Integral overlapping drying equipment

A technology of drying equipment and drying chamber, which is applied to the device for coating liquid on the surface, printing, printing machines, etc., which can solve the problems of excessive energy consumption, difficult control, and huge energy consumption, and achieve high energy efficiency of heat pumps Coefficient, improve the working environment, improve the effect of refrigeration coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

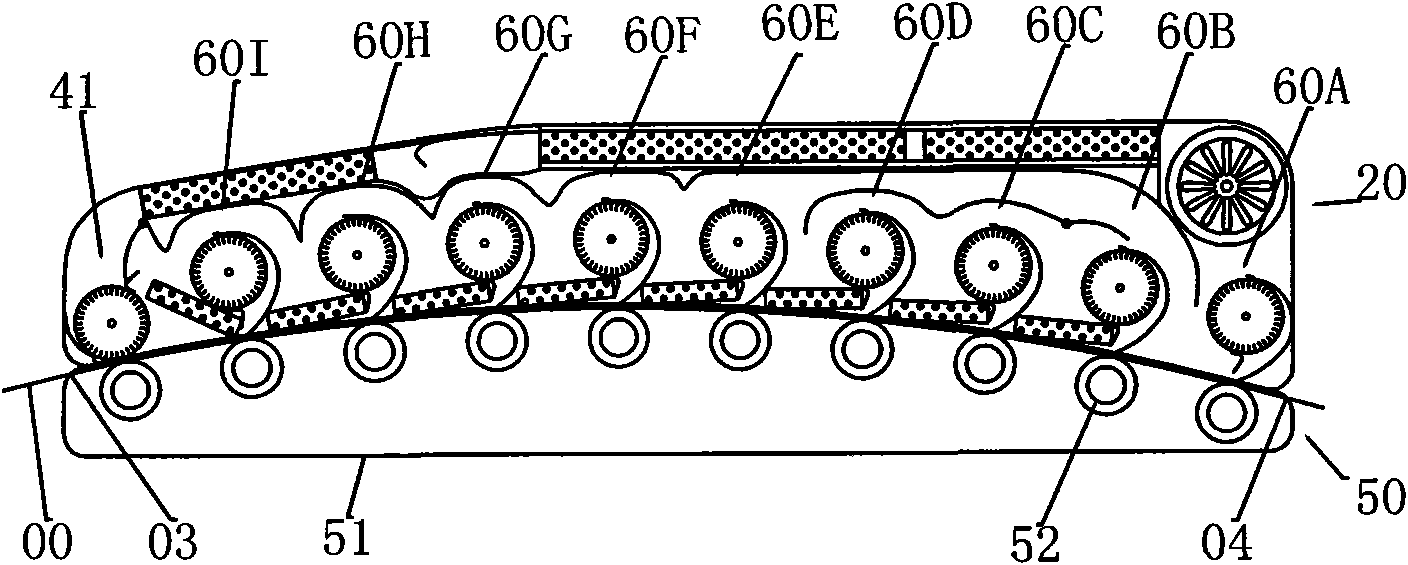

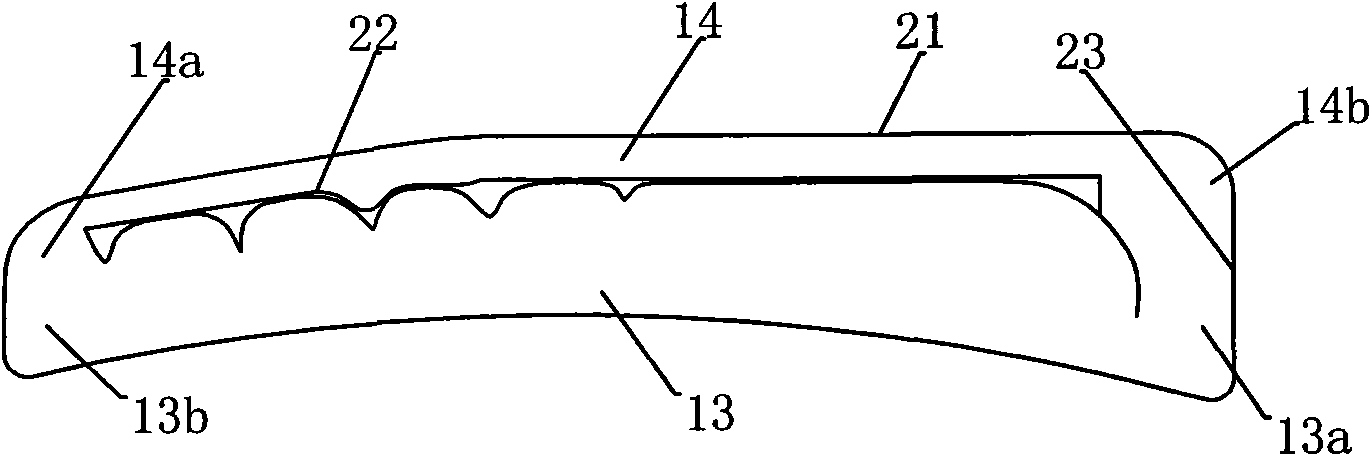

[0066] Figure 1 to Figure 9 Constitute the specific embodiment 1 of the present invention.

[0067] This embodiment is suitable for drying equipment for solvent printing machines.

[0068] Figure 1 to Figure 8 The detailed structure of the drying equipment described in this embodiment is provided, Figure 9 A schematic diagram of the heat pump device of this embodiment is provided.

[0069] The corresponding relationship between component names and reference signs in each drawing is shown in Table 1.

[0070] Table 1: Correspondence between part names and reference signs

[0071] 00——Print port 10——Oven 20——Oven cover

01——Fresh air inlet 11——Intake cavity 21——Cover parts

02——exhaust gas outlet 12——exhaust cavity 22——baffle parts

