Lithium ion battery positive electrode material recycling and regenerating process

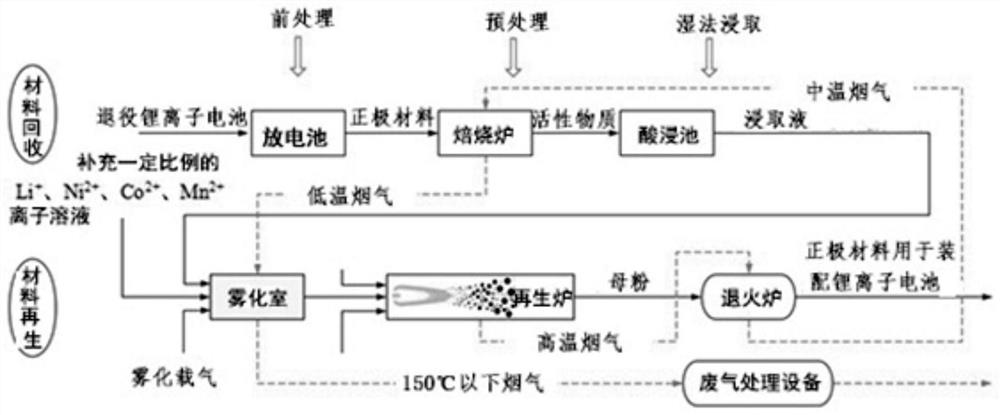

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of lithium-ion battery positive electrode material recovery and regeneration technology, can solve the problems of high recycling cost and low yield of lithium ion positive electrode materials recovered by hydrometallurgy, so as to reduce process costs and improve recovery Efficiency and economy, the effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Pretreatment: Put the retired lithium-ion battery in a 5% NaCl solution and soak it in the battery for 96 hours. Use the action of conductive salt to short-circuit the positive and negative electrodes to consume electricity, and the final battery voltage is lower than 0.5V.

[0052] Pretreatment: disassemble the lithium-ion battery pack to obtain a single battery, and then sort out the battery shell, electrodes and separators. After mechanically crushing and grinding the electrodes, they were placed in the roasting furnace for 2.5 hours, and the medium-temperature flue gas generated by the annealing furnace was used to provide heat for the roasting furnace. After the reaction is completed, the electrode sheet is taken out and cooled, and the powdery active material can be peeled off and collected from the current collector by shaking the electrode sheet lightly. Its volatile, low temperature flue gas is finally discharged after being treated by waste gas treatment equip...

Embodiment 2

[0059] Pretreatment: Decommissioned Li-ion batteries were placed in 7% MnSO 4 The solution is soaked in the battery for 100 hours, and the positive and negative electrodes are short-circuited by the action of the conductive salt to consume electricity, and the final battery voltage is lower than 0.5V.

[0060] Pretreatment: disassemble the lithium-ion battery pack to obtain a single battery, and then sort out the battery shell, electrodes and separators. After mechanically crushing and grinding the electrode sheet, it was placed in the roasting furnace for 2 hours, and the medium-temperature flue gas generated by the annealing furnace was used to provide heat for the roasting furnace. After the reaction is completed, the electrode sheet is taken out and cooled, and the powdery active material can be peeled off and collected from the current collector by shaking the electrode sheet lightly. Volatile, low temperature flue gas is finally discharged after being treated by waste g...

Embodiment 3

[0066] Pretreatment: Put the retired lithium-ion battery in 8% NaCl solution for 80h, and use the conductive salt to short-circuit the positive and negative electrodes to consume electricity, and the final battery voltage is lower than 0.5V.

[0067] Pretreatment: disassemble the lithium-ion battery pack to obtain a single battery, and then sort out the battery shell, electrodes and separators. After mechanically crushing and grinding the electrode sheet, it was put into the roasting furnace for 3 hours, and the medium-temperature flue gas generated by the annealing furnace was used to provide heat for the roasting furnace. After the reaction is completed, the electrode sheet is taken out and cooled, and the powdery active material can be peeled off and collected from the current collector by shaking the electrode sheet lightly. Volatile, low temperature flue gas is finally discharged after being treated by waste gas treatment equipment.

[0068] Wet leaching: prepare 3 mol / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com