Desulfurization wastewater chloride ion extraction and sodium sulfate and ammonium chloride production system

A technology for desulfurization wastewater and chloride ions, applied in ammonium chloride, ammonium halide, extracted water/sewage treatment, etc., can solve the problems of miscellaneous salt solid waste, nozzle atomization failure, high energy consumption, etc., and achieve investment and operating costs reduction, achieve zero emissions, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

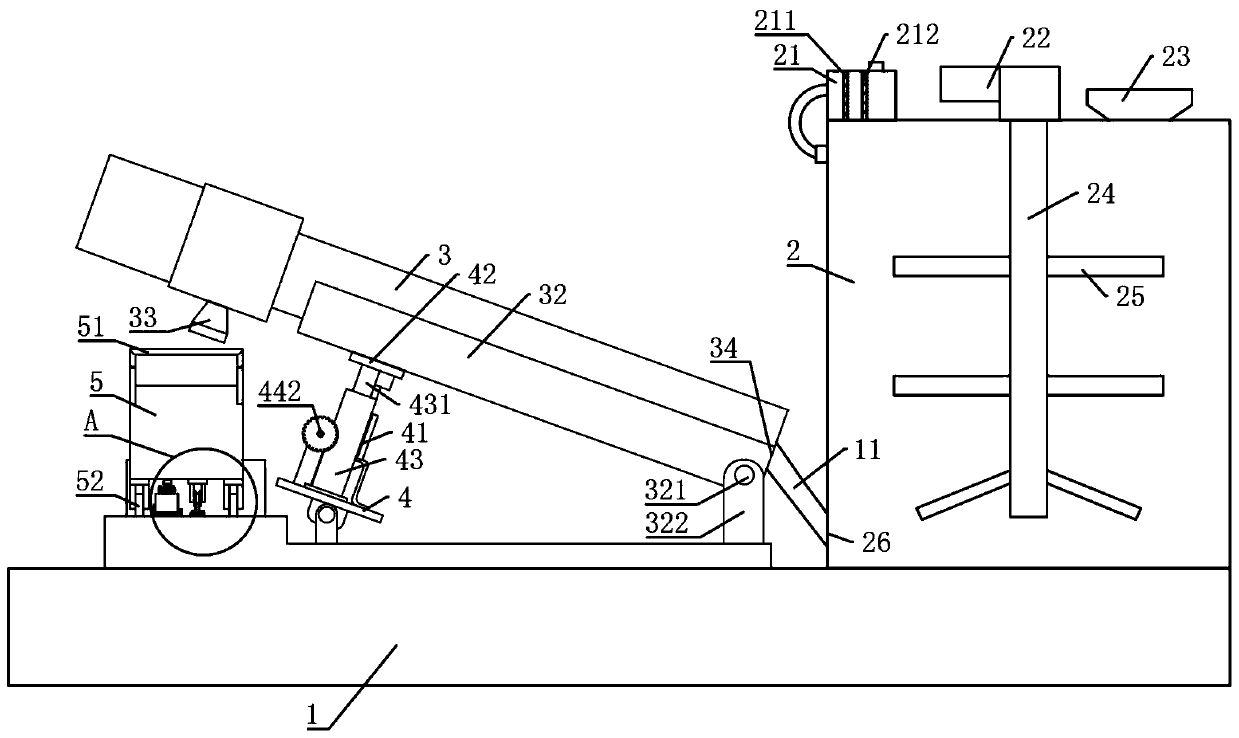

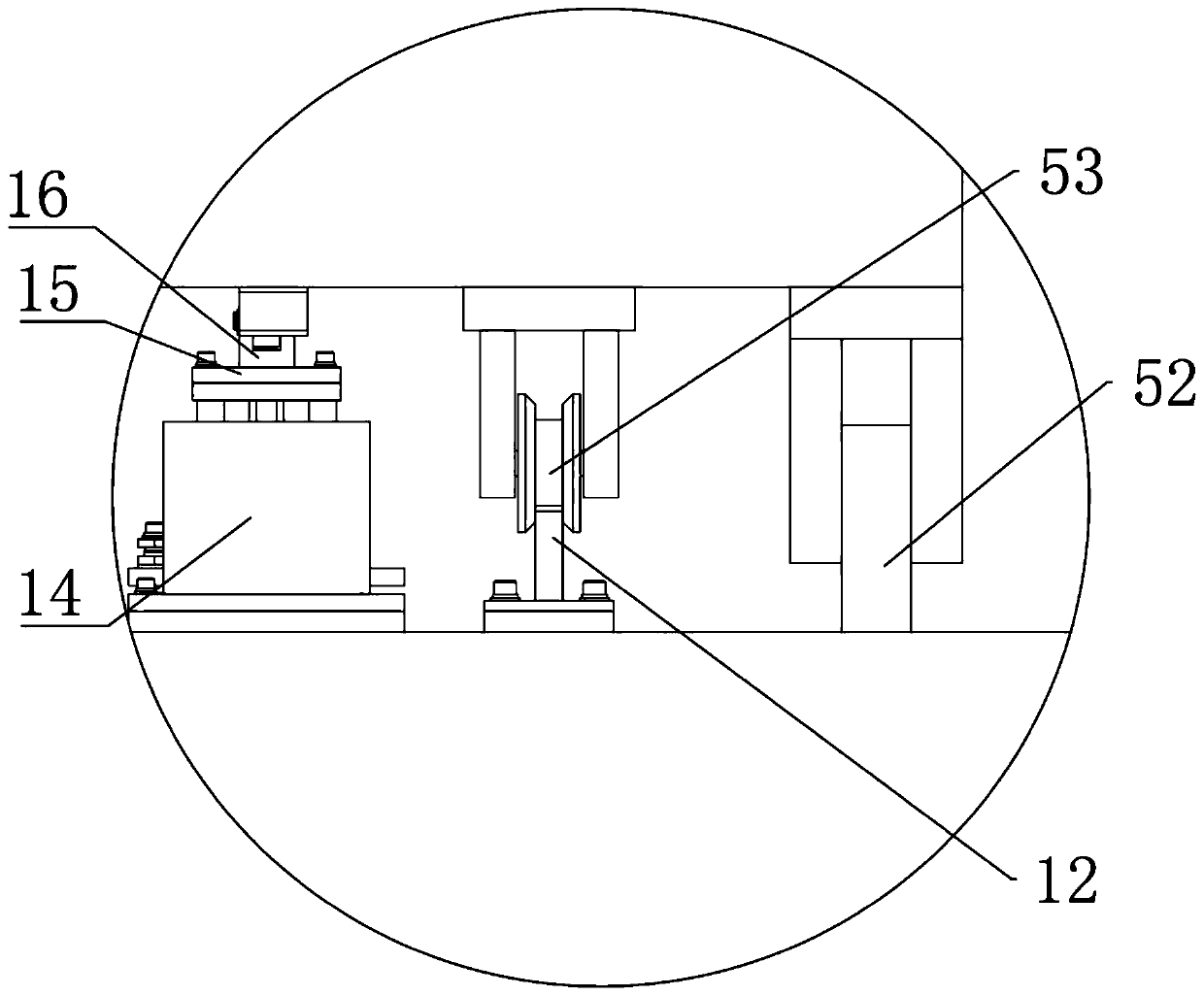

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

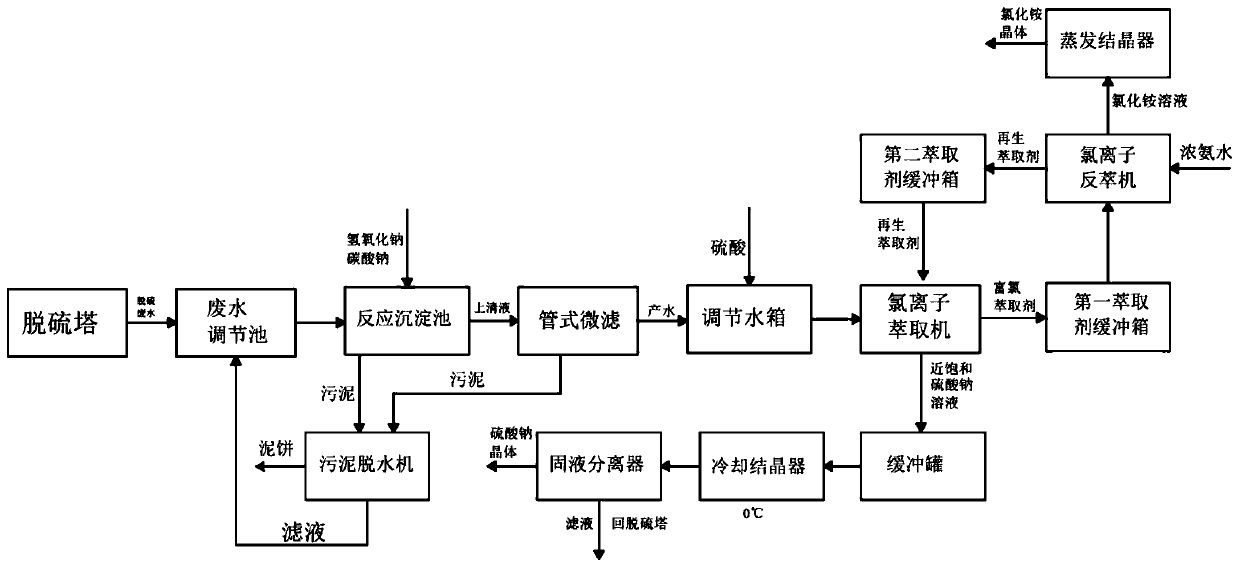

[0032] Such as Figure 1-9 As shown, the chlorine ion extraction and sodium sulfate and ammonium chloride output system of desulfurization wastewater includes successively connected desulfurization towers, wastewater regulating tanks, reaction sedimentation tanks, tubular microfiltration, regulating water tanks, and chloride ion extractors. The downstream of the extractor is respectively connected with the buffer tank and the first extractant buffer tank, and the sodium sulfate solution produced by the chloride ion extractor passes through the buffer tank, the cooling crystallizer and the solid-liquid separator successively, and the rich The chlorine extractant passes through the first extractant buffer tank and the chloride ion stripping machine in sequence.

[0033] The chlorine-rich extractant enters the chloride ion stripping machine and reacts with concentrated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com