Hydrogen production device

A hydrogen production device and hydrogen technology, applied in the direction of hydrogen, inorganic chemistry, non-metallic elements, etc., can solve problems such as low efficiency and complex structure, and achieve the effects of saving reaction space, increasing production rate, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

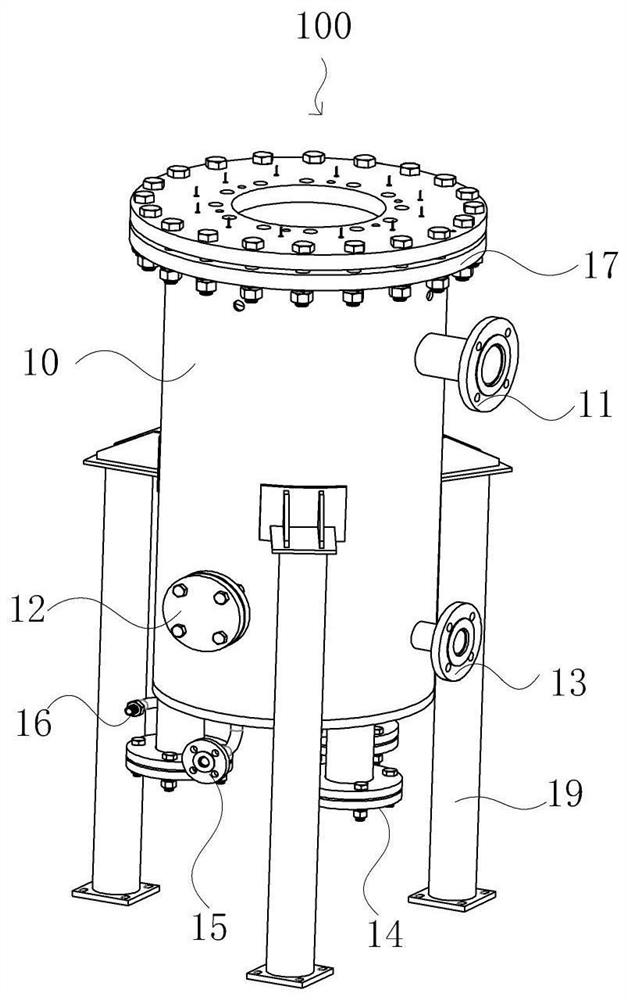

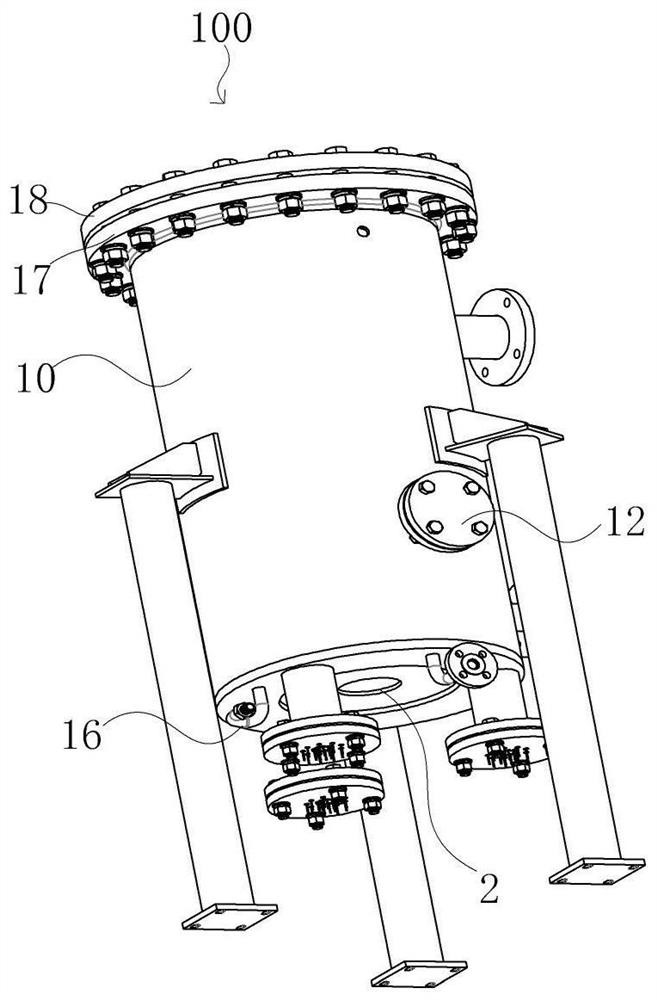

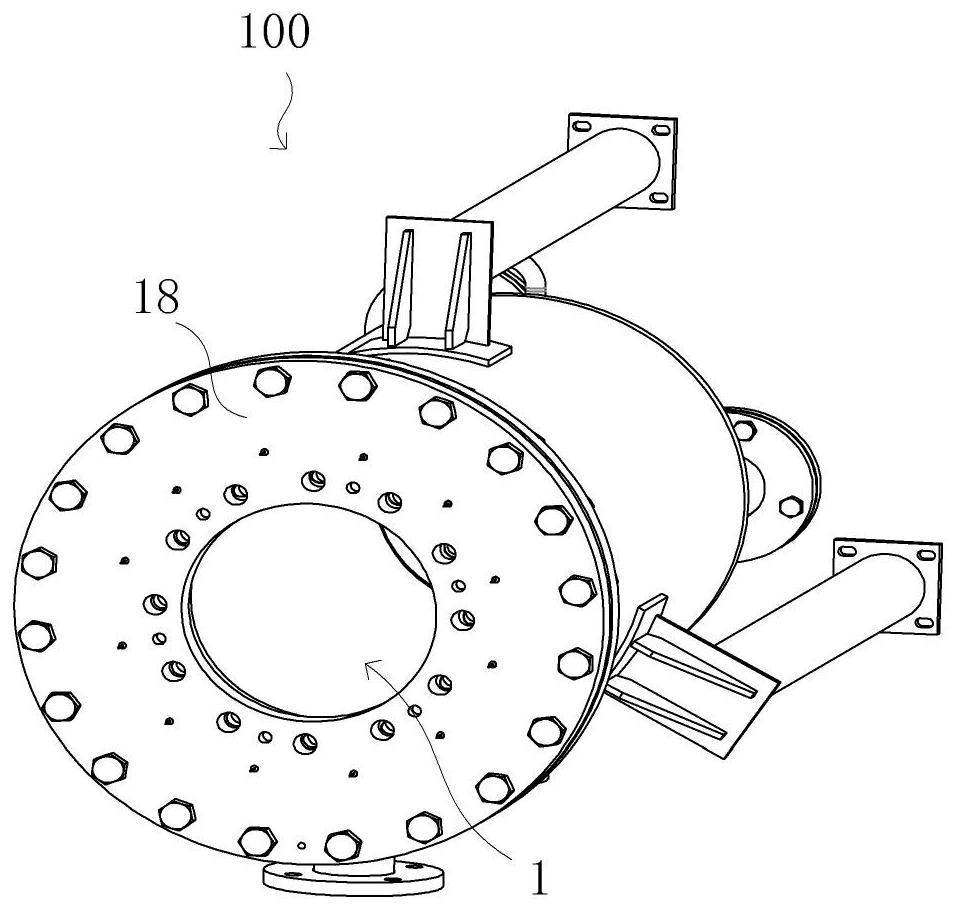

[0056] see Figure 1-Figure 5 , which is a structural schematic diagram of a steam generator 100 provided in an embodiment of the present invention, the steam generator 100 includes, for example: a housing 10, a steam space 20, a liquid chamber 21, a steam chamber 22, and a steam pipe 30; the housing 10, the interior of which is provided with a hydrogen reactor accommodation space 3; the vapor space 20 is located between the hydrogen reactor accommodation space 3 and the shell 10, and is arranged around the hydrogen reactor accommodation space 3 in an annular structure; the liquid chamber 21, Located at the bottom of the steam space 20, and the liquid chamber 21 is provided with a first heating part, and the first heating part is a first electric heater 14; the steam chamber 22 is located at the top of the steam space 20; the steam pipe 30 is located at the top of the steam space. The space 20 communicates with the liquid chamber 21 and the vapor chamber 22 . The upper end of...

no. 2 example

[0067] see Figure 10 , a hydrogen reactor 200 is also provided in the second embodiment of the present invention. The hydrogen reactor 200 includes, for example: an outer casing 110, a hydrogen output pipe 120, a third flange 130, and a fourth flange 140; the outer casing 