Patents

Literature

33results about How to "Realize a closed loop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

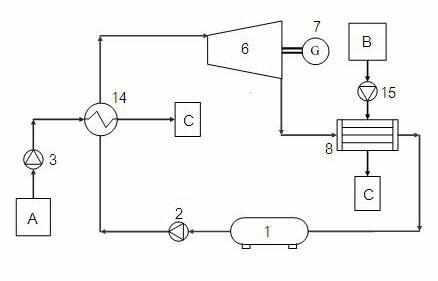

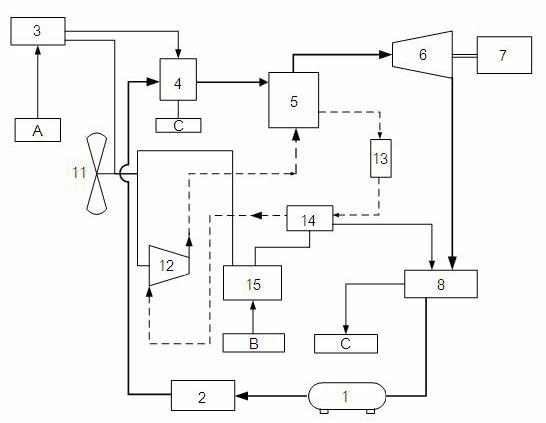

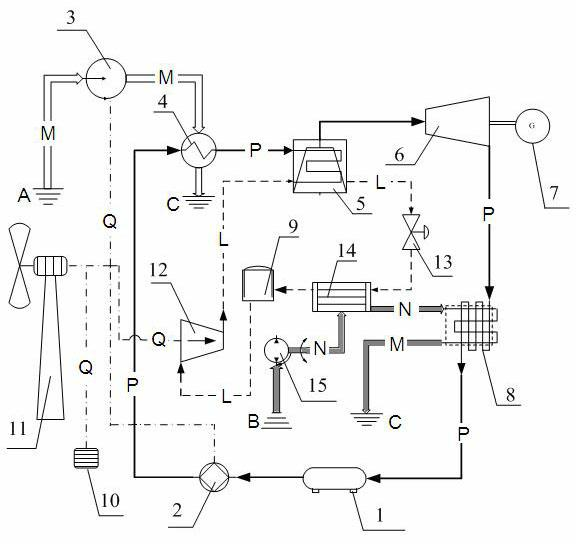

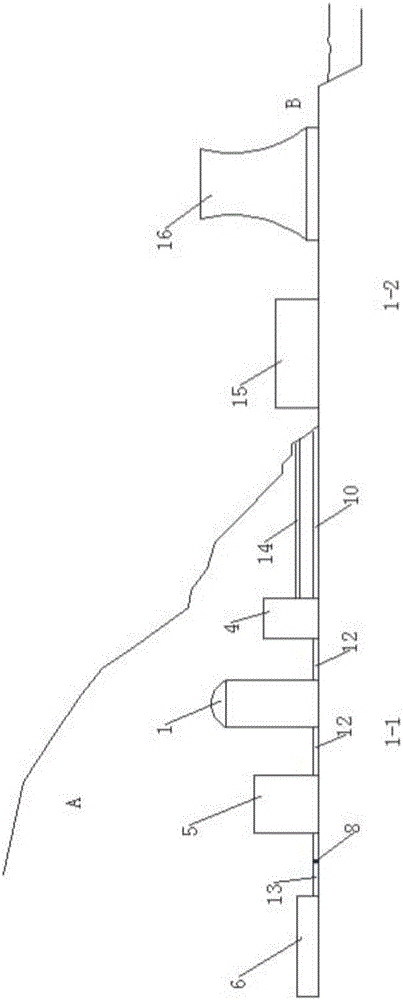

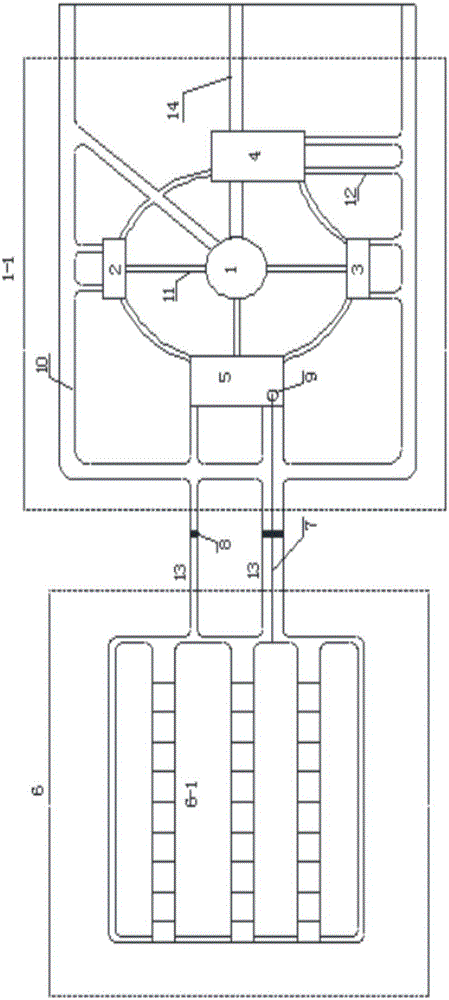

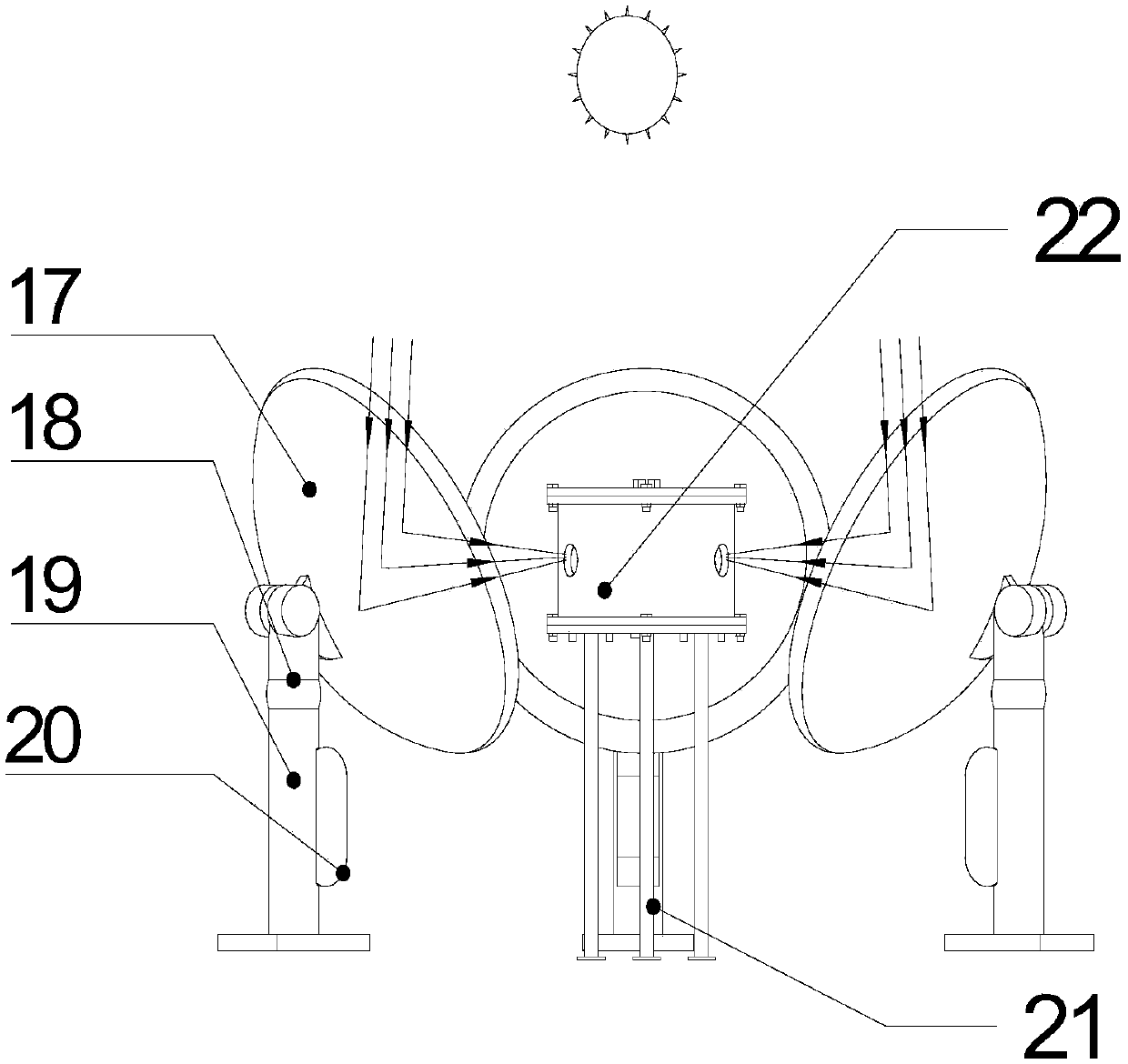

Ocean thermal energy conversion method and ocean thermal energy conversion device

ActiveCN102213199ALarge temperature differenceIncreased efficiency of closed loopsMachines/enginesMechanical power devicesThermal energyOcean thermal energy conversion

The invention provides an ocean thermal energy conversion method and an ocean thermal energy conversion device. The method comprises the following steps of: heating a low-boiling-point working medium by using hot seawater on a surface of ocean; evaporating the low-boiling-point working medium; feeding into a turbine to push a turbo generator set to work for power generation; condensing working medium gas which is exhausted from the turbine into liquid by using cold seawater on a deep layer of the ocean; heating by using the hot seawater; feeding into the turbine to make the working medium gasevaporated; pushing the turbo generator set to work for the power generation; cyclically executing the steps; and continuously carrying out power generation. Power is generated by using ocean surfacewind power, a heat pump device is driven by the power, the temperature of the working medium is further raised by using a medium of the heat pump device, and the volume expansion ratio of the workingmedium is improved; and the temperature of the cold seawater is further reduced by using the medium of the heat pump device, the working medium exhausted gas is condensed by using the low-temperatureseawater, and a condensing effect of the working medium exhausted gas is improved. The method and the device improve the efficiency of closed cycle generation of ocean thermal energy conversion, realize the comprehensive utilization of ocean thermal energy and wind energy, have an important practical value, provide environment-friendly energy sources, and are easy to use and promote in large scale.

Owner:DONGFANG TURBINE CO LTD +2

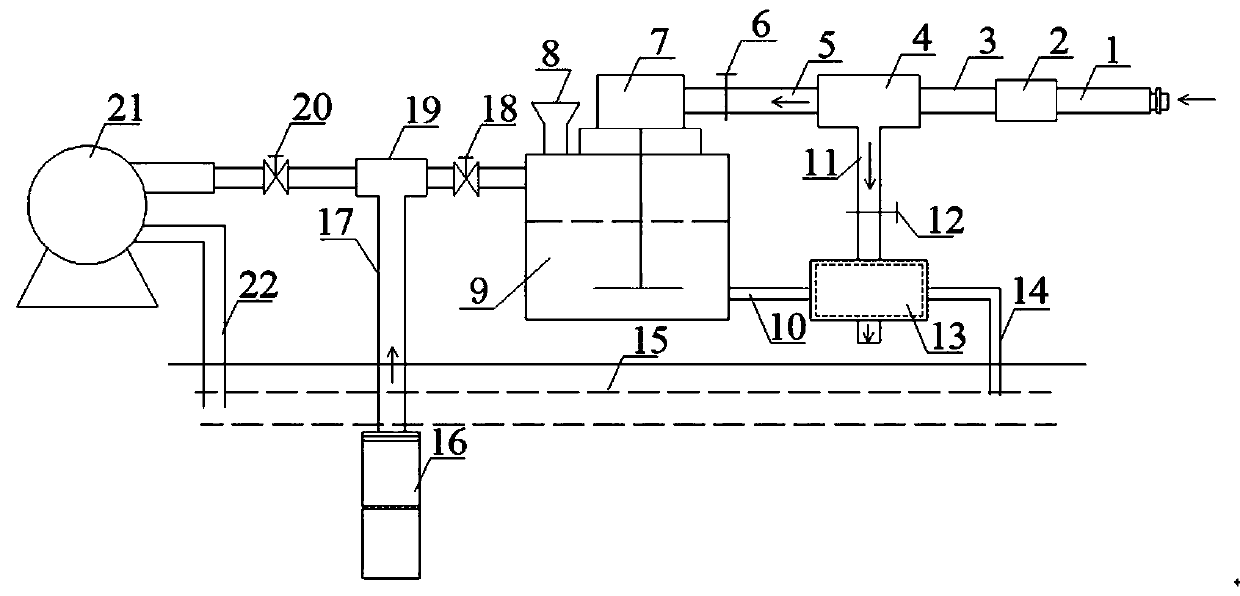

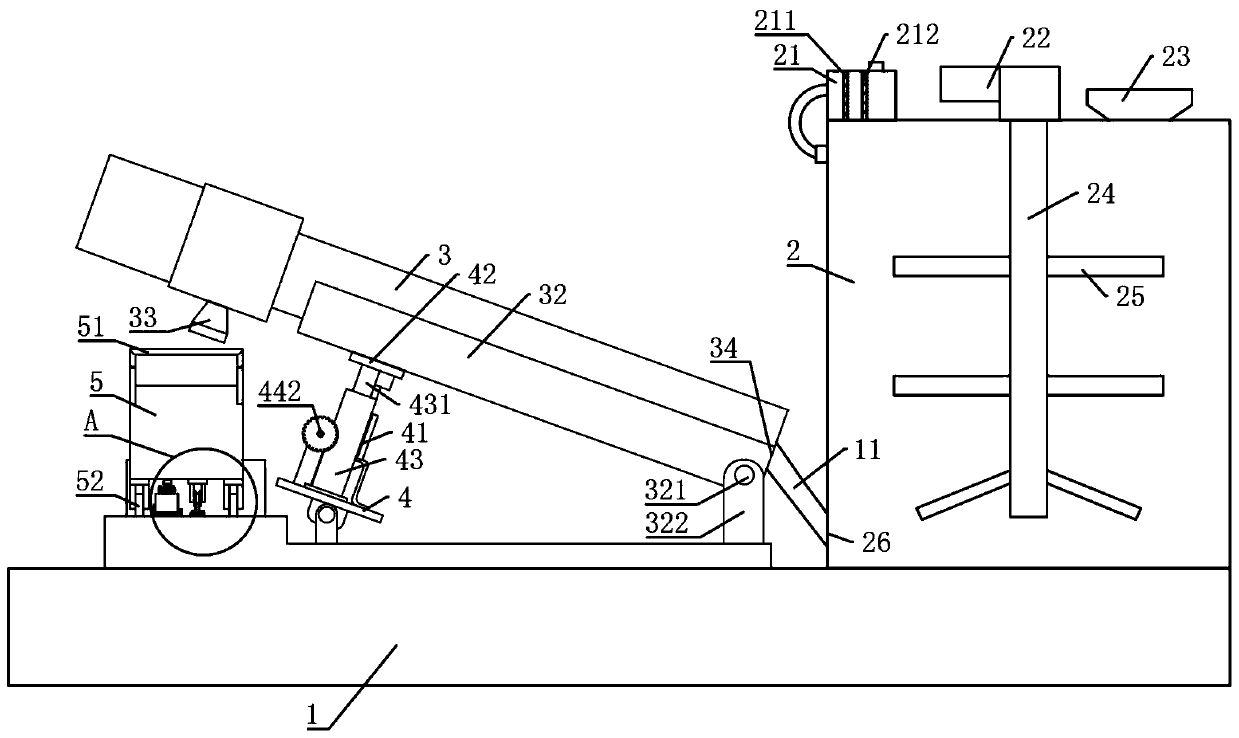

Closed circulation system for improving gas drainage pump running efficiency

ActiveCN107152400AImprove operational efficiencyAvoid enteringFlow mixersTransportation and packagingSystem structureEngineering

The invention discloses a closed circulation system for improving gas drainage pump running efficiency. A liquid inlet of a pneumatic diaphragm pump is connected with a liquid outlet of a macromolecule drag reduction solution tank, and a liquid outlet pipe of the pneumatic diaphragm pump is led into a circulation water pool. The macromolecule drag reduction solution tank is internally provided with a pneumatic stirrer, and a feeding hopper is arranged at the top. A liquid outlet of a sinking pump is connected with a liquid inlet of the macromolecule drag reduction solution tank and a liquid inlet of a gas drainage pump through a tee joint, and a liquid drainage pipe of the gas drainage pump is connected into the circulation water pool. The pneumatic stirrer and the pneumatic diaphragm pump run at a high speed so that a macromolecule drag reduction solution can be fed into the circulation water pool after being evenly mixed; and meanwhile, a liquid outlet pipe of the sinking pump supplies water to the macromolecule drag reduction solution tank, a macromolecule drag reducer is added into the feeding hopper, and continuous liquid preparation and using after preparation instantly of the drag reduction solution can be achieved. The gas drainage pump uses the macromolecule drag reduction solution as a working medium, and the gas drainage pump running efficiency can be greatly improved. The system is simple in structure and convenient to operate, and drag reduction solution supply closed circulation is achieved.

