Evaporation recovery process of methanol aqueous solution of sodium chloride

A methanol aqueous solution and sodium chloride technology, applied in the field of sodium chloride methanol aqueous solution evaporation recovery process, can solve the problems of increased burden, large amount of steam to be generated, and reduced methanol recovery rate, so as to reduce labor force and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

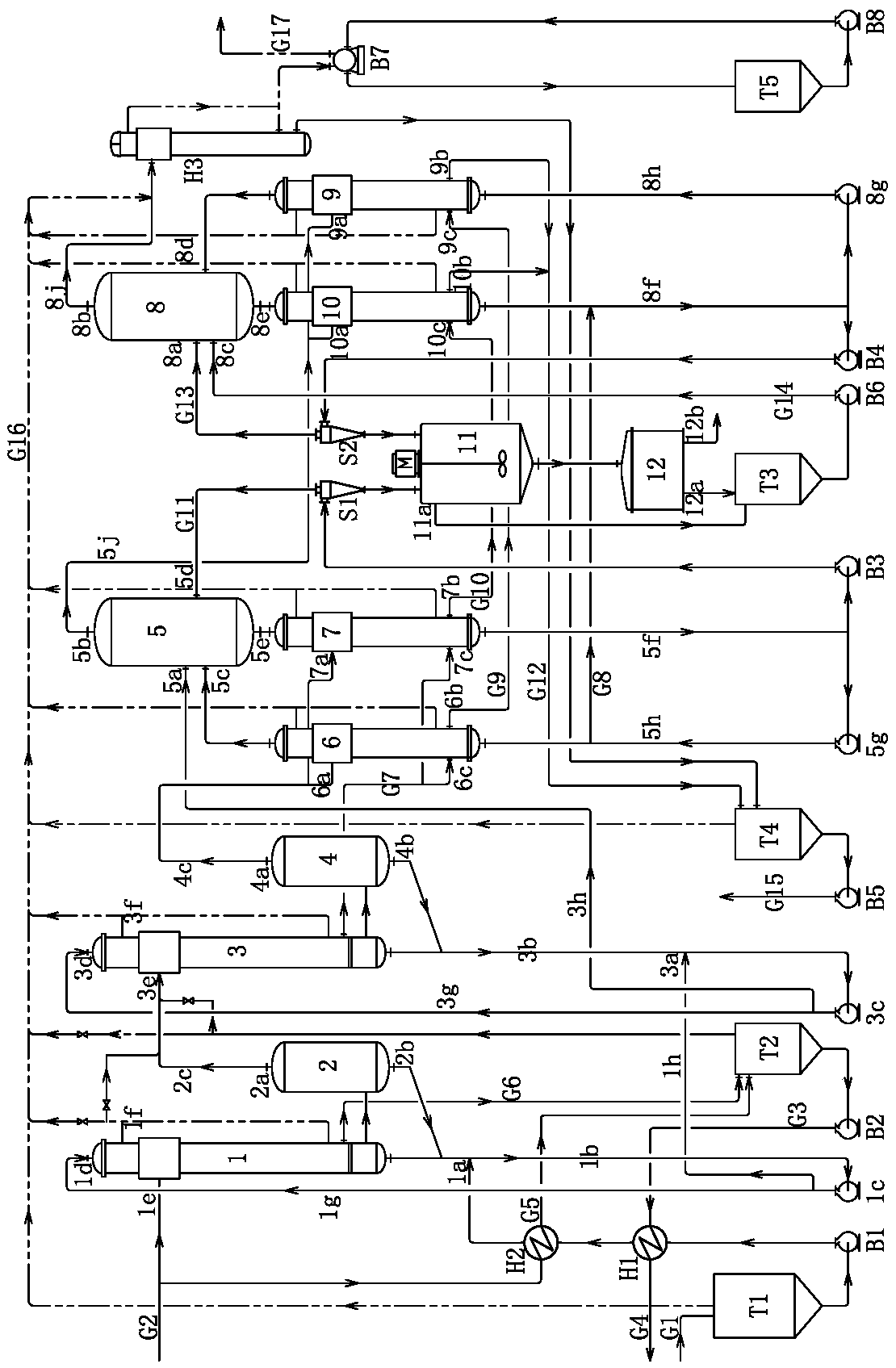

[0018] Such as figure 1As shown, the methanol aqueous solution evaporation recovery process of sodium chloride of the present invention comprises the following steps successively: (1) the methanol aqueous solution stock solution of new sodium chloride in the stock solution storage tank T1 is sent into the preheating unit by the feed pump B1 to carry out preheating and temperature rise ; (2) In the first-effect falling film evaporator 1, raw steam is used to heat, evaporate and concentrate the preheated stock solution to make it a first-effect concentrated solution, and methanol and water in the stock solution evaporate to produce first-effect steam; (3) In the second-effect drop In the membrane evaporator 3, the first-effect steam is used to further heat, evaporate and concentrate the first-effect concentrated liquid to make it into a second-effect concentrated liquid, and the methanol and water in the first-effect concentrated liquid continue to evaporate to generate the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com