110 is provided with a steam chamber 101 and a hydrogen production space 102; It is located in the outer shell 110 and connected to the hydrogen production space 102 to discharge the hydrogen generated by the reaction; the third flange 130 is detachably installed on the bottom of the outer shell 110, and the fourth flange 140 is detachably installed on the outer shell 110 top. Specifically, the hydrogen production catalyst can be filled into the hydrogen production space 102 through the detachable fourth flange 140 .

[0068] Further, see Figure 11-Figure 13 , the hydrogen reactor 200 also includes: a hydrogen production catalyst (not shown in the figure), a third heating portion, and a fixing flange 150...

no. 3 example

[0073] see Figure 15-Figure 17 , The third embodiment of the present invention also provides a hydrogen production device 300, the hydrogen production device 300 includes: a steam generator 100 and a hydrogen generator 200; wherein, the steam generator 100 is set outside the hydrogen reactor 200, here When the hydrogen reactor 200 is located in the hydrogen reactor accommodation space 3 of the gas generator 100, and is communicated by the steam output pipe 220; the steam can be transported from the steam generator 100 to the inside of the hydrogen reactor 200 through the steam output pipe 220, further, The steam output pipe 220 is provided with a steam control valve 221, which can control the delivery amount of the steam; the steam output pipe 220 is also provided with a temperature sensor 222, which is used to detect the temperature of the steam in the steam output pipe, and displays it, which can improve the production efficiency. Hydrogen efficiency.

[0074]Preferably, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com