Owner:CHINA UNIV OF MINING & TECH

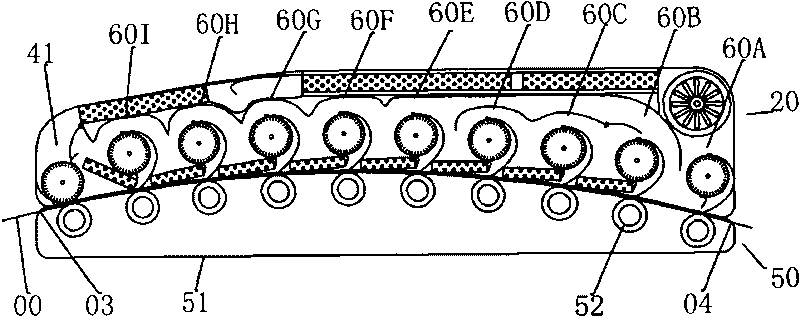

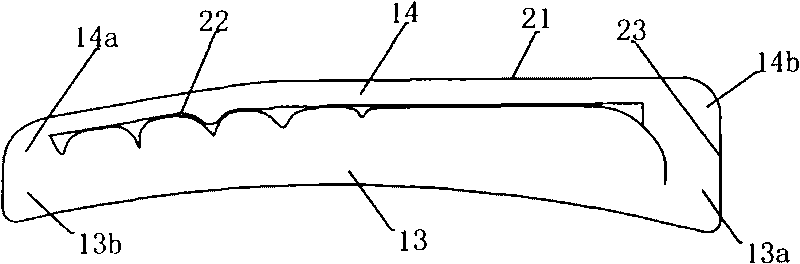

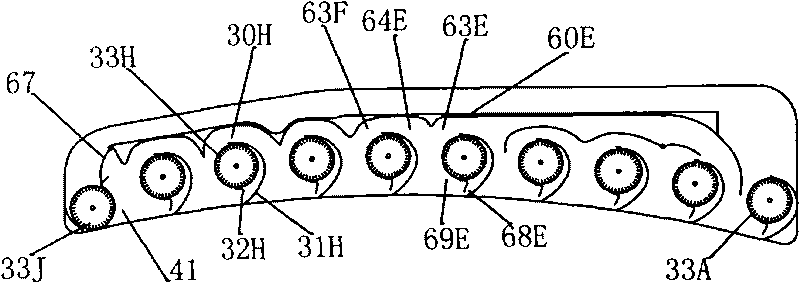

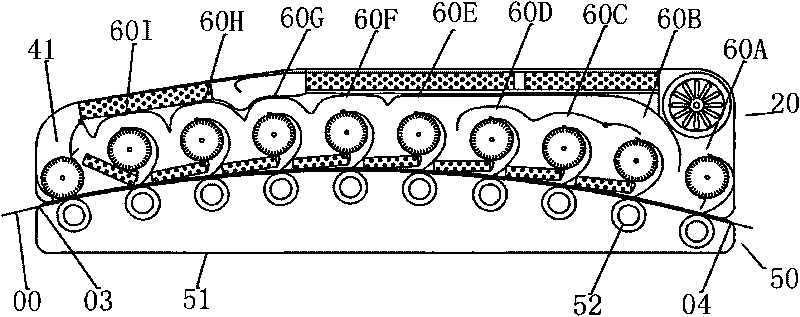

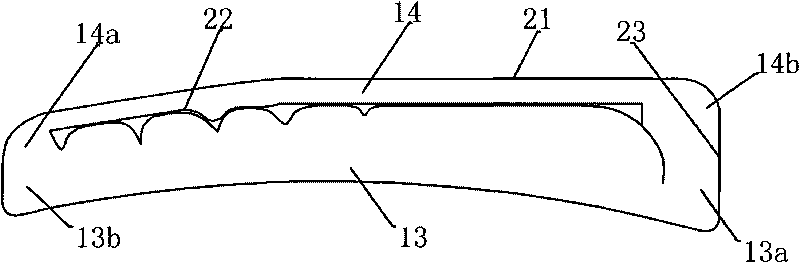

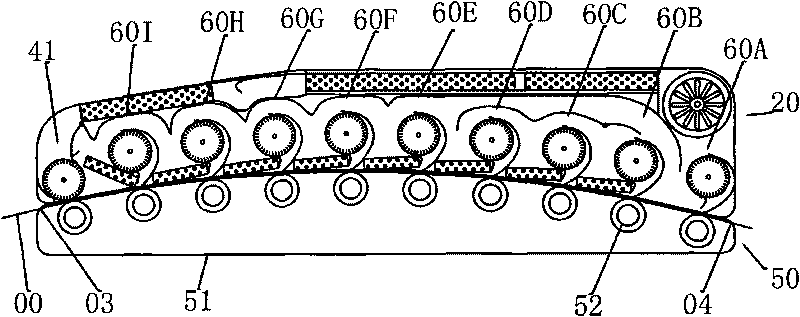

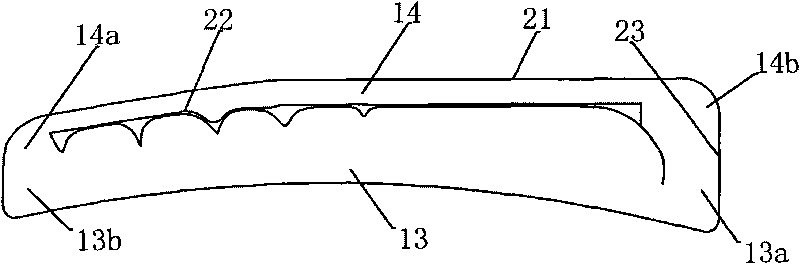

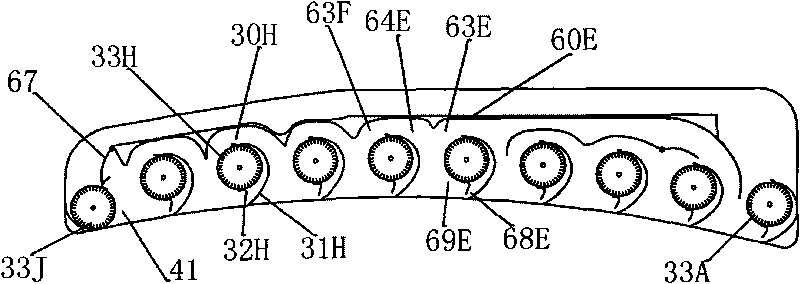

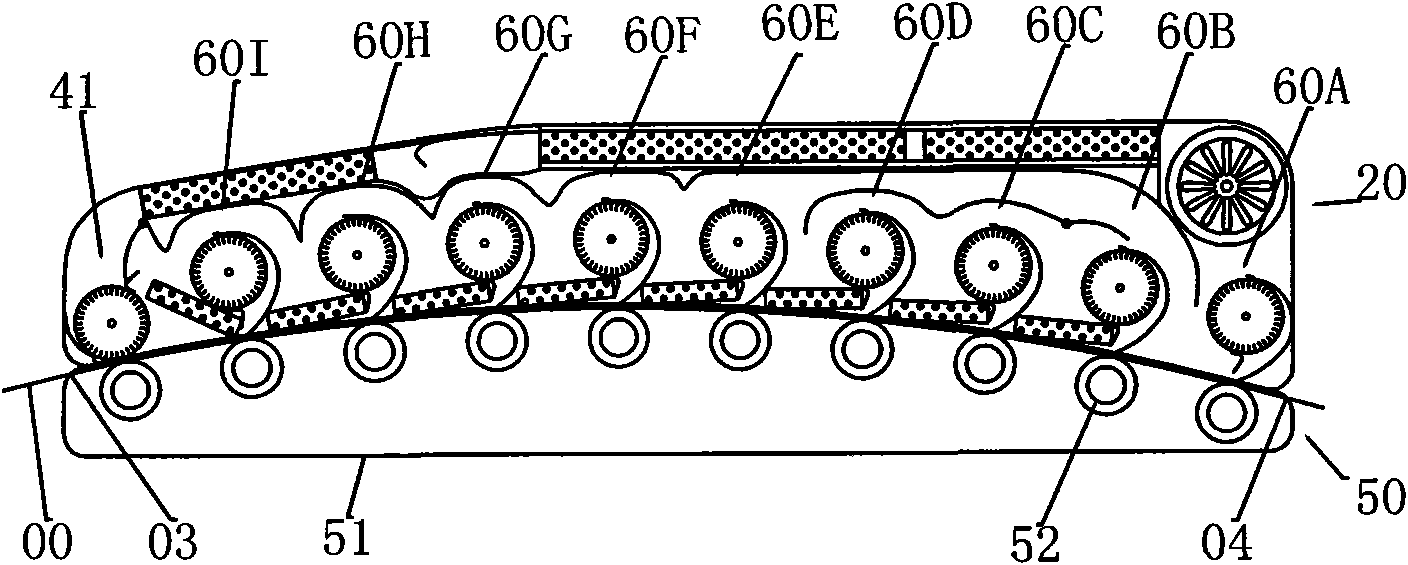

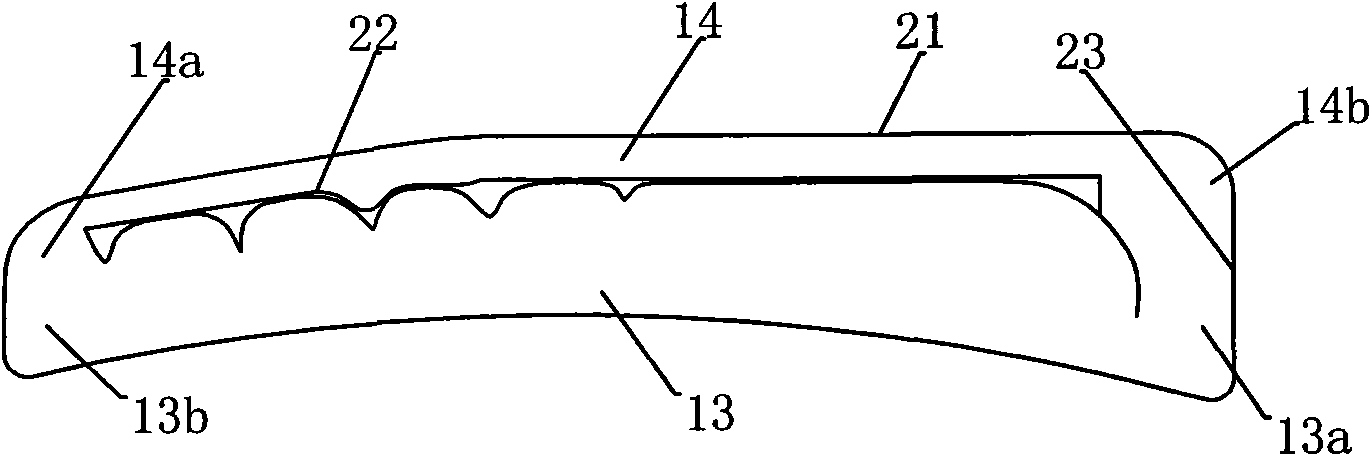

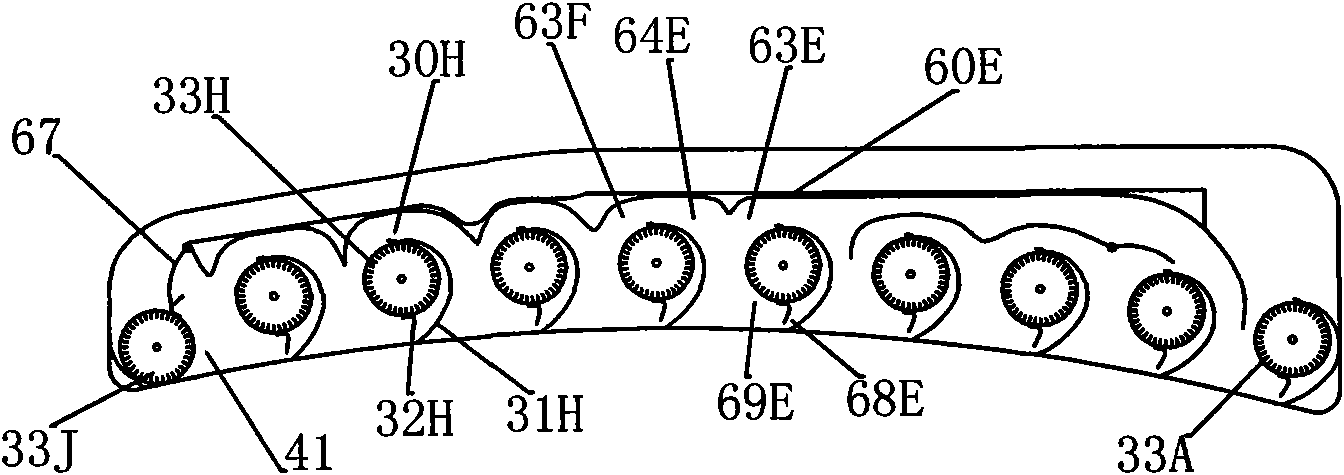

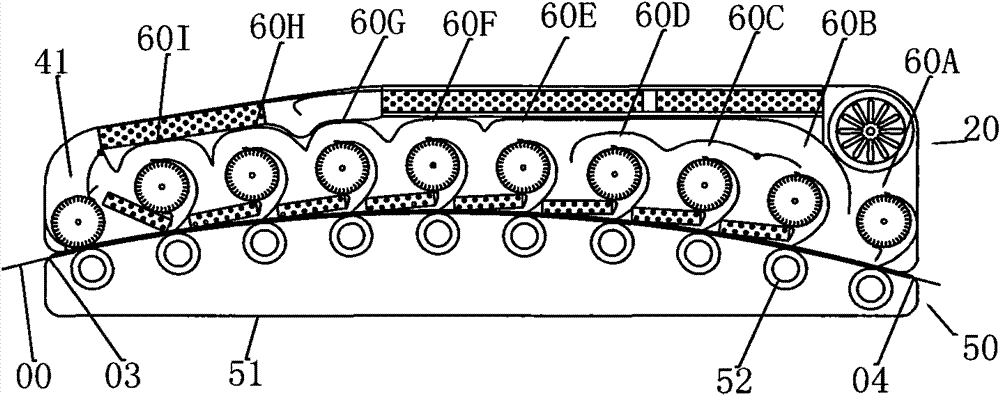

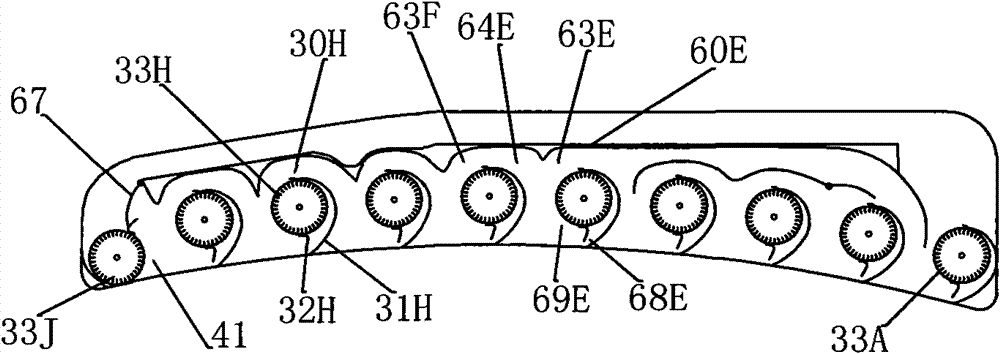

Energy-saving and environment-friendly printer

InactiveCN101700713AReduce consumptionThe effect of reducing consumption and realizing a closed loopPrinting press partsInlet channelMaterial consumption

The invention relates to an energy-saving and environment-friendly printer, comprising a printer body and a drying device (10). The energy-saving and environment-friendly printer is characterized in that the drying device (10) comprises an oven cap (20) and a base (50), and is provided with a printing product inlet (03) and a printing product outlet (04); the oven cap (20) is provided with a drying cavity (13) and a recovering cavity (14); an air supply unit (60), a heat pump condenser (88) and a refrigerating evaporator (96) are arranged in the oven cap (20); the air supply unit (60) comprises a fan (30) provided with an air inlet channel (63), an air exhaust channel (64) and an air outlet channel (68) to form an air blowing and circulating system; the heat pump condenser (88) is installed in the air supply unit (60), and the refrigerating evaporator (96) is installed in the recovering cavity (14). In the invention, drying equipment is firstly reformed, and an air channel with skillful interior is utilized to replace the original air channel with complicated structure and signal function, thereby the effects of compact structure, space saving and reduction of material consumption are achieved.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

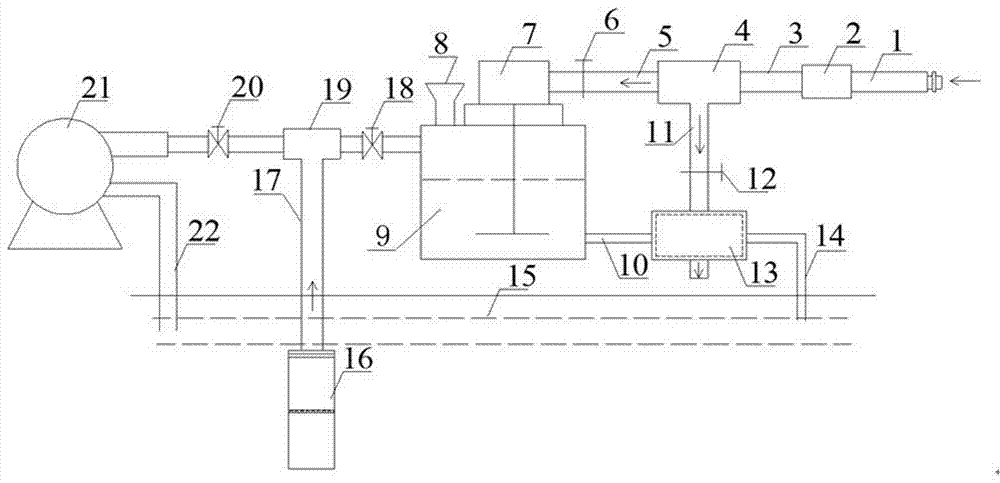

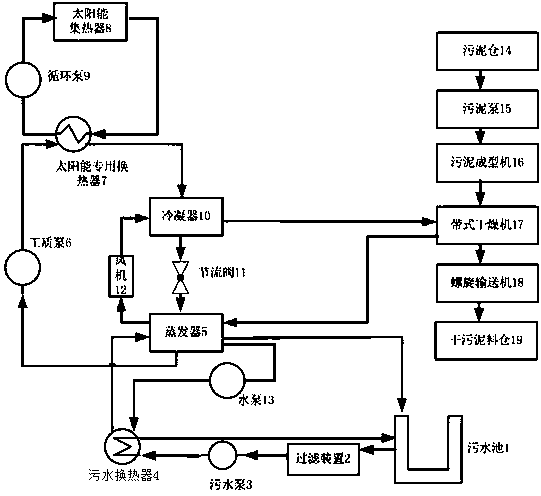

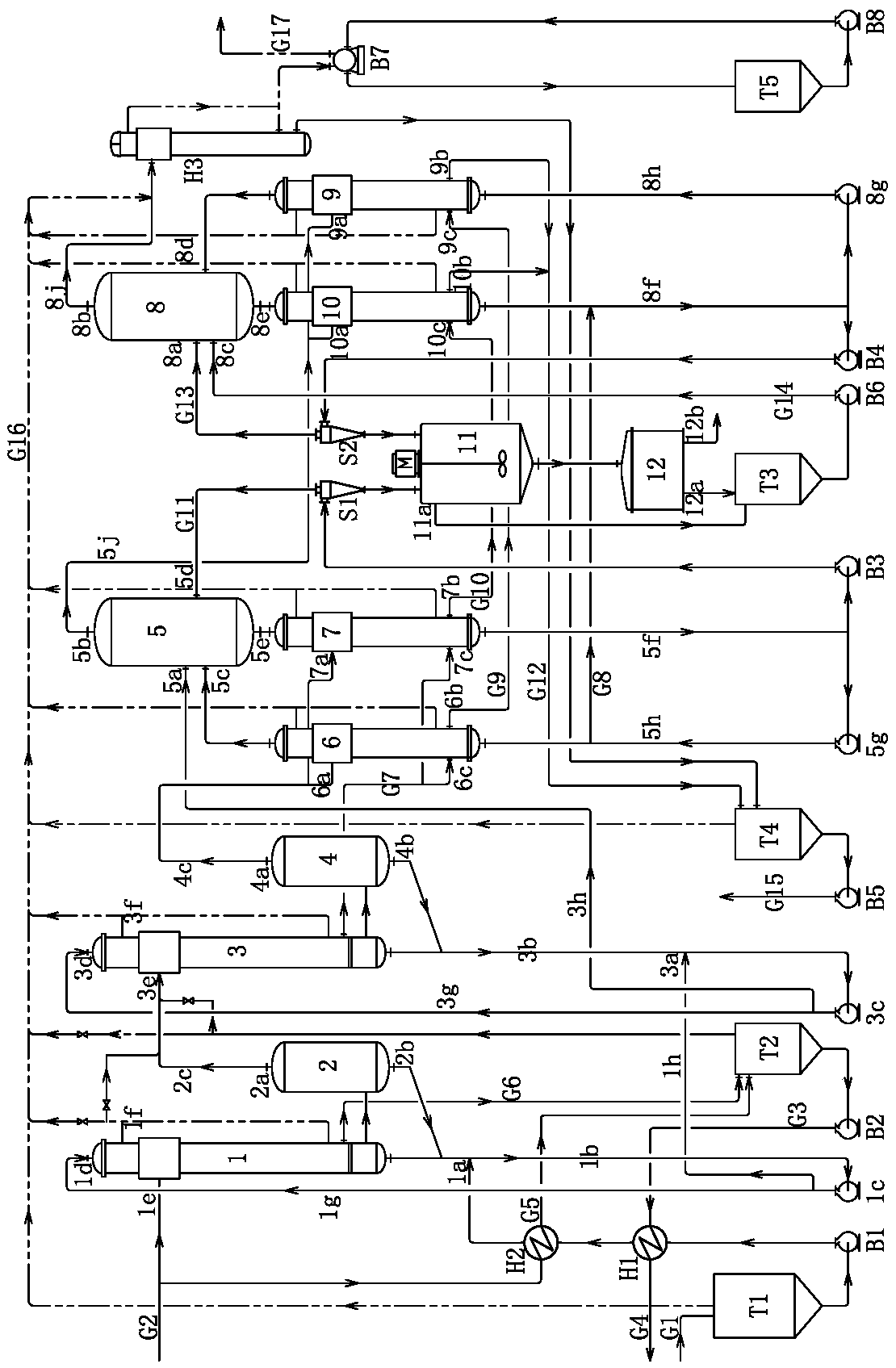

Sludge drying system and drying process based on sewage source heat pump

InactiveCN109734280AImprove production efficiencyNo combustion processSludge treatment by de-watering/drying/thickeningThermal energySludge

The invention provides a sludge drying system and a drying process based on a sewage source heat pump. The drying system comprises a sewage circulating device, an intermediate water circulating deviceand a heat pump circulating device, the sewage circulating device comprises a sewage tank connected with a sewage pump, sewage discharged by the sewage pump returns into the sewage tank through a sewage heat exchanger, the intermediate water circulating device comprises a water pump for conveying intermediate water to the sewage heat exchanger, an intermediate water outlet of the sewage heat exchanger is connected with an evaporator, a water outlet of the evaporator is connected with the water pump, the heat pump circulating device comprises a working medium pump and a condenser, a working medium of the evaporator is conveyed to the condenser through the working medium pump to release heat, a working medium outlet of the condenser is connected with the evaporator, air flows through the condenser and then is conveyed to a belt drier by the aid of a fan, and sludge is dried. According to the system and the process, heat energy of urban sewage serves as a low-level heat source of a heatpump device, hot air is generated and enters the belt drier to dry the sludge, energy is saved, and the sludge is treated.

