Welding device for nuclear-grade gate valve element seal face repairing

A welding device and sealing surface technology, which is applied in the field of nuclear power plant maintenance, can solve the problems of large space occupation, high labor intensity, and heavy manual surfacing welding workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the drawings and embodiments.

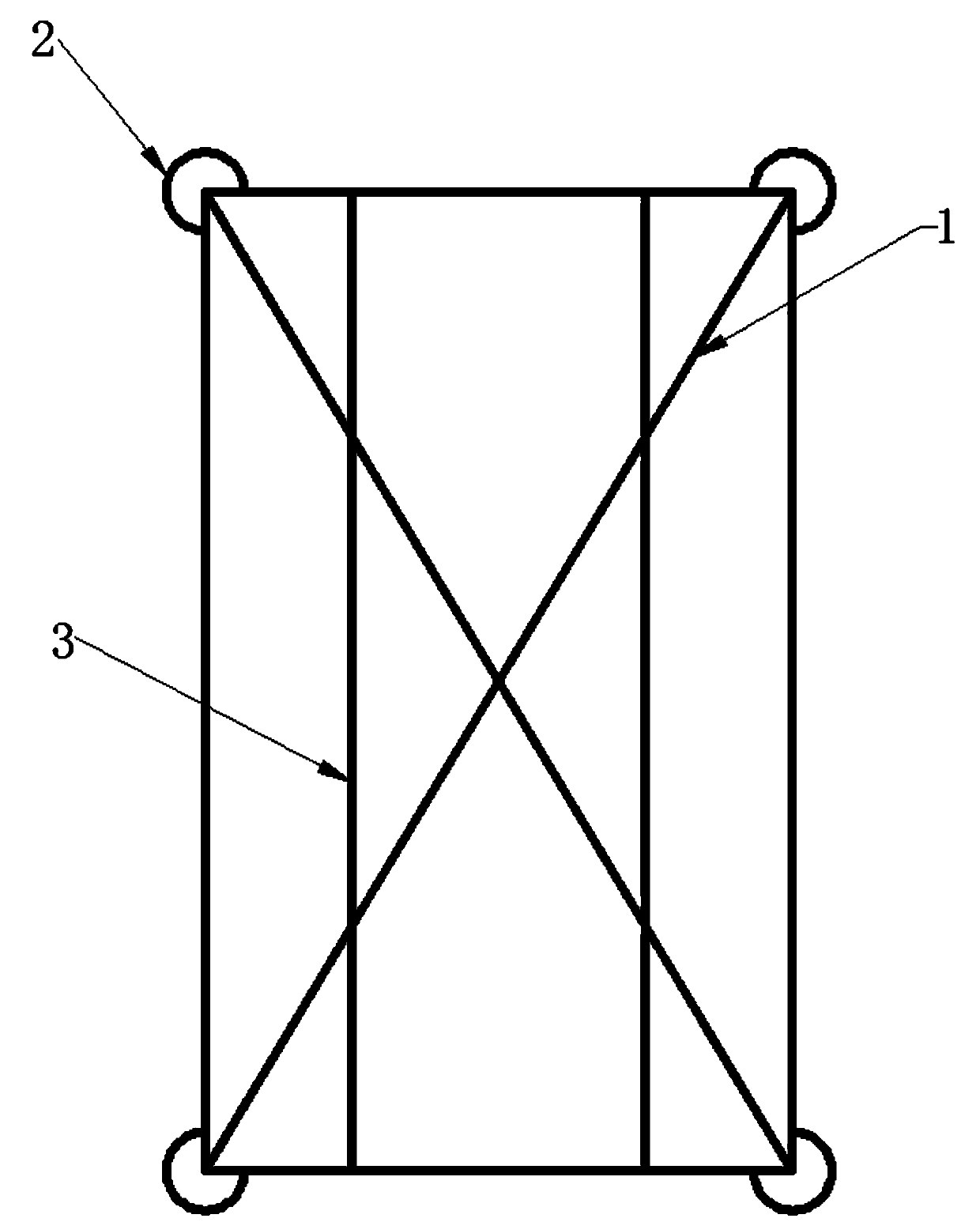

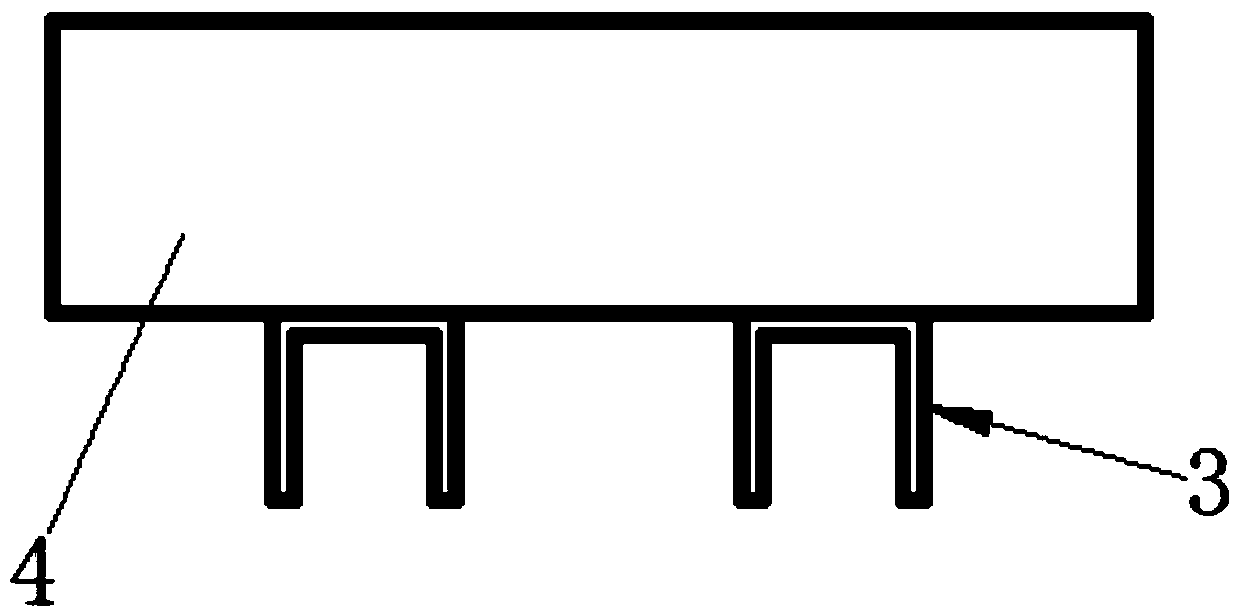

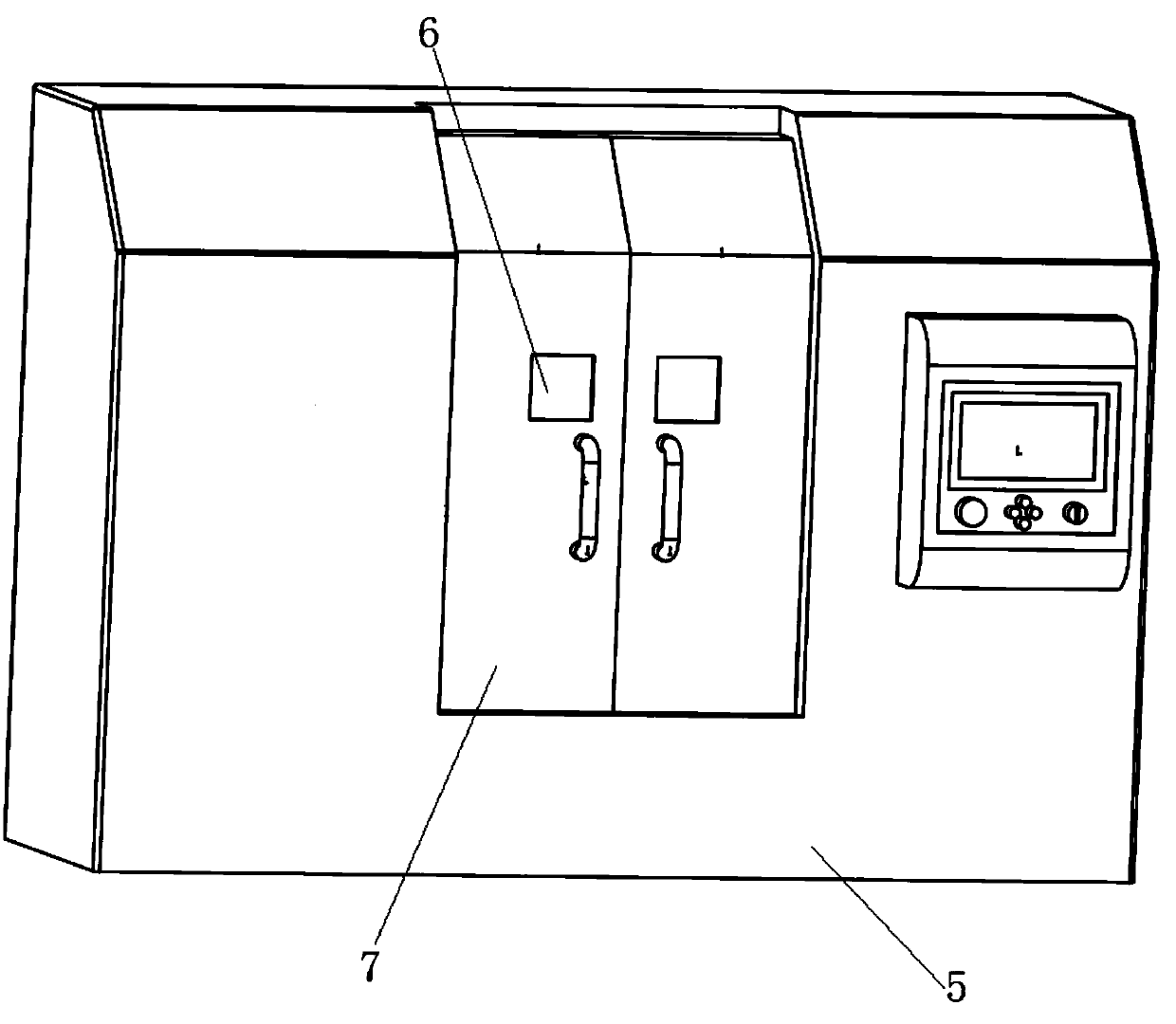

[0024] A welding device for repairing the sealing surface of a nuclear-grade gate valve core includes a base structure, a shell structure, a welding machine and an exhaust gas adsorption structure. The base structure is an integrated frame structure, used to integrate the welding machine and the exhaust gas adsorption structure, while providing a support platform for the shell structure, the welding machine and the exhaust gas adsorption structure. The welding machine is fixed on the base structure and is used to realize the welding operation during the repair of the sealing surface of the nuclear-grade gate valve spool. The exhaust gas adsorption device is fixed on the base structure and is used for adsorbing particulate matter in the exhaust gas generated during the welding process. The shell structure is fixed on the base structure and is wrapped around the welding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com