03——Print product inlet 13——Drying chamber 23——Frame parts

04——Print product outlet 14——Recovery cavity 24——Front beam

16——low temperature section 25——rear beam

17——Medium temperature section 26——Left ...

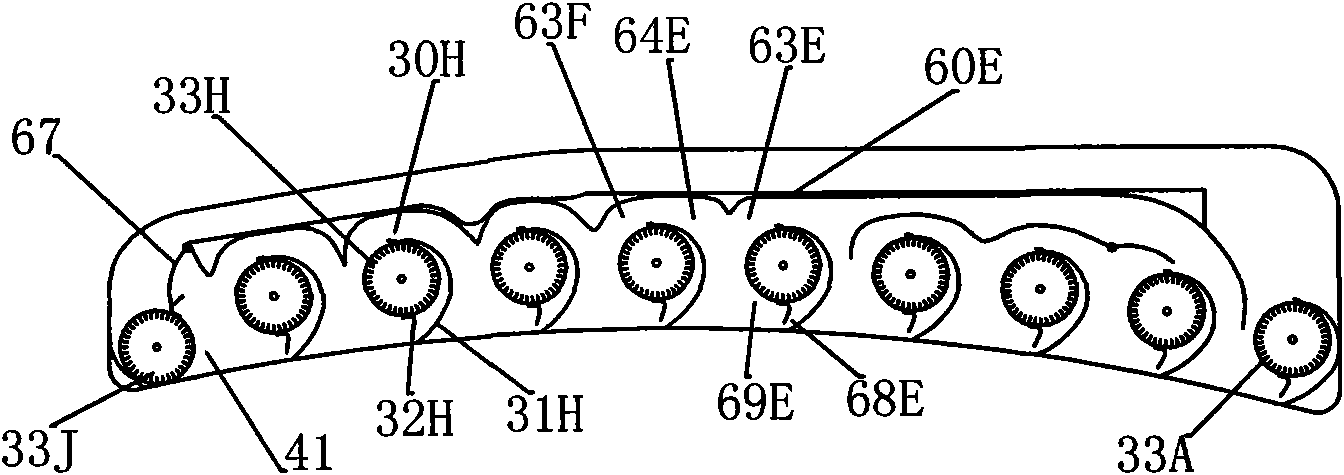

specific Embodiment 2

[0108] This embodiment is suitable for drying equipment for solvent printing presses operating under extreme conditions.

[0109] Figure 10 , Figure 11 It is the accompanying drawing of the specific embodiment 2 of the present invention, which embodies the difference between this embodiment and the specific embodiment 1 in that:

[0110] The fan 30K directly driven by the fan motor 38 is used as the circulation unit 41, and the return air damper moves accordingly.

[0111] The blower 30K adopts the large-diameter cross-flow impeller 33K to strengthen the circulating wind force.

[0112] Extend the oven cover 20, increase the low temperature section 16 air supply unit 60J, and increase the effective drying area.

[0113] The heat pump cooler 83B in Embodiment 1 is replaced by the heater 48, which is a PTC electric heater, and the heater 48 can generate hot air exceeding 100°C, meeting the extreme demands of the printing machine.

[0114] Under normal circumstances, the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com