Owner:CHINA THREE GORGES UNIV

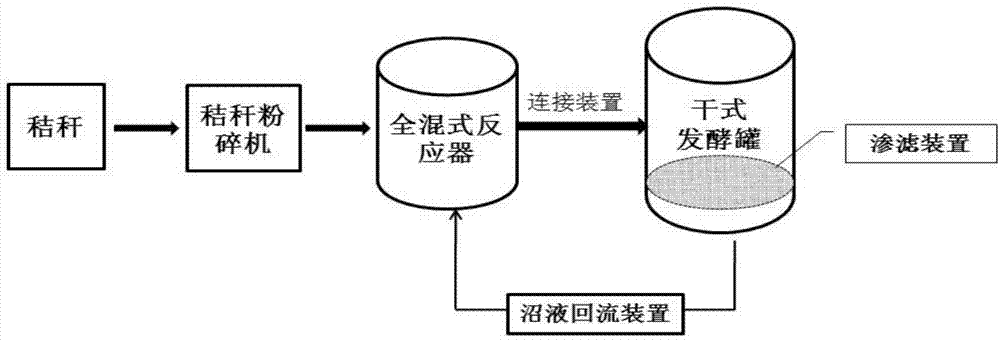

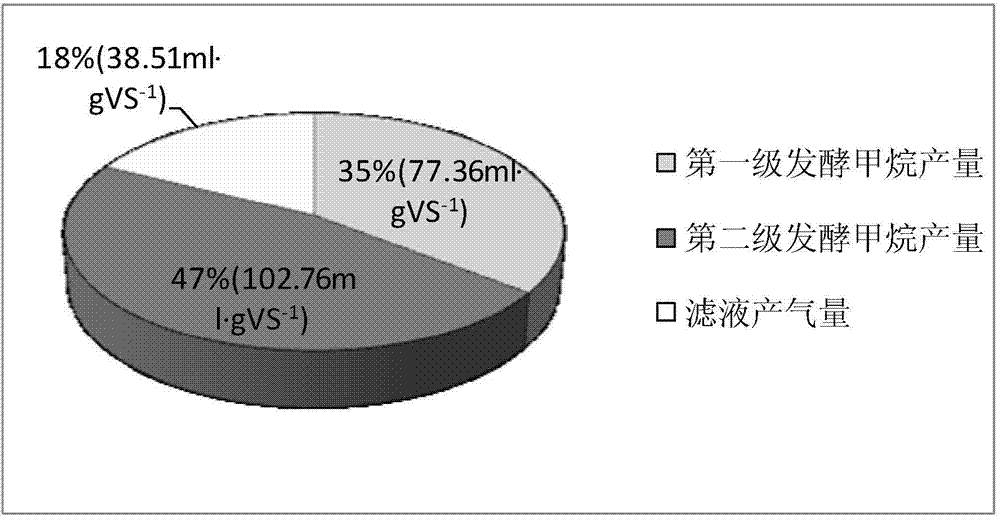

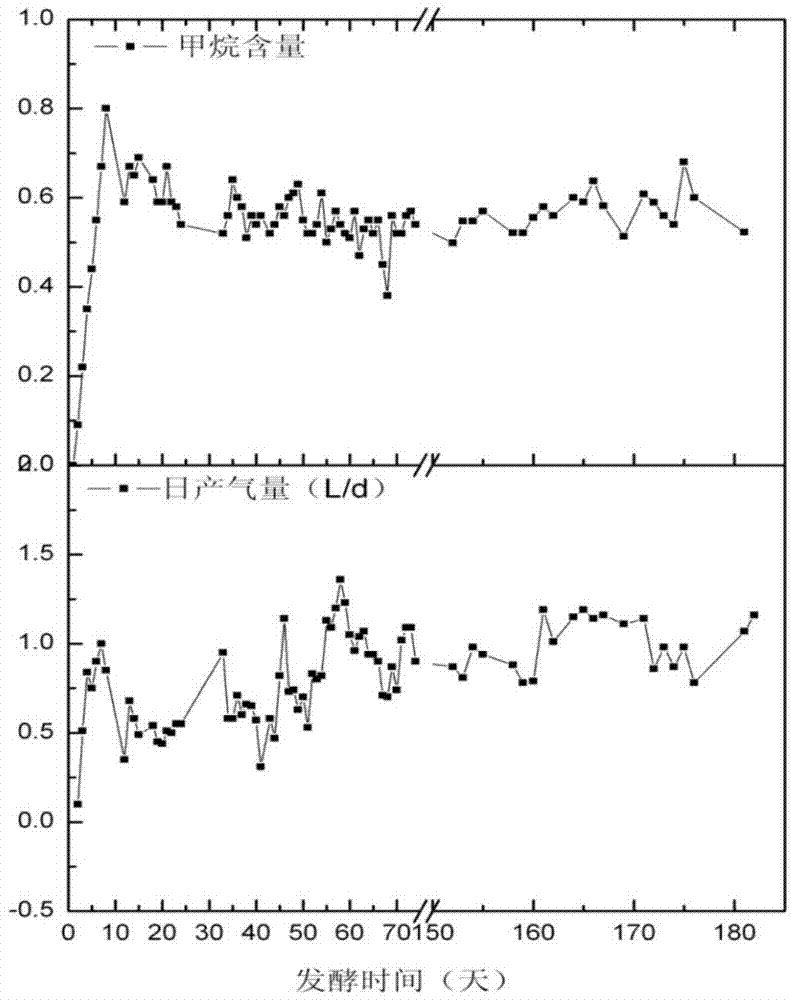

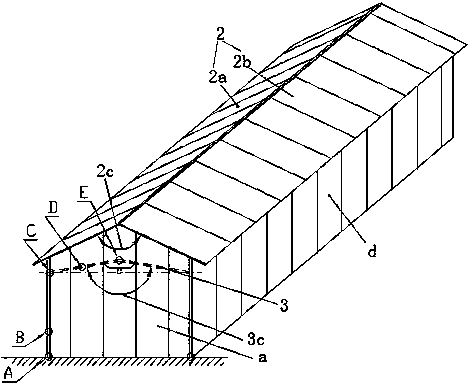

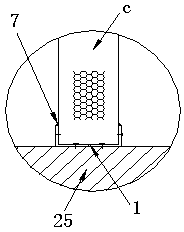

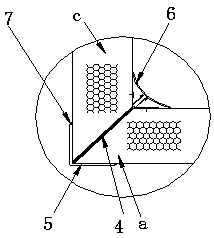

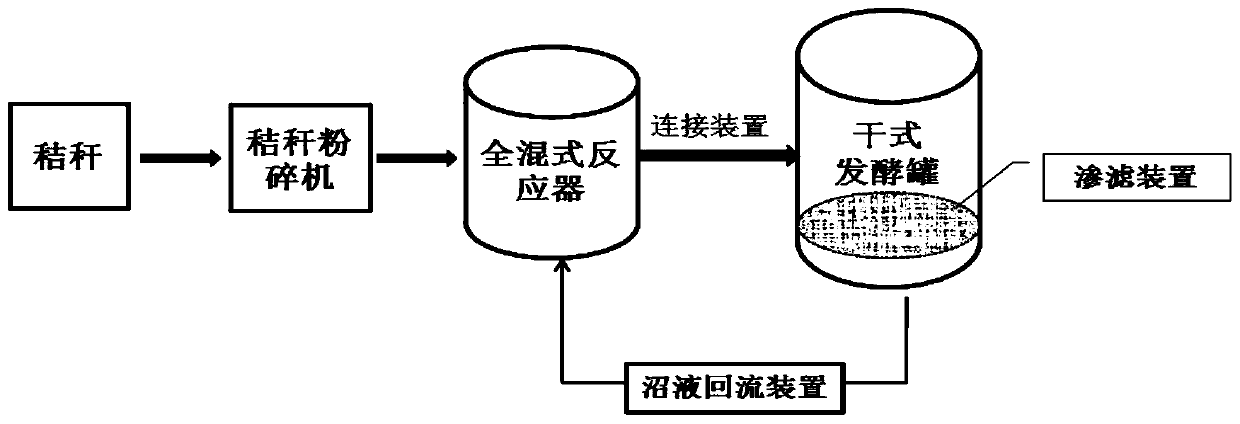

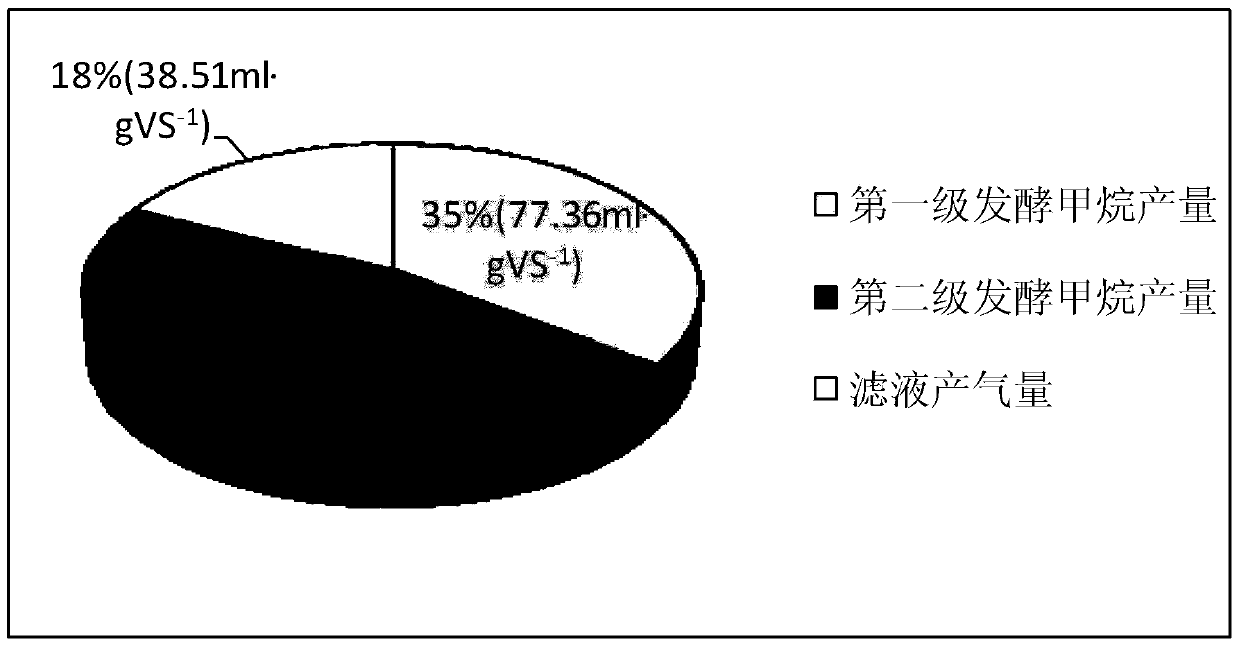

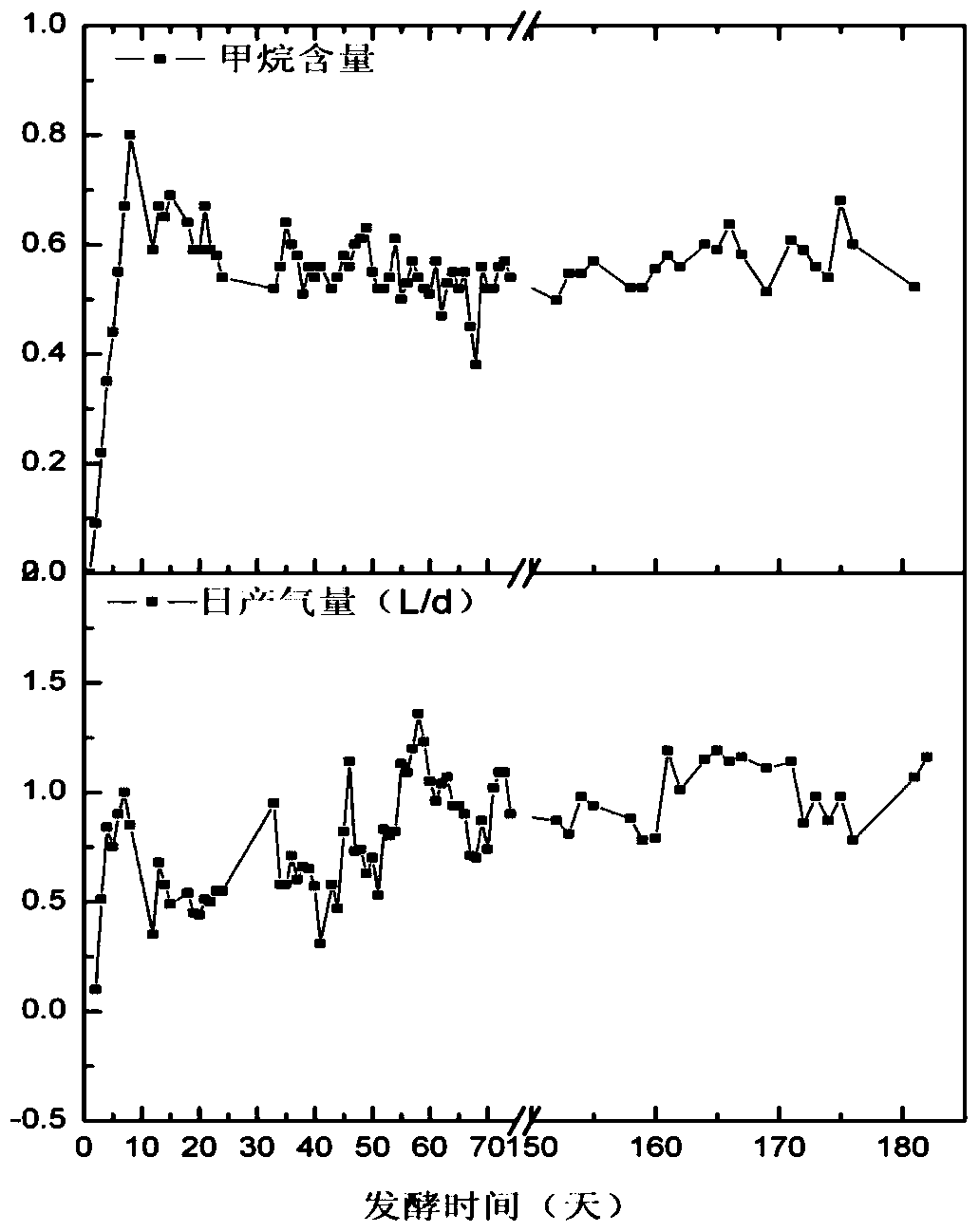

Process for production of biogas by wet method-dry method combined two-stage anaerobic fermentation

ActiveCN104745639ASolve the difficulty of fermentation inoculationSolve the problem of slow startupWaste based fuelFermentationResource utilizationDecomposition

The invention belongs to the field of solid waste disposal and resource utilization, and in particular relates to a process for production of biogas by wet method-dry method combined two-stage anaerobic fermentation. Broken solid waste and an inoculum are mixed in a full wet type reactor for wet anaerobic fermentation, the wet anaerobic fermentation period hydraulic retention time (HRT) is 5-20 days, after fermentation processing, a fermentation material can be delivered to a dry method fermentation reactor with an infiltration device at the bottom for dry solid fermentation for production of the biogas, and the process combines the dual advantages of wet method fermentation and dry method fermentation. The fermentation process integrating the advantages of fast mass transfer and easy start-up characteristics of the wet method fermentation and reaction space saving of the dry method fermentation, and the like is disclosed. By combination of biomass multistage decomposition and transformation in the fermentation process and methane producing bacteria group enrichment principle, the wet fermentation process advantage is used, the wet fermentation process is used as a homogeneous inoculation stage of the dry method fermentation process, and the problems of difficult inoculation and slow start of the dry method fermentation can be solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

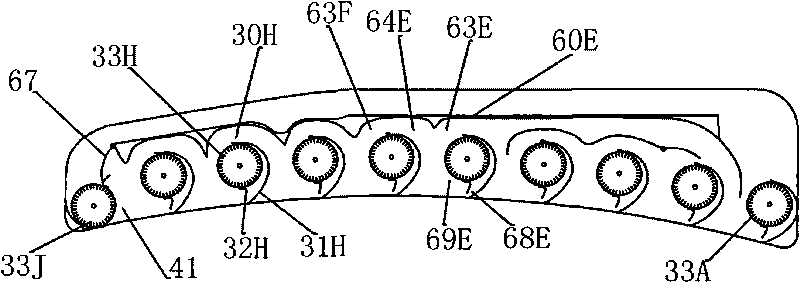

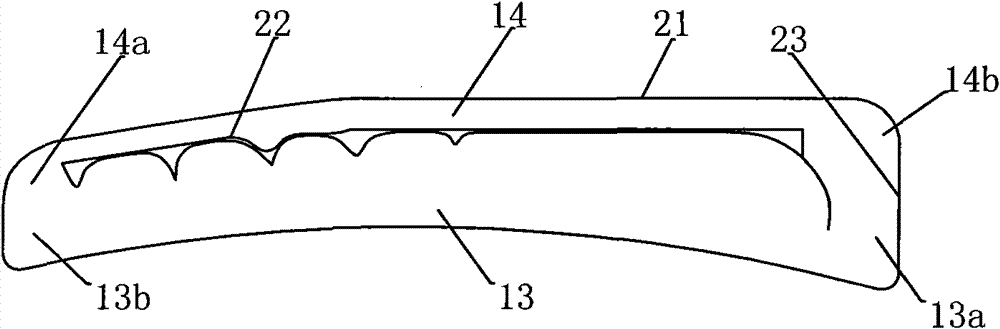

Two-stage integrative drying plant

InactiveCN101703992ACompact structurePerfect drying processPretreated surfacesCoatingsHeat pipe heat exchangerProcess engineering

