A Closed Circulation System for Improving Operation Efficiency of Gas Drain Pump

A technology for gas drainage and operating efficiency, which is applied in the direction of gas discharge, control/regulation systems, and components of pumping devices for elastic fluids, etc. Problems such as poor solubility of resist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

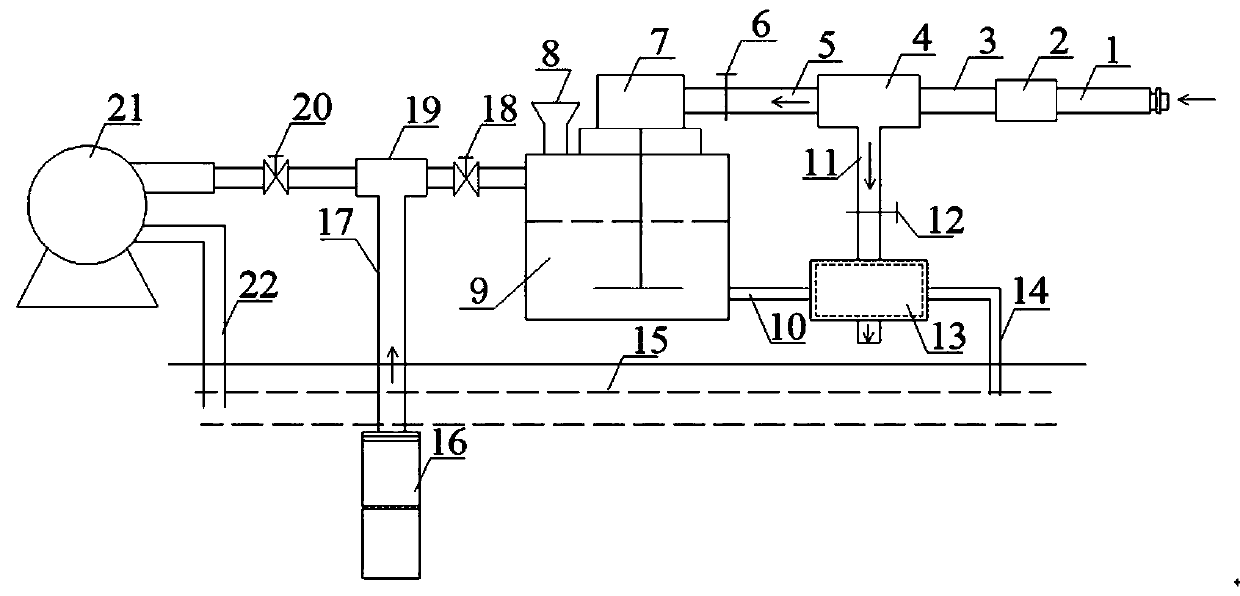

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] As shown in the drawings, the system is mainly composed of a pressure air pipe 1, a pneumatic diaphragm pump 13, a polymer drag reducing solution tank 9, a submersible pump 16, and a gas drainage pump 21. The liquid inlet of the pneumatic diaphragm pump 13 is connected to the liquid outlet of the polymer drag reducing solution tank through a connecting pipe 10 , and the liquid outlet pipe 14 of the pneumatic diaphragm pump leads into the circulation pool 15 . The polymer drag reducing solution tank 9 is provided with a pneumatic agitator 7 inside, and a feeding funnel 8 is provided at the top. The outlet pipe 17 of the submersible pump 16 is respectively connected with the liquid inlet of the polymer drag reducing solution tank and the liquid inlet of the gas pumping pump through a tee 19, and the two outlets of the tee are respectively provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com