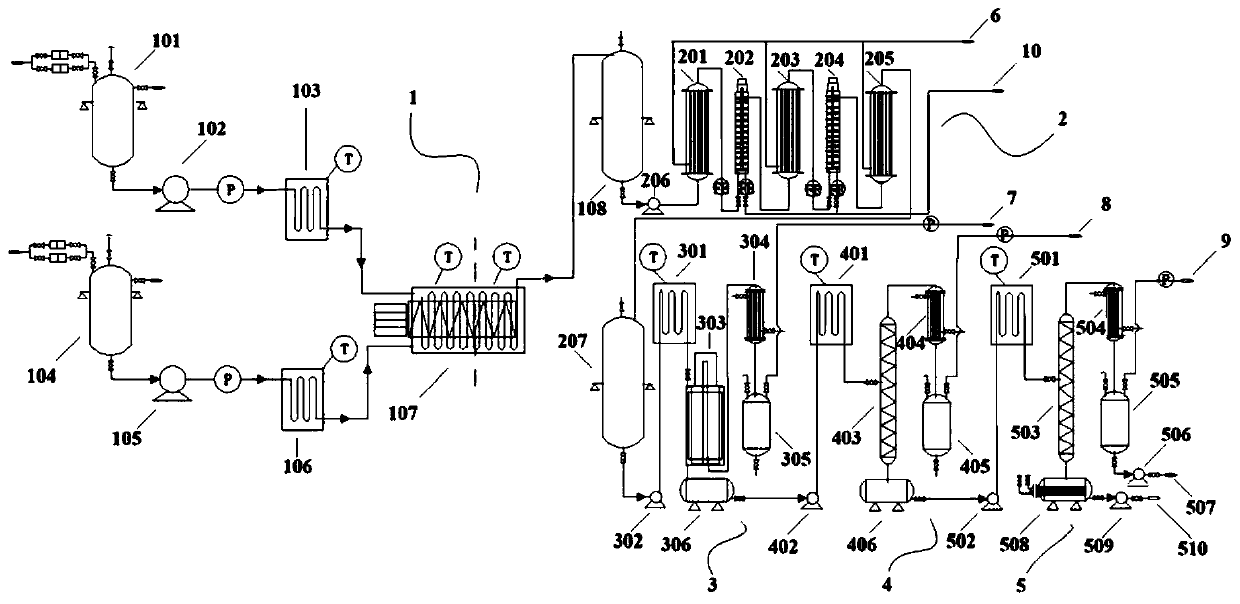

[0047] Comply with the above technical solutions, such as figure 1 As shown, the present embodiment provides a kind of whole-process continuous phenylacetonitrile production device, including successively connected reaction unit 1, washing unit 2, evaporative dehydration unit 3, light component removal unit 4 and product rectification unit 5 ;

[0048] Reaction unit 1 comprises benzyl chloride high level tank 101 links to each other with first preheater 103 by first metering pump 102; Sodium cyanide high level tank 104 links to each other with second preheater 106 by second metering pump 105; The device 103 and the second preheater 106 are respectively connected to the feed port of the tangential flow reactor 107, and the discharge port of the tangential flow reactor 107 is connected to the feed port of the first reaction mixed liquid temporary storage tank 108;

[0049] The washing unit 2 comprises a first oil-water membrane separator 201, the feed port of the first oil-wate...

Embodiment 2

[0057] The present embodiment provides a kind of continuous benzyl nitrile production technique of whole process, and this technique adopts the continuous benzyl nitrile production device of full process as in embodiment 1;

[0058] Specifically, in the reaction unit 1, two reaction sections are arranged in the tangential flow tubular reactor 107, the temperature of the first reaction section is 65-75°C, the residence time is 5-15min, and the temperature of the second reaction section is 50-60°C, the residence time is 5-15min, and the reaction pressure in the tangential flow tube reactor 107 is 0.1-0.2Mpa.

[0059] Specifically, in reaction unit 1, the mol ratio of raw material benzyl chloride and sodium cyanide is 1.0:1.05, and the concentration of sodium cyanide is 30wt.%; The sodium cyanide in the sodium cyanide head tank 104 is mixed with the phase transfer catalyst , the phase transfer catalyst is benzyl tributyl ammonium chloride, and the mass ratio of benzyl tributyl am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com