The invention relates to a two-stage integrative drying plant which is characterized by comprising an oven body (10), a drying unit (60) and a heat pump device (80), wherein the oven body (10) comprises a drying oven cover (20) and a base (50); a drying cavity (13) and a recovery cavity (14) which are mutually communicated are arranged in the drying oven cover (20); the drying unit comprises a fan (30) which is provided with an inlet channel (63), an exhaust channel (64) and an air outlet channel (68); the fan (30) is a tangential fan; the heat pump device (80) comprises a heat pump subcooler(82), a heat pump cooler (83), a middle cooler (84), a heat tube heat exchanger (95), a heat pump compressor (89), a heat pump throttling valve (87), a heat pump condenser (88), a cold compressor (99) and a refrigerant evaporator (96), wherein the cold compressor (99), the middle cooler (84), the heat pump compressor (89), the heat pump condenser (88), the heat pump throttling valve (87) and the refrigerant evaporator (96) are successively connected and loop the first and the last. The invention is suitable for processing equipment for continuous running thin strip objects and has the effectsof small volume, high efficiency and energy saving.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

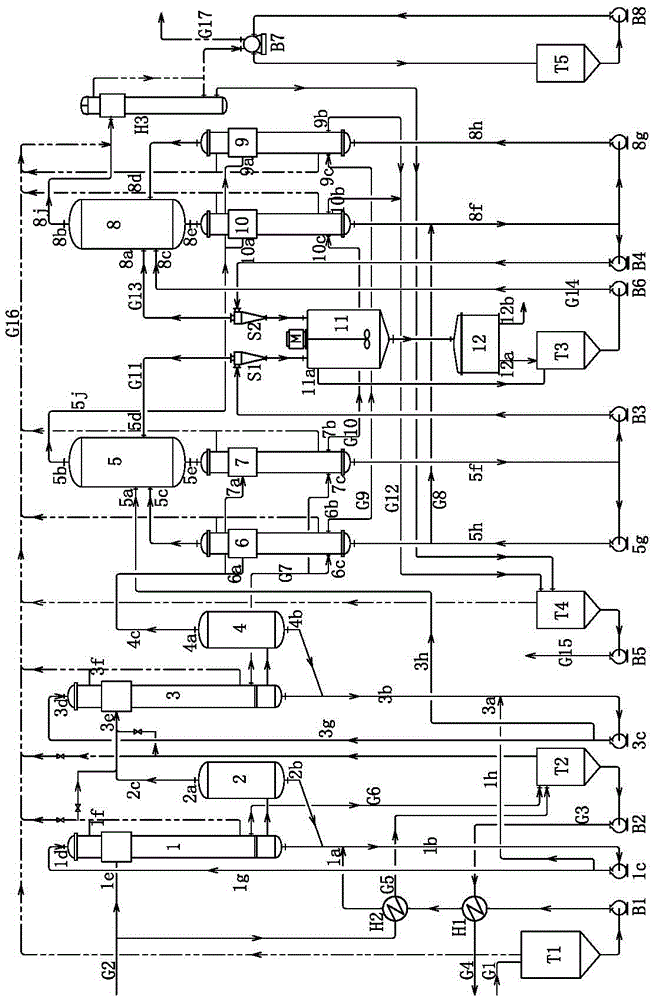

Evaporation and recycling process of methanol water solution of sodium chloride

ActiveCN106673961AImprove environmental benefitsLabor savingHydroxy compound separation/purificationAlkali metal chloridesSingle effectSolid phases

The invention relates to an evaporation and recycling process of a methanol water solution of sodium chloride. The evaporation and recycling process sequentially comprises the following steps: (1) pre-heating a new raw solution for raising the temperature; (2) heating and evaporating the raw solution by utilizing fresh steam in a single-effect falling-film evaporator to form a single-effect concentrated solution, and evaporating methanol and moisture to generate single-effect steam; (3) in a double-effect falling-film evaporator, heating and evaporating the single-effect steam by utilizing the single-effect concentrated solution to obtain a double-effect concentrated solution, and generating double-effect steam; (4) in a three-effect forced circulating evaporation and crystallization unit, heating the double-effect concentrated solution by utilizing the double-effect steam to form three-effect crystal slurry, and generating three-effect steam; (5) enabling the three-effect crystal slurry to enter a three-effect hydrocyclone for concentrating and thickening, returning a light phase back to the three-effect forced circulating evaporation and crystallization unit for circulating, and conveying a heavy phase into a thick tank for concentrating and thickening; and (6) conveying the heavy phase of the thick tank into a centrifuge for separating, discharging sodium chloride crystals from a solid-phase outlet of the centrifuge, and conveying a mother solution into a mother solution tank. The process is low in energy consumption and can realize complete recycling of sodium chloride and methanol.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

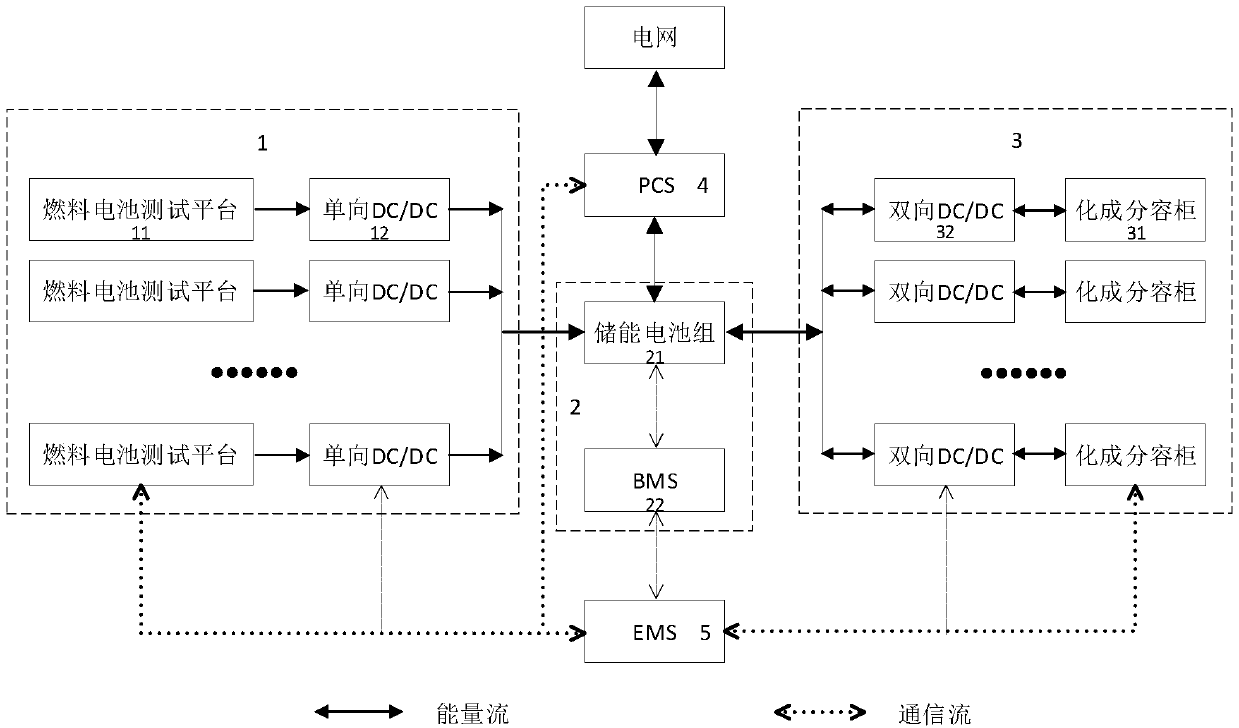

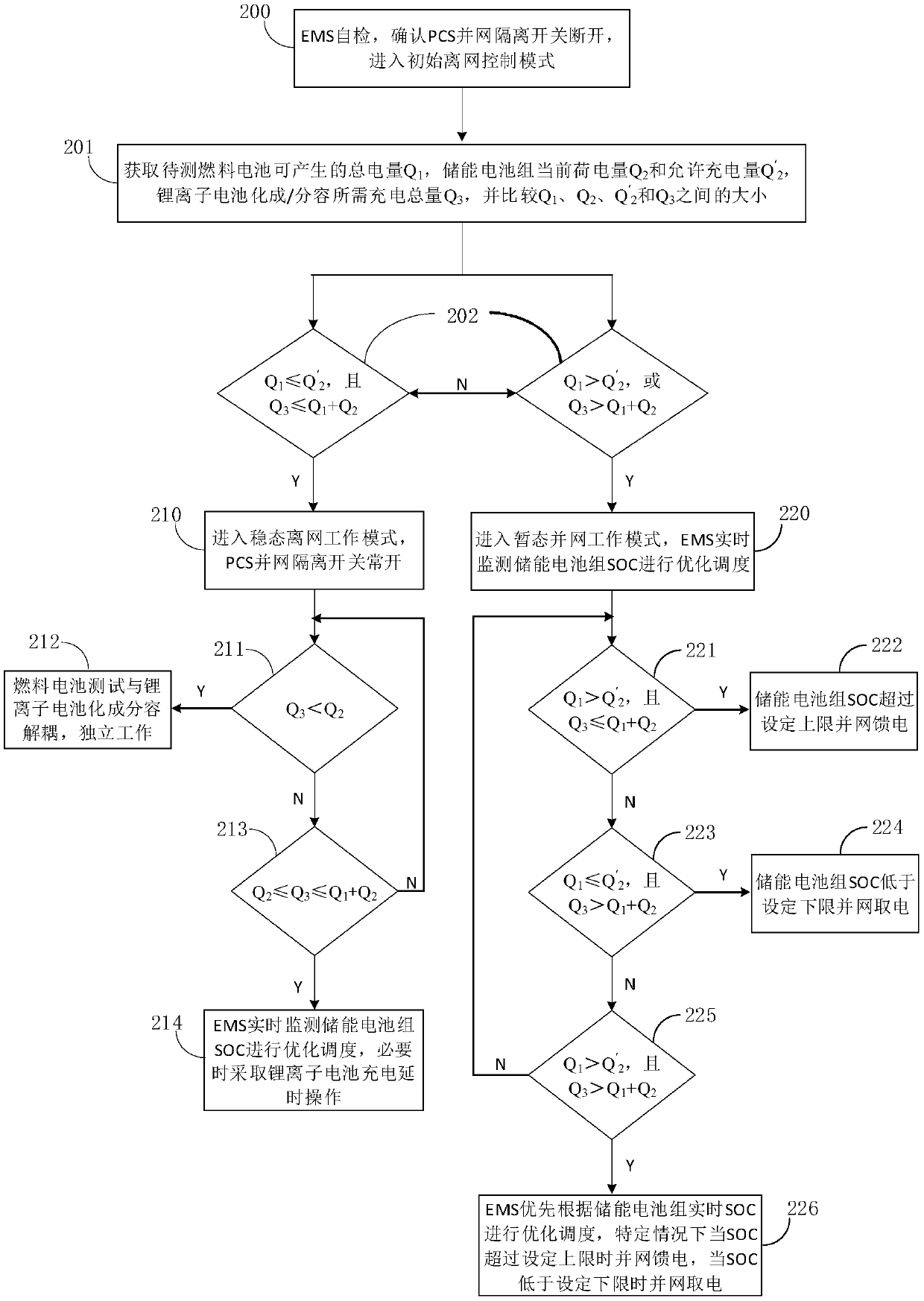

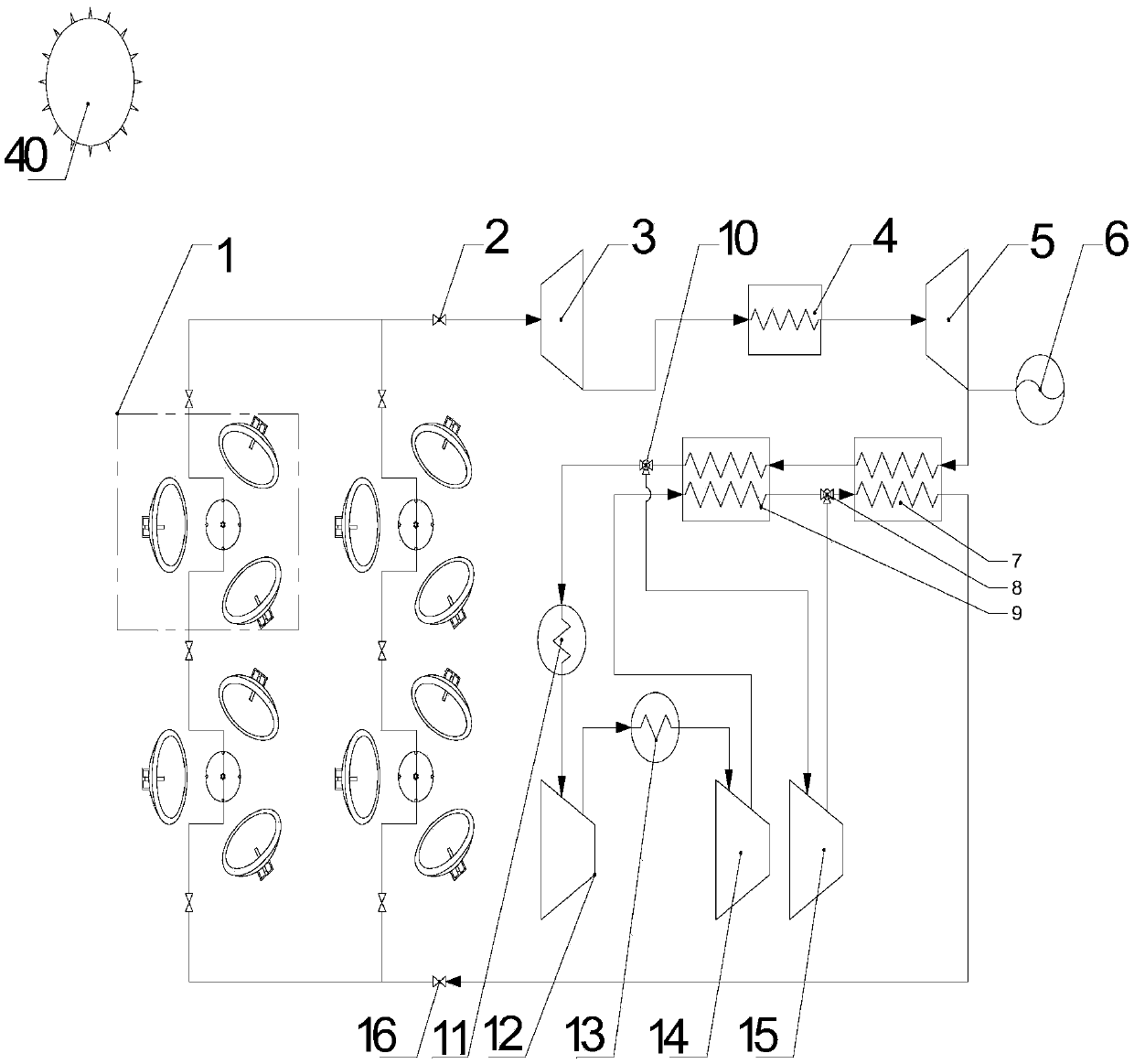

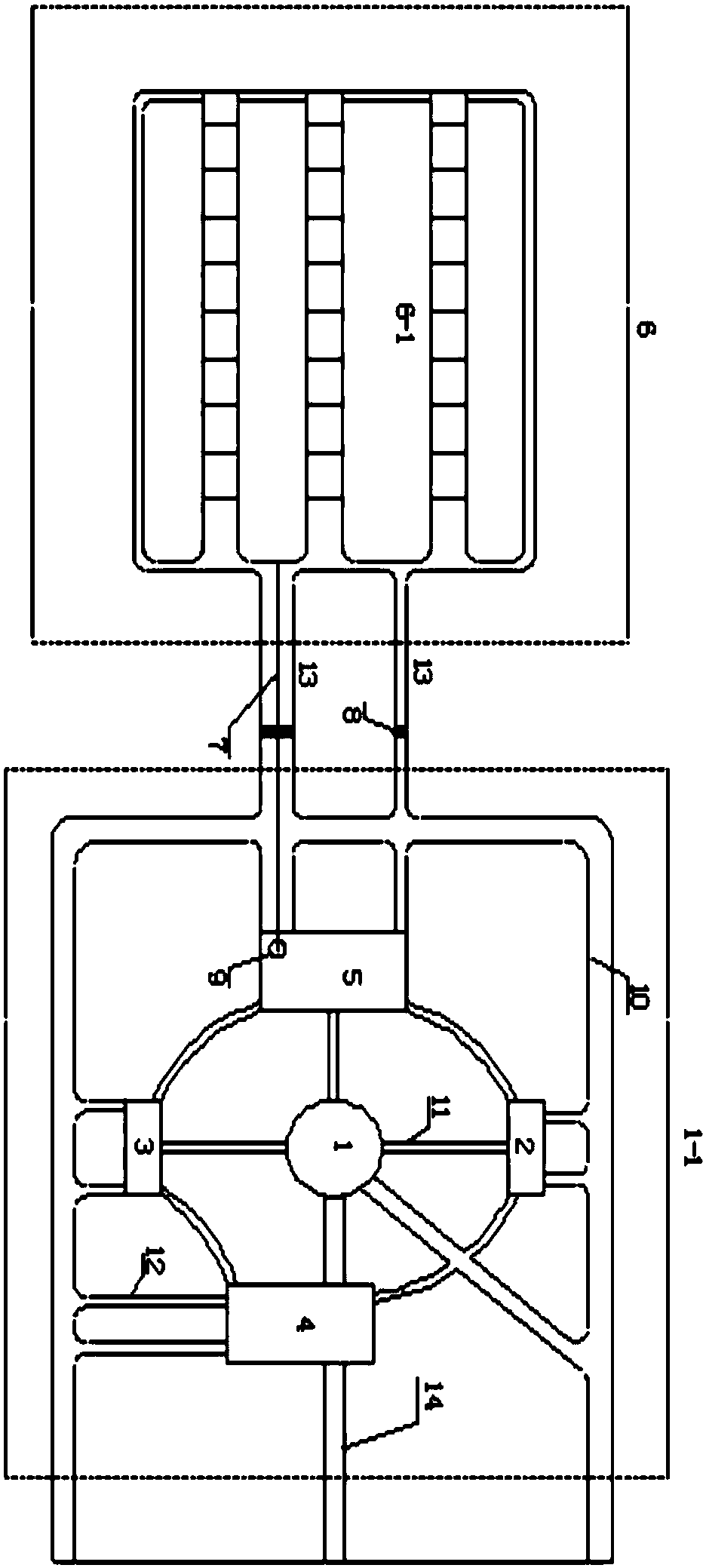

Fuel cell test and lithium ion battery formation capacity grading coupling system and method

PendingCN111381174ARealize a closed loopEfficient use ofFinal product manufactureElectrical testingFuel cellsElectrical battery

The invention discloses a fuel cell test and lithium ion battery formation capacity grading coupling system. The system comprises a fuel cell test unit, an energy storage battery, a lithium ion battery formation and capacity grading unit, an energy storage bidirectional inverter and an energy management unit; the energy management unit is in communication connection with the fuel cell test unit, the energy storage cell, the lithium ion battery formation capacity grading unit and the energy storage bidirectional inverter. The energy storage cell is electrically connected with the fuel cell testunit, the lithium ion battery formation capacity grading unit and the energy storage bidirectional inverter. The invention also discloses a control method of the fuel cell test and lithium ion battery formation capacity grading coupling system. According to the invention, the energy waste that the conventional resistive load consumes the electric energy generated by the fuel cell system through heat energy is avoided, and meanwhile, the additional electric energy consumption for the resistive load cooling equipment is also saved.

