Novel electro-hydraulic motor

A hydraulic motor and motor technology, applied in the field of hydraulic motors, can solve the problems of not being too high in speed, poor in stability at low speed, difficult to guarantee accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

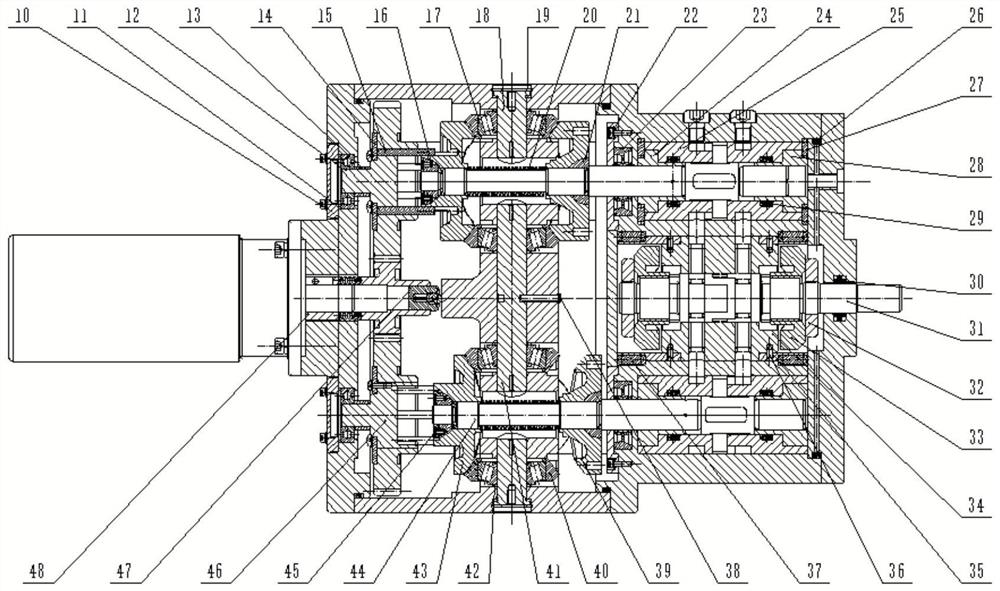

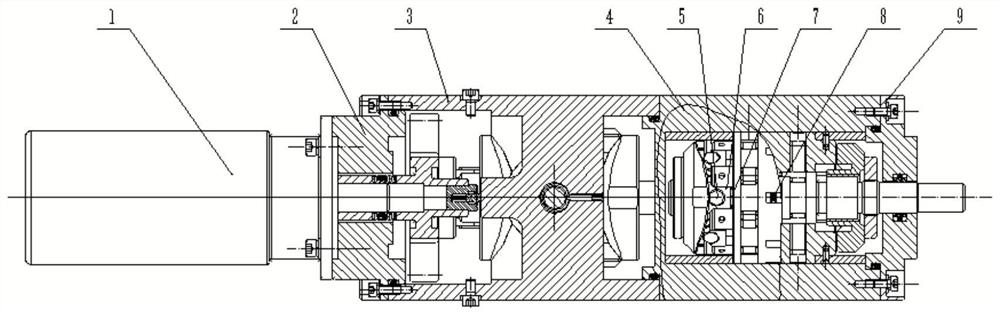

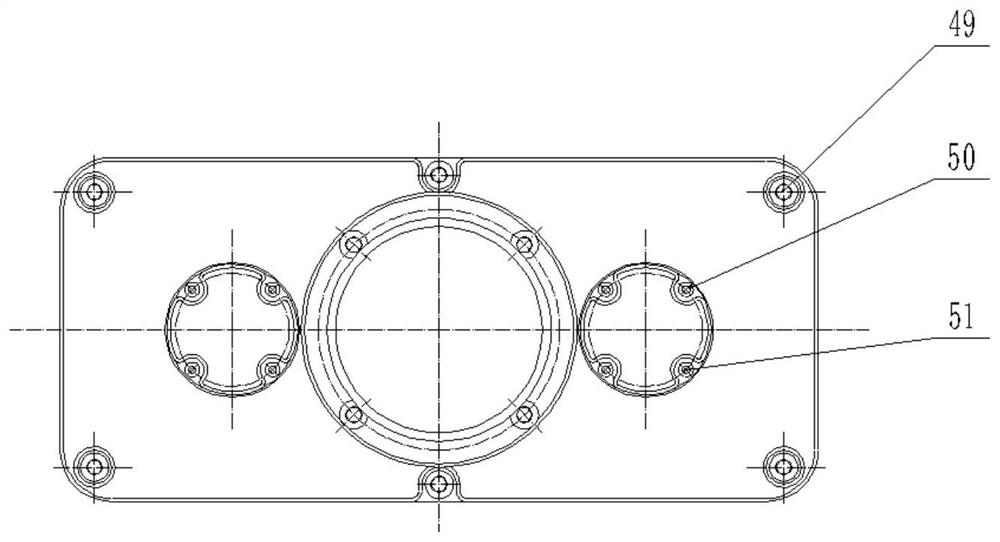

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] refer to Figure 1 to Figure 9 , a new type of electro-hydraulic motor, including motor, pump and hydraulic motor, an initial torque is input from the motor shaft, and the torque is transmitted to the space cam through the meshing transmission of the gear pair, and the space cam on the piston shaft is constrained by the cone roller , so as to generate reciprocating motion; through the reciprocating motion of the piston, the suction and extrusion of water are realized. The pressure port corresponds to the suction port of the hydraulic motor, and the suction port of the hydraulic pump corresponds to the outlet of the hydraulic motor. The fluid pushes the piston in the motor cylinder to move, and then drives the cams on both ends to rotate, converting the pressure energy into rotational mechanical energy, and then the splines on the cam make the motor shaft rotate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com