Energy-saving and environment-friendly printer

An energy-saving and environmental-friendly printing machine technology, which is applied to printing machines, printing, general-purpose parts of printing machinery, etc., can solve the problems of low heat utilization efficiency, reduced processing efficiency, and high production consumption, so as to reduce external heat dissipation of equipment and occupy an area of equipment Effects of area reduction and reduction in installation and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0048] Figure 1 to Figure 12 Constitute a specific embodiment of the present invention.

[0049] This embodiment is a solvent gravure printing machine.

[0050] in, Figure 1 to Figure 8 The detailed structure of the drying device used in this embodiment is provided, Figure 9 A schematic diagram of the heat pump device used in the drying device of this embodiment is provided.

example

[0052] The corresponding relationship between component names and reference signs in each drawing is shown in Table 1.

[0053] Table 1: Correspondence between part names and reference signs

[0054]

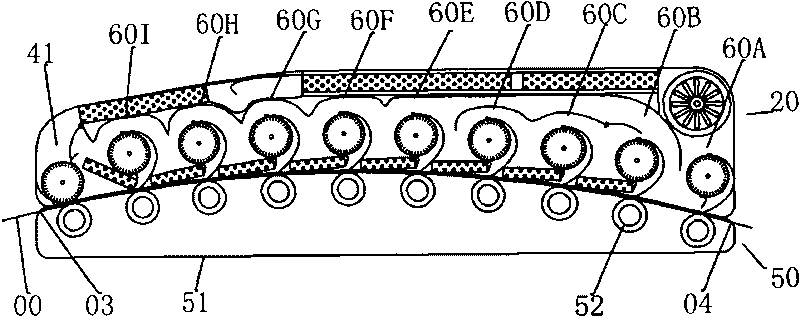

[0055] Such as figure 1 , figure 2 As shown, the drying device 10 includes an oven cover 20 , a base 50 , and is provided with a printed product inlet 03 and a printed product outlet 04 .

[0056] The base 50 includes a base housing 51 and support rollers 52 . The printed product 00 enters from the printed product inlet 03 , is blown by the air blowing unit 60 under the support of the support roller, and leaves the drying device 10 through the printed product outlet 04 after drying.

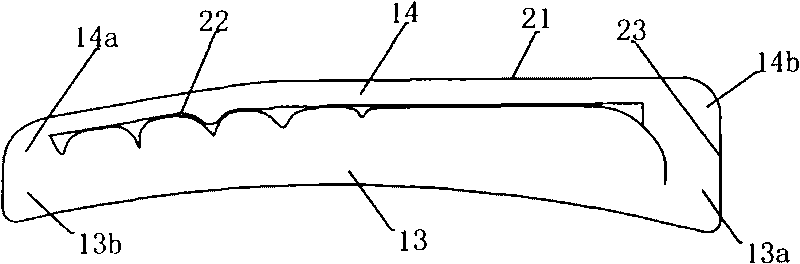

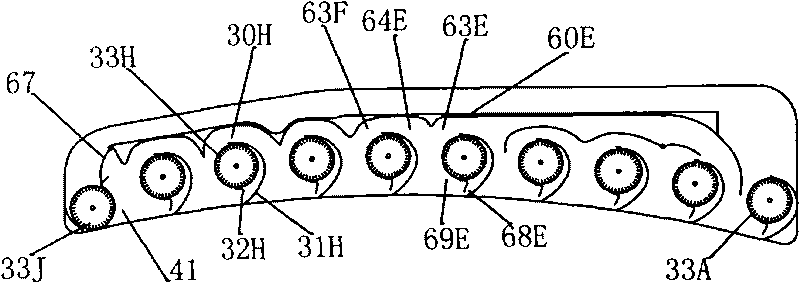

[0057] Oven lid 20 comprises outer cover part 21, partition part 22, frame part 23, nine air supply units 60A~60I, a circulation unit 41, is provided with drying chamber 13, recovery chamber 14; Drying chamber 13 is made up of partition part 22. The frame part 23 is surrounded by the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com