Owner:天津格力钛新能源有限公司 +1

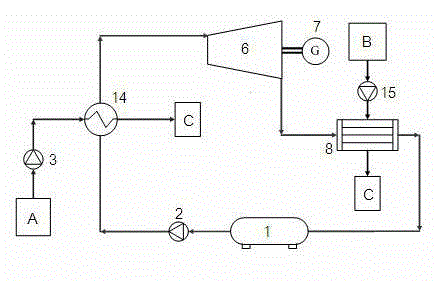

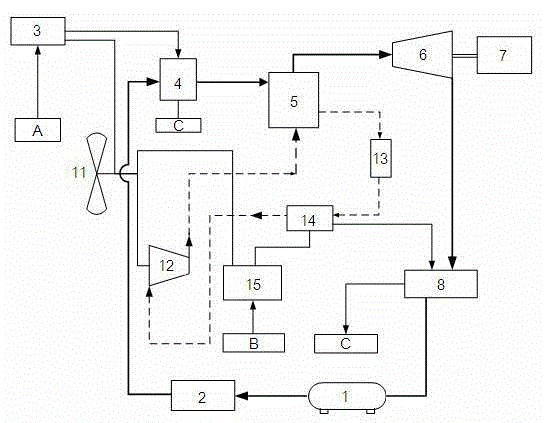

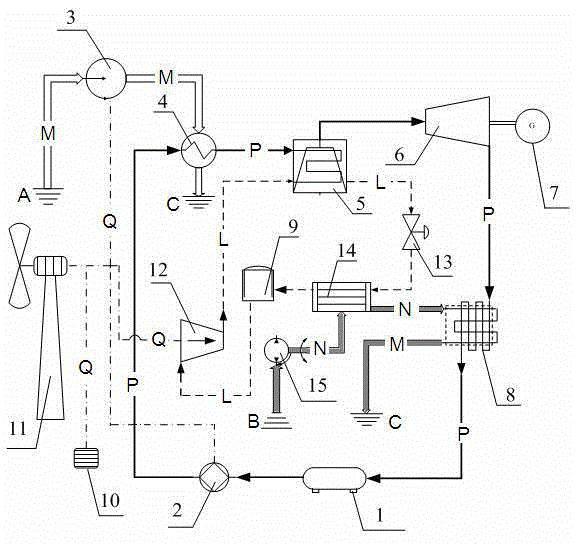

Method and device for utilizing ocean temperature difference to generate electricity

ActiveCN102213199BLarge temperature differenceIncreased efficiency of closed loopsMachines/enginesMechanical power devicesThermal energyOcean thermal energy conversion

The invention provides an ocean thermal energy conversion method and an ocean thermal energy conversion device. The method comprises the following steps of: heating a low-boiling-point working medium by using hot seawater on a surface of ocean; evaporating the low-boiling-point working medium; feeding into a turbine to push a turbo generator set to work for power generation; condensing working medium gas which is exhausted from the turbine into liquid by using cold seawater on a deep layer of the ocean; heating by using the hot seawater; feeding into the turbine to make the working medium gasevaporated; pushing the turbo generator set to work for the power generation; cyclically executing the steps; and continuously carrying out power generation. Power is generated by using ocean surfacewind power, a heat pump device is driven by the power, the temperature of the working medium is further raised by using a medium of the heat pump device, and the volume expansion ratio of the workingmedium is improved; and the temperature of the cold seawater is further reduced by using the medium of the heat pump device, the working medium exhausted gas is condensed by using the low-temperatureseawater, and a condensing effect of the working medium exhausted gas is improved. The method and the device improve the efficiency of closed cycle generation of ocean thermal energy conversion, realize the comprehensive utilization of ocean thermal energy and wind energy, have an important practical value, provide environment-friendly energy sources, and are easy to use and promote in large scale.

Owner:DONGFANG TURBINE CO LTD +2

Single-stage integrated drying equipment

InactiveCN101703991ACompact structurePerfect drying processPretreated surfacesCoatingsProcess engineeringProduct gas

The invention relates to single-stage integrated drying equipment which is characterized by comprising a box body (10), a drying unit (60) and a heat pump device (80), wherein the box body (10) comprises a baking oven cover (20) and a base (50); a drying cavity (13) and a recovering cavity (14) which are mutually communicated are arranged in the baking oven cover (20), and a gas passage with internal circulation drying is formed; the drying unit comprises a blower (30) and is provided with an air inlet passage (63), an air exhaust passage (64) and an air outlet passage (68); the heat pump device (80) comprises a heat pump compressor (89), a heat pump throttling valve (87), a heat pump condenser (88) and a refrigeration evaporator (96); and the heat pump compressor (89), the heat pump condenser (88), the heat pump throttling valve (87) and the refrigeration evaporator (96) are sequentially connected to form an end-to-end circulation structure. The invention is widely suitable for processing equipment to dry thin belt-shaped objects which move continuously, and has the advantages of small volume and no discharge of waste gas, very obvious social benefit and economic benefit, and energy is saved by more than 60%.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

Integral overlapping drying equipment

InactiveCN101648181AImprove adaptabilityReduce cryogenic stage cooling requirementsPretreated surfacesCoatingsRefrigeration compressorProcess equipment

The invention relates to integral overlapping drying equipment which is characterized by comprising a box body (10), a blowing unit (60) and a hot pump device (80), wherein the box body (10) comprises a drying box cover (20) and a base (50); the drying box cover (20) is internally provided with drying cavities (13) and recovering cavities (14) which are mutually connected end to end and; the blowing unit (60) comprises a blower (30) and is internally provided with a wind inlet passage (63), a wind discharge passage (64) and a wind outlet passage (68); the hot pump device (80) comprises a hot pump compressor (89), a hot pump throttle valve (87), an evaporation condenser (85), a hot pump condenser (88), a refrigeration compressor (99), a refrigeration evaporator (96) and a refrigeration throttle valve (97) to form a hot pump system and a refrigeration system; and the hot pump system and the refrigeration system are overlapped by the evaporation condenser (85) to form the hot pump devicetogether. The integral overlapping drying equipment is widely suitable for processing equipment for drying thin strip-shaped objects continuously traveling and has the advantages of simplified structure, small volume, zero waste gas discharge and energy consumption reduction.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

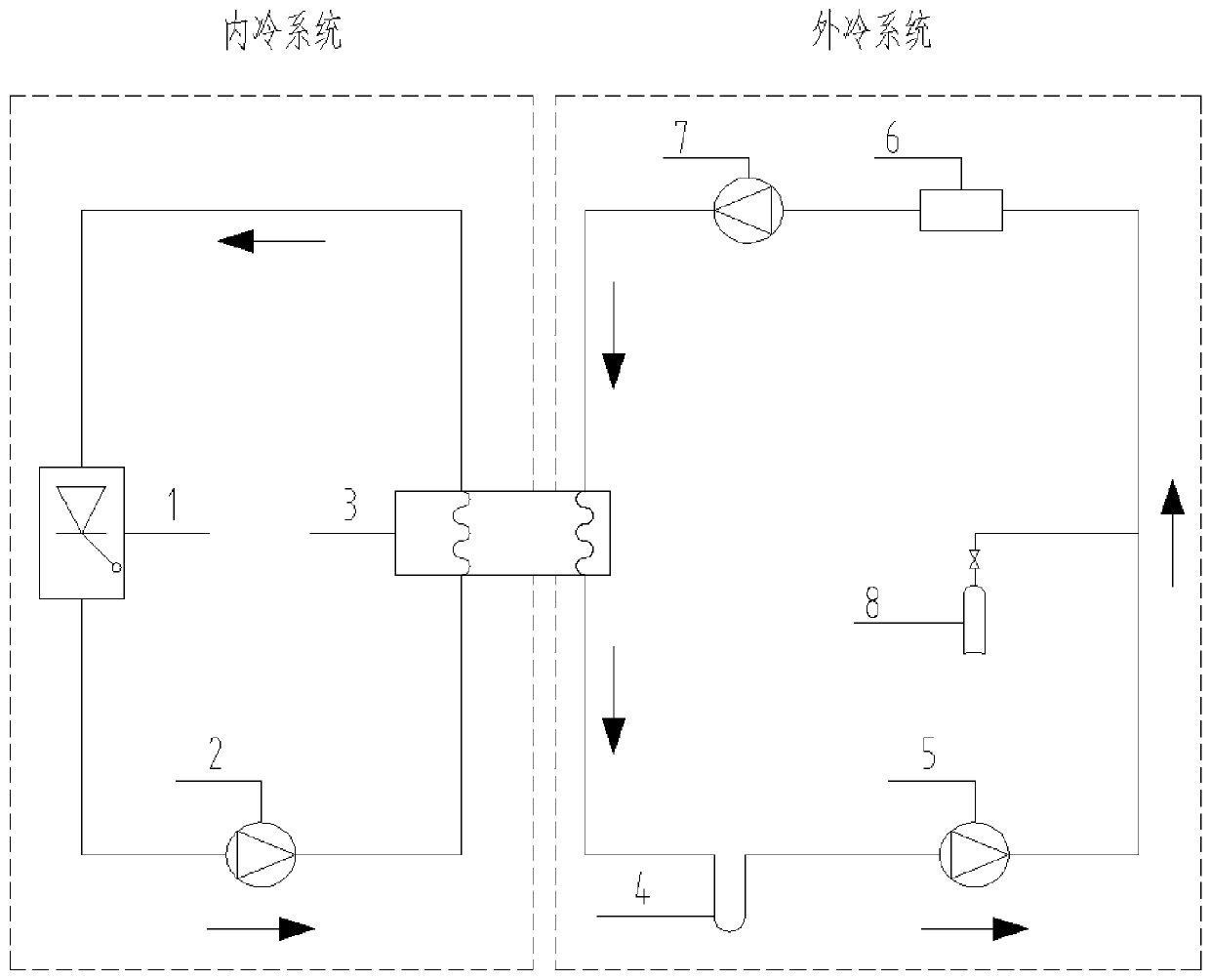

Closed converter valve external cooling system and method based on soil source heat exchange

PendingCN110806053ARealize a closed loopSmall footprintLighting and heating apparatusCooling fluid circulationAtmospheric sciencesEngineering

The invention discloses a closed converter valve external cooling system and method based on soil source heat exchange. A cooling system comprises an intermediate heat exchanger for transmitting heatof an internal cooling system to the external cooling system; and the external cooling system is internally provided with an underground heat exchanger; a heat transfer medium, receiving heat generated by the internal cooling system, of the intermediate heat exchanger is transmitted to the underground heat exchanger, the underground heat exchanger discharges the system heat load brought by the heat transfer medium to the ground, and the cooled heat transfer medium is injected into the intermediate heat exchanger to be circulated. The intermediate heat exchanger is adopted to cool a circulationcooling working medium of the internal cooling system, the heat transfer medium receiving the heat is transmitted to the underground heat exchanger, the underground heat exchanger discharges the system heat load to the ground, and soil in the ground is utilized as a natural cooling medium; and compared with a cooling mode of a water cooling tower, water resources are greatly saved, the occupied area of equipment on the ground is greatly decreased compared with that of an air cooler, and the equipment operation noise is reduced.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

Sewage purifying method for coal conveying system

InactiveCN106745938AAchieving zero emissionsImplement zero emissionsTreatment involving filtrationMultistage water/sewage treatmentSludgeSmall footprint

The invention discloses a sewage purifying method for a coal conveying system. The method comprises the following steps: step 1, introducing conveyed coal washing water; step 2, treating sewage in a secondary sedimentation tank; step 3, treating sewage large-particle suspended solids; step 4, treating sewage small-particle suspended solids; step 5, absorbing and intercepting sewage filtered in a filtering area through a filtering layer, so that water flows into a clear water tank after being purified and rising to a clear water area, and sludge in a sludge concentration area is intermittently discharged into a primary sedimentation tank for sedimentation through a sludge discharging valve at the bottom of a water purifier. The sewage purifying method disclosed by the invention has the benefits that that a wastewater recycling system is brief in process, reliable in performance, relatively low in investment cost, relatively high in price performance ratio, small in area occupied by system equipment, relatively low in running cost, and obvious in environmental benefits and economic benefits.

Owner:HARBIN HAOWEI WEIYE TECH DEV CO LTD

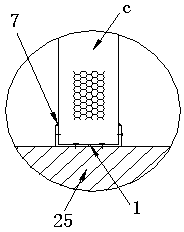

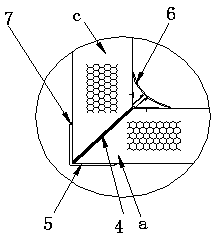

Vacuum atomization phase change refrigeration plant

ActiveCN108061402ANo cloggingEndothermic vaporization completeRefrigeration machinesEngineeringPressure difference

The invention discloses a vacuum atomization phase change refrigeration plant which comprises an atomizer, an atomization cavity, a self-adaption pressure control valve, a heat exchanger and a vacuumpump. The atomizer is used for atomizing refrigerating fluid and is installed in the atomization cavity, the self-adaption pressure control valve comprises a valve channel, a valve plate plugging theinterior of the valve channel and at least one pressure control valve body distributed on the valve plate, the inlet end of the valve channel communicates with the atomization cavity, the outlet end of the valve channel communicates with a cold source inlet of the heat exchanger, different opening degrees of the pressure control valve bodies can be formed according to different pressure differences of the two sides of the valve plate, air mist can enter the cold source inlet of the heat exchanger through the pressure control valve bodies, and an air sucking opening of the vacuum pump communicates with a cold source outlet of the heat exchanger. By means of the vacuum atomization phase change refrigeration plant, the refrigerating efficiency is improved, the running cost is reduced, energyconservation and environmental protection are achieved, and no special requirement for the refrigerating fluid is needed.

Owner:ELIVAC COMPANY

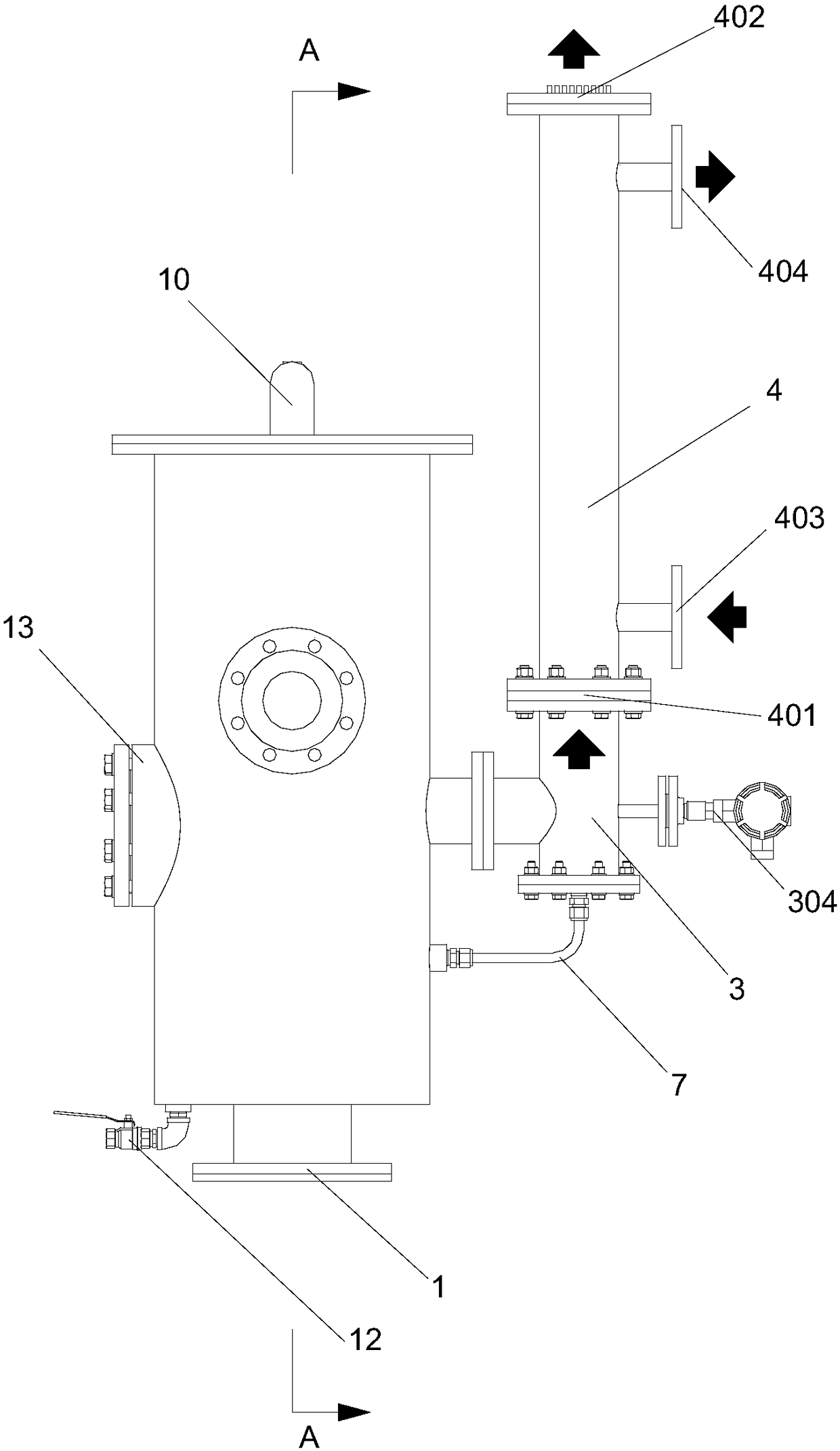

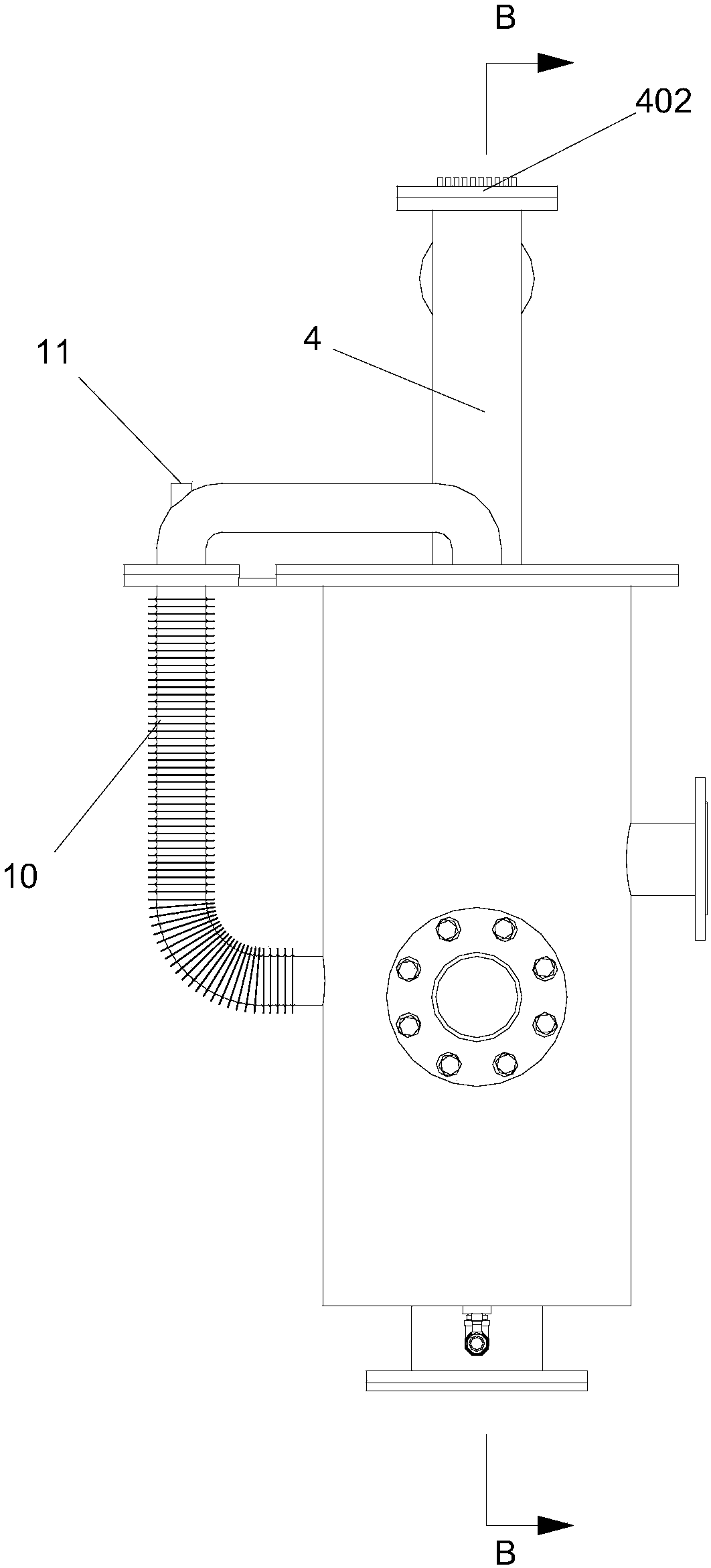

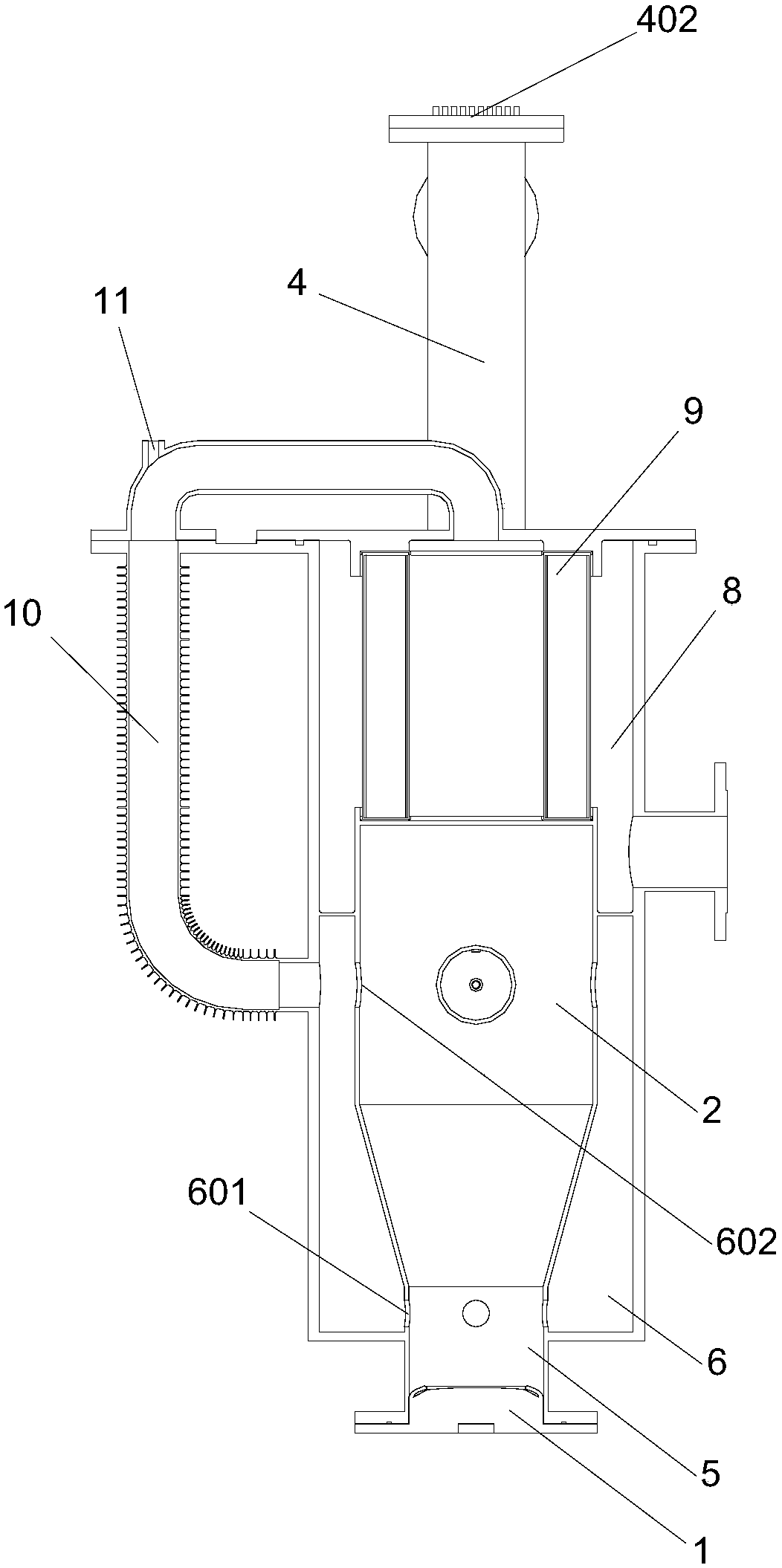

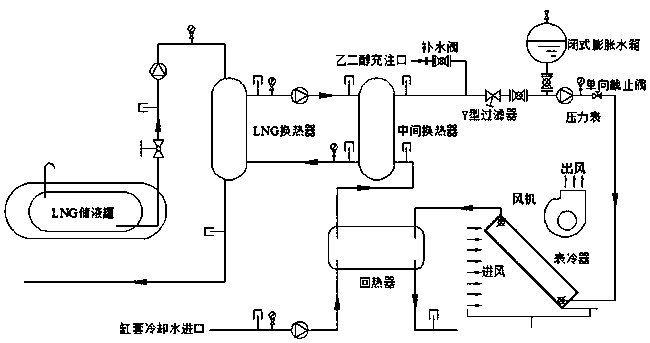

LNG cold energy utilization device

InactiveCN109539626ARealize a closed loopPressure vesselsContainer discharging from pressure vesselsExpansion tankIntermediate heat exchanger

The invention relates to an LNG cold energy utilization device including an LNG liquid storage tank, an LNG heat exchanger, an intermediate heat exchanger, a Y-type filter, a closed expansion water tank, a pressure gauge, a fan, a surface air cooler and a heat regenerator; an outflow pipe of the LNG liquid storage tank communicates with an inflow pipe of the LNG heat exchanger through a circulating medium circulation pump, an outflow pipe of the LNG heat exchanger communicates with an inflow pipe of the intermediate heat exchanger through a circulating medium circulation pump, a glycol fillingport communicates with a water supply valve through a pipeline, the water supply valve communicates with the Y-type filter through a pipeline, an outflow pipe of the intermediate heat exchanger communicates with the Y-type filter, the Y-type filter communicates with the pressure gauge through the water supply valve, the closed expansion water tank communicates with the pressure gauge through thewater supply valve, and the pressure gauge communicates with the surface air cooler through a one-way stop valve, and the surface air cooler communicates with the heat regenerator through a pipeline.The LNG cold energy utilization device has the advantages that LNG cold energy on a ship is applied to ship air conditioning systems, and energy saving and environmental protection are achieved.

Owner:ZHEJIANG OCEAN UNIV

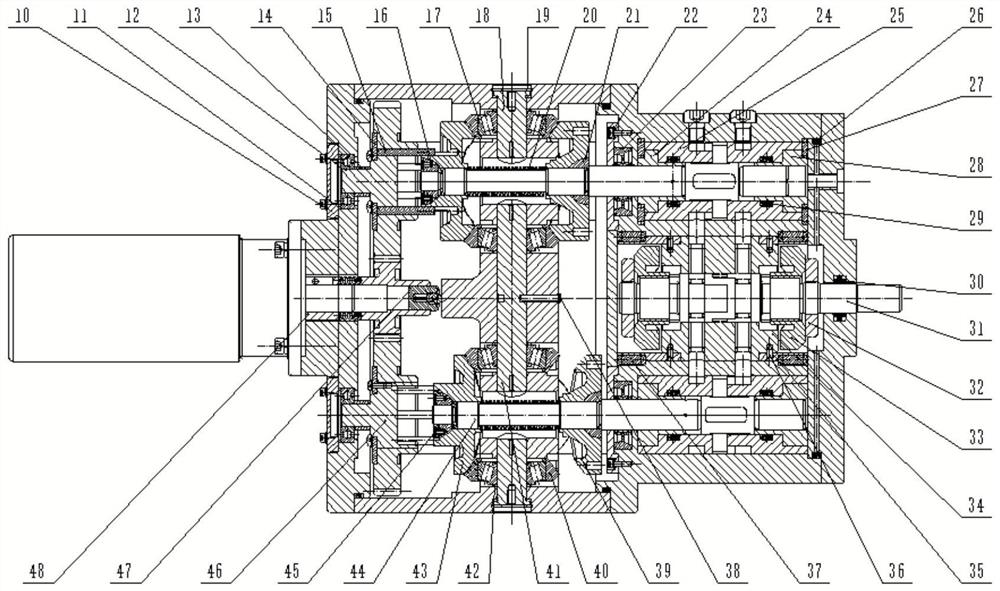

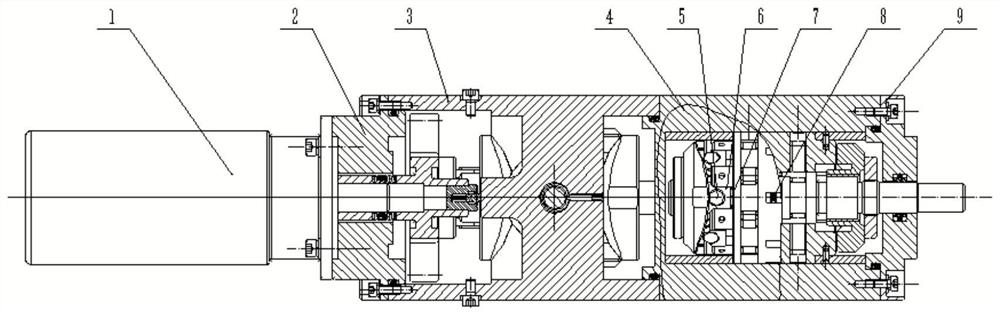

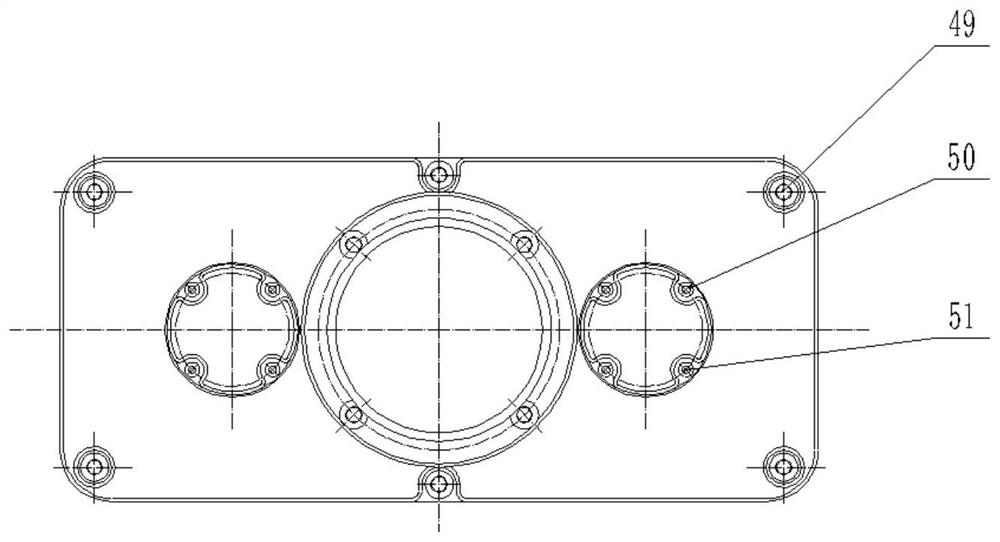

Novel electro-hydraulic motor

PendingCN112196760ARealize a closed loopImprove efficiencyPlungersTrunk pistonsHydraulic motorGear wheel

A novel electro-hydraulic motor comprises a motor, a pump and a hydraulic motor. Initial torque is input through a motor shaft, the torque is transmitted to a space cam through meshing transmission ofa gear pair, and a space cam on a piston shaft generates reciprocating motion under the constraint of a bevel roller. Water is sucked in and pressed out through reciprocating motion of the piston, apressing opening of the piston corresponds to a suction opening of the hydraulic motor, a suction opening of the hydraulic pump corresponds to an outlet of the hydraulic motor, and therefore a closedloop between the pump and the hydraulic motor is achieved; high-pressure fluid pushes the piston in a motor cylinder body to move, and then two end face cams are driven to rotate to convert pressure energy into rotating mechanical energy; and splines on the cams enable a motor shaft to rotate. The working efficiency of the novel electro-hydraulic motor is greatly improved, on the other hand, the service life of the electro-hydraulic motor is prolonged, and the novel electro-hydraulic motor has the advantages of being large in torque and small in overall structure.

Owner:ZHEJIANG UNIV OF TECH

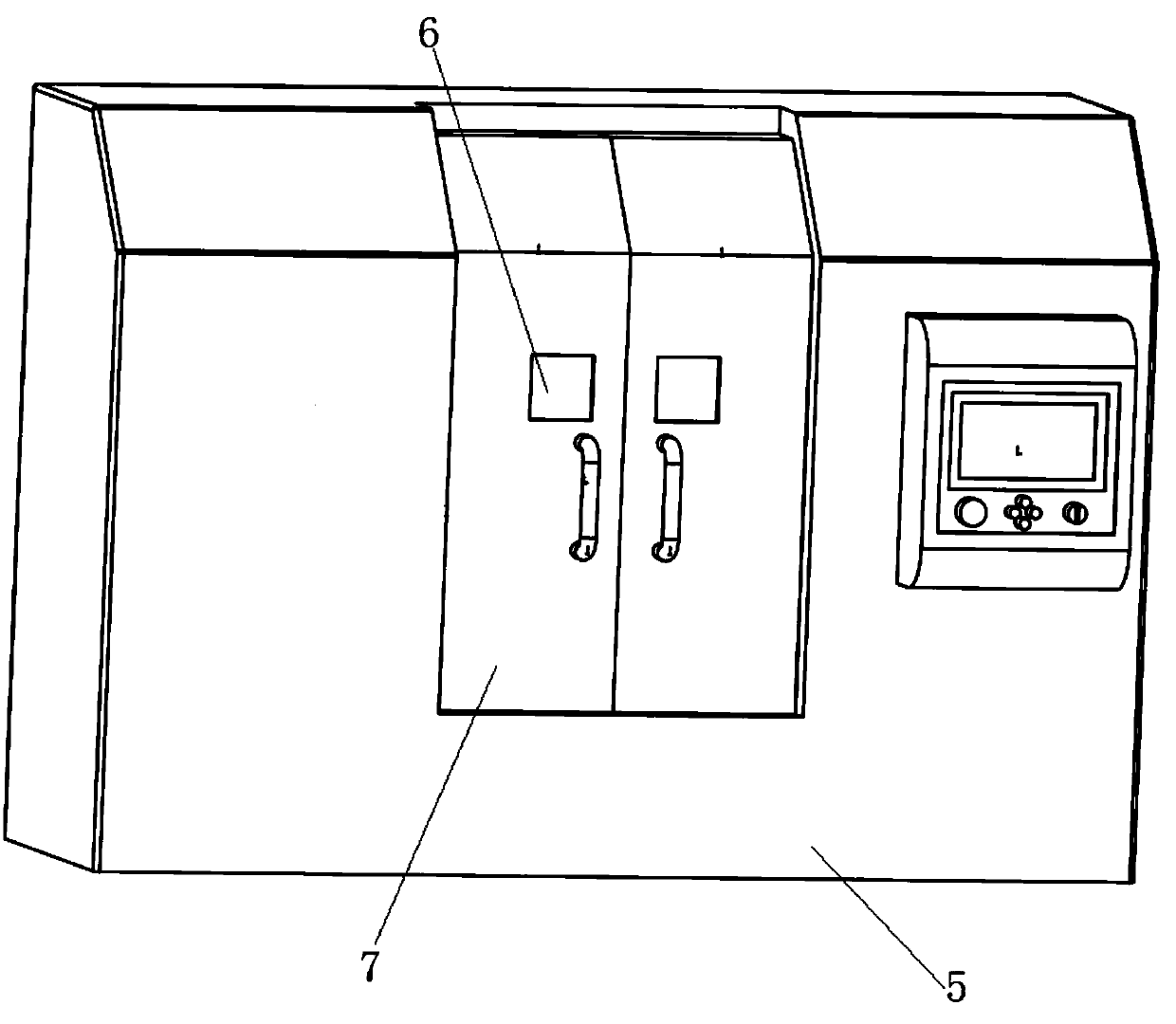

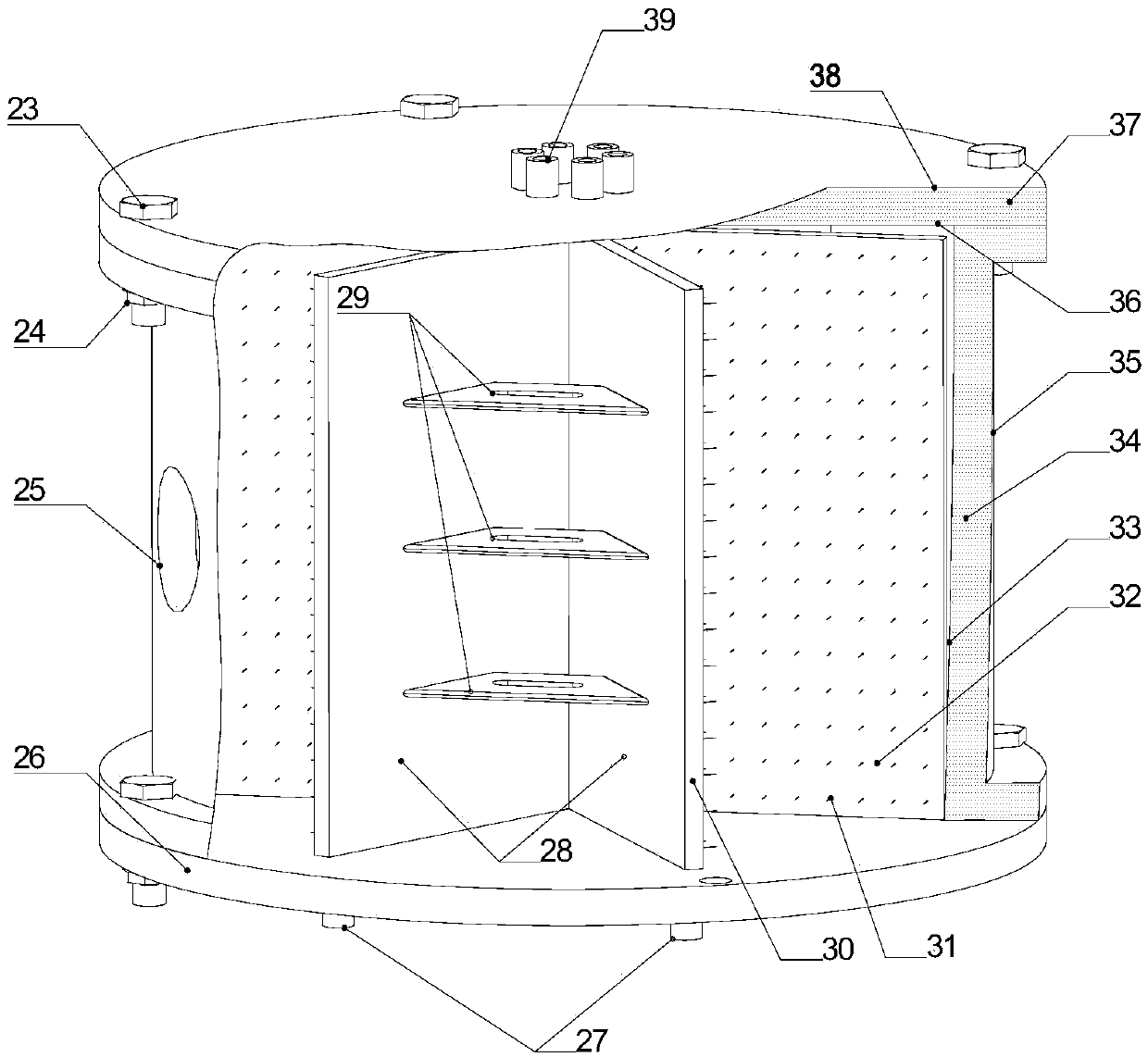

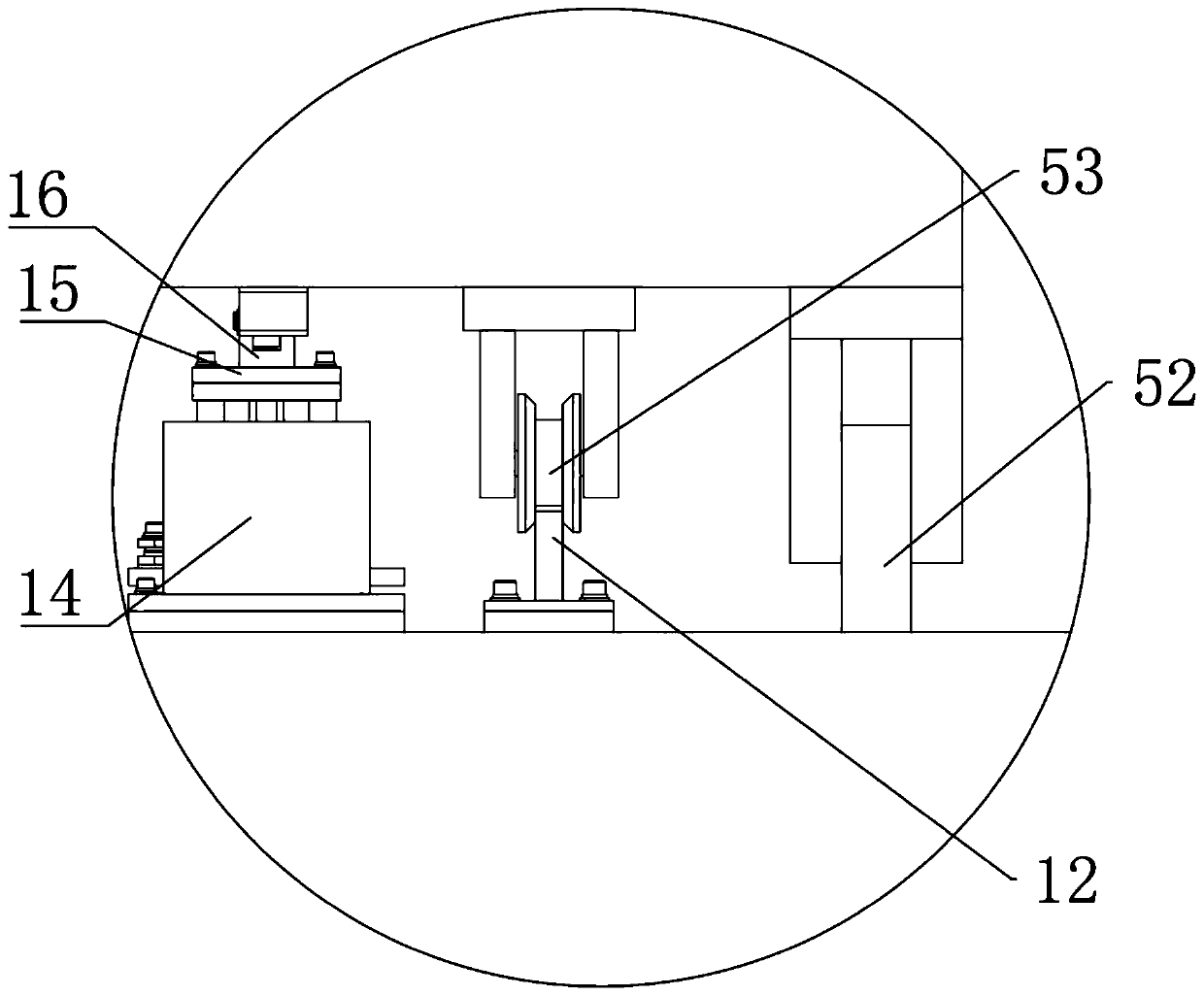

Welding device for nuclear-grade gate valve element seal face repairing

PendingCN109955008AEasy to shipSmall footprintWelding/cutting auxillary devicesAuxillary welding devicesNuclear gradeNuclear engineering

The invention belongs to the technical field of nuclear power plant overhauling, and particularly relates to a welding device for nuclear-grade gate valve element seal face repairing, and aims at achieving the purpose that for limitation of existing technologies and equipment, welding equipment applied to online repairing of a radioactive stained nuclear-grade gate valve plate in a nuclear power plant radioactive workshop is invented to repair the nuclear-grade gate plate in which cracks, large pits or corrosion or the like exist in the seal face, the vacancy in the domestic online nuclear-grade gate valve plate repairing is filled up, and meanwhile the construction environment is improved, wherein the above defects cannot be repaired only through turning and grinding. The welding device is characterized by comprising a base structure, a shell structure, a welding machine and a waste gas adsorption structure; and since a surfacing device can be applied into the nuclear power plant workshop, the polluted valve plate can be repaired online without being taken out of the workshop, and the problem that radioactive stained equipment cannot be taken out of the workshop for offline overhauling is effectively solved.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

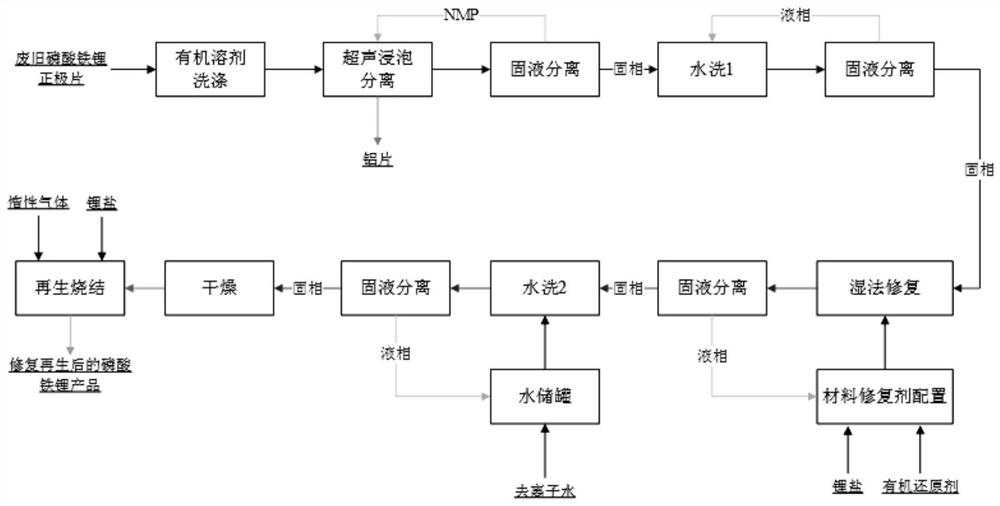

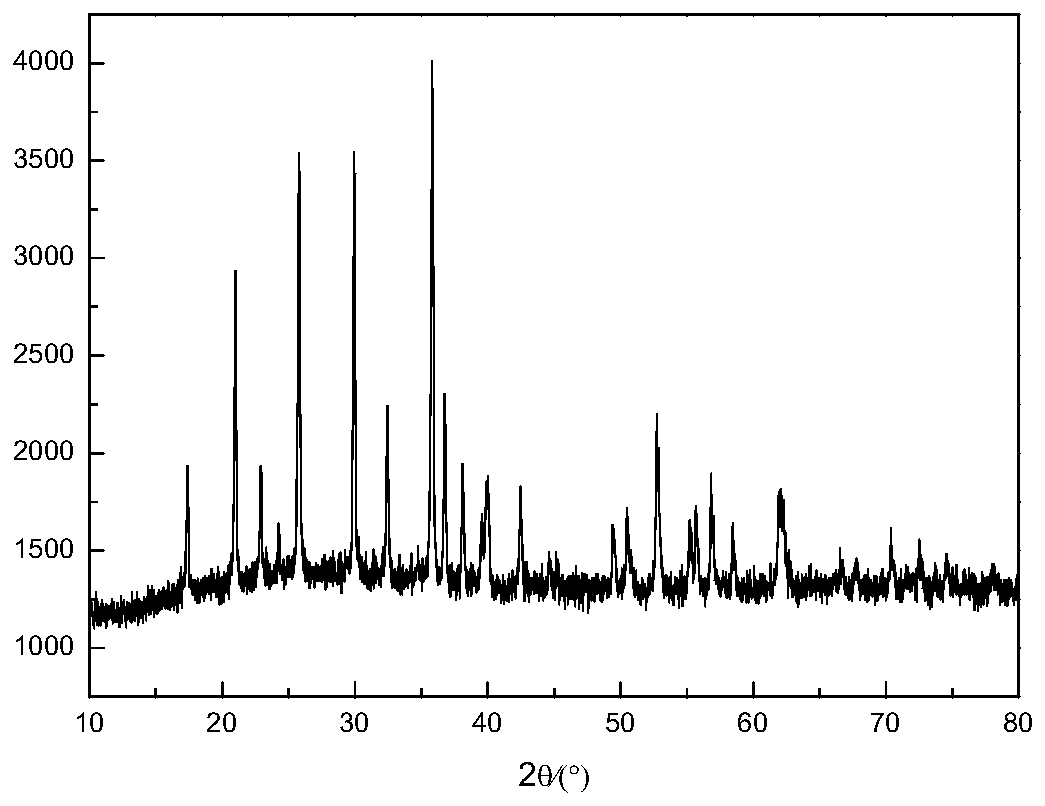

Wet repair and regeneration method for waste lithium iron phosphate positive electrode material

PendingCN114835098ARich sourcesEasy to recyclePositive electrodesWaste accumulators reclaimingLithium iron phosphateOrganic solvent

The invention discloses a wet repair and regeneration method for a waste lithium iron phosphate positive electrode material, which comprises the following steps: S1, soaking a waste lithium iron phosphate positive electrode plate by using an organic solvent, and drying to obtain a clean lithium iron phosphate positive electrode plate; s2, soaking the clean lithium iron phosphate positive plate in N-methyl pyrrolidone, performing ultrasonic treatment, and performing solid-liquid separation to obtain LFP powder and an aluminum sheet; s3, the LFP powder is placed in a material repairing agent for material repairing, and repaired LFP powder is obtained through solid-liquid separation and water washing; and S4, mixing the dried and repaired LFP powder with excessive Li2CO3 or LiOH, and carrying out regeneration sintering under the protection of a nitrogen or argon atmosphere to obtain the regenerated and repaired lithium iron phosphate powder. According to the method, the failure mechanism of the lithium iron phosphate is fully utilized, the damaged lithium iron phosphate positive electrode material is directly repaired in a wet repair mode, chemical components in the lithium iron phosphate positive electrode material are recycled to the maximum extent, and the recycling cost of the material is saved to the maximum extent.

Owner:SHANGHAI ELECTRICGROUP CORP

Two-stage integrative drying plant

InactiveCN101703992BReduce consumptionImprove energy efficiencyPretreated surfacesCoatingsRefrigeration compressorProcess equipment

The invention relates to a two-stage integrative drying plant which is characterized by comprising an oven body (10), a drying unit (60) and a heat pump device (80), wherein the oven body (10) comprises a drying oven cover (20) and a base (50); a drying cavity (13) and a recovery cavity (14) which are mutually communicated are arranged in the drying oven cover (20); the drying unit comprises a fan (30) which is provided with an inlet channel (63), an exhaust channel (64) and an air outlet channel (68); the fan (30) is a tangential fan; the heat pump device (80) comprises a heat pump subcooler(82), a heat pump cooler (83), a middle cooler (84), a heat tube heat exchanger (95), a heat pump compressor (89), a heat pump throttling valve (87), a heat pump condenser (88), a cold compressor (99) and a refrigerant evaporator (96), wherein the cold compressor (99), the middle cooler (84), the heat pump compressor (89), the heat pump condenser (88), the heat pump throttling valve (87) and the refrigerant evaporator (96) are successively connected and loop the first and the last. The invention is suitable for processing equipment for continuous running thin strip objects and has the effectsof small volume, high efficiency and energy saving.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

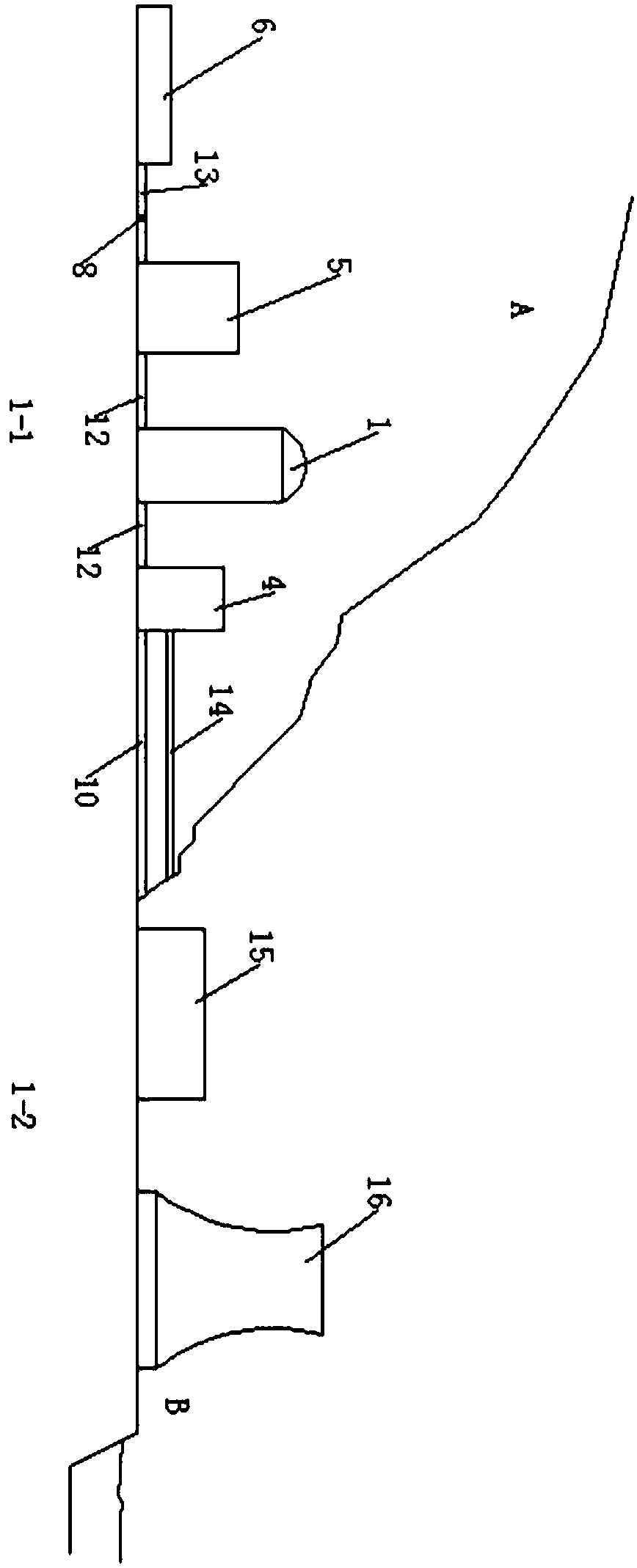

Underground nuclear power plant having low-and-intermediate-level radioactive waste disposal site

ActiveCN106128534ASave design and construction costsAvoid radioactive releaseNuclear energy generationFacility decommissioningNuclear plantCyclic process

The invention discloses an underground nuclear power plant having a low-and-intermediate-level radioactive waste disposal site. The underground nuclear power plant comprises a nuclear island arranged in an underground cavern group of a nuclear island of a mountain and a conventional island arranged on a ground platform at the outer side of the mountain. The nuclear island consists of a reactor workshop arranged at the center, a nuclear fuel workshop, a safety workshop, an electrical workshop, and a nuclear auxiliary workshop, wherein the nuclear fuel workshop, the safety workshop, the electrical workshop, and the nuclear auxiliary workshop encircle the reactor workshop. And the nuclear island also includes a low-and-intermediate-level radioactive waste disposal site arranged in the underground cavern group of the nuclear island of the mountain; and the low-and-intermediate-level radioactive waste disposal site is communicated with the nuclear auxiliary workshop of the nuclear island by a waste transport tunnel. According to the invention, on the basis of combination of characteristics of the underground nuclear power plant, the processing requirement of the low-and-intermediate-level radioactive waste can be met, the closed circulation of fuels can be realized, and the radioactive contamination possibly occurring during the fuel cycle process can be reduced; and the unified planning and building of the nuclear power plant and the disposal site can be realized and costs are saved.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

A recovery method for lithium iron phosphate material

ActiveCN107275705BRealize a closed loopAvoid wastingWaste accumulators reclaimingBattery recyclingLithium iron phosphateElectrical battery

The invention discloses a method for recovering and repairing a lithium iron phosphate material. The method disclosed by the invention comprises the following steps: by taking positive leftover materials in a battery production process, positive plates obtained after dismantling defective batteries and / or positive plates obtained by recovering and dismantling waste batteries as raw materials, heating, maintaining the temperature, and separating current collector aluminum foils so as to obtain the recovered lithium iron phosphate material; and repairing the lithium iron phosphate material in a manner of adding an element source. According to the method disclosed by the invention, more elements are added according to a stoichiometric ratio, the re-synthetic repair reaction is fully carried out, the recovered and repaired lithium iron phosphate material is a pure phase lithium iron phosphate material, and the ordinary commercial lithium iron phosphate material level can be reached. The method uses lithium iron phosphate in the battery production process and the recovery phase and has the advantage of capacity of realizing closed cycle.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Disc type power generation device based on V-shaped heat absorption wall cavity type solar absorber

PendingCN109539583AGood for heat returnReduce absorptionSolar heating energyFrom solar energyBrayton cycleSolar disc

The invention discloses a disc type power generation device based on a V-shaped heat absorption wall cavity type solar absorber. The device comprises a light-heat conversion unit and a supercritical CO2 brayton cycle power generation system; the light-heat conversion unit comprises a V-shaped heat absorption wall cavity type solar absorber, collecting lenses and CO2 pipeline, wherein a plurality of collecting lenses are uniformly arranged on the periphery of the V-shaped heat absorption wall cavity type solar energy absorber, and the V-shaped heat absorption wall cavity type solar energy absorber is connected to the supercritical CO2 brayton cycle power generation system through the CO2 pipeline; the V-shaped heat absorption wall cavity type solar energy absorber is internally provided with a V-shaped heat absorption cavity assembly, wherein the V-shaped heat absorption cavity assembly comprises a plurality of heat exchange layers, an included angle alpha is formed between every two adjacent heat exchange layers, V-shaped closed spaces are arranged as heat preservation chambers or heat absorption cavities, the heat preservation chambers and the heat absorption chambers are alternately arranged, and an optical incident window directly faces the heat absorption chamber; and a heat exchange pipe is embedded into the heat exchange layers. The device has the advantages of being highin thermoelectric conversion efficiency, high in power generation efficiency, low in cost and the like. The invention belongs to the technical field of solar disc type power generation.

Owner:SOUTH CHINA UNIV OF TECH +1

A Closed Circulation System for Improving Operation Efficiency of Gas Drain Pump

ActiveCN107152400BImprove operational efficiencyAvoid enteringFlow mixersTransportation and packagingDiaphragm pumpReducer

The invention discloses a closed circulation system for improving the operating efficiency of a gas drainage pump. The liquid inlet of a pneumatic diaphragm pump is connected with the liquid outlet of a polymer drag-reducing solution tank, and the liquid pipe of the pneumatic diaphragm pump leads into a circulating water pool. A pneumatic agitator is arranged inside the polymer drag reducing solution tank, and a feeding funnel is arranged on the top. The liquid outlet of the submersible pump is respectively connected with the liquid inlet of the polymer drag reducing solution tank and the liquid inlet of the gas drainage pump through a tee, and the discharge pipe of the gas drainage pump is connected to the circulating pool. The high-speed operation of the pneumatic agitator and the pneumatic diaphragm pump is used to mix the polymer drag-reducing solution evenly and send it into the circulating pool. At the same time, the outlet pipe of the submersible pump supplies water to the polymer drag-reducing solution tank, and the polymer drag-reducing solution is added through the feeding funnel. agent to realize the continuous dosing of drag reducing solution, ready to use. The gas drainage pump uses polymer drag reducing solution as the working medium, which can greatly improve the operating efficiency of the gas drainage pump. The system is simple in structure, easy to operate, and realizes a closed cycle of drag reducing solution supply.

Owner:CHINA UNIV OF MINING & TECH

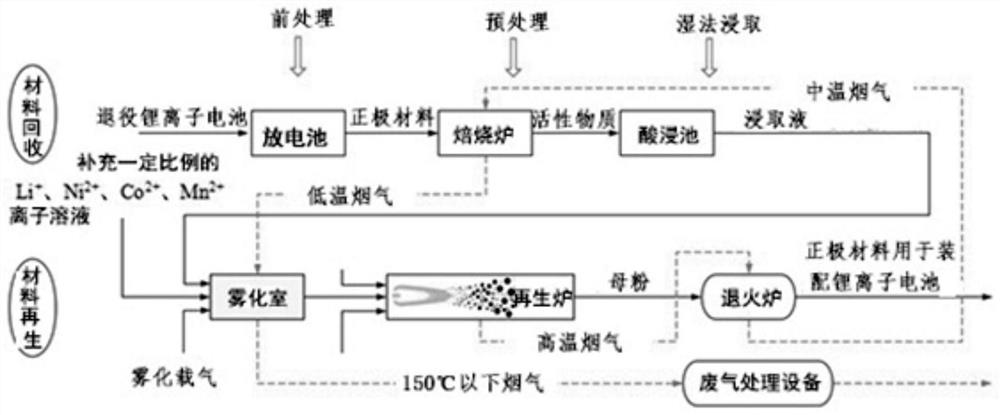

Lithium ion battery positive electrode material recycling and regenerating process

PendingCN114824541AAvoid the cumbersome problem of separationIncrease added valuePositive electrodesWaste accumulators reclaimingElectrical batteryManganese

The invention discloses a lithium ion battery positive electrode material recycling and regenerating process, which does not separate and purify valuable metals in a leaching solution, but directly supplements elements and adjusts the proportion of the elements to regenerate the positive electrode material, so that the tedious separation step is omitted, and the process cost is reduced. The method has the advantages that the problem of complicated element separation of a nickel, cobalt, manganese and lithium mixed solution system can be avoided, the lithium loss is reduced, the additional value of regenerated products can be obviously increased, the recovery efficiency and the economical efficiency are improved, and the closed circulation of waste lithium ion battery materials is realized; high-temperature flue gas generated by the regeneration furnace is conveyed to the annealing furnace, the roasting furnace and the atomizing chamber for multi-stage full utilization, multi-stage utilization of high-temperature flue gas, medium-temperature flue gas, low-temperature flue gas and waste gas is achieved in the whole flue gas circulation process, energy consumption in the process is saved, and heat loss of the system is reduced.

Owner:TSINGHUA UNIV

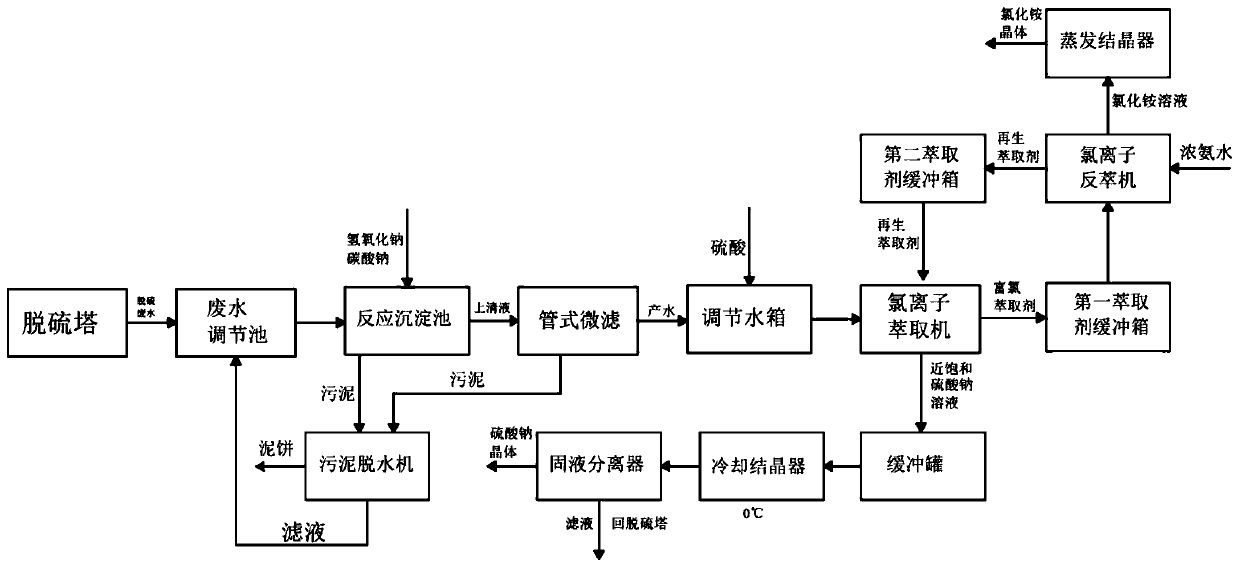

Desulfurization wastewater chloride ion extraction and sodium sulfate and ammonium chloride production system

PendingCN110963614AAchieving zero emissionsRealize a closed loopWater contaminantsWaste water treatment from gaseous effluentsChemistryProcess engineering

The invention discloses a desulfurization wastewater chloride ion extraction and sodium sulfate and ammonium chloride production system. The system comprises a desulfurizing tower, a wastewater regulating tank, a reaction sedimentation tank, a tubular microfiltration device, a regulating water tank and a chloride ion extractor which are connected in sequence. The downstream of the chloride ion extractor is communicated with a buffer tank and a first extractant buffer tank; a sodium sulfate solution generated by the chloride ion extractor sequentially passes through the buffer tank, a cooling crystallizer and a solid-liquid separator, and a chlorine-rich extraction agent sequentially passes through the first extraction agent buffer tank and a chloride ion reverse extraction machine and reacts with concentrated ammonia water in the chloride ion reverse extraction machine to generate an ammonium chloride solution and a regenerated extraction agent. The ammonium chloride solution passes through an evaporation crystallizer, and the regenerated extraction agent flows back to the chloride ion extractor through a second extraction agent buffer tank. Through the arrangement, the system achieves closed circulation, and the zero emission of desulfurization wastewater can be achieved; chlorine ions are extracted and separated, and the investment and operation cost are greatly reduced compared with membrane separation and evaporation separation.

Owner:ZHEJIANG TUNA ENVIRONMENTAL SCI & TECH

Evaporation recovery process of methanol aqueous solution of sodium chloride

ActiveCN106673961BDraw as soon as possibleImprove heat transfer efficiencyAlkali metal chloridesHydroxy compound separation/purificationSlurryMoisture

The invention relates to an evaporation and recycling process of a methanol water solution of sodium chloride. The evaporation and recycling process sequentially comprises the following steps: (1) pre-heating a new raw solution for raising the temperature; (2) heating and evaporating the raw solution by utilizing fresh steam in a single-effect falling-film evaporator to form a single-effect concentrated solution, and evaporating methanol and moisture to generate single-effect steam; (3) in a double-effect falling-film evaporator, heating and evaporating the single-effect steam by utilizing the single-effect concentrated solution to obtain a double-effect concentrated solution, and generating double-effect steam; (4) in a three-effect forced circulating evaporation and crystallization unit, heating the double-effect concentrated solution by utilizing the double-effect steam to form three-effect crystal slurry, and generating three-effect steam; (5) enabling the three-effect crystal slurry to enter a three-effect hydrocyclone for concentrating and thickening, returning a light phase back to the three-effect forced circulating evaporation and crystallization unit for circulating, and conveying a heavy phase into a thick tank for concentrating and thickening; and (6) conveying the heavy phase of the thick tank into a centrifuge for separating, discharging sodium chloride crystals from a solid-phase outlet of the centrifuge, and conveying a mother solution into a mother solution tank. The process is low in energy consumption and can realize complete recycling of sodium chloride and methanol.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

An underground nuclear power plant with a disposal site for low and intermediate radioactive waste

ActiveCN106128534BSave design and construction costsAvoid radioactive releaseNuclear energy generationFacility decommissioningCyclic processNuclear plant

The invention discloses an underground nuclear power plant with a disposal site for low and intermediate radioactive waste, which includes a nuclear island placed in the cavern group of the nuclear island of the mountain and a conventional island placed on the ground platform outside the mountain. The reactor building, the nuclear fuel building, the safety building, the electrical building and the nuclear auxiliary building arranged around the reactor building also include the low and intermediate level waste disposal site placed in the mountain nuclear island cavern group, and the low and intermediate level waste disposal site passes through the waste The transport tunnel is connected with the nuclear auxiliary plant of the nuclear island. Combining the characteristics of underground nuclear power plants, the present invention can not only meet the disposal requirements of low and intermediate radioactive wastes, realize closed cycle of fuel, reduce possible radioactive pollution in fuel cycle process, but also realize unified planning and construction of nuclear power plants and disposal sites, cut costs.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

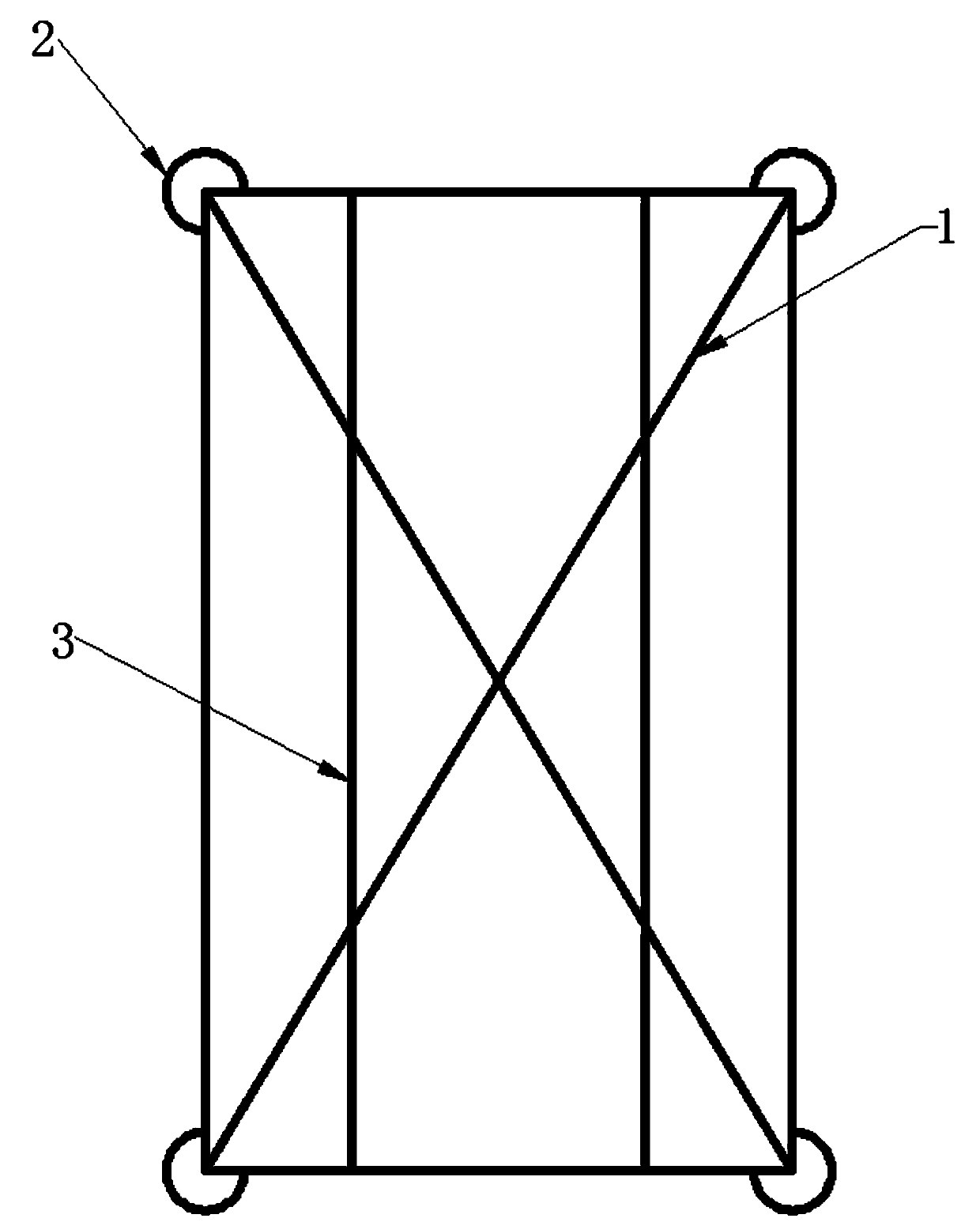

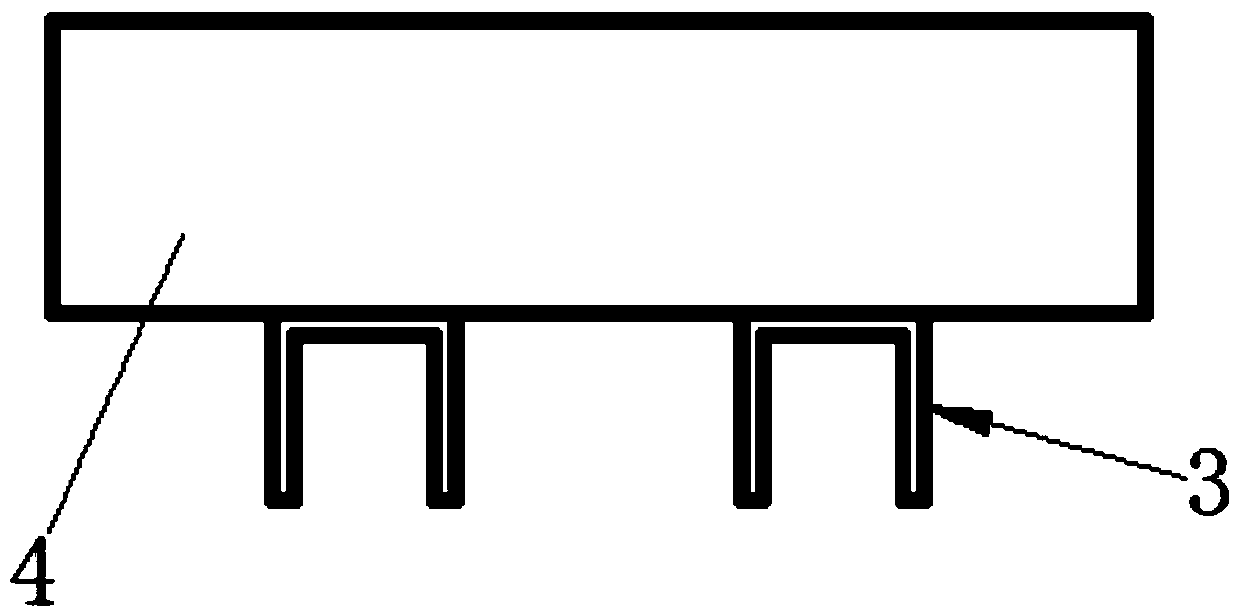

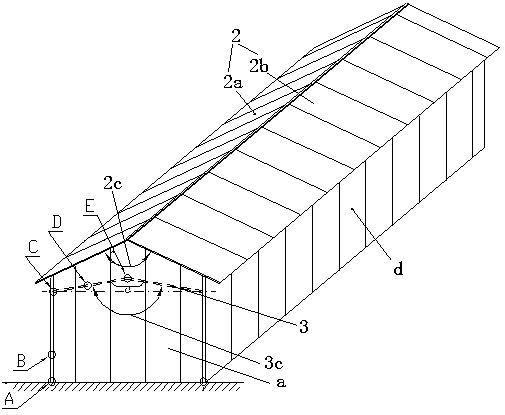

Manned test device and working method of man, fish and Hongping

ActiveCN108012910BRealize a closed loopHigh simulationMeasurement of fluid loss/gain rateClimate change adaptationMarine engineeringStructural engineering

The invention relates to a manned test device for people, fishes and Azolla imbircata and a working method. The device comprises a cabin body which is composed of a front side plate, a rear side plate, a left side plate, a right side plate and a ceiling, wherein each side plate of the cabin body is assembled by assembling color steel plates separately, each color steel plate has film attached to double sides, and the lower end of each side plate of the cabin body is sleeved by slot aluminum which is connected with the foundation; the ceiling is composed of two inclined plates, an angle betweenthe two inclined plates is an obtuse angle, and the inclined plates are obtained by assembling colored steel corrugated sheets; a hung ceiling is arranged below the ceiling and in the cabin body, thehung ceiling is composed of two second inclined plates, and an angle between the two second inclined plates is an obtuse angle. The device not only has a simple mechanism, but also can be conveniently applied to ground simulation researches, and meanwhile an air tightness test method is simple and convenient.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

Human, fish and vegetable manned test device and working method

ActiveCN108020382BRealize a closed loopHigh simulationDetection of fluid at leakage pointMeasurement of fluid loss/gain rateWorking setEngineering

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

A wet-dry combined two-stage anaerobic fermentation biogas production process

ActiveCN104745639BSmall reaction spaceRealize a closed loopWaste based fuelFermentationResource utilizationDecomposition

The invention belongs to the field of solid waste disposal and resource utilization, and in particular relates to a process for production of biogas by wet method-dry method combined two-stage anaerobic fermentation. Broken solid waste and an inoculum are mixed in a full wet type reactor for wet anaerobic fermentation, the wet anaerobic fermentation period hydraulic retention time (HRT) is 5-20 days, after fermentation processing, a fermentation material can be delivered to a dry method fermentation reactor with an infiltration device at the bottom for dry solid fermentation for production of the biogas, and the process combines the dual advantages of wet method fermentation and dry method fermentation. The fermentation process integrating the advantages of fast mass transfer and easy start-up characteristics of the wet method fermentation and reaction space saving of the dry method fermentation, and the like is disclosed. By combination of biomass multistage decomposition and transformation in the fermentation process and methane producing bacteria group enrichment principle, the wet fermentation process advantage is used, the wet fermentation process is used as a homogeneous inoculation stage of the dry method fermentation process, and the problems of difficult inoculation and slow start of the dry method fermentation can be solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com